Stone Processing Technology and Process Quality Control

Lizzy

Stone Processing Technology and Process Quality Control

Stone processing involves a complete process from mining to the final product. This process includes multiple steps, each with its quality control points to ensure the final product's quality.

Stone Production Technology Process (Standard Plate)

Quality Control

Rough Stone Selection: Twice selection to control color difference.

Light Plate Selection: Once selection.

Standard Plate Layout: Four strict selections in an environment without direct sunlight.

Main Processing Technology and Quality Control

Quarry Rough Stone Selection

Choose mines with high quality, large reserves, and strong mining capabilities.

Use the six-side water spray method for quality acceptance.

Factory Rough Stone Selection Before Production

Meticulously select rough stones based on engineering drawings.

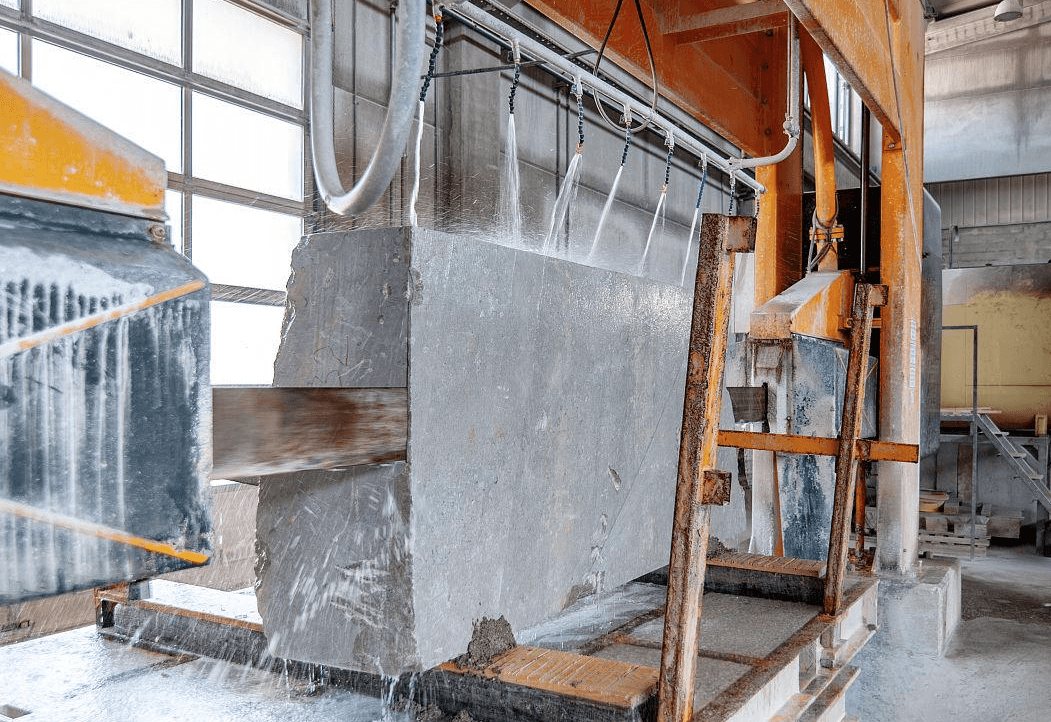

Sawing Large Plates

Use the Italian imported GASPARI MENOTI saw.

Rough Plate Grinding and Polishing

Adopt the Italian Breton automatic continuous grinding and polishing line.

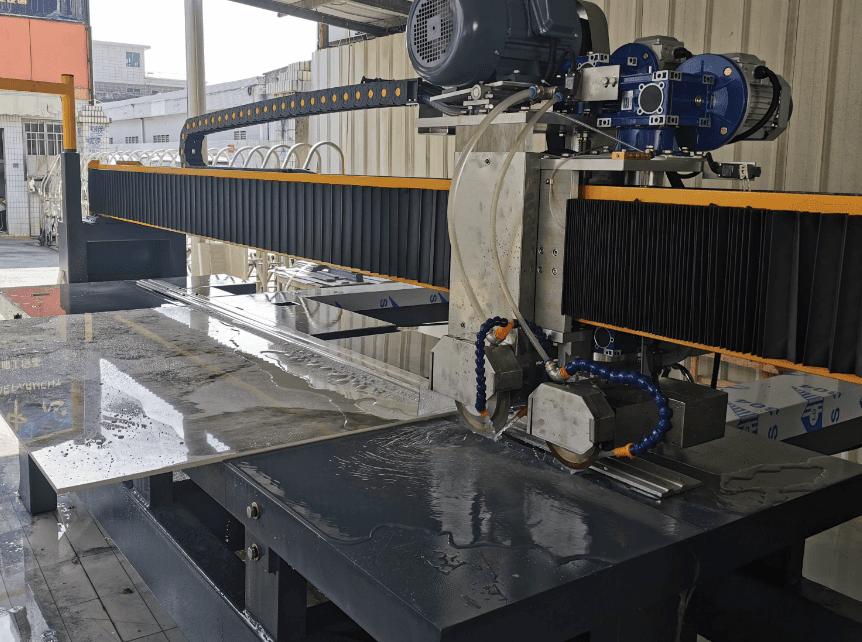

Cutting Standard Plates

Use the infrared electronic bridge cutting machine.

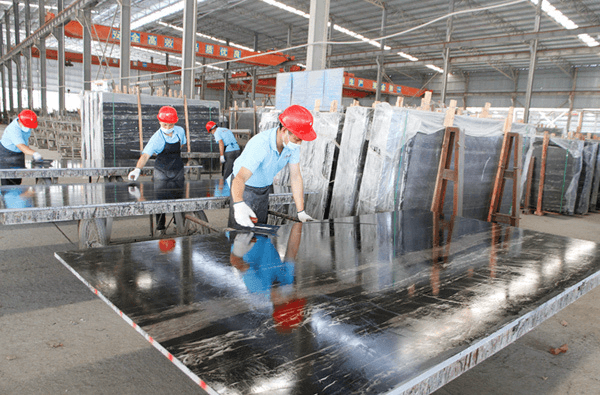

Layout and Numbering

Layout and color adjustment in an environment without direct sunlight.

Edge Grinding, Grooving, and Chamfering

Use a dedicated edge grinding machine for high-precision processing.

Drying and Protection

Protective treatment to waterproof, anti-fouling, and extend service life.

Packing and Transportation

Ensure stable packaging, moisture-proof, and have appropriate instruction signs.

Conclusion

Quality control in the stone processing process is key to ensuring product quality. Each step from mining to the finished product requires strict quality control to ensure that the color, texture, and overall quality of the stone meet the requirements of the project.