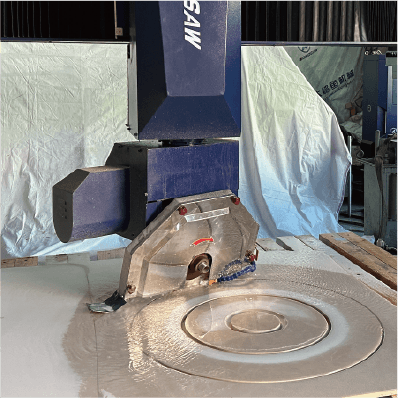

Intelligent 5 Axis CNC Bridge Cutting Machine

WZQJ-5N

Product features

1.Built-in 4G module in the machine.

2.24hours to check the operating status of the machine on the mobile phone.

3.Intelligent analysis of machine working data.

4.Machine life cycle management.

5.5 minutes skilled operation6.No programming design required, the system comes with a drawing library.

Technical parameters

Product Description

Functions of 5-axis bridge cutting machines included: all kinds of stone lines designs, arc-edge, French edge, straight edge, bevel edge, abnormity edge, antiskid slot, dry-hang, wash basin processing, and so on. Multifunction, Covering small areas, Low energy consumption, Simple operation, Accurate processing, easy and fast transformation between different functions. This makes the 5-axis bridge-cutting machine a sharp weapon for stone processing enterprises.

Product Advantage

Control System

CNC touch screen system. Easy setting with the automatic processing function. Make machining job easy, high efficient.

Hydraulic tilt table(optional)

The hydraulic tilt table allows fabricators to more easily loads materials. This feature reduces slab breakage, especially when loading exotic materials. The single cylinder lift system has a load capacity of 2,000 lbs. The tilt table can also be retrofitted onto a standard non-tilt table at a later date if desired.

Stable support

The hydraulic cylinder is used to control the turning movement of the table.

High precision cutting

Integrated drive servo motor, designed to achieve total digital integration with the CNC control system, creates a reliable controlling power for X, Y, Z axis.

Safe & Stable

Quality electrical components used to ensure stable performance.

All electrical components are housed and wired in an electrical cabinet. This allows for easy access and repairing when needed.

Maintainance

Auto Lubrication Hydraulic System

Automatic oil feeding lubrication system, make regular maintenance easy and reduce waste.

Maintain precision

Linear Guide take up with famous brand top quality linear to insure the movement of the machine in each axis.

Application

Stone, Slate, Artificial stone, Granite, Marble and various large, Medium and small stone decoration projects.

Certificate&Our partener

About us

Packing&Delivery

FAQ

Q:Are you manufacturer or trading company?

A:We have two factories, one for stone processing machines and another for diamond tools. Besides, we are the only new composite technology company in China's stone machinery industry that integrates AI+IOT software development team, electrical engineer team, mechanical design team, and mechanical production team.

Q:What is your maximum processing size?

A:Our biggest model is WZQJ-5N, its max. cutting size is 3200*2000mm. Can also be customized as per specific requirement.

Q:What's the warranty time?

A:One year, not including diamond blade,diamond segment etc. After warranty, we will continue to provide service support for client.

Q:Is it difficult to operate your machine?

A:Our machine is very simple and easy to operate. It takes around 2~3 days for installation & training, no need to learn programming or design, no need to have CNC background. We have patent for our operation system and cutting template gallery,such as countertop,Circle, Triangle, Rhombus, Sector etc.

Q:How do I install and operator the machine,after receiving it?

A:We will provide an installation video which will make the whole thing as easy as possible for the user. If there is any problem, our engineers can go abroad to help you install and debug the machine, and teach you how to operate and maintain the machine correctly.