The Benefits and Techniques of Polishing Diamond Tool Heads

Yuki

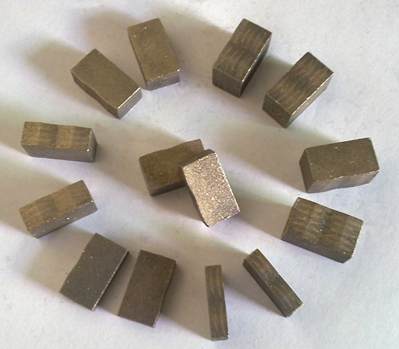

I. Advantages of Polishing Diamond Tool Heads

Enhanced Surface Smoothness: Polishing significantly improves the surface smoothness of diamond tool heads, reducing friction during cutting and enhancing efficiency.

Increased Durability: The process removes minor cracks and impurities from the surface of the diamond tool head, enhancing its durability and extending its service life.

Improved Heat Dissipation: A smoother surface post-polishing allows for better heat dissipation, preventing damage caused by heat concentration.

Increased Contact Area with Cooling Fluid: Polishing increases the contact area between the diamond tool head and cooling fluid, thereby enhancing the cooling effect and preventing overheating.

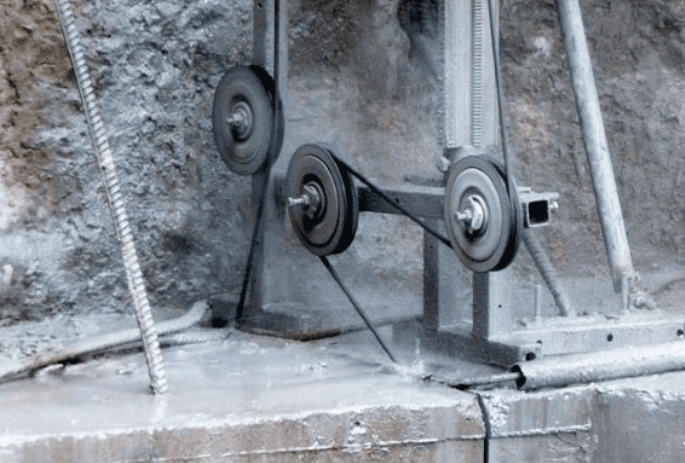

II. How to Polish Diamond Tool Heads

Selecting the Right Polishing Agent: Choose an appropriate polishing agent based on the material of the diamond tool head and the polishing requirements, such as diamond grinding fluid or polishing paste.

Preparing Polishing Tools: Select the right polishing wheel, polishing machine, and other tools, ensuring the tool's rotation speed and the supply of polishing agents are suitable.

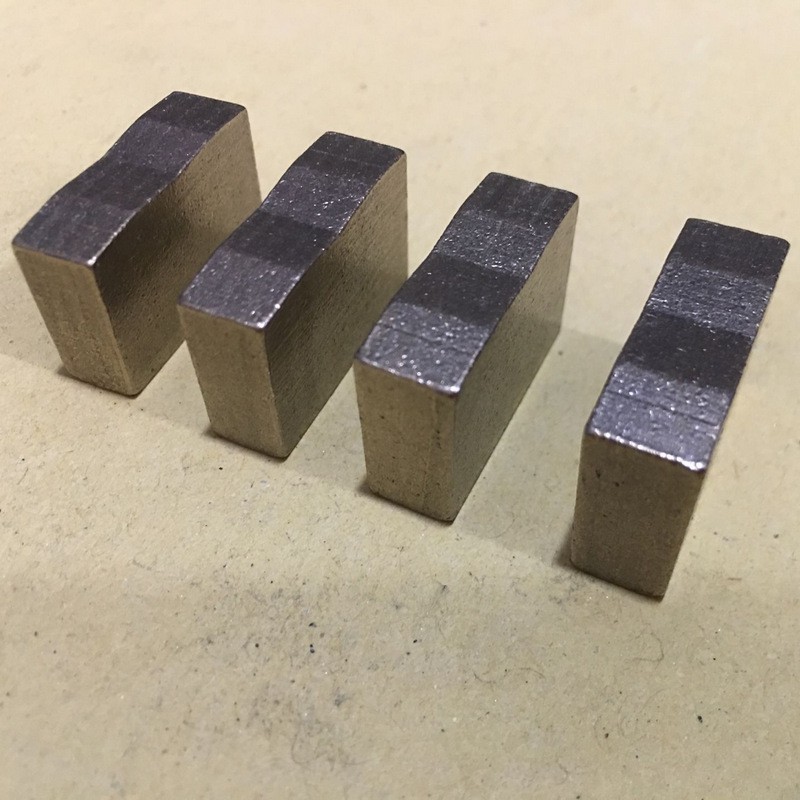

Coarse Polishing: Place the diamond tool head on the polishing wheel, apply an adequate amount of polishing agent, and perform preliminary polishing to remove burrs and oxidation layers from the surface.

Fine Polishing: Based on coarse polishing, use a finer polishing agent for fine polishing to achieve a higher level of surface smoothness.

Cleaning and Drying: After polishing is complete, clean the diamond tool head with a cleaning agent and then dry it with a clean cloth.

III. Precautions During the Polishing Process

Controlling Polishing Pressure: Control the polishing pressure during the process to avoid surface damage to the diamond tool head due to excessive pressure.

Maintaining Polishing Wheel Cleanliness: Regularly check the cleanliness of the polishing wheel during the process to avoid affecting the polishing outcome.

Controlling Polishing Time: Control the duration of the polishing process to prevent excessive wear on the diamond tool head's surface.

Avoiding High Temperatures: Prevent high temperatures during polishing to avoid thermal damage to the diamond tool head.

Using Safety Equipment: Utilize safety equipment such as protective goggles and gloves to prevent injuries.

Proper Storage: After polishing, store the diamond tool head properly to avoid contamination and damage.

In Conclusion, polishing diamond tool heads can improve surface smoothness, durability, and heat dissipation performance. However, during the polishing process, it is crucial to control parameters such as pressure and time to ensure no damage is inflicted on the diamond tool heads.