Terrazzo Prefabricated Slabs: Production, Performance, and Construction Details

Lizzy

Terrazzo Prefabricated Slabs: Production, Performance, and Construction Details

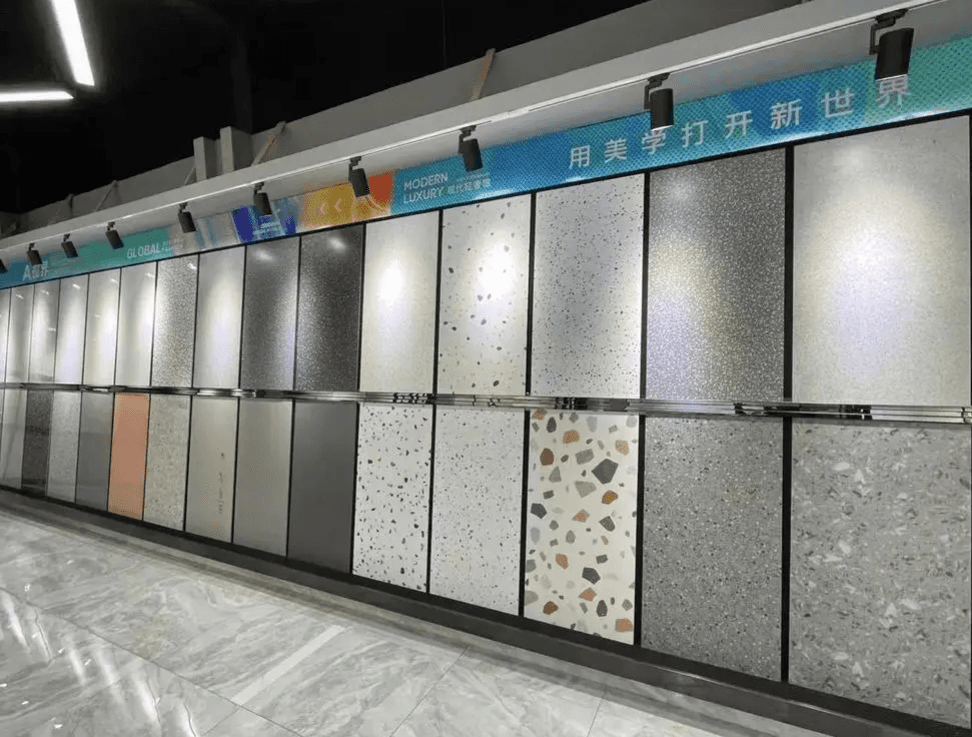

Terrazzo, once a nostalgic material from the 1980s, has transformed into a symbol of luxury and fashion in modern design. Today's terrazzo prefabricated slabs are versatile, suitable for flooring, and can be crafted into various decorative items. Here's a detailed overview of terrazzo prefabricated slabs.

Production Technologies

A. Pressing Technology

A traditional method where materials are mixed and pressed, requiring a curing period post-pressing. Common sizes are 600x600mm and 800x800mm, known for their low cost.

B. Raw Material Technology

Derived from engineered stone technology, originating from Italy and now domestically produced in China. Sizes typically include 1800x2700mm, 1600x2400mm, and 1600x3200mm, with a variety of imported materials and large aggregate options, moderately priced.

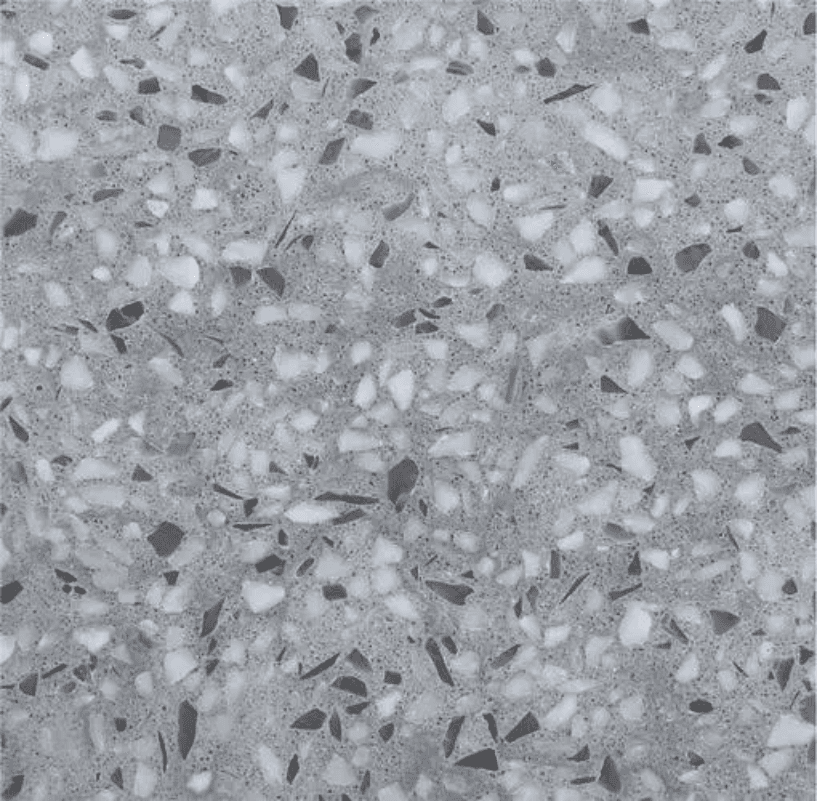

C. Vacuum Stone Technology

An innovative production process using "vacuum heterogeneous polymerization" technology, without glue or resin but with about 5% resin to fill internal voids. Common sizes are 1200x2400mm, known for excellent performance, stain resistance, durability, and slightly higher pricing.

D. Ceramic Tile Technology

A mature production technique distinct from engineered stone production, offering diverse designs but with printed surface patterns, suitable for cost-effective projects.

Performance Evaluation

Water Absorption Rate

Pressing: 1.33%-3.1%

Raw Material: 0.24%-1.33%

Vacuum Stone: 0.03%-0.17%

Abrasion Resistance

Pressing: 65.8mm

Raw Material: 44.2mm

Vacuum Stone: 28.6mm

Slip Resistance

Pressing: Dry 48, Wet 8

Raw Material: Dry 50, Wet 10

Vacuum Stone: Dry 51, Wet 14

Chemical Resistance to Acid and Alkali

Pressing: Not Tested

Raw Material: Acid Resistance C1, Alkali Resistance C4

Vacuum Stone: Acid Resistance C4, Alkali Resistance C4

Bending Strength

Pressing: 10.1 MPa

Raw Material: 13.1 MPa

Vacuum Stone: 72.1 MPa

Construction Details

Substrate Preparation

Ensure the substrate is solid, smooth, free of voids, clean, and free of oil, form-release agents, dust, and loose materials.

Adhesive Selection

It is recommended to use Type II cementitious adhesive for cost-effective leveling, but be aware of potential efflorescence, especially with white terrazzo styles.

Seam Methods

Seamless: Suitable for small areas to avoid bulging.

Small seams: 1mm, more aesthetic but may lead to inconsistent repairs.

Standard seam: 2mm, most suitable for both maintenance and appearance, especially in dark colors.

Grout Materials

Use matching color grout for seamless effects; polished with terrazzo for the best results.

Dry Hanging Methods

For walls over 3 meters, dry hanging is mandatory per national standards, similar to stone cladding methods.

Conclusion

Comparing performance indicators, vacuum stone stands out as superior. Raw material technology is slightly inferior but can be enhanced post-construction. Pressing technology is average, recommended for flooring only.

This comprehensive guide to terrazzo prefabricated slabs covers production processes, performance evaluations, and essential construction details to ensure the best results in your projects.