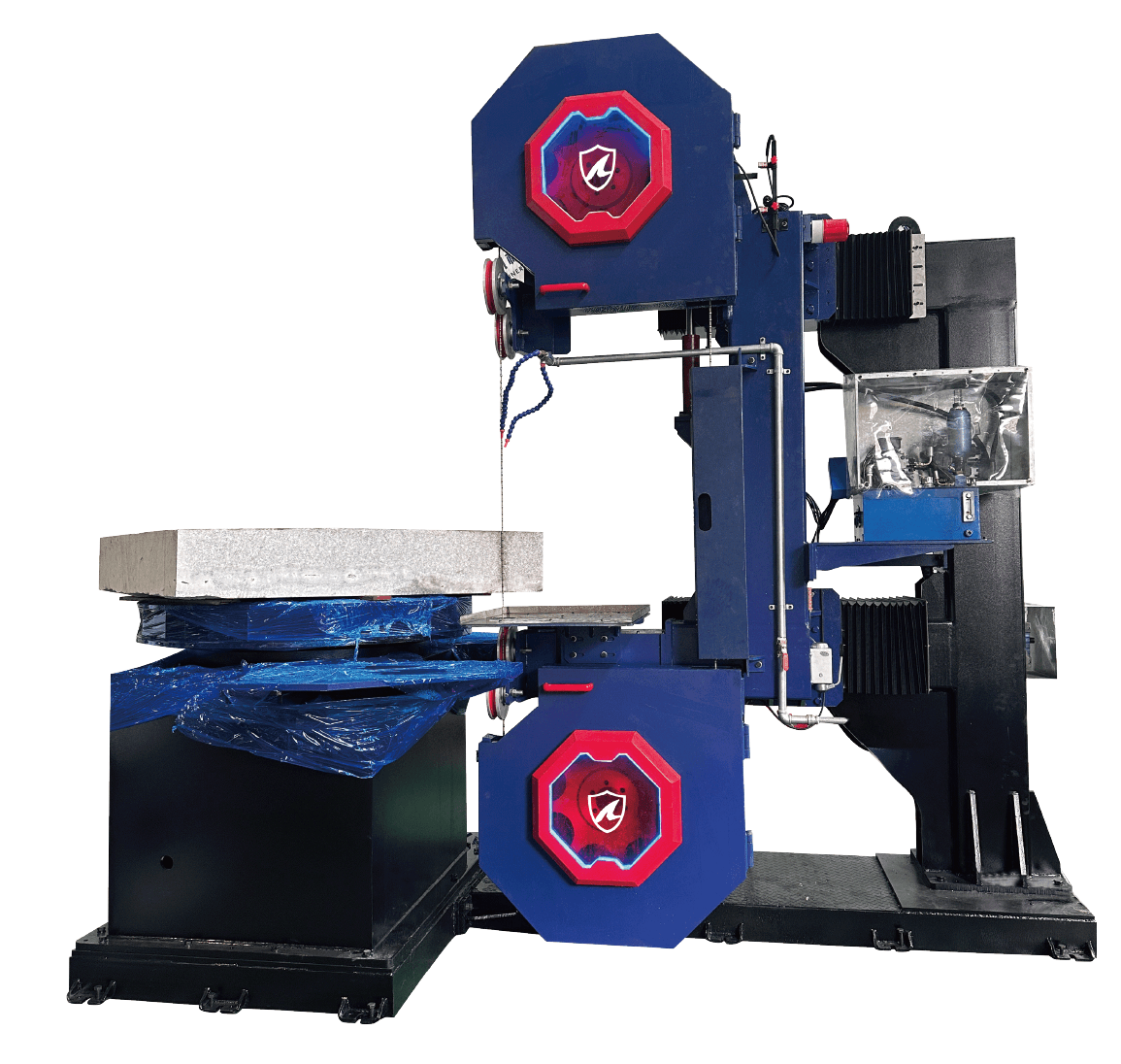

Vertical Diamond Wire Saw Cutting Machine

LSSJ-800

The Vertical Diamond Wire Saw Cutting Machine is designed specifically for small-scale stone processing, concrete, and metal cutting. Its compact design and high cutting performance make it an ideal choice for stone factories, especially for applications such as tombstone cutting, curb stone cutting, stone sculpture, and rough cutting of decorative stone products.

Product Overview of Vertical Diamond Wire Saw Cutting Machine

With its vertical cutting structure, this machine breaks through the traditional horizontal cutting methods. The Vertical Diamond Wire Saw Cutting Machine offers high cutting speed and exceptional precision while occupying minimal space, making it perfect for small-scale stone processing factories requiring high precision and multifunctional cutting. Compared to other large wire saw machines, it has lower investment and maintenance costs, making it an ideal tool for cutting irregular stone shapes, small stone blocks, and complex designs.

Key Features of Vertical Diamond Wire Saw Cutting Machine

Compact Design and Space-Saving:

The Wire Saw Cutting Machine adopts a compact design, occupying only 1.2 square meters. Compared to traditional horizontal wire saw machines and large wire saw machines, this equipment operates more efficiently in small-scale factory environments with limited space.Cost-Effective and Efficient:

This machine offers a more cost-effective solution than large wire saw machines. Despite its lower cost, it still maintains excellent performance and high cutting accuracy, making it a great investment for stone processing factories.High Cutting Efficiency and Precision:

The Vertical Diamond Wire Saw Machine can cut at precision of up to 1mm, meeting various cutting needs, including straight and irregular shape cuts.Multifunctional Cutting Ability:

This machine can be equipped with different types of diamond wire saws, such as concrete wire saw and diamond wire saw for metal, allowing it to cut stone, concrete, and metal according to the requirements. It is especially suitable for industries with high precision stone processing needs.Easy-to-Operate PLC Control System:

The PLC control system makes operating the machine simple. Users can easily adjust parameters via an intuitive interface. The PLC system enhances operational precision and stability while simplifying the machine’s use.

Applications of Vertical Diamond Wire Saw Cutting Machine

Small-Scale Stone Processing Factories:

The Vertical Diamond Wire Saw Cutting Machine is an ideal choice for small-scale stone processing factories. It can efficiently cut granite, marble, and other types of stone, meeting the needs for various shapes and sizes.Concrete Cutting:

When equipped with a concrete wire saw, this machine can easily cut concrete blocks, making it suitable for construction demolition and concrete structure cutting.Metal Cutting:

The Vertical Diamond Wire Saw Cutting Machine can also be equipped with a diamond wire saw for metal to cut different types of metals. Whether it is steel or aluminum, this machine provides an efficient metal cutting solution.Tombstone Cutting:

In the production of tombstones, the Vertical Diamond Wire Saw Cutting Machine can precisely cut stone, meeting the complex and customized needs of tombstone cutting.Curb Stone Cutting:

In urban construction and landscaping projects, this machine can quickly cut curb stones, ensuring precise shapes and smooth surfaces.Stone Sculpture Cutting:

This equipment can be used for rough cutting of stone sculptures, helping customers create exquisite sculptural works.Rough Cutting for Stone Decorations:

The machine is perfect for the production of stone decorations, capable of fast rough cuts.

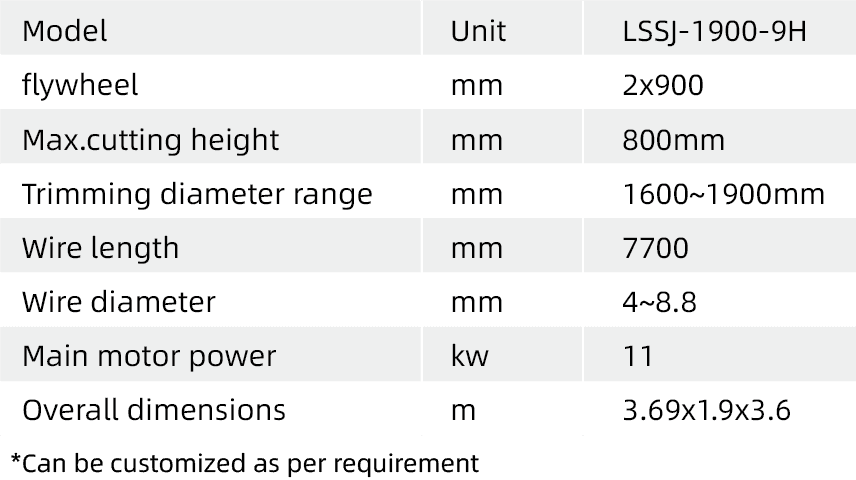

Technical Specifications

Why Choose This Product

Space-Saving, Suitable for Small Factories:

The compact design makes it suitable for small-scale stone processing factories with limited space.Highly Cost-Effective:

Despite its low cost, this machine offers excellent performance, reducing investment pressure on businesses.High-Precision Cutting and Flexible Adaptability:

Capable of cutting various shapes and sizes of stone, concrete, and metal, it meets diverse cutting needs from customers.Easy Operation and Increased Efficiency:

The PLC control system makes the operation of the machine simple, reducing the complexity of manual operation and increasing production efficiency.Strong Multifunctionality:

This machine is versatile, suitable for cutting not only stone but also concrete and metal, adapting to the needs of various customers.