Are Chinese CNC Machines Worth Buying?

Karma

Introduction

In modern manufacturing, CNC (Computer Numerical Control) technology is widely used in metalworking, engraving, woodworking, and many other industries. CNC machines, known for their precision, efficiency, and automation, have become indispensable tools in many sectors. However, with the rapid development of Chinese manufacturing, an increasing number of businesses are choosing CNC machines made in China. So, how good are Chinese CNC machines? Can they compete with European and American brands in terms of quality, performance, and value? In this article, we will explore the advantages of Chinese CNC machines, their ideal applications, and how to make an informed purchasing decision.

How Is the Quality of Chinese CNC Machines?

Continuous Technological Advancements

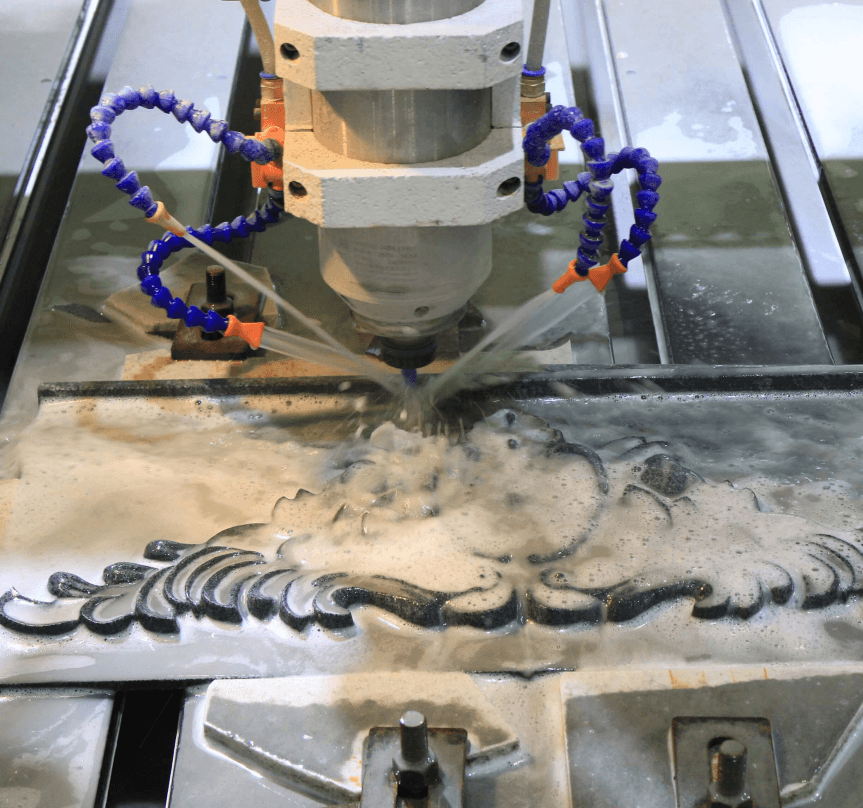

In recent years, Chinese CNC machine manufacturers have made significant technological advancements. From simple machining to handling complex parts and high-precision tasks, Chinese CNC machines are gradually catching up with international brands. For example, many Chinese brands have introduced advanced servo control systems, making machines more stable and precise during the processing.

According to the 2023 China Manufacturing Industry Development Report, China's CNC machine industry has made remarkable progress in technological standards, especially in mid-to-high-end products. Many Chinese manufacturers are adopting international cutting-edge technologies and localizing them, greatly improving the performance of their products.

Strict Quality Control

Quality control for Chinese CNC machines has significantly improved over the years. Many manufacturers have achieved ISO 9001, CE, and other international certifications, ensuring that every step of the production process is carefully monitored, enhancing the reliability of the machines. Unlike the past, quality discrepancies among modern Chinese CNC machines have greatly narrowed, especially in the mid-to-high-end market, where some brands are now on par with international standards.

According to the International Machine Tool Market Research Report, China's CNC machine exports have steadily increased, with more products now meeting international standards. This shows that CNC machines made in China are gaining global recognition for their quality.

Price Advantage and Value for Money

Price Competitiveness

Compared to European and American CNC machines, Chinese CNC machines offer significant price advantages. For machines with similar functions and performance, Chinese CNC machines are typically 30%-50% cheaper than their international counterparts. This allows more small and medium-sized enterprises to acquire high-quality equipment at a much lower cost.

According to the China Machinery Industry Federation, the market share of CNC machines from China accounted for nearly 45% of the global market in 2022. This growth can be attributed to the highly competitive pricing of Chinese CNC machines. For small and medium-sized businesses with budget constraints, purchasing Chinese CNC machines is a sensible choice that helps increase production efficiency while significantly lowering labor costs.

Value for Money

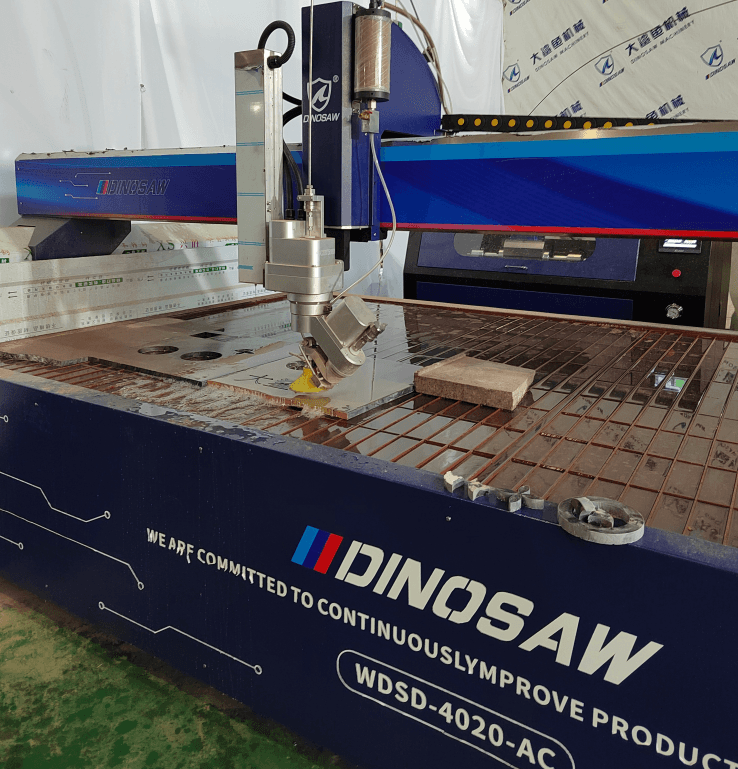

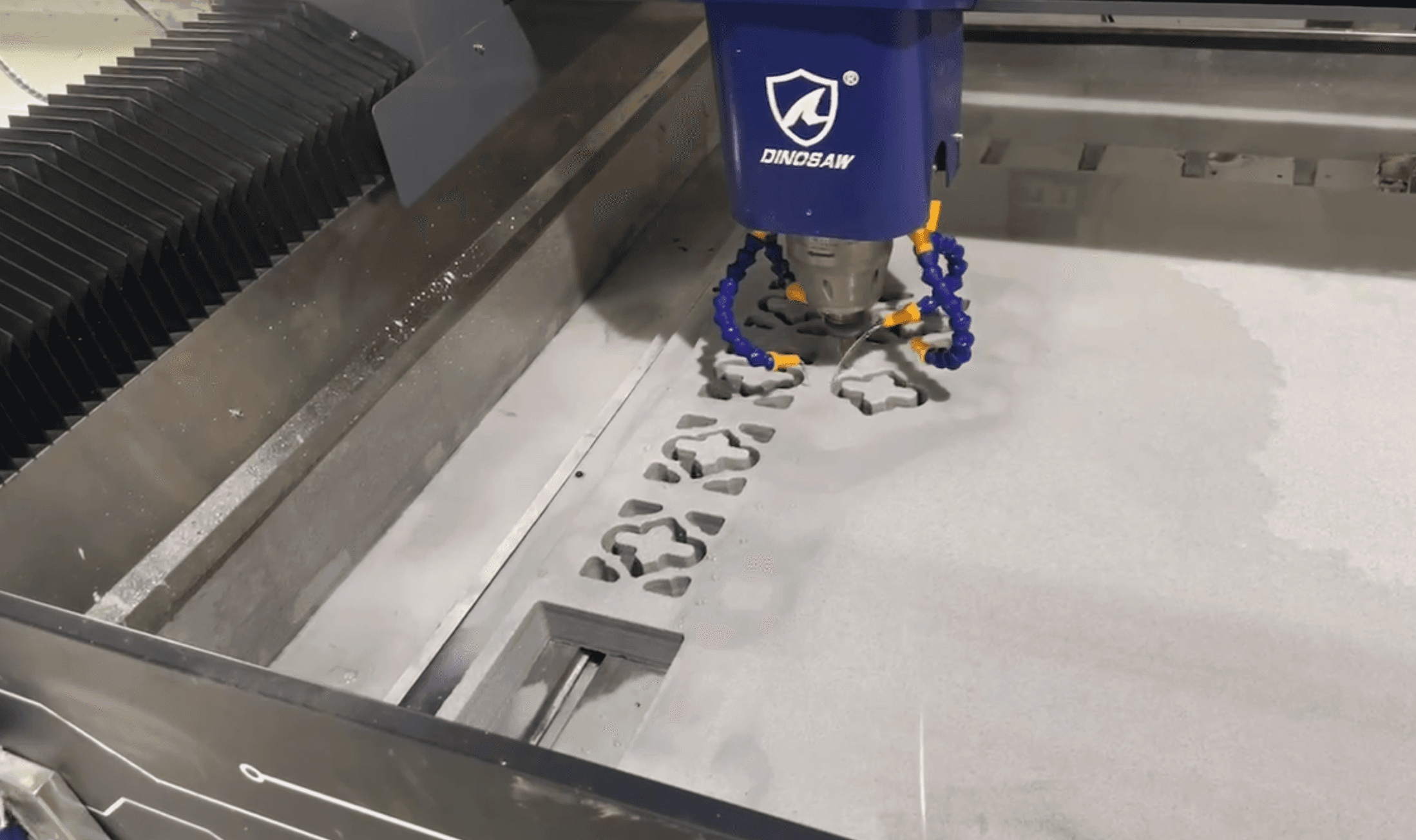

Despite their lower prices, Chinese CNC machines are by no means inferior in performance. With ongoing improvements in manufacturing processes and technology, many Chinese brands' CNC machines offer performance on par with high-end international brands. For example, the ZDDK-1325 engraving machine from Dinosaw Machine costs half of what an international brand would charge but has been praised for its stability and processing precision in numerous user reviews.

Data from the China Machinery Industry Federation shows that more and more small and medium-sized enterprises are prioritizing value for money when purchasing equipment. This is another key factor driving the growth of the Chinese CNC machine market.

Performance and Reliability

Performance

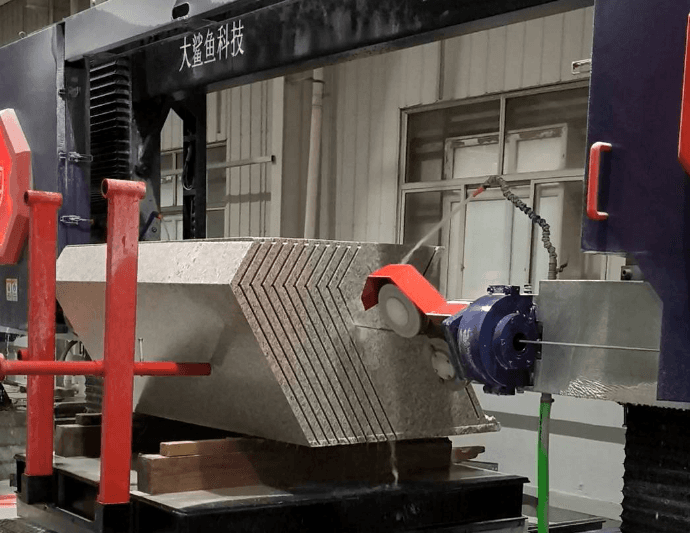

Chinese CNC machines perform exceptionally well in cutting, engraving, milling, and other operations, making them suitable for a wide range of production needs. For example, in the jewelry manufacturing industry, many Chinese CNC machines can provide extremely high engraving precision, with errors controlled to within one-thousandth of an inch. In industrial production, some Chinese machines also have very fast processing speeds, which meet the needs of large-scale production.

According to the China Machine Tool Industry Annual Report, the performance of Chinese CNC machines has improved significantly, especially in the processing of high-hardness metals and special materials. They are gradually entering high-end industries like aerospace and automotive manufacturing. Chinese CNC machines are now competitive with some traditional brands, making them the preferred choice for many industries.

Reliability and Durability

Chinese CNC machines have gained market recognition for their reliability, especially for mid-to-high-end brands. However, some lower-end Chinese CNC machines may still exhibit performance fluctuations, so special care should be taken when selecting them. Regular maintenance and servicing are critical for extending the lifespan of the machines.

Compared to European and American brands, the after-sales service network for Chinese brands is still expanding, particularly in international markets, where after-sales service coverage may not be fully established. Therefore, when purchasing a Chinese CNC machine, it is advisable to choose a brand that offers comprehensive after-sales service and warranty periods.

How to Choose the Right Chinese CNC Machine?

Choose Reputable Brands and Manufacturers

When selecting a Chinese CNC machine, the most important consideration is the reputation of the brand. Brands with a global influence, such as Dinosaw and Huada, have built a solid reputation in the international market. You can evaluate the quality and reliability of a product by reviewing user feedback and checking for certifications (e.g., ISO 9001, CE).

In addition, the manufacturer's production background and experience are crucial in determining the quality of the product. Opting for established manufacturers with mature technology ensures product performance and after-sales support.

Choose Based on Your Needs

Different businesses have different needs when it comes to CNC machines, so selecting the right machine requires a clear understanding of production requirements. For businesses with high-precision machining needs, it is advisable to choose machines that offer greater accuracy. On the other hand, businesses that require high-volume production can opt for machines with faster processing speeds and higher capacity.

After-Sales Service and Warranty

After-sales service and warranty policies are also important factors to consider when choosing a Chinese CNC machine. Quality after-sales service ensures that any issues with the machine can be promptly addressed, minimizing disruptions to production. Therefore, it is recommended to choose a brand that offers long-term warranty and has a well-established after-sales service network.

Conclusion

In conclusion, Chinese CNC machines offer excellent value for money with their competitive prices, high performance, and improving reliability. As technology continues to advance, Chinese CNC machines are gradually competing with international top-tier brands, especially in terms of precision and processing speed. When selecting a Chinese CNC machine, it is essential to evaluate the manufacturer's reputation, product performance, and after-sales service. Moving forward, as the Chinese CNC machine industry continues to develop, its global competitiveness will continue to grow, making it a key player in global manufacturing.