Stone Mine Extraction Technology and Equipment Analysis

Lizzy

Stone Mine Extraction Technology and Equipment Analysis

The extraction of stone from mines is a complex process involving various technologies and equipment. Here is a detailed analysis of stone mine extraction technology and equipment.

Types and Components of Stone Mines

Open Pit and Underground Mining

Open Pit Mining: Includes hillside open pit mining, depression open pit mining, and shaft mining.

Underground Mining: Divided into cave type mining and adit type mining.

Main Components

Working platform

Safety platform

Cleaning platform

Transportation trench

Mine Development and Development Transportation Methods

Mine Development

Development tasks include transporting rough stones, waste stone to the waste dump, and transporting tools, materials, equipment, and personnel.

Development Transportation Methods

Highway development, single truck transportation

Inclined slope winch truck transportation

Fixed derrick crane and truck transportation combined

Aerial tramway transportation

Open trough transportation

Joint development

Stone Mine Extraction Technology

Extraction Technology Process

Stripping

Separation

Topping

Segmentation

Finishing

Lifting and transportation

Scrap and waste removal

Main Steps Detail

Stripping: Remove the parts of the ore body that do not meet the processing requirements on the surface.

Separation: Separate the strip stone from the ore body.

Topping: Turn over the strip stone for easy segmentation.

Segmentation: Segment the strip stone into rough stones.

Finishing: Trim the rough stone into standard rough stone.

Lifting and transportation: Use cranes and other equipment for lifting and transportation.

Scrap and waste removal: Clean up waste stone to protect the environment.

Classification of Stone Mine Extraction Methods

Extraction Methods

Splitting method

Blasting method

Cutting method

Fire cutting method

Basis for Method Selection

Geological conditions

Rock types

Mine size

Rough stone specifications

Geographical conditions

Environmental protection requirements

Technical and economic indicators

Splitting Method Detail

Mechanism: Utilizes the relatively low tensile strength of rocks to cause rupture.

Applicable conditions: Rocks with near-horizontal fractures, more suitable for granite.

Blasting Method

General blasting: Uses black powder.

Controlled blasting: Uses a variety of explosives, precisely designed.

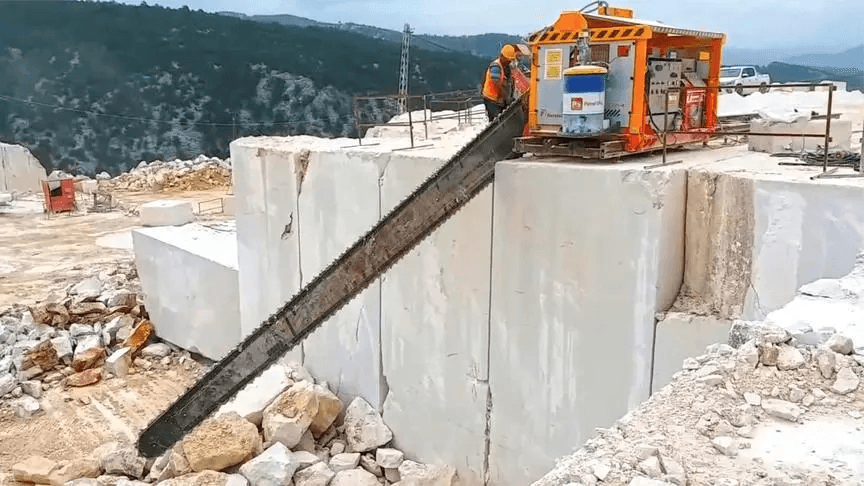

Cutting Method

Mechanical cutting: Uses mechanical equipment to directly separate blocks from the rock mass.

Fire Cutting Method

Mechanism: Utilizes the difference in thermal expansion coefficients of minerals in rocks for cutting.

Conclusion

Stone mine extraction is a technology-intensive process that requires the selection of appropriate extraction methods and equipment based on specific geological conditions, rock types, and environmental protection requirements. The correct extraction technology can not only improve resource utilization but also protect the environment and ensure safe production.