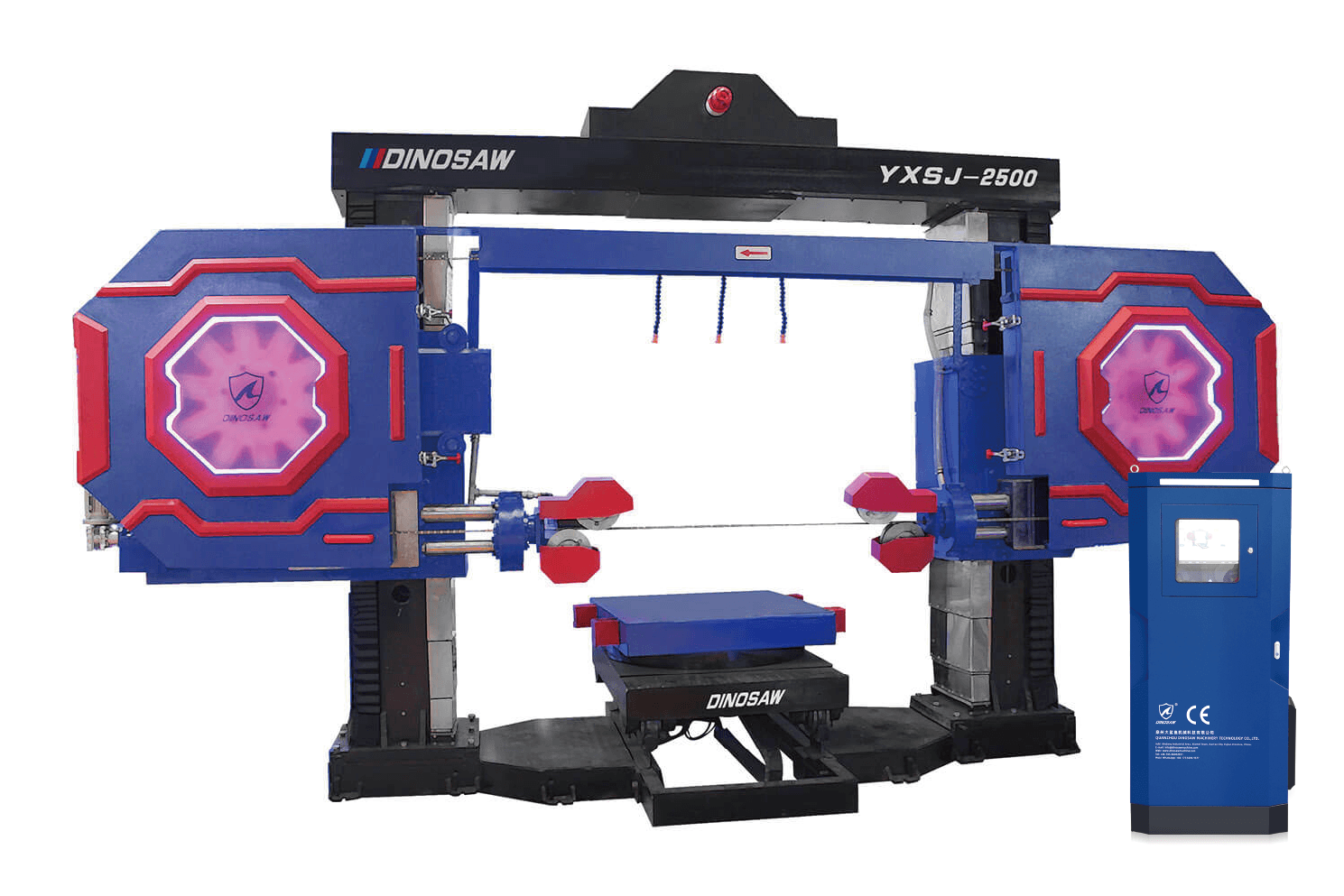

Intelligent CNC Wire Saw Machine

YXSJ-2000/2500/3000-15H

Product features

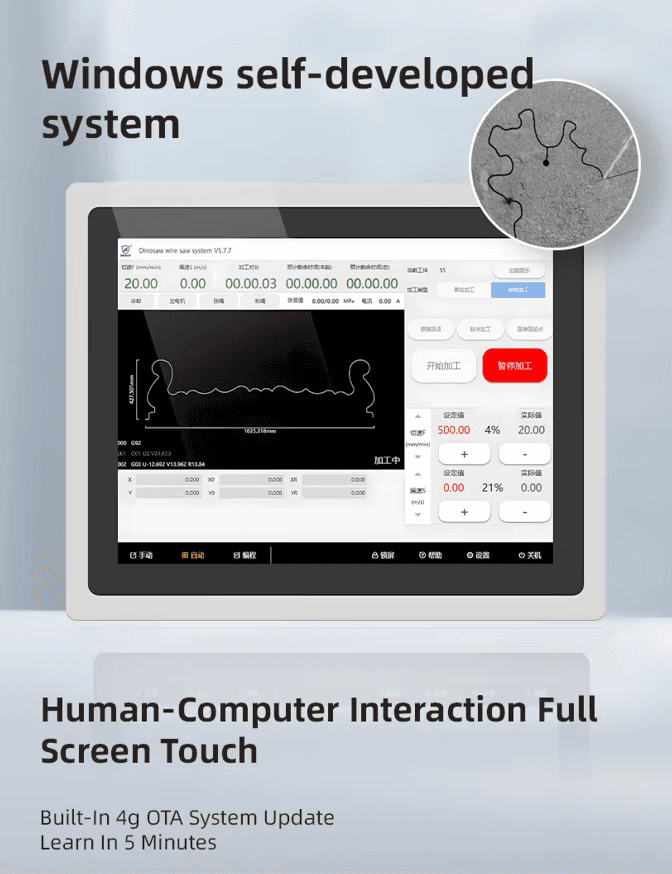

1. Patented operation system,easy to operate, train in 1~2days, no need to learn G code;

2. High cutting accuracy & Fast cutting speed;

3.Heavy duty structure,robust design, longer lifetime;

4.Remote service system,one-click automatic upgrade;

5.Turning cutting system is controlled by frequency convertorand will automatically identify,slow down the speed,reducethe loss of stone and tools;

Technical parameters

Product Description

Product Advantage

Why choose us?

Cutting speed 1.5-2.0㎡/h

Cutting accuracy within 1mm

50% faster high efficiency & accuracy

Easy operation, within in 5minitues

Built-in 4G & OTA system to upgrade

No CAD & No programming

Use App to get cutting information

Simple operation solves the problem of many buttons and complicated operation of the traditional wire saw machine, and reduces the learning time and cost of workers.

Under the same processing conditions, the cutting efficiency is 2-3 times faster than ordinary heterosexual wire saw machines, which improves the production efficiency of the factory.

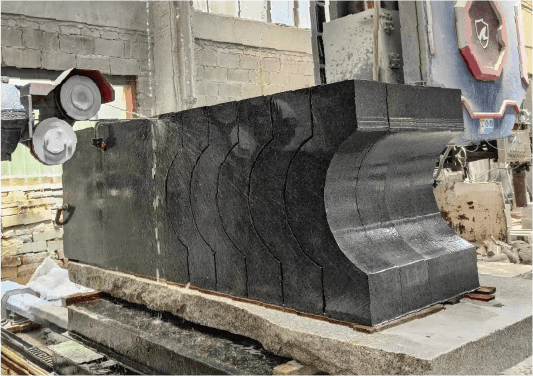

This machine can process various shapes of arc plates, Roman columns, numbers, letters of various countries, Chinese characters, etc.

Application&feature

Certificate&Our partener

About us

Packing&Delivery

FAQ

Q:Are you manufacturer or trading company?

A:We have two factories, one for stone processing machines and another for diamond tools. Besides, we are the only new composite technology company in China's stone machinery industry that integrates AI+IOT software development team, electrical engineer team, mechanical design team, and mechanical production team.

Q:What is your maximum processing size?

A:Our biggest model is YXSJ-4000-25H, its max. cutting size is 4000*4000*2500mm. Can also be customized as per specific requirement.

Q:Is your wire saw easy to get broken?

A:No. Our machine is equipped with hydraulic tension device + pressure sensor, which can automatically balance the wire pressure during production(accuracy up to 0.1Mpa), so that the wire always maintains tension and thus not easy to break.

Q:Is it difficult to operate your wire saw machine?

A:Our machine is very simple and easy to operate. It takes around 2~3 days for installation & training, no need to learn complicated G code, no need to have CNC background. We have patent for our operation system;

Q:How many tons stones can your trolley load?

A:We have different design for option, 20T, 30T or 50T etc. For trolley we apply heavy duty rail, which is same used for train, thus lifetime is longer. The trolley rotation adopts rotary support(same applied on loader), this is more stable and can bear more load compared to gear structure.

Q:What's the warranty time?

A:One year, not including wire saw, guide wheels, rubber ring, rubber strips etc. After warranty, we will continue to provide service support for client;

Q:Does your machine have remote control system?

A:Yes. Once connected with Internet, our service center engineer can enter the system to help check machine running status and correct setting parameters/datas if needed. Also we can transfer G Code or CAD drawing to the system and help upgrade the system future for free.