Why Choose DINOSAW Stone CNC Machines?

Upgrade your stone processing with DINOSAW's precision-engineered CNC machines.

Designed for granite, marble, quartz, and engineered stone, our CNC equipment delivers ±0.02mm accuracy, 30% faster production, and 24/7 technical support.

Whether you’re crafting intricate sculptures or cutting industrial slabs, this guide helps you pick the right machine, compare specs, and unlock maximum ROI.

DINOSAW Stone CNC Machine Types

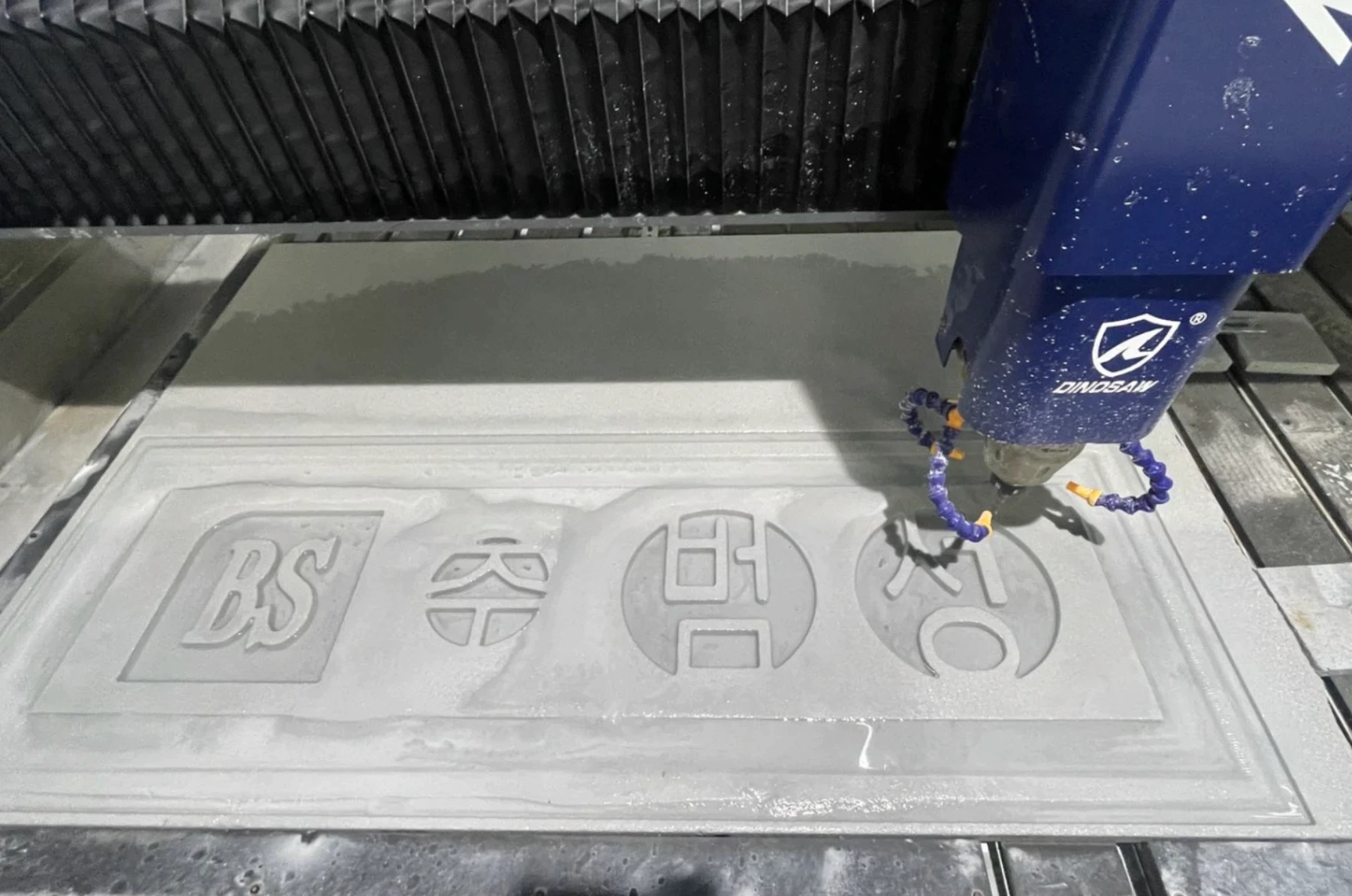

CNC Stone Engraving Machine

Ideal for detailed engravings on tombstones, decorative panels, or art pieces.

Key specs: 5-axis control, 24,000 RPM HSD water-cooled spindle, ±0.03mm accuracy.

Best for: Workshops needing high-detail work.

Customer story: A memorial supplier reduced engraving errors by 75% after switching to CNC Engraver.

CNC Stone Cutting Machine

Built for fast, straight cuts on countertops and slabs.

Key specs: 3 axis/4 axis/5axis cutting, 1350mm max thickness, multi-blade/rotatable worktable.

Best for: Factories processing 500+ slabs monthly.

Advantage: Reduces material waste with AI-optimized cutting paths.

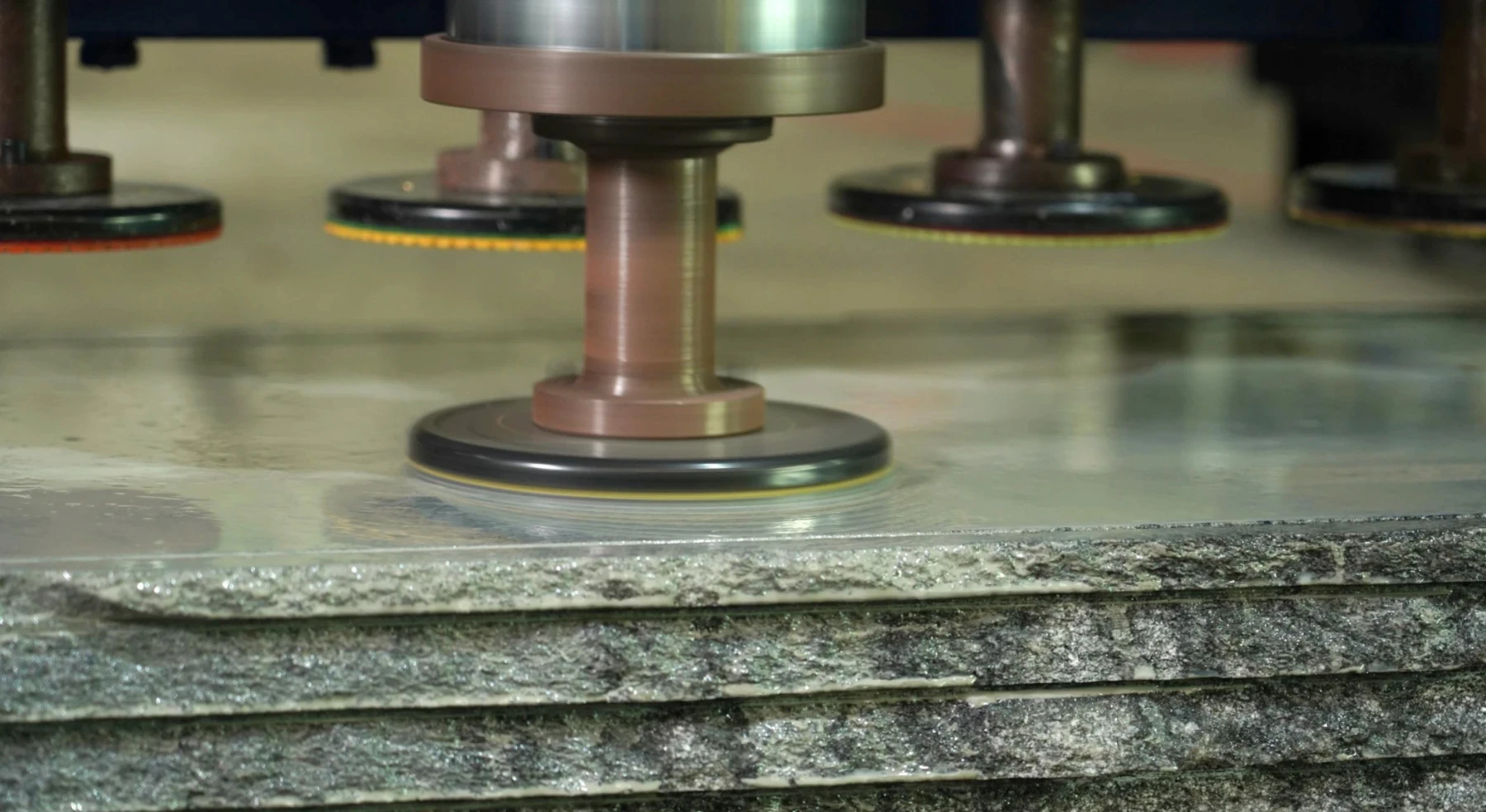

CNC Stone Polishing Machine

One-click setting of stone grinding parameters, automatic grinding and polishing, suitable for different shapes, heights and surfaces of stone.

Key specs: Max cutting size 3000*3500*60, Automatic polishing tools Changing, Multi-Material Compatibility.

Best for: Tombstone,stone table,countertop manufacturers replacing manual polishing.

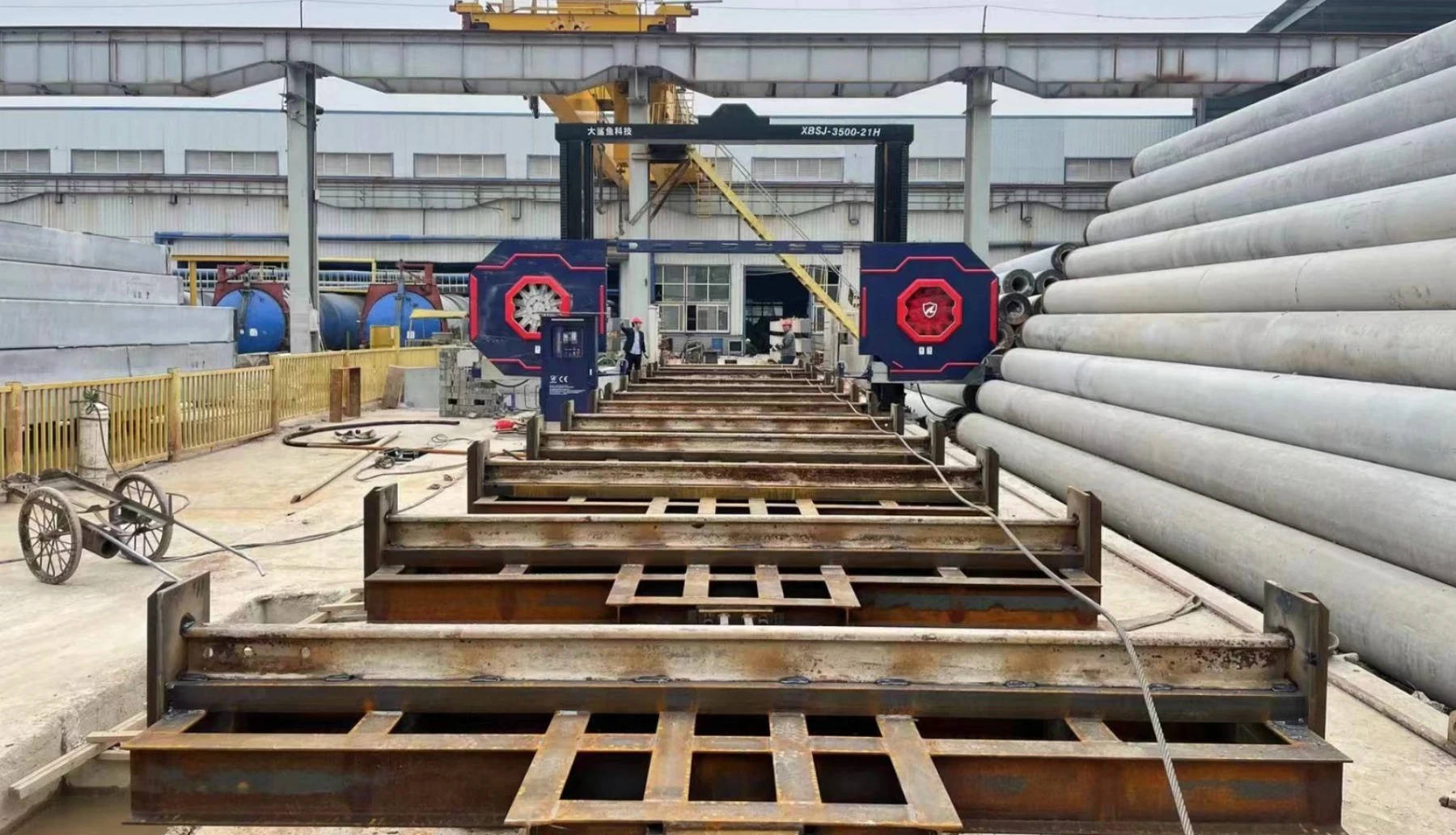

CNC Diamond Wire Saw Machine

Cut massive stone blocks (up to 10m length) in quarries or large-scale projects.

Key specs: Diamond bead rope lasts 300+ hours, variable speed control.

Best for: Mining operations,monument and complex shape makers handling oversized stone.

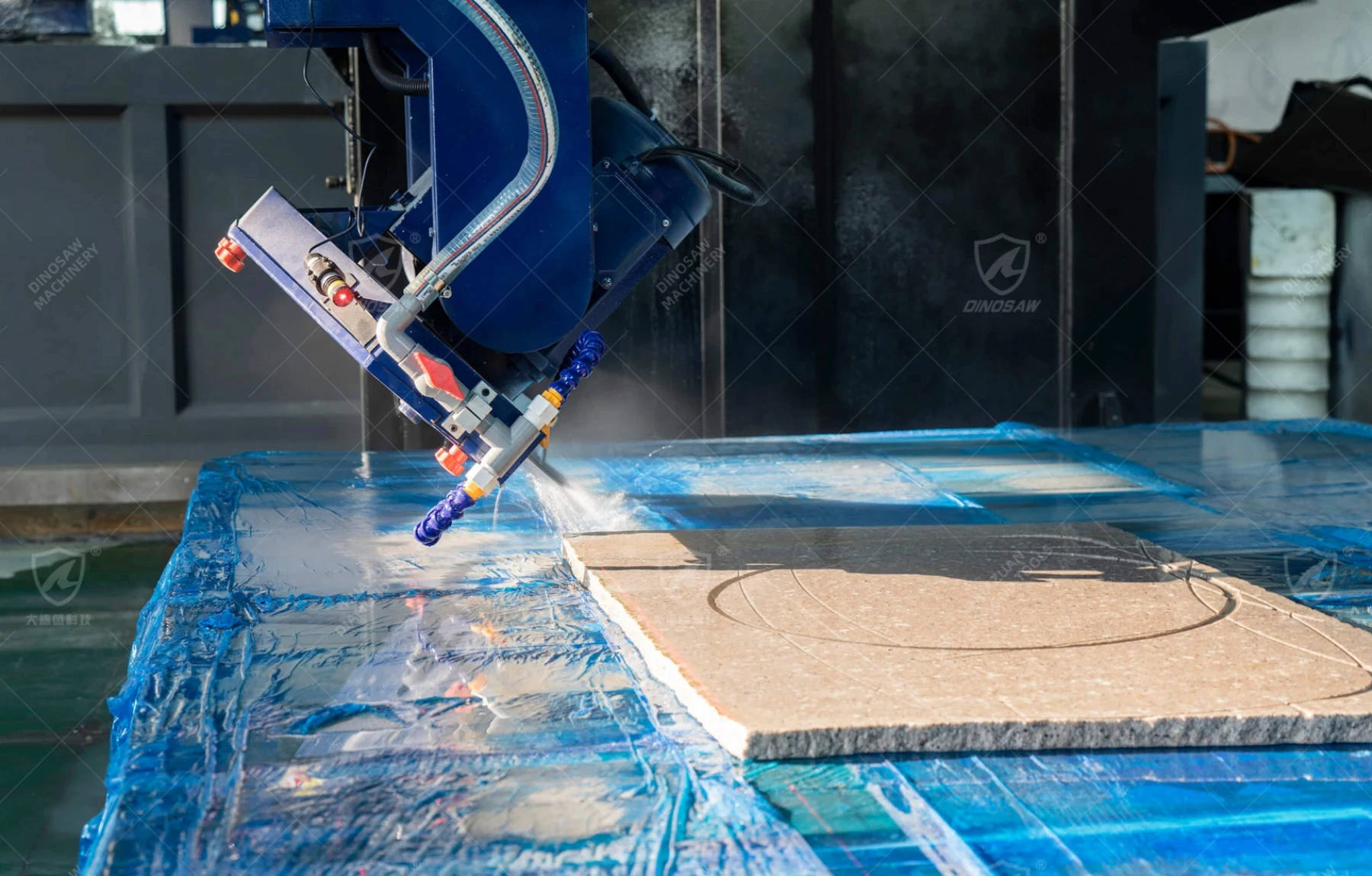

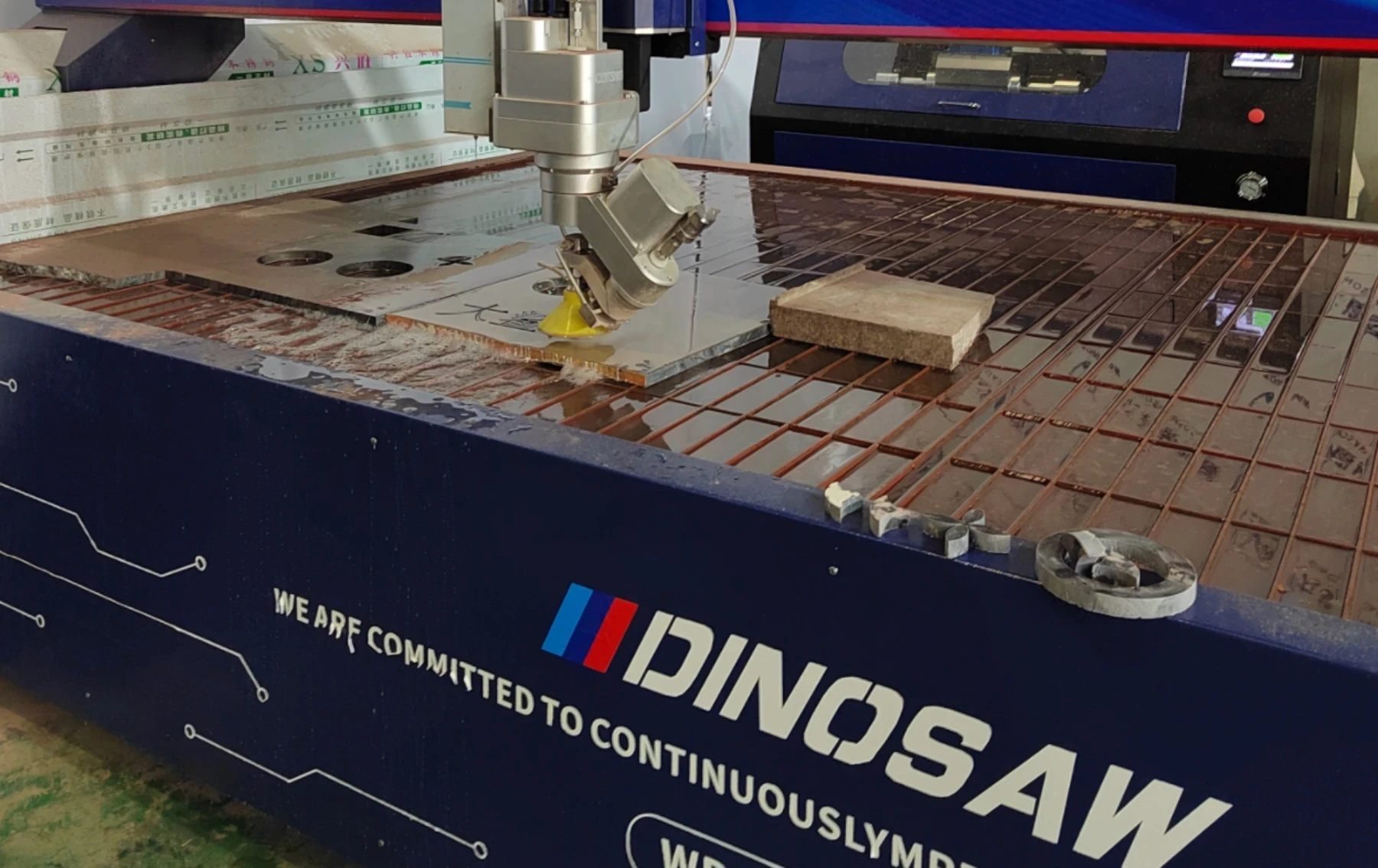

CNC Waterjet Cutter

Cut complex shapes without heat damage. Perfect for mixed materials like stone-metal composites.

Key specs:±0.1mm accuracy, Rated pressure upto 550MPa, 3 axis/5 axis optional.

Best for: Aerospace or architectural firms needing no-edge-chipping cuts.

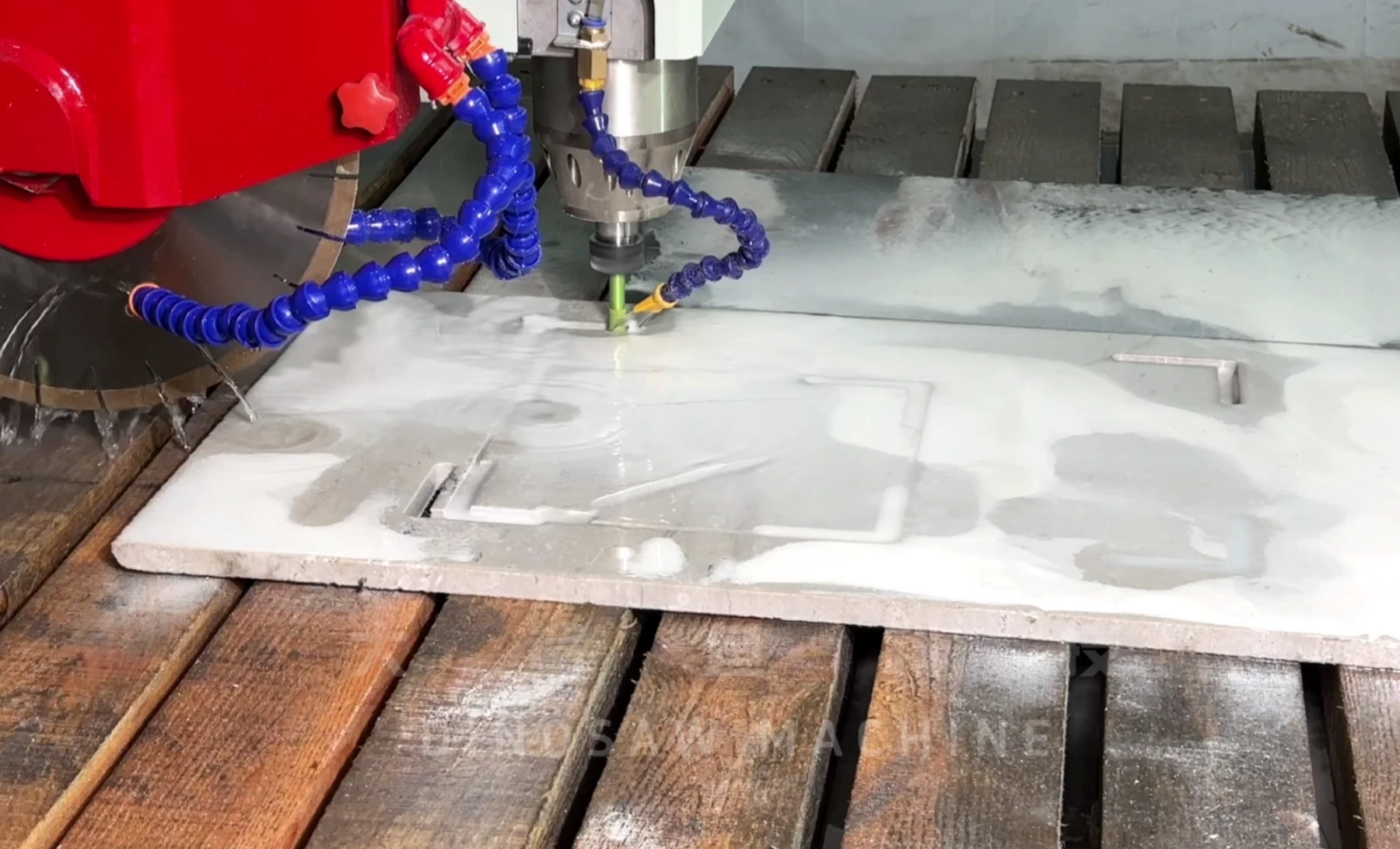

CNC Stone Profiling Machine

High-precision shaping for marble,granite, foamed ceramic and more.

Key specs:Continuous grinding and one-pass forming, automatic blade compensation system, direct CAD File Import.

Best for: Railings,handrails,columns, and decorative panels.

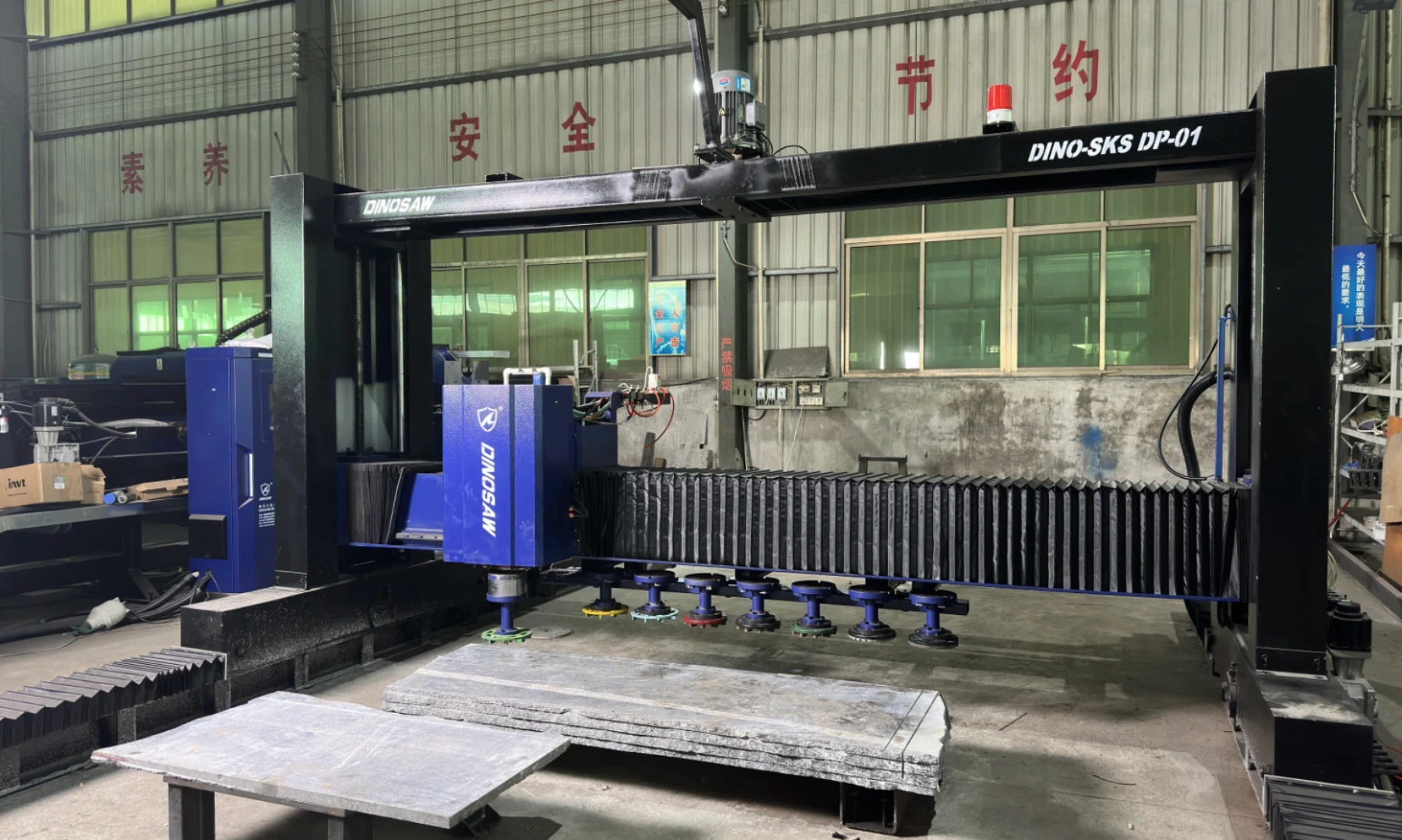

CNC Stone Machining Center

Handle stone cutting, drilling, and carving in one setup.

Key specs: Automatic diamond tools changing, ±0.01mm repeatability, CAD/CAM compatibility.

Best for: Factories consolidating multiple machines into one.

The whole process guarantee of CNC stone machinery purchase

Pre-sale transparency

3D basic drawings of equipment (including workshop layout suggestions)

Customer case video in the same region (authorized to contact for verification)

Delivery standardization

Including Chinese/English/other dozens of languages operation interface

10 safety operation certification trainings (delivered with a 100% pass rate)

Zero worries after sales

3 years for spindle/guide rail/lifetime maintenance of control system

Free software feature updates twice a year

24/7 remote support or on-site after-sales engineer direct access

FAQs about CNC Stone Machine you should know

Can a CNC machine cut stone?

CNC machines can cut stone. They are widely used in stone processing for precise cutting, engraving and shaping.

They can handle materials like marble, granite, artificial stone, etc., using high-speed rotating tools such as diamond tips or water jets. These machines can also do complex carving and pattern design, suitable for architectural, interior decoration and artwork production.

Their advantages are high precision, efficiency and automation, which greatly improve stone processing quality and efficiency.

What machine carves stone?

Stone Carving Machines: The main machines for carving stones are stone carving engraving machines, also known as stone cutting machines.Types and Functions:

CNC Stone Engraving Machine

It uses computer control and a diamond-tipped knife to carve stone with precision. It's suitable for making complex designs like monuments and statues.

Waterjet Cutter

This machine uses a high - pressure stream of water and an abrasive particle mixture to cut stones. It doesn't generate heat, so it doesn't alter the material's original structure and is good for engraving fine patterns.

Diamond Wire Saw Machine

It uses continuous diamond - coated wire loops to cut stones. It's suitable for cutting large stones and complex shapes.

Laser Engraving Machine

This machine uses a laser beam to engrave stone. It's suitable for engraving fine patterns and text.

Get Started With DINOSAW CNC Machine Today

Transform your stone business with DINOSAW’s CNC machine series.

Download free technical guides, compare models side-by-side, or book a live demo at our factory.

Contact DINOSAW experts now for a personalized quote—upgrade your stone workshop in 3 easy steps!