Introduction

Stone engraving machines play a vital role in modern industries, driving efficiency, precision, and profitability. From construction and decoration to custom memorials, these machines enable businesses to produce intricate and high-quality designs with unmatched accuracy and speed.

Selecting the right machine is not just a technical decision—it’s a strategic one. A poorly matched machine can lead to subpar results, wasted resources, and diminished customer satisfaction. Conversely, the right machine can optimize production, reduce costs, and elevate the quality of your products, giving you a significant competitive edge.

This guide is designed to help you navigate the complexities of selecting a stone engraving machine. By offering expert insights and practical recommendations, we aim to ensure you make an informed decision tailored to your specific business needs and production goals.

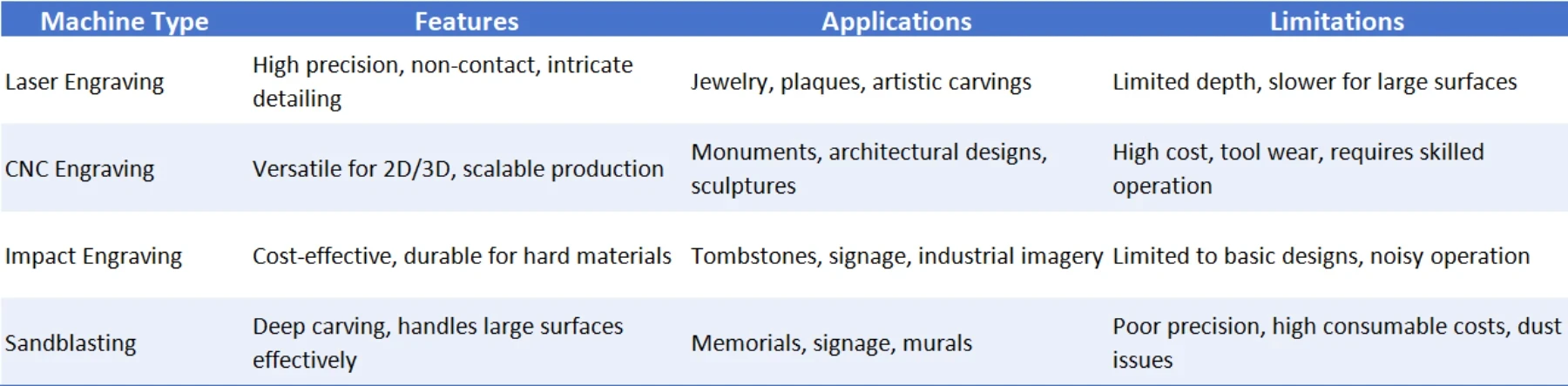

Comprehensive Overview of Stone Engraving Machines

Understanding the features, applications, and limitations of different stone engraving machines is critical to making an informed decision. Below is a detailed analysis of the four primary machine types.

Laser Engraving Machines

click the link for Trotec Laser Engraving Machine

How It Works:

Laser engraving machines use concentrated beams of light to vaporize the top layer of stone, creating precise and intricate designs without physical contact.Key Advantages:

Superior precision for fine detailing and intricate patterns.

Non-contact processing minimizes the risk of surface damage.

Versatile for various soft stones, such as marble and slate.

Applications:

Ideal for personalized designs, decorative plaques, jewelry engraving, and artistic projects requiring high resolution and fine craftsmanship.Limitations:

Cannot achieve significant carving depth, making it unsuitable for deep engravings.

Struggles with harder materials like granite without expensive high-powered lasers.

Less efficient for large-scale or high-volume production.

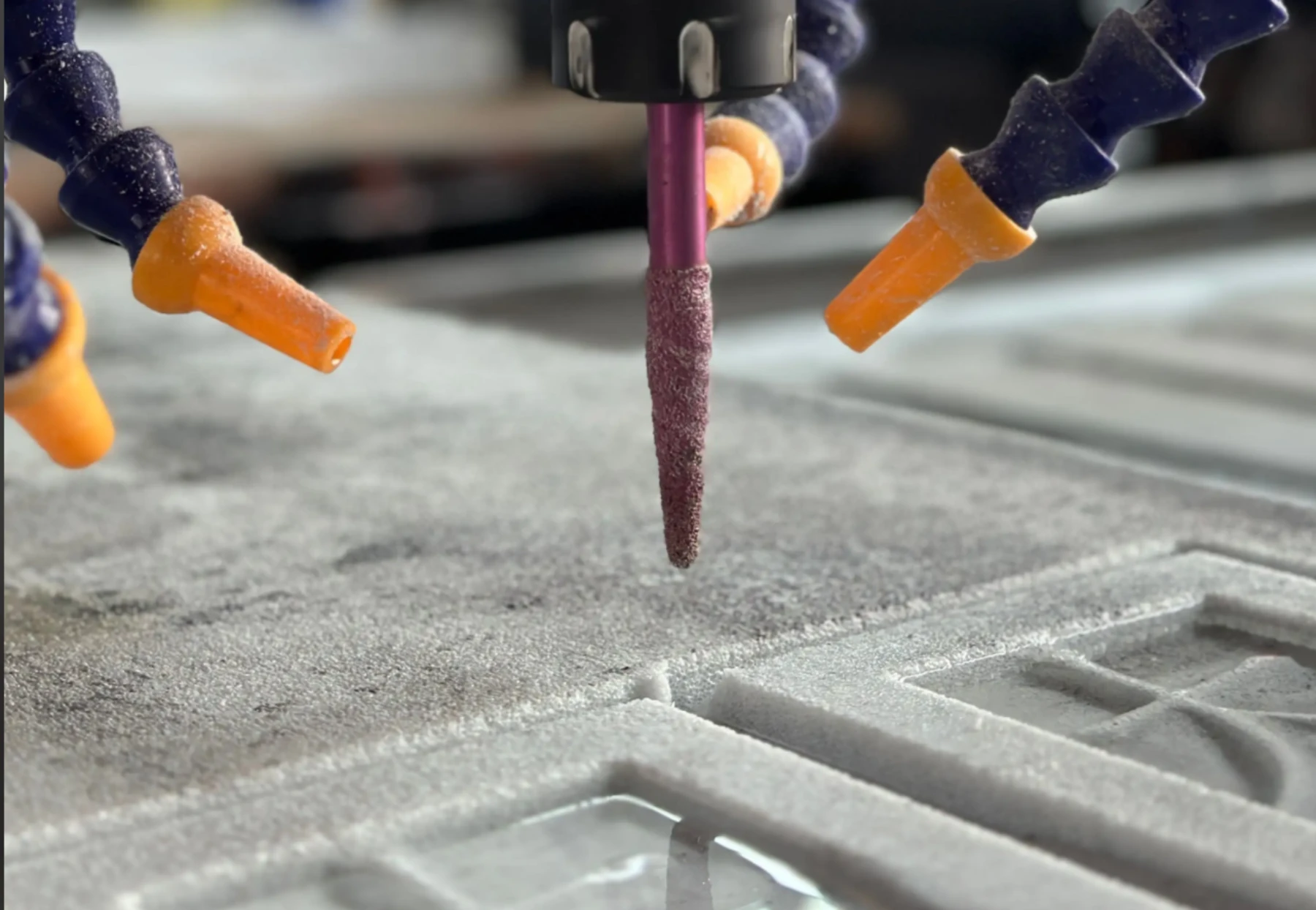

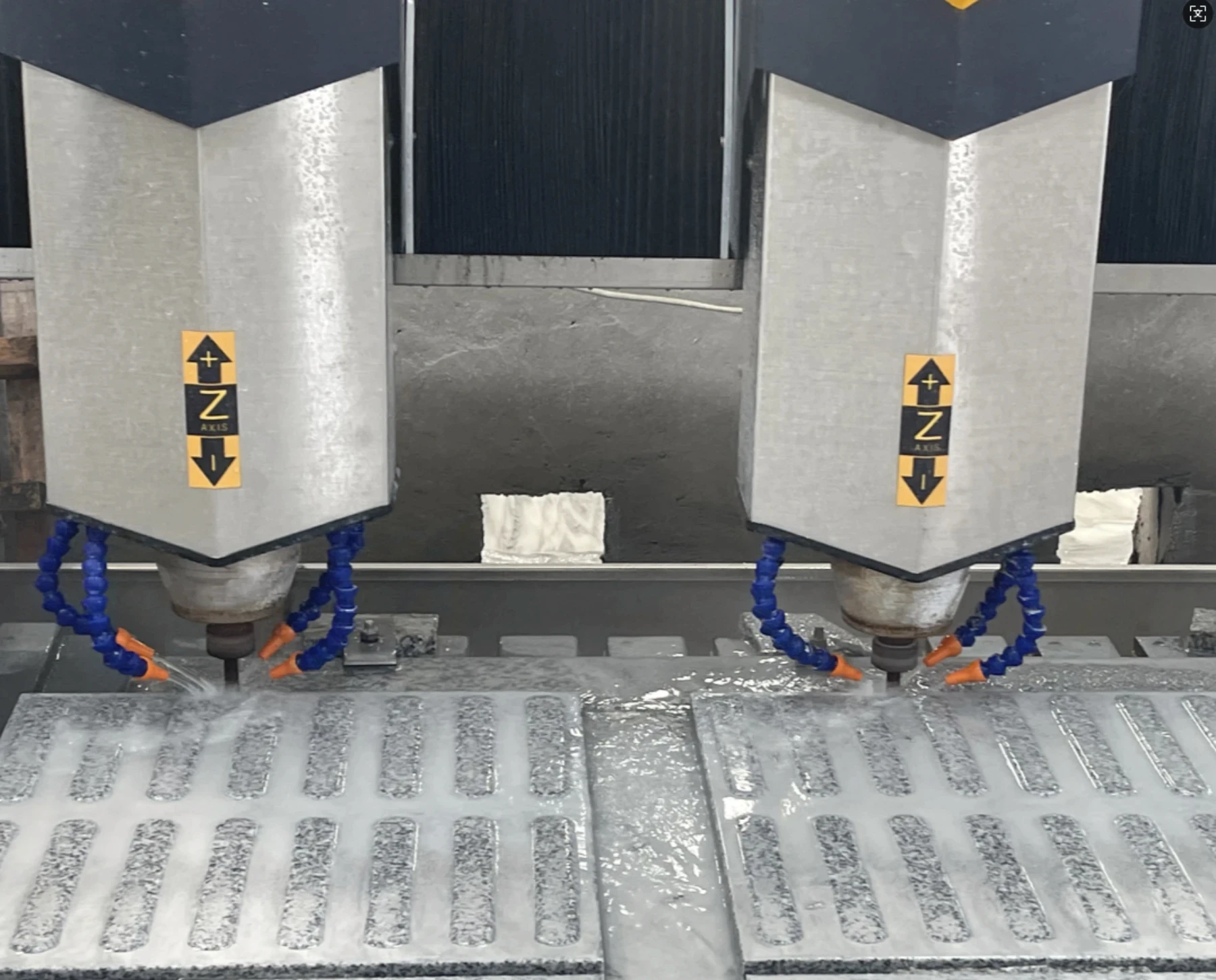

CNC Engraving Machines

click the link for DINOSAW CNC Engraving Machines

How It Works:

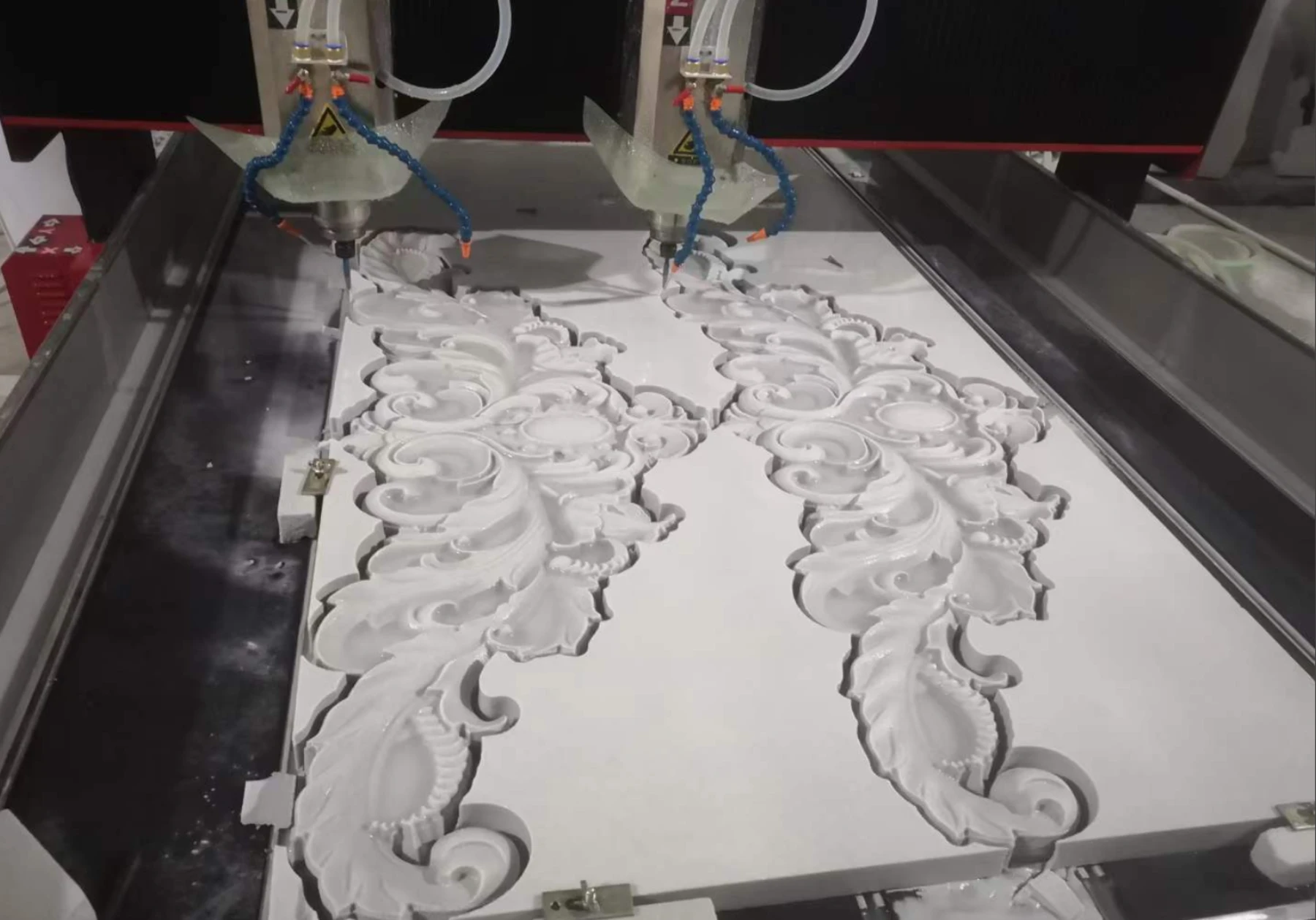

CNC machines use computer-controlled rotary tools to carve 2D or 3D designs into the stone. They rely on precise programming to ensure consistent and intricate results.Key Advantages:

Versatile enough to handle complex 2D and 3D designs.

Scalability for batch production with consistent precision.

Compatible with a wide range of stone materials, from soft limestone to hard granite.

Applications:

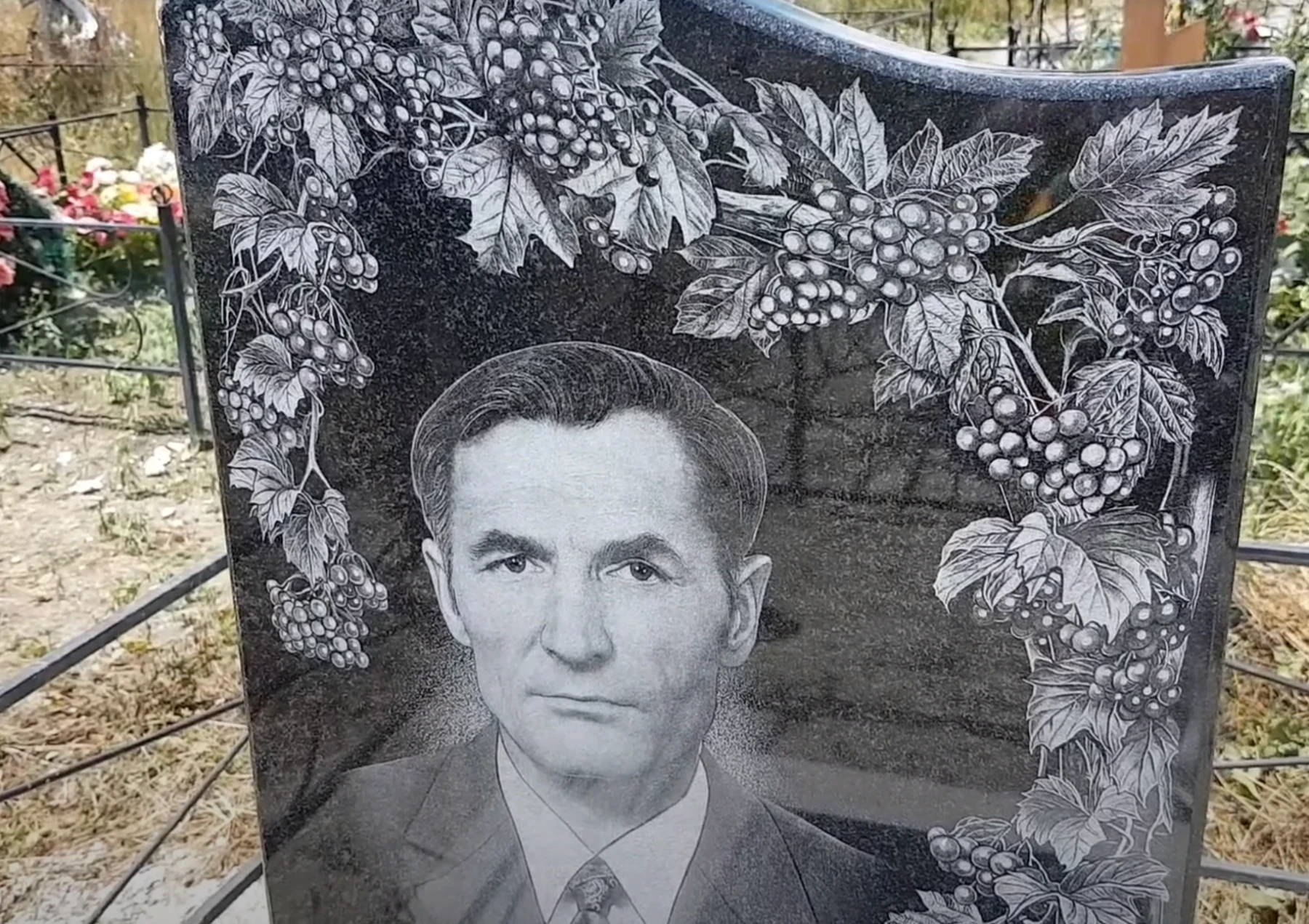

Perfect for monument engraving, architectural designs, intricate furniture inlays, and commercial logos.Limitations:

High initial investment and ongoing maintenance costs.

Cutting tools experience wear and tear, requiring regular replacement.

Requires skilled operators for setup and programming.

Impact Engraving Machines

click the link for Mirtels Impact Engraving Machine

How It Works:

These machines use mechanical tools to strike the stone surface, creating impressions through a durable impact process.Key Advantages:

Cost-effective for text and simple imagery engravings.

Highly reliable for hard materials like granite and quartz.

Simple operation and low-maintenance design make it ideal for industrial environments.

Applications:

Commonly used for tombstones, plaques, and industrial labeling where durability is a priority.Limitations:

Limited to simpler designs; not suitable for intricate patterns or 3D engravings.

Slower processing for large-scale projects compared to CNC or sandblasting machines.

Generates noise and vibrations during operation, requiring a sturdy workspace.

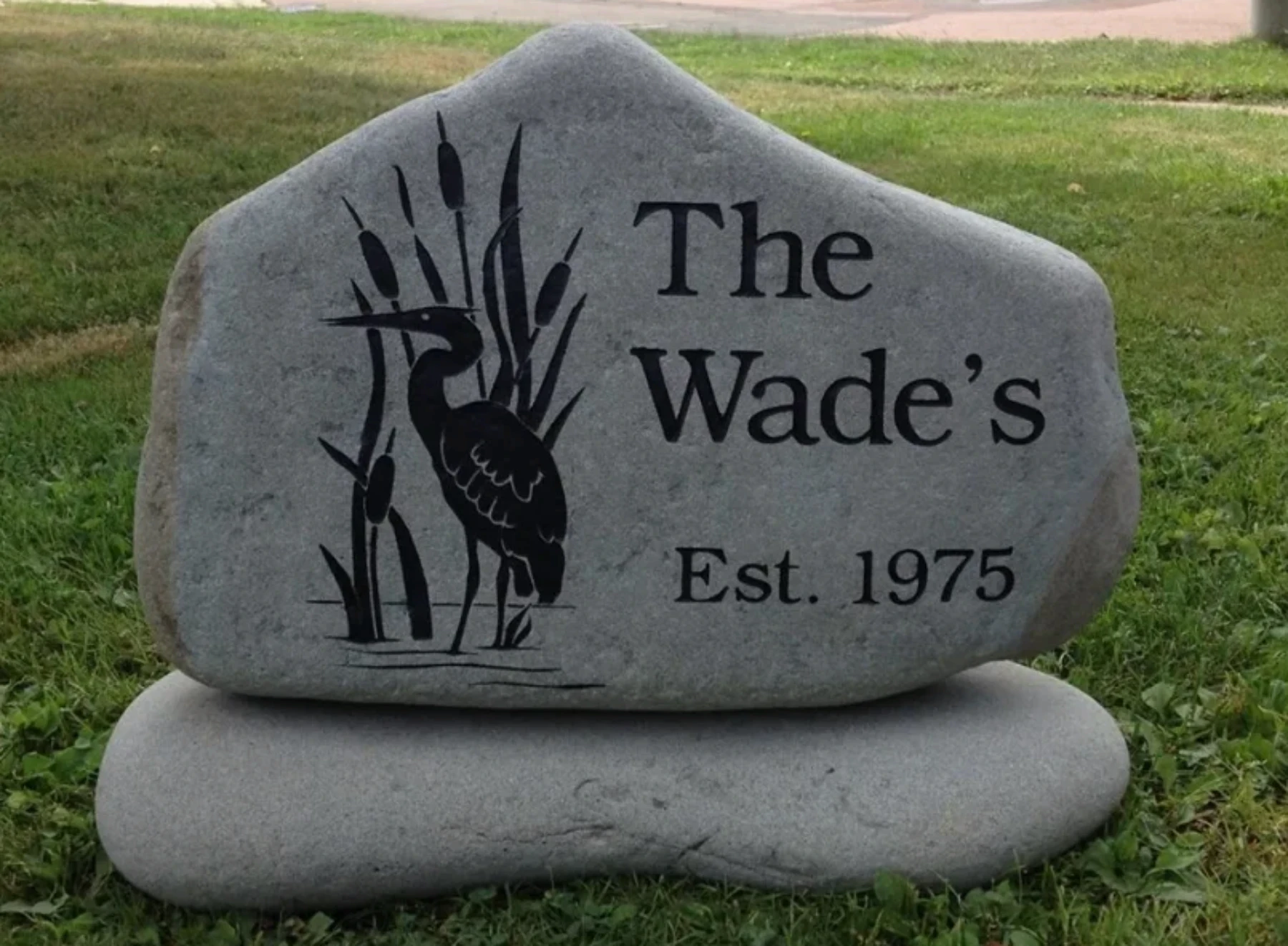

Sandblasting Machines

click the link for SCM Sandblasting Machines

How It Works:

Sandblasting machines propel abrasive particles at high speeds to carve deep and bold designs into stone surfaces.Key Advantages:

Exceptionally efficient for large surfaces and deep carvings.

Durable results suitable for industrial and outdoor use.

Handles hard and heavy materials with ease.

Applications:

Widely used in memorial production, large signage, and decorative panels where bold and durable designs are required.Limitations:

Limited precision makes it unsuitable for intricate detailing or fine patterns.

Higher operational costs due to the need for abrasive materials.

Dust generation requires specialized filtering and safety measures.

Practical Guide to Choosing the Right Stone Engraving Machine

To ensure you choose the right stone engraving machine, follow this step-by-step guide. Each step addresses key factors that will influence your decision.

Step 1: Identify Your Material and Design Needs

What types of stone will you be engraving?

If you work primarily with soft stones (e.g., marble, limestone):

Recommended Machine: Laser engraving machines for precise and intricate designs.

Alternative: CNC machines for a balance of precision and scalability.

If you work with hard stones (e.g., granite, quartz):

Recommended Machine: CNC machines equipped with diamond carving bits for durability and efficiency.

Alternative: Impact engraving machines or sandblasting machines for deep and bold engravings.

What type of designs will you produce?

For fine details or personalized designs: Laser engraving machines are ideal.

For 3D carvings or intricate patterns: CNC machines offer unmatched precision.

For bold, deep engravings or simple designs: Sandblasting and impact machines are the better options.

Step 2: Evaluate Your Production Volume

How many projects do you plan to produce daily?

For low-to-moderate volumes: Laser engraving machines are sufficient for precision-focused tasks.

For large-scale production: CNC machines excel with their scalability and consistent performance.

For industrial-scale bulk engravings: Sandblasting machines are efficient for processing large surfaces.

Step 3: Determine Your Budget

What is your initial investment capacity?

If your budget allows for advanced technology:

CNC and laser machines are top choices for versatility and precision.

If you’re looking for a cost-effective solution:

Impact engraving or sandblasting machines are more affordable options.

Have you considered long-term operational costs?

CNC Machines: Costs include replacing diamond bits and maintenance of moving parts.

Laser Machines: Require minimal maintenance but have higher energy consumption.

Sandblasting Machines: Consumable abrasives can add to ongoing expenses.

Step 4: Assess Ease of Use and Maintenance

Who will operate the machine?

For small teams or less-experienced operators: Look for machines with user-friendly interfaces, like laser systems or pre-programmed CNC setups.

For skilled teams: CNC machines with customizable programming offer more flexibility.

What kind of support will you need?

Check if the supplier provides detailed training, user manuals, and accessible spare parts.

Prioritize brands like DINOSAW known for their robust customer support and training programs.

Step 5: Choose a Reliable Supplier

How do you evaluate a supplier’s reliability?

Look for industry experience and reviews.

Ensure they offer warranties, after-sales support, and a steady supply of consumables like diamond bits and abrasives.

Consider suppliers like DINOSAW, who are recognized for their expertise in stone engraving machines and comprehensive services.

FAQs

1. What is the best machine for engraving hard stones like granite?

CNC engraving machines equipped with diamond carving bits are the most effective for hard stones, offering precision and durability. Sandblasting machines are also suitable for deep, bold carvings.

2. How do I choose a machine for fine and intricate designs?

Laser engraving machines are ideal for fine detailing and intricate patterns, especially on soft stones like marble and slate.

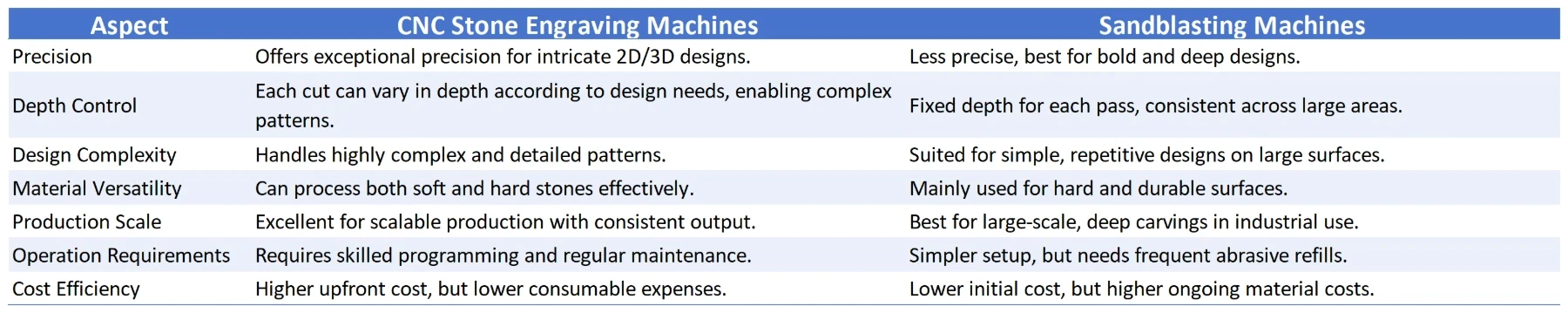

3. What is the differences between CNC stone carving machine and sandblasting machine as they can carve deeper?

4. Can one machine handle both soft and hard stones?

CNC machines offer the most versatility, handling a wide range of materials from soft limestone to hard granite with appropriate tools.

5. How important is after-sales support when choosing a supplier?

After-sales support is crucial for training, spare parts availability, and troubleshooting. Reliable suppliers like DINOSAW provide comprehensive support to ensure long-term operational success.