Common Quality Issues with Diamond Tool Heads in Stone Processing

Yuki

Diamond tool heads, essential in the production of stone materials, can encounter various issues during manufacturing that affect their performance. These issues can stem from improper operation, formula errors, or problems in the mixing of binders, and often result in tool heads that are unusable or inefficient, impacting production efficiency and increasing costs. The common quality issues with diamond tool heads include:

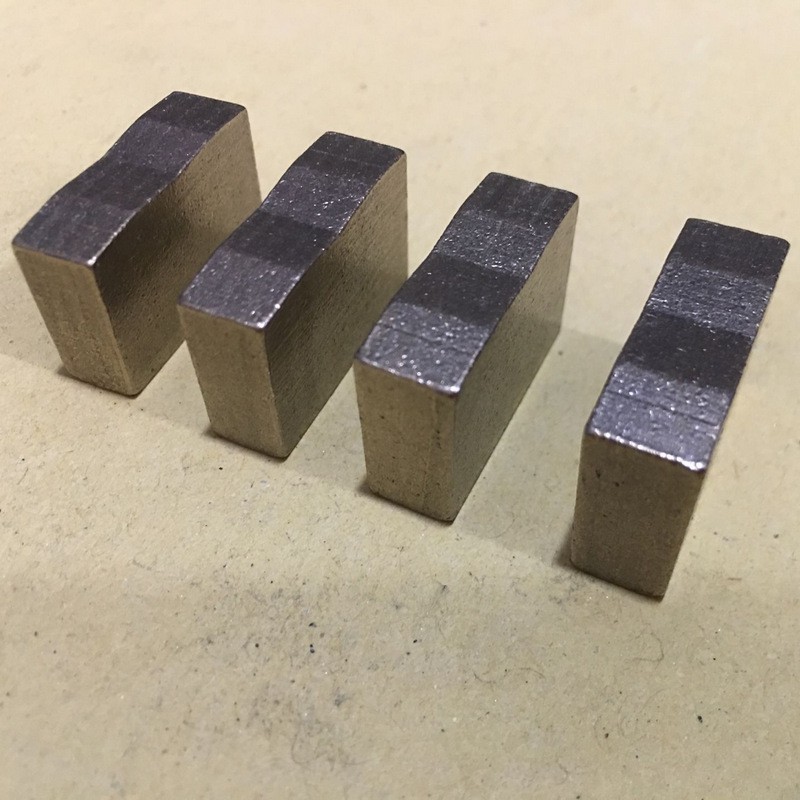

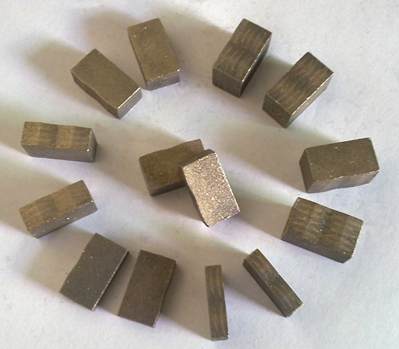

Dimension and Specification Problems Diamond tool heads, made from a mixture of metal alloy and diamond sintered in a fixed mold, are subject to variations due to uneven pressure or temperature during sintering. This can lead to inconsistent sizes, most notably in the height of the tool head, where insufficient pressure results in higher spots, and excessive pressure leads to lower areas. It is crucial to maintain consistent pressure and temperature during production, and to accurately weigh the cold-pressed material before pressing. Issues such as non-compliant dimensions, inadequate density, insufficient hardness, impurities in the transition layer, and insufficient tool head strength can occur.

Insufficient Density and Tool Head Softness Tool heads with insufficient density are prone to breakage during the cutting process, rendering them unusable. Whether local or complete, such breakage signifies the end of the tool head's utility. Even short of breaking, a tool head with low density may fail to cut stone effectively or may wear out quickly due to its lower Mohs hardness. Ensuring the density of the tool head is critical to its performance.

This situation often arises from incorrect sintering temperature, insufficient holding time, inadequate pressure, poor binder material selection, or an overly high diamond content. Such occurrences are common and can be due to improper operation by workers or, in the case of new formulas, a lack of precise understanding of the formula by design personnel. Designers must fine-tune the formula, taking into account temperature and pressure to establish optimal sintering conditions.

Inability to Cut Stone The primary reason a diamond tool head fails to cut stone is due to insufficient strength, which can be attributed to:

Insufficient or poor-quality diamonds;

Internal mixing of the tool head material with impurities such as graphite particles or dust, especially when the mixing process is not uniform;

Excessive carbonization of diamonds due to high temperatures, causing diamond particles to easily detach during cutting;

An unreasonable tool head formula or sintering process, leading to low strength in the working and transition layers (or poor binding between the working and non-working layers), a common issue with new formulas;

The binder being too soft or hard, leading to disproportionate wear of diamonds and metal binders, causing the binder to fail in holding the diamond powder.

Tool Head Detachment Detachment of the tool head can be caused by various factors, such as excessive impurities, temperatures that are too high or too low, insufficient holding pressure and time, inappropriate formula ratios, or unreasonable welding layers. Differences in the formulas of the working and non-working layers can lead to different coefficients of thermal expansion, causing stress at the junction during cooling, which reduces the tool head's strength and can lead to detachment. To address this, ensure the powder material is well mixed without impurities, apply appropriate pressure, temperature, and holding pressure time, and try to keep the coefficients of thermal expansion of the working and non-working layers similar.

Other issues that may arise during the processing with diamond tool heads include rapid wear, jamming, or uneven grinding. Many of these problems are not solely related to the tool head itself but may be caused by machinery or the type of stone being processed.