The Art of Chamfering: Crafting Curbstones with Precision

Yuki

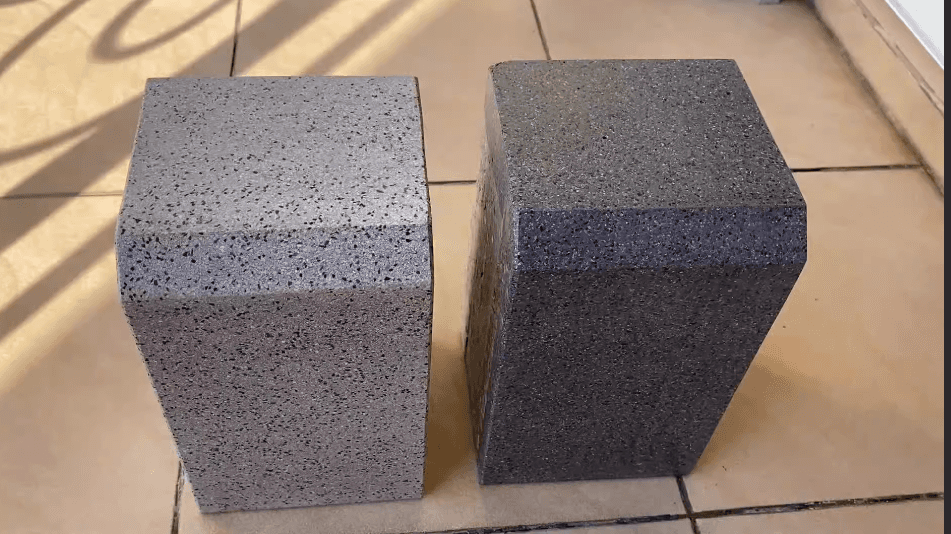

Curbstones are one of the most prevalent types of decorative stone, often beginning as a square prism when quarried. However, the curbstones we commonly encounter feature beveled or rounded edges, a process known as chamfering. Chamfering refers to the technique of cutting edges at a certain angle to create a slanted surface. So, how is chamfering performed on curbstones? There are various methods for chamfering curbstones, including fully automatic, semi-automatic, and manual approaches.

Fully automatic chamfering utilizes specialized chamfering machines that operate autonomously once parameters are set. However, these machines are not widely adopted due to their space consumption and infrequent use. Most stone factories produce not only curbstones but also a variety of other stone products such as flamed boards, polished slabs, and bush-hammered surfaces. Therefore, semi-automatic and manual chamfering methods are more commonly used.

Semi-automatic chamfering involves the use of infrared cutting machines. After rough-cutting the stone to the required thickness, the slab is then cut to specification, and finally, the saw blade's inclination is adjusted to achieve the chamfer. This method is suitable for beveled edges but not for rounding.

Manual chamfering is most frequently used for rounding edges. Generally, a 1-2cm quarter-circle edge is the easiest to create, as it can be simply ground with a grinder. The most challenging is the large round edge of about 5cm, which requires meticulous grinding by workers to ensure a consistent curvature, crucial for the neat arrangement of curbstones.

The most commonly used methods currently are semi-automatic infrared cutting machines for beveled edges and manual grinding for rounded edges. The price for beveled edges ranges from 2-3 USD per meter, while for 1-2cm rounded edges, it is 3 USD per meter, and for 4-5cm rounded edges, it is 5 USD per meter.

Curbstones, a type of dimension stone, are elongated, block-shaped objects cut from stone material and used as boundary stones along road edges. They are also known as kerbstones or pavement stones. Curbstones serve to delineate boundaries between vehicle lanes, sidewalks, green spaces, and other parts of the road, ensuring pedestrian and vehicle safety and maintaining the neatness of the road edge. Based on their cross-sectional dimensions, curbstones can be classified into H-type, T-type, R-type, F-type, TF-type, and P-type. They are also categorized by line type into curved and straight curbstones. Flamed curved curbstones can be used in conjunction with straight curbstones. With the ever-changing urban landscape, the beautification of urban spaces has become an urgent demand. The emergence of new, scientifically designed colored pavement bricks and anti-color tiles has played a new movement in beautifying urban living spaces, characterized by high strength, high texture, wear resistance, non-fading, and smooth lines, making them a main theme in today's urban spaces.

Quality Standards for Curbstones: Straightness: 10mm; Height difference between adjacent blocks: 3mm; Joint width: ±3mm; Side stone top elevation: ±10mm.

The installation forms of curbstones include vertical, slanted, and flat styles. Walking on curbstones is a simple and effective walking method to regulate the balance of the body's organs, increasing enjoyment, preventing and treating diseases, and extending life, all while ensuring pedestrian and vehicle safety and maintaining the neatness of the road edge. The construction process of curbstones, from excavating the roadbed, installation, to back reinforcement, is introduced, along with a summary of quality requirements and considerations to ensure construction quality and enhance the aesthetics of roads.

Material Requirements for Curbstones: The stone material for curbstones is made from uniformly textured natural macstone, mechanically cut and processed. The strength of the stone must be qualified, with uniform color, no cracks on the surface, complete edges and corners, consistent appearance, no obvious spots or color differences, and no signs of weathering. During handling, it is forbidden to drop, smash, hit, or bump to avoid damage.

Processing Requirements for Curbstones: Material is cut to a uniform length, with exposed surfaces requiring machine cutting and polishing. The allowable error in length is within ±20mm, and the allowable error in width, thickness, and height is within ±2mm.