Quick Selection Guide for Stone CNC Router

Different stone processing needs require specific equipment types. Find the right CNC machine for your application:

Application | Key Requirements | Recommended Equipment | ||

|---|---|---|---|---|

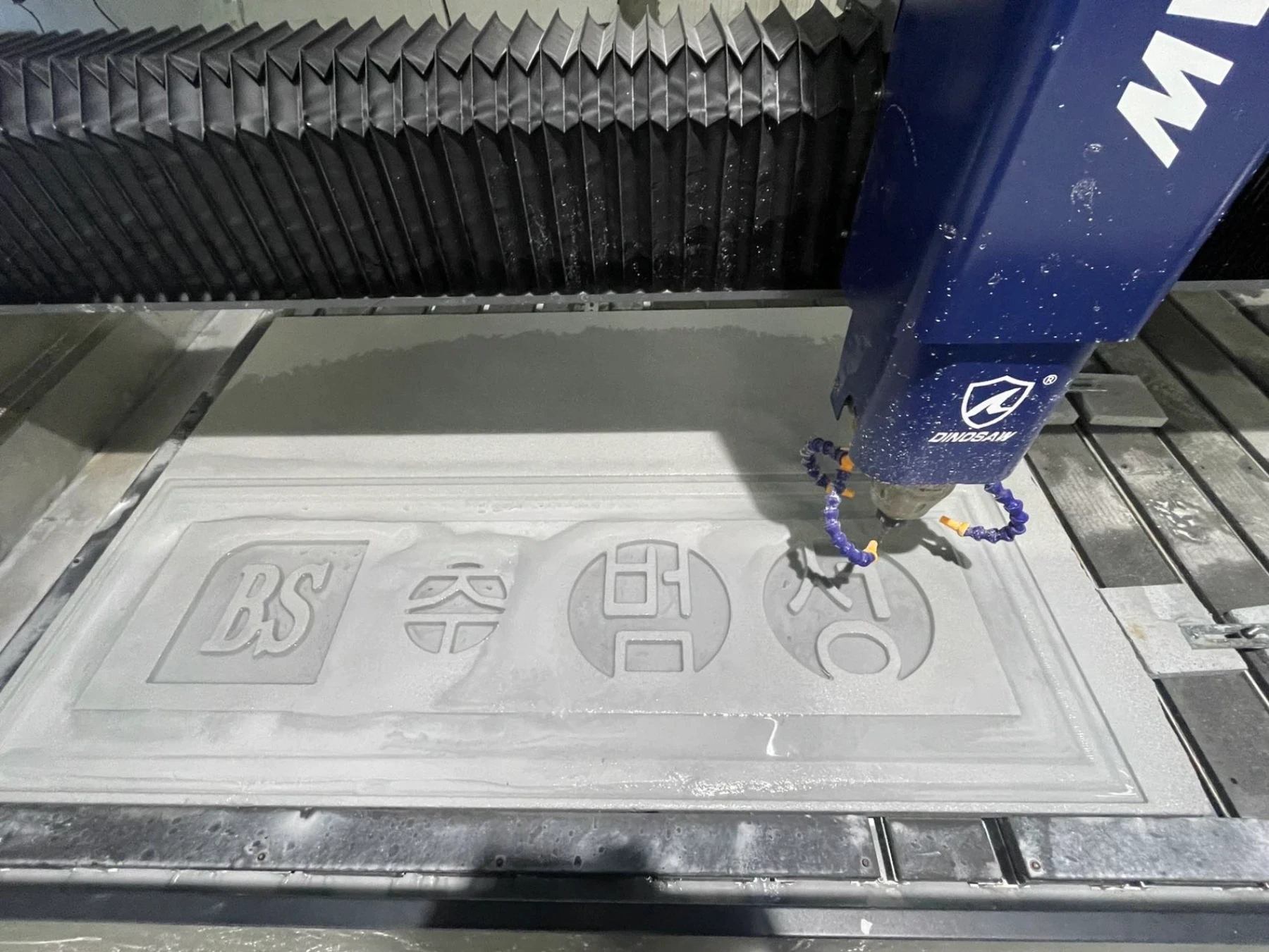

Monument Production | Text engraving, relief patterns, Fine engraving capability, medium work area, easy operation | 3-axis engraving machine, small to medium CNC router | ||

Countertop Processing | Cutting, sink cutouts, edge finishing, Large-size processing capacity, high-precision cutting, multi-functionality | Bridge saw, CNC with sink cutout function | ||

Artistic Sculptures | 3D shapes, complex curves, Multi-axis processing capability, high-precision control, complex path planning | 4-axis or 5-axis router, high-end CNC engraving machine | ||

Small Workshop | Various small-scale processing, limited space, Compact size, versatility, cost-effectiveness | Desktop CNC, small multi-functional machine | ||

Inqury for your Stone CNC Router now

Stone Industry Needs and Processing Solutions Integration

Industry Applications and Stone Materials Requirements

Industry Applications | Recommended Equipment | |

|---|---|---|

Interior Design & Stone Countertops Processing Kitchen and bathroom countertops, fireplace surrounds, and window sills. Requires precise cutting, sink cutouts, and edge treatment capabilities. Suitable for engineered materials like quartz, ceramic, marble requiring high-speed cutting capacity and efficient cooling systems. | 4 axis CNC Bridge saw with 1 carving finger, with sink cutout function, especially suitable for countertop manufacturers and factories requiring high-precision cutting. | |

Monument & Tombstone Fabrication | CNC wire saws cut multiple monuments at once, greatly improving efficiency. CNC engraving machines are for details. For maximum output, choose heavy-duty machines with multiple spindles. | |

Artistic Projects & Stone Sculptures Used for creating 3D statues, wall art and architectural elements. Requires multi-axis processing and complex path planning. Works with various stone types, from soft sandstone (Mohs 2-4) to harder granite. Needs precise control and specialized tools. | 4-axis or 5-axis router or high-end CNC engraving machine that can work from any angle for complex shapes. Large sculptures benefit from CNC wire saws for initial outline cutting of stone blocks. | |

Machine Solutions for Stone Fabricators

Suitable for Countertop manufacturers, factories requiring high-precision cutting | Suitable for Monument production, decorative relief, text engraving | All-in-one solution combining cutting, engraving, and polishing functions.Suitable for Comprehensive stone processing facilities |

CNC Stone Processing Core Functions & Technical Advantages

CNC Function | Key Capabilities | Business Benefits | ||

|---|---|---|---|---|

Engraving Technology | Fine engravings from simple text to complex portraits with 0.1mm precision | Access to high-end markets with 30-50% additional profit margin | ||

Cutting Precision | Clean edges and precise dimensions with computer-optimized cutting paths | Reduces waste to 1/3 of traditional methods and improves efficiency by 15-20% | ||

Drilling Capabilities | Precise, crack-free holes in hard materials with minimal waste | Essential for sink installation, fixtures and decorative elements, ensuring smooth installation | ||

Polishing Finish | Smooth edges and professional-grade surface finishes using specialized tools | 70% faster than manual methods with more consistent quality, improving both aesthetics and safety | ||

Stone CNC Router Selection Framework & Key Features for Stone Fabricators

Step 1: Define Application Scenarios and Technical Requirements

Single-Task Focus for Specialized Workshops | Multi-Task Requirements for Fabrication Business |

|---|---|

If you mainly do basic engraving or straight-line cutting (like decorative plaques or standard cutting), choose specialized engraving machines or bridge saws. These offer better performance at lower cost for focused tasks. | If you handle various jobs with frequently changing requirements, a multi-functional CNC router works better. Though initially more expensive, it replaces multiple machines. This saves space, reduces total costs and improves workflow. |

Step 2: Key Technical Features for Quality Stone Processing

Component quality directly affects precision, efficiency and service life. Focus on these key features when selecting stone CNC equipment:

CNC Control System | Determines precision and ease of use. Good systems provide accurate calculations that reduce errors. They offer intuitive interfaces that are easier to learn. Critical for fine patterns and consistent products. | ||

|---|---|---|---|

High-Speed Spindle | 24,000 RPM spindles maintain constant force during cutting, preventing speed drops and overheating with hard stones. Professional spindles work 40% faster while creating smoother surfaces. | ||

Diamond Tools | Essential for precise cuts in hard materials like granite and marble. Fabricator Supplies tests show quality diamond tools last 3-5 times longer than standard tools. | ||

Solid Frame Structure | Cast iron frames absorb vibration, improving precision and surface quality. Prevents resonance during high-speed work, essential for fine polished surfaces. | ||

Dust Management System | Good dust systems protect tools and work areas by collecting processing dust. Quality systems remove over 90% of airborne particles, protecting operator health and extending equipment life. | ||

Software Integration | Smooth integration with CAD/CAM programs like AutoCAD or ArtCAM is essential. Advanced software integration cuts programming time by 60%, improving workflow efficiency. | ||

Configuration Flexibility | Consider customization options for table size, accessory compatibility and software upgrades. Flexible systems adapt as your business grows, preventing early obsolescence. | ||

Step 3: Evaluating Manufacturer Support & Knowledge Transfer for Customer Success

Manufacturer support and training directly affect equipment value. Good manufacturers provide both equipment and knowledge:

🔧Custom Design for Workshop Layout | 👨🏫Installation & Operator Training | 🔄Lifetime Maintenance Support |

|---|---|---|

Customizing machine setup for your workshop layout improves space use and workflow efficiency. | On-site setup and training help you start using the machine confidently. You'll understand its functions and maintenance needs clearly. | Remote troubleshooting and parts supply keep your machine running smoothly when needed. |

Stone CNC Router Technology & Workflow for Finished Products

Stone CNC routers use computer-controlled tools to shape stone surfaces precisely. They handle complex engraving, cutting and etching. The process works like this:

Upload 3D models or vector files to the software as working blueprints.

Select appropriate tools—diamond, carbide, or granite router bits—based on the hardness of the processing material.

The spindle operates at high speeds of 15,000 to 24,000 RPM, moving along X, Y, and Z axes to shape the stone.

Built-in vacuum systems effectively manage debris removal, keeping the work area clean.

CNC Stone Equipment Maintenance & Performance Optimization Guide

Proper maintenance directly affects machine performance and lifespan. Here are best practices from industry experts:

Weekly Cleaning Routine

Clean spindles and guide rails regularly to prevent dust buildup. Dust accelerates wear on critical parts. Weekly cleaning reduces maintenance needs by 40%.

Tool Replacement Strategy

Replace diamond tools based on actual wear, not fixed schedules. Watch for: declining cut quality, longer processing time or increased noise.Quality tools cost more initially but last longer and cut better. This reduces overall operating costs over time.

Software Updates

Update software regularly for latest improvements. This prevents failures and maintains compatibility with modern design software.

Professional Inspection Schedule

Schedule professional inspections twice yearly. Early detection of issues keeps the machine performing optimally throughout its life.

Stone CNC Equipment Technical FAQs for Machine Operators

Can CNC Routers Cut Stone Materials?

Yes. CNC routers cut stone effectively when using proper tools and settings.Professional stone CNC routers with diamond tools handle granite, marble and quartz well. Tool selection is crucial. Different stone hardnesses need specific diamond tool types.

Why Do CNC router Cutting Tools Break? Prevention Methods

Stone CNC tool breakage happens due to: wrong processing settings, poor tool quality, uneven material hardness, impurities, and machine vibration.

Prevention: Use proper diamond tools for each stone type. Adjust cutting speed and feed rate. Maintain machines to reduce vibration. Use proper cooling to prevent overheating.

When cutting hard stone like granite, increase depth gradually instead of cutting through in one pass. This reduces tool breakage and extends tool life.

Water Cooling vs. Air Cooling Systems for Stone Machining

Stone CNC routers use two main cooling systems: water and air. Water cooling offers better heat removal, ideal for hard stones in continuous use. Its drawback is potential freezing in cold environments.

Air cooling is easier to maintain with no leakage or freezing issues. However, it has lower cooling capacity and isn't suitable for intensive, long operations. In cold shops, water cooling systems need antifreeze.

Production facilities should use water cooling, while small shops with occasional use might prefer air cooling. High-end equipment like DINOSAW includes temperature monitoring to prevent spindle damage.

Is Training Included for CNC Routers Operators?

Most good suppliers include training with equipment delivery. Training typically covers software, maintenance and basic troubleshooting.

Quality training shortens the learning curve and speeds up return on investment. When choosing a supplier, ask detailed questions about training content, length and follow-up support.

Some advanced features may need extra specialized training. Clarify this before purchase.

How to Extend Stone CNC Router Service Life?

A CNC router's service life directly affects your investment return. Key maintenance includes: regular cleaning of guide rails and spindles to remove stone dust; maintaining proper workshop temperature; and regularly inspecting and replacing worn parts.

According to industry guidelines, weekly cleaning reduces maintenance needs by 40%. For water cooling systems, replace coolant regularly and check for pipe blockages.

Follow manufacturer's operating guidelines and avoid overloading to extend core component life. Schedule 2-3 professional inspections yearly.

Solving Uneven Processing & Precision Issues

Uneven processing typically results from: misaligned spindle and table; tool problems; control card failures; Z-axis drive or screw issues; or uneven work table.

Solutions: Recalibrate spindle-to-table alignment. Use better quality tools. Check control system settings. Inspect and adjust Z-axis drive systems. Ensure table flatness.

When working with soft stones like marble, control cutting depth and speed carefully. Fast feed rates often cause uneven cutting depths. For precision work, do test cuts before final processing.

Technical Consultation & Custom Solutions for Stone Fabrication Business

Choosing stone processing equipment requires considering: process needs, production volume, material types and business plans. The stone processing industry grows 7.5% yearly, with technology driving efficiency and precision gains.

Our team provides custom consultation for your specific needs. We help find the best solution from many options. Whether you run a small shop or large factory, we offer tailored technical advice.

Professional Technical Support Services for Stone Fabricators

Needs analysis and equipment configuration recommendations

Process optimization and efficiency improvement solutions

Operation training and technical knowledge transfer

After-sales maintenance and spare parts support