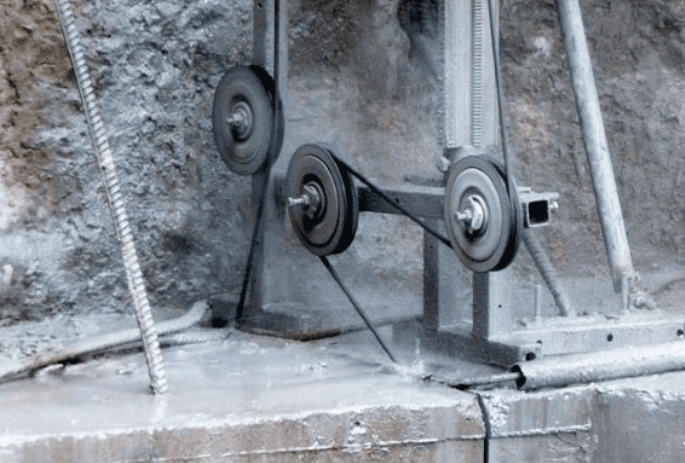

Addressing Vibrations in Diamond Wire Saw Cutting Processes

Yuki

Vibrations during the cutting process with a diamond wire saw can arise from various factors, which may act individually or in combination. Here are some common causes and their respective solutions:

Inhomogeneous Cutting Material: If the density or hardness of the cutting material is uneven, the diamond wire saw may vibrate as it moves through different material areas. The solution is to ensure material uniformity and select appropriate cutting parameters when possible.

Insufficient Wire Tension: If the tension of the wire saw is inadequate, it may become loose and cause vibrations. Check and properly adjust the tension of the wire saw to ensure it remains within the correct range.

Wire Saw Damage or Aging: A wire saw may lose stability due to damage or aging, leading to vibrations. Regularly inspect the condition of the wire saw and replace it promptly if it is damaged.

Excessive Cutting Speed: High-speed cutting can cause the diamond wire saw to bounce on the material, resulting in vibrations. Reduce the cutting speed to make it more controllable.

Inconsistent Cutting Depth: If the cutting depth varies across different parts, the saw head may encounter different levels of resistance, causing vibrations. Ensure consistent cutting depth and make adjustments as needed.

Loose Saw Head: If the saw head is not properly secured or is loose, it may vibrate during cutting. Check and ensure the saw head is firmly installed.

Unstable Worktable: The instability of the worktable can also lead to vibrations during the cutting process. Ensure the worktable is stable, and consider using more stable work supports.

Improper Cutting Angle: The cutting angle can affect the stability of the cut. Ensure the cutting tool is correctly adjusted to the required cutting angle.

Inappropriate Saw Head Selection: Sometimes, an unsuitable saw head can cause vibrations. Ensure the saw head chosen is suitable for the cutting task at hand.

Lack of Operator Experience: The experience and skill of the operator are crucial in avoiding vibrations. Training and improving the operator's skill level can reduce the occurrence of vibrations.

Wire Saw Wear and Aging: Prolonged use can wear down the wire saw, affecting the stability of the cut. Regularly inspect the degree of wear on the wire saw and replace it if it has aged.

Addressing vibration issues requires a comprehensive consideration of the above factors, taking appropriate measures based on specific situations. Typically, regular inspection and maintenance of the cutting equipment, correct selection of saw heads and cutting parameters, and training of operators are effective ways to reduce vibration problems.