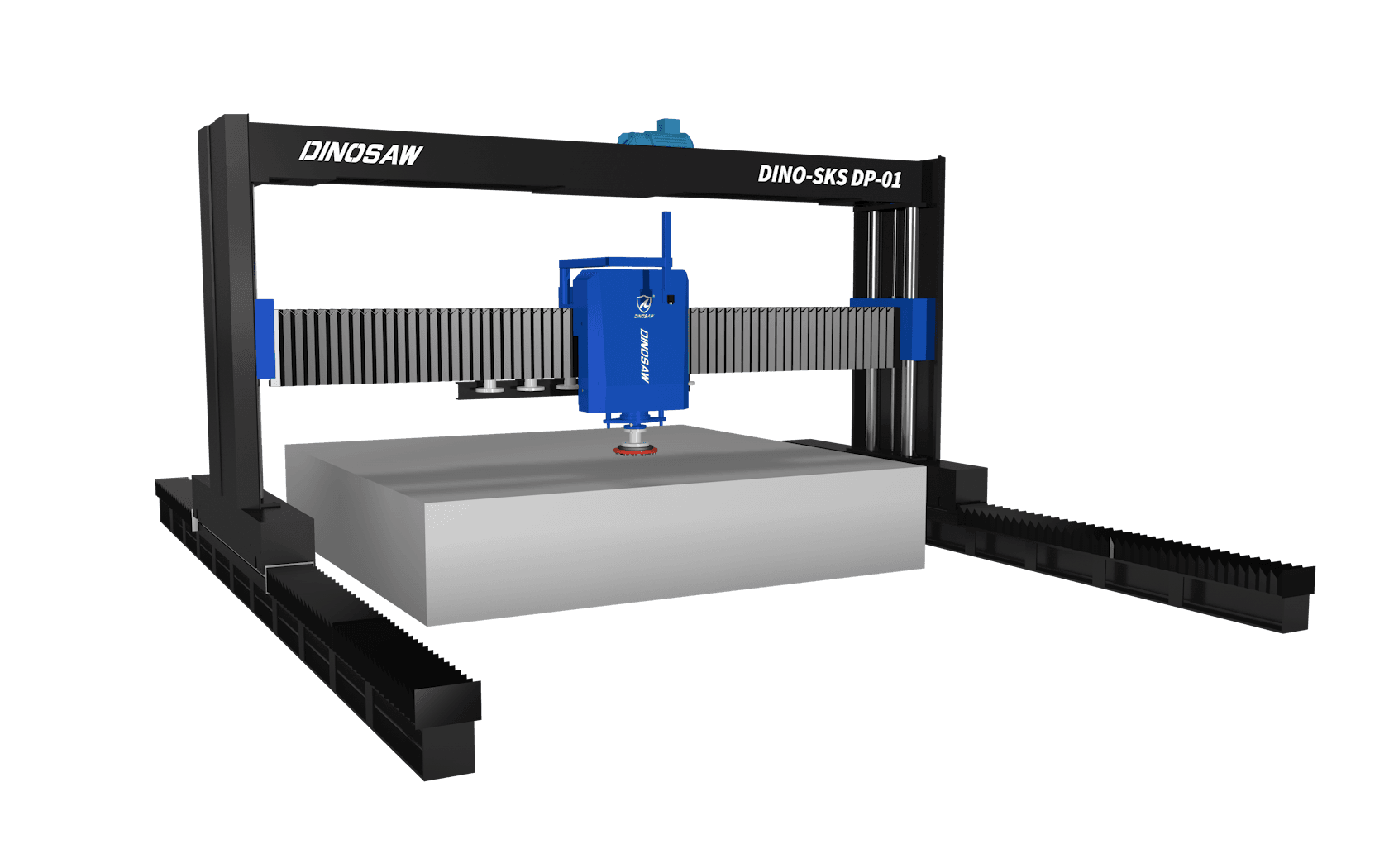

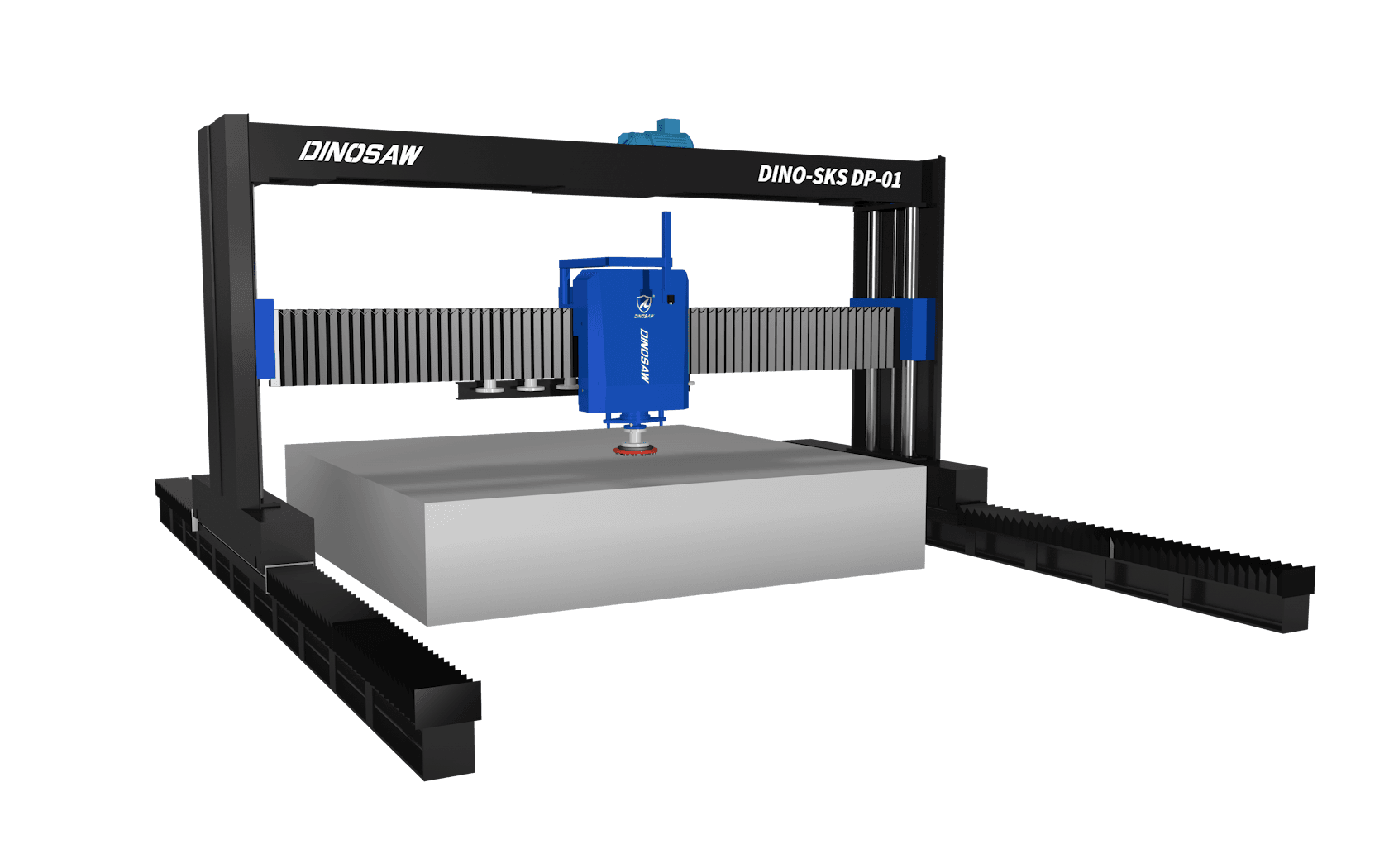

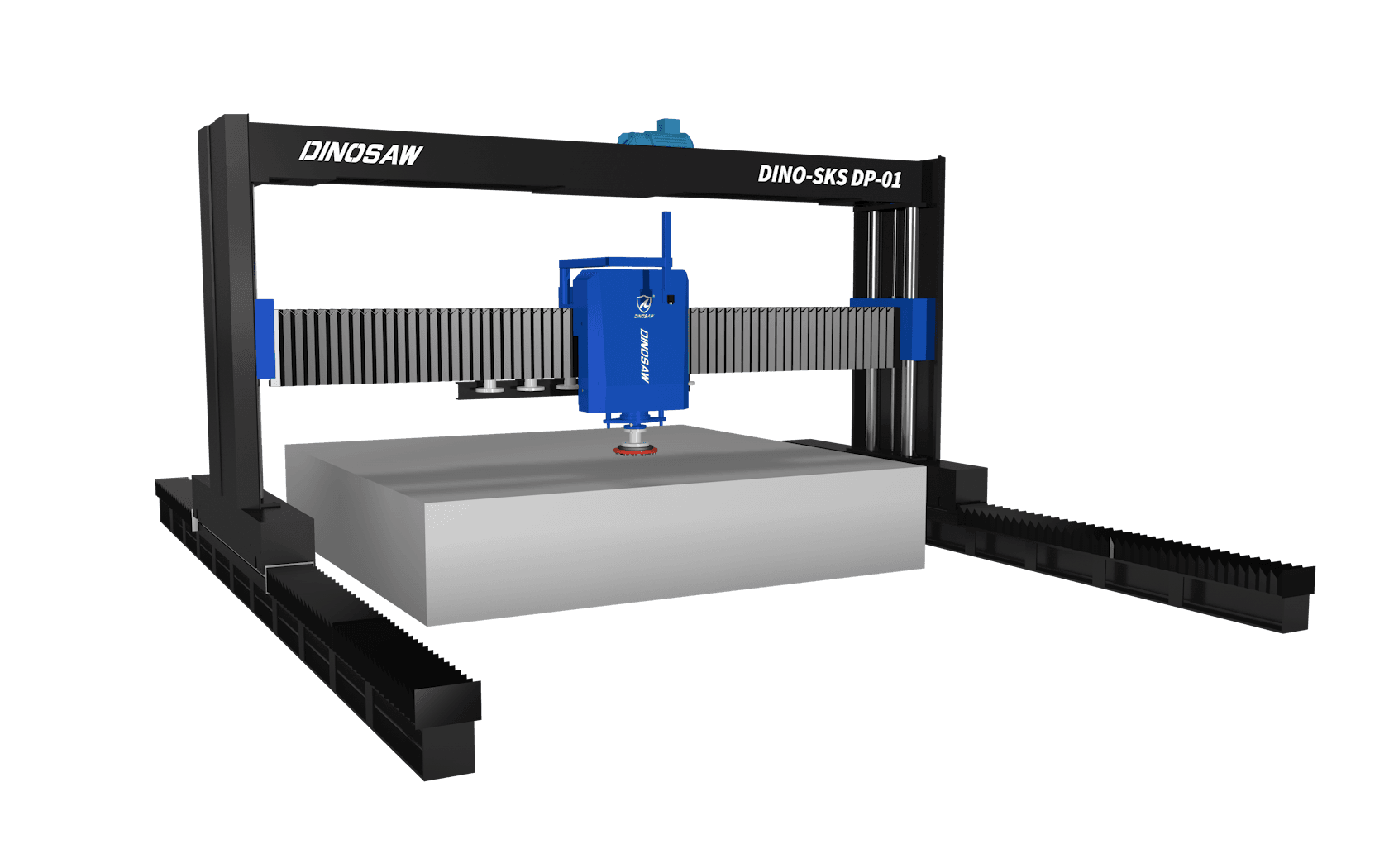

CNC Stone Engraving Machine for Precision Carving

ZDDK-3015/1325

DINOSAW CNC Stone Engraving Machine offers 3-in-1 functionality for flat engraving, relief carving, and 3D sculpture. Features 3-5 axis options, 0.05mm positioning accuracy, 40m/min rapid travel speed, and 35m/min engraving speed. Processes materials from soft limestone to ultra-hard granite, including marble and sandstone. Suitable for tombstones, monuments, railings, corbels, decorative panels, and artistic sculptures.

Compatible Materials & Products

Granite to Sandstone: Memorial, Art & Architectural Applications

Granite ❯ Tombstones & Memorials

Marble ❯ Artistic Sculptures

Limestone ❯ Decorative Panels

Sandstone ❯ Railings

▶ Product Demo

|

Granite memorials demand exceptional durability and precision detailing. DINOSAW machines utilize high-torque spindles and diamond carving bits specifically designed for Mohs 7 hardness materials, ensuring clean cuts through challenging granite compositions while maintaining tool longevity. Advanced 3D simulation prevents tool collisions during intricate religious figure carving. Automated depth control delivers consistent lettering across multilingual epitaphs, eliminating the 18% rejection rate common in manual stone carving operations. |

Granite ❯ Tombstones & Memorials

Marble ❯ Artistic Sculptures

Limestone ❯ Decorative Panels

Sandstone ❯ Railings

▶ Product Demo

|

Granite memorials demand exceptional durability and precision detailing. DINOSAW machines utilize high-torque spindles and diamond carving bits specifically designed for Mohs 7 hardness materials, ensuring clean cuts through challenging granite compositions while maintaining tool longevity. Advanced 3D simulation prevents tool collisions during intricate religious figure carving. Automated depth control delivers consistent lettering across multilingual epitaphs, eliminating the 18% rejection rate common in manual stone carving operations. |

Consult DINOSAW Material Expert →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Scale Your Architectural Carving →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Scale Your Architectural Carving →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Scale Your Architectural Carving →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Scale Your Architectural Carving →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Specs and options

Specifications customizable upon request.

Product Model | ZDDK-1318 | ZDDK-1325 | ZDDK-1825 | ZDDK-2025 | ZDDK-2030 |

|---|---|---|---|---|---|

Platform Size /mm | 1300×1800 | 1300×2500 | 1800×2500 | 2000×2500 | 2000×3000 |

Feeding Height /mm | 380/430/450/530/600 | ||||

Idle Speed /(m/min) | 40 | ||||

Processing Speed /(m/min) | 35 | ||||

Spindle Power | 7.5kW Variable - frequency Water - cooled Motor | ||||

Spindle Speed /(rpm/min) | 6000 or 24000 | ||||

Working Voltage | AC380V / 50Hz | ||||

Engraving Tools /mm | 3.175/4/6/12.7 | ||||

File Format | G - code / HPGL | ||||

Positioning Accuracy /mm | 0.05 | ||||

Repeat Positioning Accuracy /mm | 0.01 | ||||

Control System | Nc Studio System | ||||

Contact DINOSAW technical team for details →

Advanced engineering meets practical design excellence.

Precision. Power. Performance.

User-Friendly Operation

Built-in pattern library and CAD import capability simplify workflow.

35m/min High-Speed Engraving

7.5kW stone-specific spindle with 40m/min rapid travel speed delivers industrial-grade power

±0.05mm Ultra-High Precision

Full servo system control ensures exceptional accuracy

Inqury for Details →

Resume Carving After Power Outage

Brake motor system prevents tool dropping during power failures.

Enhanced Structural Stability

Triple-reinforced beam and galvanized components

Reduced Maintenance Requirements

Oil-immersed guide rails and stainless steel water tank minimize maintenance needs

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Cutting Machine for Slabs

High-precision cutting for stone blocks and architectural panels. Advanced linear guide systems ensure straight cuts up to 3000mm length. Ideal for preparing materials before detailed engraving work.

Streamline Your Stone Preparation Process →

Diamond Carving Bits

Professional-grade diamond tools designed for stone engraving machines. Extended tool life and superior finish quality. Complete range from roughing to finishing bits for all stone hardness levels.

Upgrade Your Carving Performance →

CNC Stone Polishing Machine

Intelligent polishing system with photo recognition technology for irregular tombstones. Auto-detects different areas, sets custom polishing processes, and changes grinding heads automatically. One-click operation handles varied shapes and heights for perfect finishing on memorial stones.

Transform Your Memorial Stone Finishing Process →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

How do I choose the right number of spindles for my engraving machine?

What stone materials can this machine process effectively?

How does CNC stone engraving compare to laser engraving?

What level of precision can I expect for detailed carving work?

How much training is required to operate the machine?

What maintenance schedule should I follow?

Need more assistance? Click to contact DINOSAW →

Ready to revolutionize your stone carving?

Transform precision, speed and quality with DINOSAW CNC stone engraving technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Engraving Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Stone Carving: Expert Tips & Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC Stone Engraving Machine for Precision Carving

ZDDK-3015/1325

DINOSAW CNC Stone Engraving Machine offers 3-in-1 functionality for flat engraving, relief carving, and 3D sculpture. Features 3-5 axis options, 0.05mm positioning accuracy, 40m/min rapid travel speed, and 35m/min engraving speed. Processes materials from soft limestone to ultra-hard granite, including marble and sandstone. Suitable for tombstones, monuments, railings, corbels, decorative panels, and artistic sculptures.

Compatible Materials & Products

Granite to Sandstone: Memorial, Art & Architectural Applications

Granite ❯ Tombstones & Memorials

Marble ❯ Artistic Sculptures

Limestone ❯ Decorative Panels

Sandstone ❯ Railings

▶ Product Demo

|

Granite memorials demand exceptional durability and precision detailing. DINOSAW machines utilize high-torque spindles and diamond carving bits specifically designed for Mohs 7 hardness materials, ensuring clean cuts through challenging granite compositions while maintaining tool longevity. Advanced 3D simulation prevents tool collisions during intricate religious figure carving. Automated depth control delivers consistent lettering across multilingual epitaphs, eliminating the 18% rejection rate common in manual stone carving operations. |

Granite ❯ Tombstones & Memorials

Marble ❯ Artistic Sculptures

Limestone ❯ Decorative Panels

Sandstone ❯ Railings

▶ Product Demo

|

Granite memorials demand exceptional durability and precision detailing. DINOSAW machines utilize high-torque spindles and diamond carving bits specifically designed for Mohs 7 hardness materials, ensuring clean cuts through challenging granite compositions while maintaining tool longevity. Advanced 3D simulation prevents tool collisions during intricate religious figure carving. Automated depth control delivers consistent lettering across multilingual epitaphs, eliminating the 18% rejection rate common in manual stone carving operations. |

Consult DINOSAW Material Expert →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Memorial Manufacturing

Eliminating 92% Defects in Granite Monument Production

Italian manufacturer faced 45% scrap rates from manual carving inconsistencies. DINOSAW CNC with 6mm diamond tools achieved 0.1mm font consistency across multilingual epitaphs, increasing daily output from 3 to 15 pieces while eliminating customer rejections.

Transform Your Memorial Production →

Architectural Projects

Precision Facade Carving for 8,000m² Limestone Project

Dubai firm needed arabesque patterns on limestone facades. 2000×3000mm worktable with automatic tool changer maintained 0.05mm variance throughout 4-month production, ensuring geometric consistency across the entire building exterior.

Bring Your Artistic Vision to Life →

Artistic Sculpture

Converting 3D Scans to Stone Masterpieces

Artist needed exact replication of clay models in stone materials. 3D capabilities achieved <1% dimensional variance when processing basalt and marble, allowing artists to focus on creativity while machines handled precision execution.

Bring Your Artistic Vision to Life →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Product Model | ZDDK-1318 | ZDDK-1325 | ZDDK-1825 | ZDDK-2025 | ZDDK-2030 |

|---|---|---|---|---|---|

Platform Size /mm | 1300×1800 | 1300×2500 | 1800×2500 | 2000×2500 | 2000×3000 |

Feeding Height /mm | 380/430/450/530/600 | ||||

Idle Speed /(m/min) | 40 | ||||

Processing Speed /(m/min) | 35 | ||||

Spindle Power | 7.5kW Variable - frequency Water - cooled Motor | ||||

Spindle Speed /(rpm/min) | 6000 or 24000 | ||||

Working Voltage | AC380V / 50Hz | ||||

Engraving Tools /mm | 3.175/4/6/12.7 | ||||

File Format | G - code / HPGL | ||||

Positioning Accuracy /mm | 0.05 | ||||

Repeat Positioning Accuracy /mm | 0.01 | ||||

Control System | Nc Studio System | ||||

Contact DINOSAW technical team for details →

Advanced engineering meets practical design excellence.

Precision. Power. Performance.

User-Friendly Operation

Built-in pattern library and CAD import capability simplify workflow.

35m/min High-Speed Engraving

7.5kW stone-specific spindle with 40m/min rapid travel speed delivers industrial-grade power

±0.05mm Ultra-High Precision

Full servo system control ensures exceptional accuracy

Inqury for Details →

User-Friendly Operation

Built-in pattern library and CAD import capability simplify workflow.

35m/min High-Speed Engraving

7.5kW stone-specific spindle with 40m/min rapid travel speed delivers industrial-grade power

±0.05mm Ultra-High Precision

Full servo system control ensures exceptional accuracy

Inqury for Details →

Resume Carving After Power Outage

Brake motor system prevents tool dropping during power failures.

Enhanced Structural Stability

Triple-reinforced beam and galvanized components

Reduced Maintenance Requirements

Oil-immersed guide rails and stainless steel water tank minimize maintenance needs

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Cutting Machine for Slabs

High-precision cutting for stone blocks and architectural panels. Advanced linear guide systems ensure straight cuts up to 3000mm length. Ideal for preparing materials before detailed engraving work.

Streamline Your Stone Preparation Process →

Diamond Carving Bits

Professional-grade diamond tools designed for stone engraving machines. Extended tool life and superior finish quality. Complete range from roughing to finishing bits for all stone hardness levels.

Upgrade Your Carving Performance →

CNC Stone Polishing Machine

Intelligent polishing system with photo recognition technology for irregular tombstones. Auto-detects different areas, sets custom polishing processes, and changes grinding heads automatically. One-click operation handles varied shapes and heights for perfect finishing on memorial stones.

Transform Your Memorial Stone Finishing Process →

3D Scanning System for Stone Replication

Professional 3D scanning technology that creates precise digital models for CNC stone engraving. Generate accurate 3D designs from physical objects with 0.1mm precision. When paired with our engraving machines, enables rapid and precise 3D carving with minimal setup time.

Elevate Your 3D Stone Reproduction Capabilities →

Get a Custom Solution →

Faqs

Common Questions About CNC Stone Engraving Machine

How do I choose the right number of spindles for my engraving machine?

How do I choose the right number of spindles for my engraving machine?

What stone materials can this machine process effectively?

What stone materials can this machine process effectively?

How does CNC stone engraving compare to laser engraving?

How does CNC stone engraving compare to laser engraving?

What level of precision can I expect for detailed carving work?

What level of precision can I expect for detailed carving work?

What Is CNC (Computer Numerical Control)? - User Guide

How much training is required to operate the machine?

What Is CNC (Computer Numerical Control)? - User Guide

What maintenance schedule should I follow?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to revolutionize your stone carving?

Master Stone Carving: Expert Tips & Insights

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy CNC Engraving Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Stone Carving: Expert Tips & Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: