Causes of Injuries in Stone Processing and How to Prevent Safety Accidents

Yuki

In the production and processing of stone products, there are various operational links such as lifting, cutting, sawing, grinding, polishing, resin filling, carving, handling, loading and unloading, and packaging. To better manage these processes, workers often need to be in specific production environments, accompanied by large stone materials and complex machinery.

As a result, there are many potential safety hazards around the workers, which increase the chances of them suffering physical injuries. Therefore, in the daily production process, it is necessary to seriously identify various potential factors that may cause harm to the workers and take appropriate regulations and protections to effectively strengthen and improve the safety production management of the stone industry.

So, what are the common causes of injuries in daily stone production and processing?

01. Mechanical Injuries

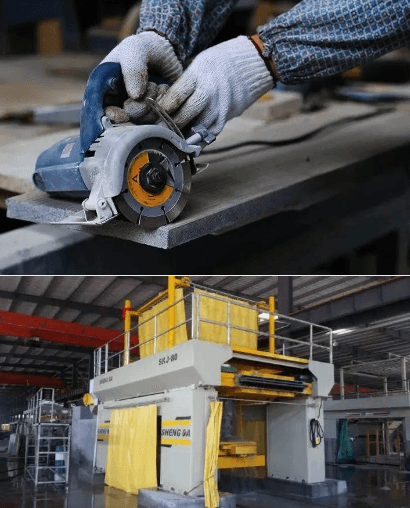

Since stone products are almost all completed by cold processing methods such as cutting, unlike cement, glass, bricks, and ceramics that require high-temperature firing. Therefore, in general stone production and processing workplaces, we can usually see rough cutting equipment, slab grinding and polishing equipment, slab cutting equipment, special-shaped processing equipment, wastewater treatment equipment, etc. The presence of these cutting devices is one of the biggest potential safety hazards for workers.

Over the years, safety accidents caused by various cutting equipment have been common. For example, during the processes of cutting, grinding, polishing, resin filling, carving, etc., workers may operate improperly during the manual feeding process, leading to finger sawing or bruising; for example, when replacing worn saw blades, if the nut is not tightened and power is suddenly applied, causing the saw blade to rotate at high speed and fly out, causing bodily harm; for example, workers enter the operating area when the rough material processing equipment such as the diamond frame saw is not completely stopped, resulting in the equipment hitting the body and causing serious injury; for example, during the operation of manual polishing machines, the grinding wheel bursts, causing fragments to fly out and injure the hand; and for example, during the processes of lifting, handling, loading and unloading, and packaging, a little negligence can also lead to workers being pinched by steel wire ropes or pricked by broken wire heads.

02. Slab Injuries

In addition to the potential for personal injury from machinery, being crushed, scratched, or hit by slabs is also a common cause of injury during the stone processing. After all, processing several tons to dozens of tons of rough material into slabs with a thickness of 1-3cm requires multiple steps such as cutting, lifting, handling, loading and unloading. Frequently working with stone does not guarantee that it will not cause physical harm to workers.

Over the years, there have been many news and videos about safety accidents of workers being crushed or hit by slabs in the stone industry. From these cases, it is not difficult to summarize the various ways in which slabs can harm workers. For example, when forklifts are used to transport stone or for lifting operations, workers manually support falling or broken slabs and rough materials, leading to stone crushing or crushing to death; for example, during the processes of cutting, trimming, and polishing, some stones may suddenly break, causing stone blocks to fall and injure the legs; and for example, when manually loading and unloading slabs, the sharp edges and corners of the slabs and the wire mesh can cut the palms of workers who do not wear protective gloves, causing serious injury.

03. Other Injuries

Because there are many high-altitude operations in the stone production and processing process, high-altitude falling accidents are also common. Most of these accidents occur during the stacking of rough materials, as stone rough materials are often not flat, and the stacking is not neat and uniform, so it is very unstable for people to step on, and a slight carelessness or rough material shaking during the operation may lead to personnel falling.

Due to environmental protection needs, wet operations are often seen in stone processing. In the workshop, there is a lot of dust and mud during the production process, which requires constant water spraying for dust suppression and mud removal. Saw blade cooling fluid and resin filling fluid will also often spill on the ground, and the ground needs to be cleaned from time to time, so some working areas are prone to being in a slippery state, leading to frequent slip and fall accidents.

In addition, a large number of wooden frames and wooden packaging boxes are needed for transportation, so a large number of nails are used in the stone processing operation. This leads to the fact that even if the working area is cleaned in time, scattered nails or wooden boards with nails can still be seen on the ground from time to time, and the presence of these nails often leads to careless workers being pricked.

In addition to the above common types of injuries, there are also types of injuries such as lifting injuries, vehicle injuries, electric shock, drowning, burns, fires, and container explosions during the stone processing process. Although the probability of such accidents is not high, it is still worth paying attention to by practitioners.

04. How to Prevent the Occurrence of Safety Accidents

It should be pointed out that in the daily production and processing process, the prevention of safety accidents by workers has a decisive role. The level of risk awareness and the strength of responsibility are crucial for the safe operation of the work site. Therefore, enterprises should resolutely stop the phenomenon of unlicensed workers, the擅自离岗 of maintenance personnel, and the untimely transfer of shifts, and strengthen the standardization and training of workers.

Firstly, relevant operators should undergo professional safety education and training, be familiar with safety production regulations and procedures, have the necessary safety production knowledge, and master the safety operation skills of their positions.

Secondly, some professional management positions should use professional personnel with certificates.

Thirdly, guide employees to seriously do a good job in handover work, organize and summarize the operation and maintenance of relevant equipment and work areas, thoroughly check whether each piece of equipment is running normally, record the results in detail, clean the site environment and equipment, and organize materials seriously.

Fourthly, enterprises should also strengthen the professional technical training of mining enterprise personnel, enhance the operation, maintenance, and management capabilities of the equipment management team, and focus on stimulating the enthusiasm of enterprise employees to learn knowledge and skills. In addition, enterprises should establish and improve safety protection measures. On the one hand, in addition to the traditional direct safety protection measures such as grounding, insulation, isolation, and spacing, it is also necessary to strengthen the automated transformation of safety protection devices such as leakage and electric shock, and actively apply monitoring systems to achieve remote monitoring and automated operation of the working status of main equipment. On the other hand, enterprises should establish a long-term mechanism to prevent equipment production safety accidents, formulate emergency rescue plans and on-site disposal plans for accidents, and strengthen drills. It is necessary to clarify the main hidden dangers that are prone to accidents and strengthen equipment management. In the whole process of preventing, supervising, and punishing accidents, it is important to focus on and strengthen the prevention link in advance, eliminate accident hidden dangers in time, and prevent accidents before they happen. Equally important is the purchase and maintenance of the equipment itself. On the one hand, when enterprises select and purchase electrical equipment, they should focus on the safety performance of the equipment and not overly pursue production efficiency. On the other hand, enterprises should establish a daily maintenance and regular maintenance system for equipment, adhere to the principle of "prevention first, maintenance and planned maintenance equally important", give full play to the enthusiasm of operators and maintenance workers, inspect the equipment on time, and confirm that there are no problems before it can be put into use. Once a problem occurs, it should be promptly taken according to the actual situation of the equipment. measures such as shutdown, replacement, and maintenance should be taken. Only by ensuring that the equipment will not have problems can the production efficiency of related work be greatly improved and the accident rate of related mining work be reduced to the lowest.

In summary, for every enterprise, it is very important to prevent the occurrence of safety accidents. Only by standardizing the safety production behavior of the enterprise, implementing safety technical measures, and increasing the safety management of equipment can the long-term safety production of the enterprise be achieved.