Safety and Quality Issues in Stone Application

Lizzy

Safety and Quality Issues in Stone Application

Ensuring safety and quality in stone application processes is crucial. Here are some key points that can help prevent accidents and ensure the longevity and aesthetics of stone products and projects.

Safety Precautions

Handling and Storage

Use appropriate handling equipment such as forklifts and cranes to avoid manual handling of heavy stone slabs.

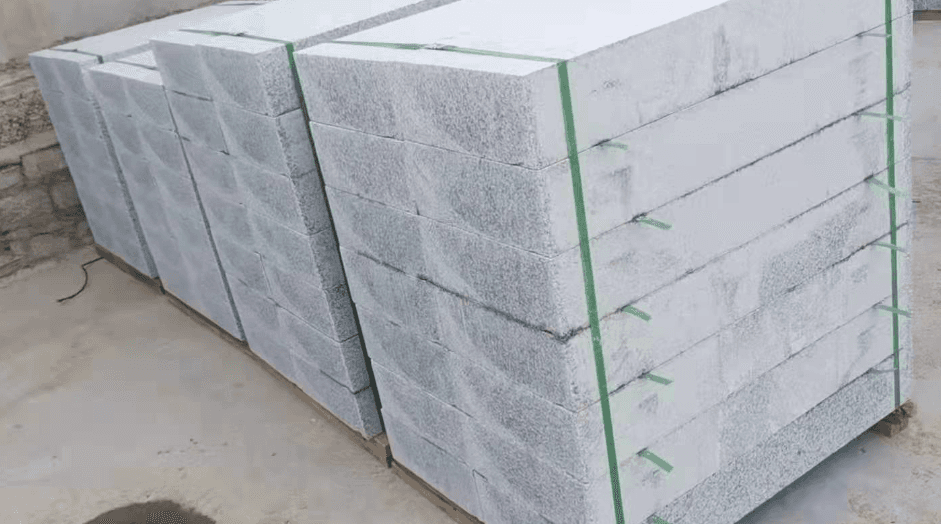

Properly store stone materials, ensuring stable stacking to prevent collapse.

Processing Operations

Always follow the manufacturer's safety guidelines when operating machinery.

Use protective gear such as safety goggles, dust masks, earplugs, and steel-toe boots.

Equipment Maintenance

Regularly maintain and inspect stone processing equipment to ensure it is in good condition.

Quality Issues

Material Selection

Choose high-quality stone materials that are consistent in color and free from cracks and defects.

Processing Accuracy

Ensure precise dimensions during the processing to avoid cutting and polishing errors.

Surface Treatment

The stone surface should be smooth, without scratches or cracks.

Construction Techniques

Use correct installation techniques and methods during construction.

Regular Inspections

Regularly inspect installed stone to ensure it is securely fastened and repair any damage promptly.

Conclusion

Safety and quality are paramount considerations in stone application. By taking appropriate preventive measures and quality control methods, you can ensure the beauty and durability of stone while protecting the safety of workers and the public.