The Impact of Stone Slab Thickness on Usage

Yuki

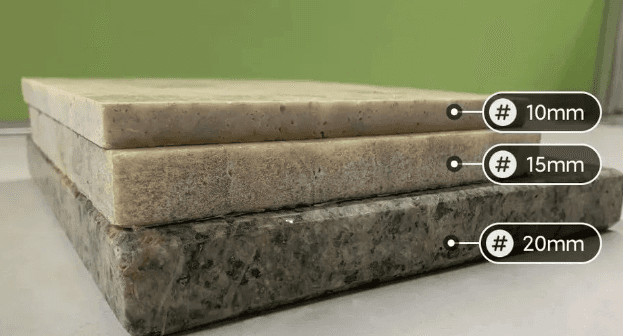

When it comes to the use of natural decorative stone, the thickness of the slabs plays a critical role in determining their performance, durability, and aesthetic appeal. The market commonly sees a variety of thicknesses, each with its own set of implications for use.

Influence on Cost: The thickness of the stone slab directly affects the yield rate during the cutting process from the block. Thinner slabs increase the yield rate, which can reduce costs. For instance, with marble, the yield per cubic meter varies with slab thickness: an 18mm thick slab can yield 45.5 square meters, while a 20mm thick slab yields 41.7 square meters, and so on. This indicates that thinner slabs, while potentially more cost-effective, may also be more fragile and prone to damage.

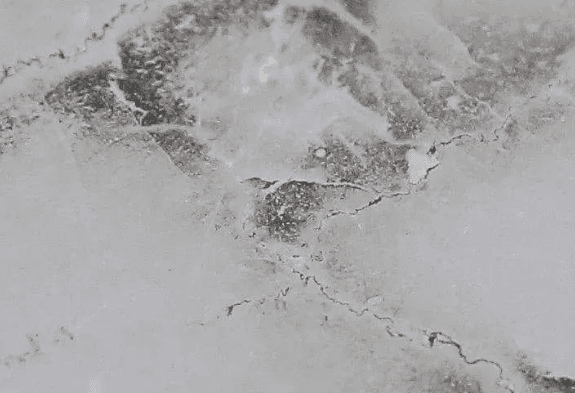

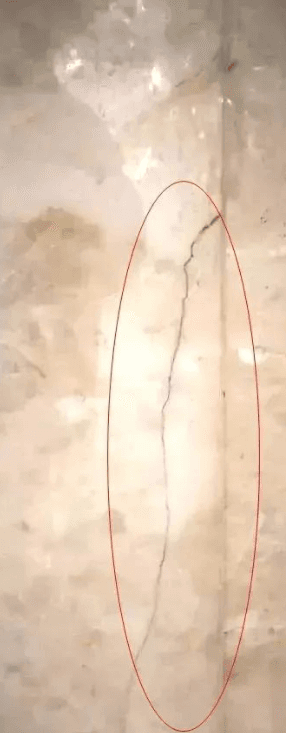

Impact on Stone Quality: The thinner the slab, the weaker its compressive strength, making it more susceptible to breakage. Thicker slabs, on the other hand, offer greater resistance to pressure and are less likely to crack or chip. However, excessively thin slabs may also be more prone to staining from adhesives like cement, which can seep through and discolor the stone's surface. Additionally, they may be more likely to warp or delaminate over time.

Effect on Service Life: Stone, with its unique properties, can be restored to a like-new condition through polishing and refurbishment after prolonged use. However, this process involves some wear and tear on the stone. Slabs that are too thin may eventually risk quality degradation due to the cumulative effects of such maintenance procedures.

To prevent issues associated with thin stone slabs, it's crucial to select the appropriate thickness based on the application. For instance, slabs used for flooring or exterior cladding may require a thicker specification to withstand the elements and heavy foot traffic. Interior applications, such as wall coverings or countertops, may have more flexibility in terms of thickness, although even here, a balance must be struck between aesthetics and practicality.

In conclusion, while thinner stone slabs can offer cost savings and a lighter alternative for certain applications, it's essential to consider the potential impact on durability, resistance to damage, and long-term maintenance requirements. Thicker slabs may come with a higher upfront cost but can provide a more robust and enduring solution for many projects.