Processing Methods for Sesame Grey Granite Flamed Slabs

Lizzy

Processing Methods for Sesame Grey Granite Flamed Slabs

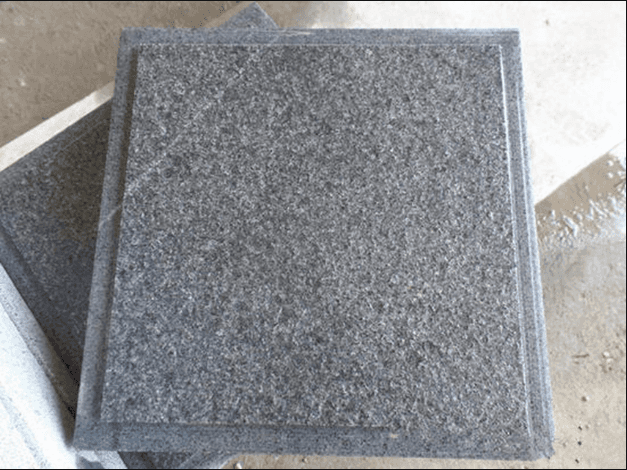

Sesame grey granite flamed slabs are popular for their distinctive appearance and anti-slip properties. Here are the common processing methods for sesame grey stone flamed slabs:

1. Processing Methods for Edge-Cut Sesame Grey Stone Flamed Slabs

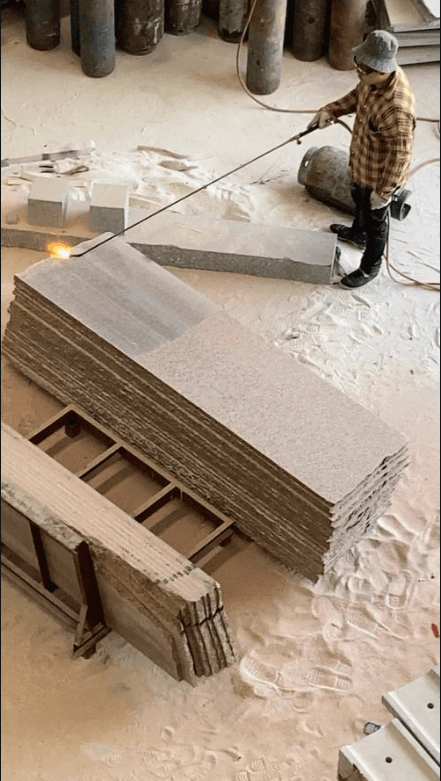

(1) Flame First, Then Cut

Worktable: Use an iron frame worktable to place the rough slabs.

Gas Cutting Torch: Position at a 60° angle to the slab surface.

Water and Gas: Control water flow to 2L/min and adjust oxygen and liquefied gas consumption.

Feed Speed: Ensure even heating and adjust the torch's lateral and longitudinal movement speeds based on the slab thickness.

(2) Cut First, Then Flame

Rough Cutting: Cut the rough slabs to size first.

Worktable: Place the sized rough slabs on an iron frame worktable with firebricks around to protect against heat.

Gas Cutting Torch: Adjust the torch's position relative to the slab and control the feed speed for even heating.

2. Processing Methods for Rough-Edge Sesame Grey Stone Flamed Slabs

Grooving: Place the flamed side down on the worktable and groove according to specifications with a 3-4mm thick disc saw blade, leaving 3-4mm thickness.

Prying: Use a lever-type steel plate to pry open and obtain rough-edged sesame grey stone flamed slabs.

Processing Notes

Even Heating: Ensure even heating of the stone to prevent local overheating and cracking.

Cutting Precision: Control feed speed during cutting to ensure precision.

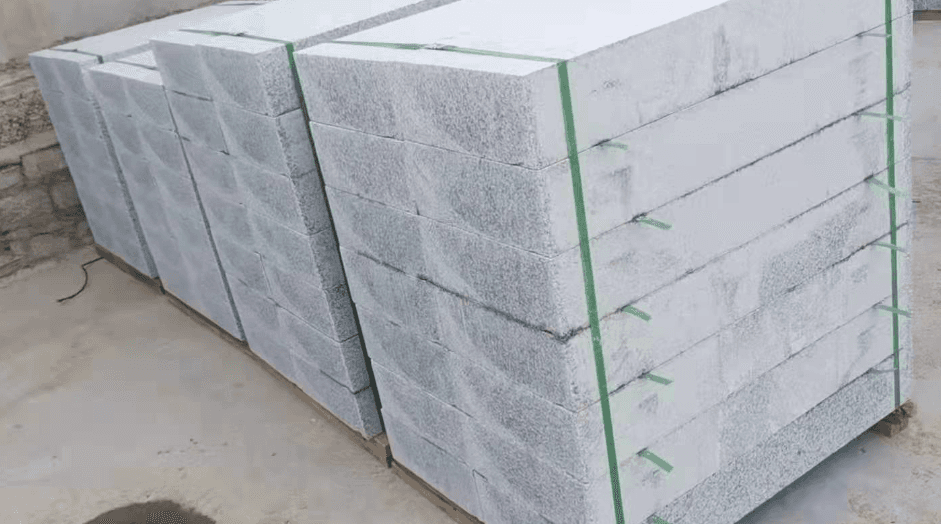

Post-processing: Flamed stone needs edge treatment for safe use.

Conclusion

The processing of sesame grey granite flamed slabs requires precise operation and appropriate equipment to ensure the final product's quality and aesthetics. Whether it's flaming first and then cutting or cutting first and then flaming, all parameters in the processing must be strictly controlled.