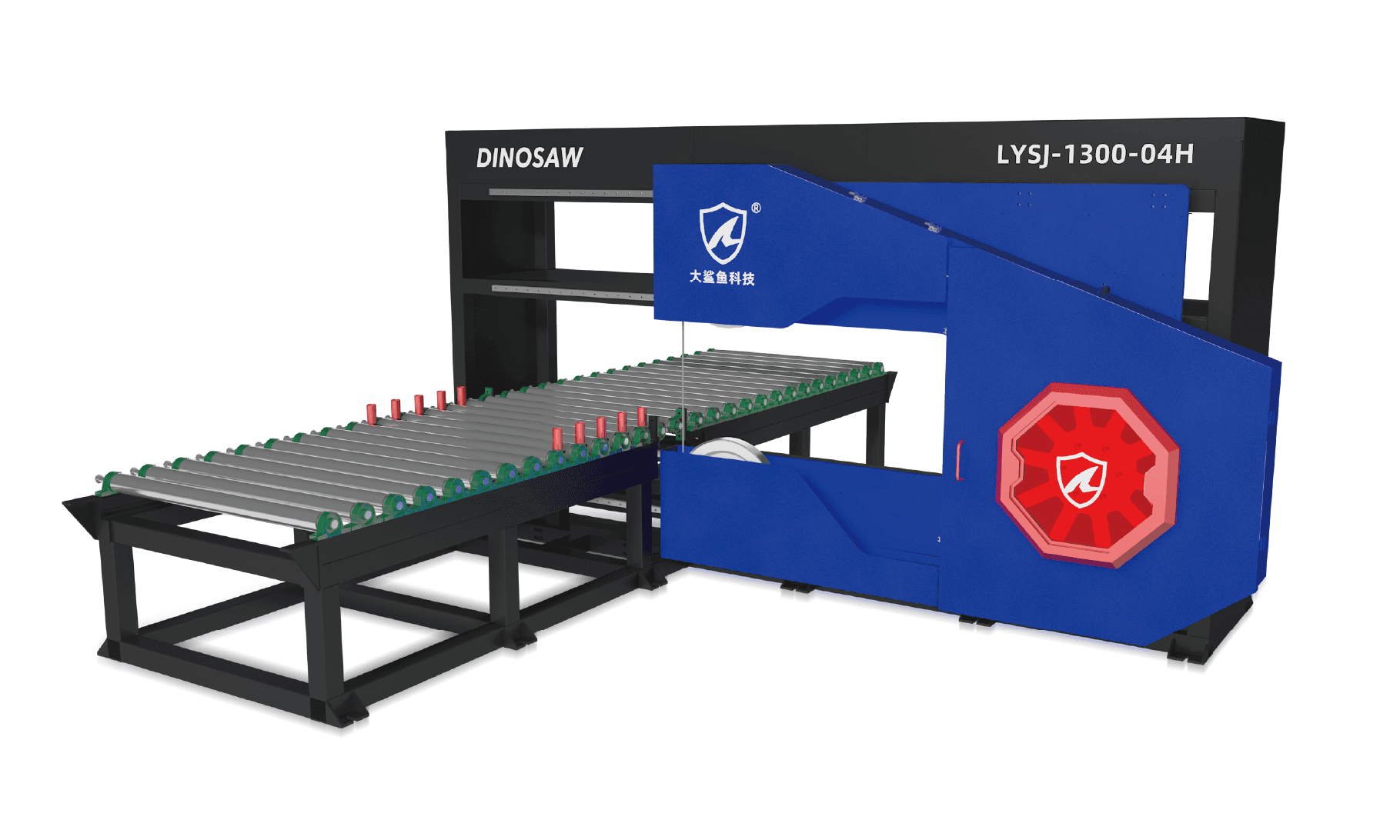

Intelligent vertical wire saw machine

LYSJ-1300-04H

Product features

Cutting accuracy of 1-3mm, micron-level servo motor control, high waterproof and dustproof grade, no loss of accuracy under poor working conditions.

Self-developed special system for arc cutting, replacing the traditional manual cutting, efficiency up to 1.5 square meters/h.

Stable cutting, not easy to break the rope, equipped with hydraulic tensioning device and pressure sensor, automatically increase or decrease the pressure during the cutting process.

Five-minute quick start, user-friendly operation interface.

Technical parameters

Product Description

The machine replaces manual cutting of curved stone slabs, with a cutting efficiency of up to 1.5 m²/h, which is 300% more efficient than the traditional way. It adopts CNC programmable control system and man-machine operation interface, supplemented by ultra-high precision rotary encoder positioning, and the speed can be adjusted according to the stone material. The key components are imported high-quality parts, with high cutting efficiency, strong stability, easy to operate and other advantages, especially suitable for batch cutting of curbstone and paving stone.

Specification

CNC control system

support multi-language

control cutting movement and cutting depth more precisely

High precision cutting

Dinosaw machinery uses branded motors to ensure cutting accuracy, coupled with the use of the reducer, it can ensure the high precision, high efficiency and high reliability of the stone machinery.

Safe & Stable

High-quality electrical components are used to ensure stable performance. All electrical components are

installed and wired in the electrical cabinet. This allows for easy access and repairs when needed.

Maintainance

Auto Lubrication Hydraulic System Automatic oil feeding lubrication system, make regular maintenance easy and reduce waste.

Maintain precision

Linear guides reduce wear and maintain accuracy for a long time

Application

Stone, cement, concrete, artificial stone, granite, marble, as well as road, park, garden stone decoration works.

Certificate&Our partener

About us

Packing&Delivery

FAQ

Q:Are you manufacturer or trading company?

A:We have two factories, one for stone processing machines and another for diamond tools. Besides, we are the only new composite technology company in China's stone machinery industry that integrates AI+IOT software development team, electrical engineer team, mechanical design team, and mechanical production team.

Q:What is your maximum processing size?

A:Our biggest model is YXSJ-4000-25H, its max. cutting size is 4000*4000*2500mm. Can also be customized as per specific requirement.

Q:Is your wire saw easy to get broken?

A:No. Our machine is equipped with hydraulic tension device + pressure sensor, which can automatically balance the wire pressure during production(accuracy up to 0.1Mpa), so that the wire always maintains tension and thus not easy to break.

Q:Is it difficult to operate your wire saw machine?

A:Our machine is very simple and easy to operate. It takes around 2~3 days for installation & training, no need to learn complicated G code, no need to have CNC background. We have patent for our operation system;

Q:How many tons stones can your trolley load?

A:We have different design for option, 20T, 30T or 50T etc. For trolley we apply heavy duty rail, which is same used for train, thus lifetime is longer. The trolley rotation adopts rotary support(same applied on loader), this is more stable and can bear more load compared to gear structure.

Q:What's the warranty time?

A:One year, not including wire saw, guide wheels, rubber ring, rubber strips etc. After warranty, we will continue to provide service support for client;

Q:Does your machine have remote control system?

A:Yes. Once connected with Internet, our service center engineer can enter the system to help check machine running status and correct setting parameters/datas if needed. Also we can transfer G Code or CAD drawing to the system and help upgrade the system future for free.