What is a Water Jet Used For?

Lizzy

Water jets, renowned for their precision and versatility, are cutting tools that have transformed various industries. From intricate designs in construction to advanced manufacturing processes, water jets offer unparalleled advantages over traditional cutting methods. This article delves into what water jets are, their benefits, applications, case studies, and future developments.

What is a Water Jet?

How Water Jets Work

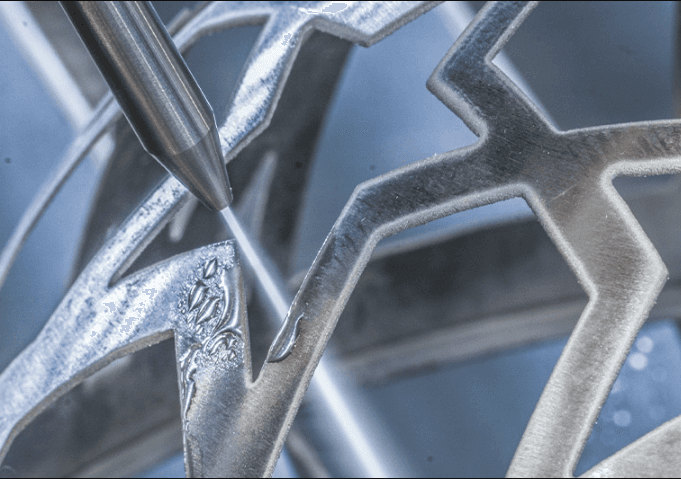

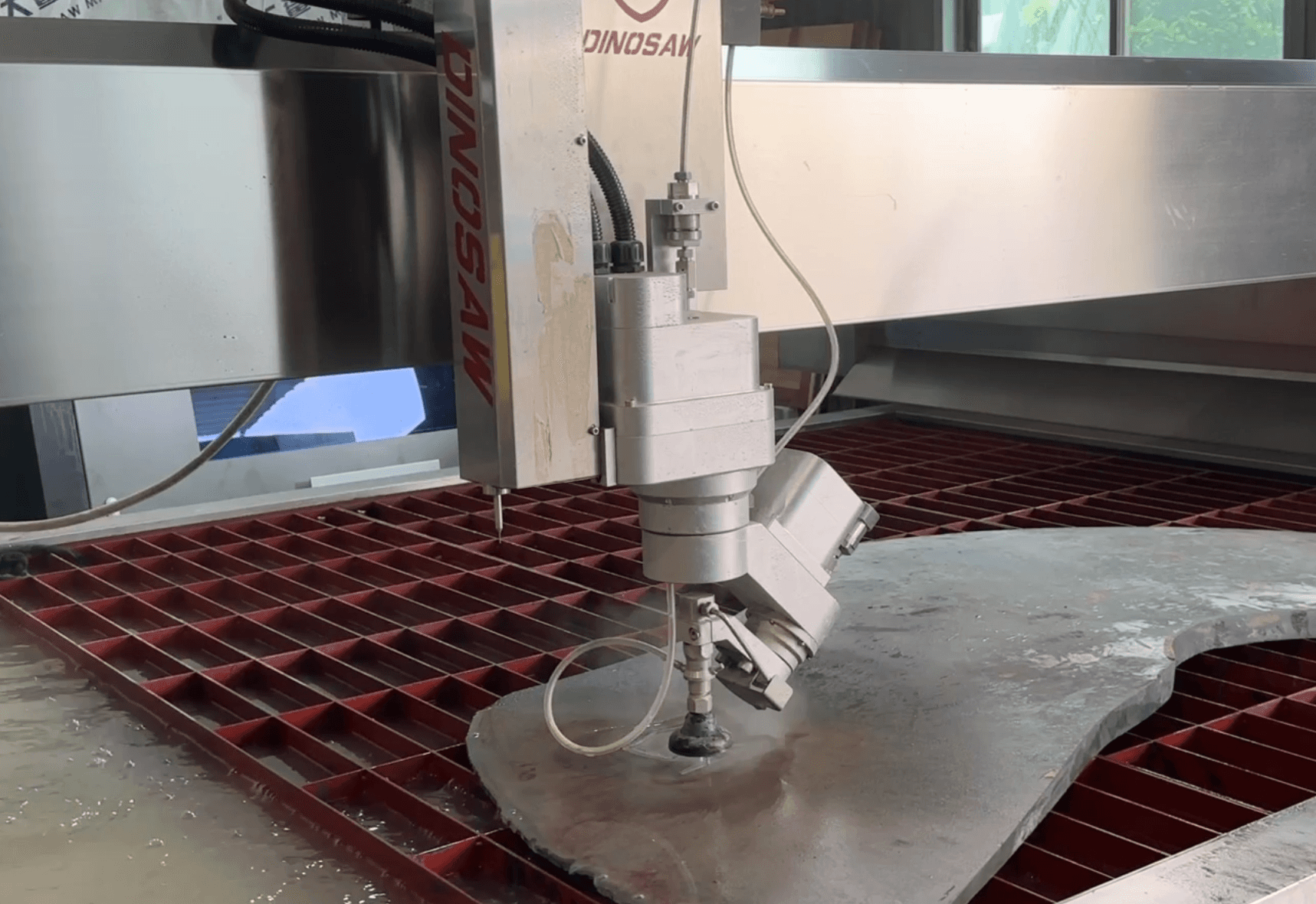

Water jets utilize high-pressure water streams, sometimes mixed with abrasives, to cut through materials. These streams are pressurized by ultra-high-pressure pumps and ejected through nozzles at incredible speeds, creating a cutting force capable of slicing through various materials. This cold-cutting process avoids heat-affected zones, preserving the integrity of the material.

Main Types of Water Jets

Pure Water Jets: Primarily used for cutting soft materials like rubber, foam, and wood.

Abrasive Water Jets: By adding abrasives to the water, these jets can cut through hard materials like metal and stone, making them a popular choice in industrial manufacturing.

Benefits of Water Jets and Comparison with Other Cutting Technologies

Key Advantages of Water Jets

No Heat-Affected Zone: The cold cutting process prevents high temperatures, ensuring the material's properties remain intact.

High Precision: Water jets can achieve intricate shapes and precise cuts with tolerances down to microns.

Eco-Friendly: Water jets primarily use water and abrasives, generating no harmful emissions, and the water can often be recycled.

Comparison with Other Technologies

Laser Cutting: While fast, lasers are less effective on thick materials and may cause thermal effects.

Plasma Cutting: Suitable for metals but lacks the precision of water jets.

Electrical Discharge Machining (EDM): Effective for hard metals but slower and suited for specific scenarios.

Applications of Water Jets

Industrial Manufacturing

Water jets are extensively used in the aerospace and automotive industries for cutting high-precision components. In aerospace, water jets are employed to process aircraft structural parts requiring strength and precision. In the automotive sector, they are used to cut complex shapes in chassis and engine parts, often meeting assembly-ready standards without additional machining.

Architecture and Decoration

Water jets play a pivotal role in high-end architectural and decorative applications due to their outstanding performance. Key use cases include:

Materials: Marble, granite, ceramics, and concrete. Water jets can effortlessly cut these materials, achieving crack-free, high-precision results.

Products: Customized mosaic flooring, intricate wall designs, and large sculptures. With water jets, designers can push the boundaries of traditional techniques, achieving intricate textures and refined aesthetics.

Scenarios:

Interior Design: Decorative wall tiles and floor tiles with seamless pattern integration.

Outdoor Landscaping: Fountain embellishments and engraved granite slabs, adding unique artistic touches.

Building Facades: Creating textured concrete surfaces that enhance aesthetic appeal and slip resistance.

Water jets have become indispensable in the architectural and decorative sectors, offering designers and architects limitless possibilities.

Medical and Food Industries

In the medical field, water jets are used to precisely cut high-strength metals and plastics for medical equipment. In food processing, they enable rapid, contamination-free cutting of seafood, meat, and frozen foods, meeting stringent hygiene standards.

Case Studies

High-End Decorative Materials

A premium interior design company used water jet technology to create custom mosaic flooring and artistic wall panels for a luxury hotel. These items, made from marble and granite, were cut with exceptional precision and smooth edges, greatly enhancing their artistic value. Client feedback highlighted reduced production time and material waste.

Aerospace Component Manufacturing

An aerospace manufacturer utilized water jets to cut high-strength alloy materials for critical airplane wing components. Traditional thermal cutting methods caused material deformation, but water jets eliminated this issue while ensuring dimensional accuracy. The adoption of this technology improved production efficiency by 30% and met stringent aerospace industry quality standards.

Food Industry

A large food processing plant used water jets to cut frozen fish and chicken. This method increased cutting speed while avoiding contamination risks associated with traditional blades, ensuring food safety and quality.

Future Developments

Advancements in Automation and Intelligence

With the rise of Industry 4.0, water jet systems are expected to become more intelligent and automated, enabling unmanned operations and real-time monitoring.

Development of Micro Water Jets

Future micro water jets will cater to precision industries like electronics manufacturing, achieving nanometer-level accuracy.

Sustainability Improvements

New water recycling systems will further reduce resource consumption, advancing eco-friendly industrial practices.

Closing Note

For more detailed specifications and technical parameters of water jets, view the waterjet product or consult us for comprehensive guidance.