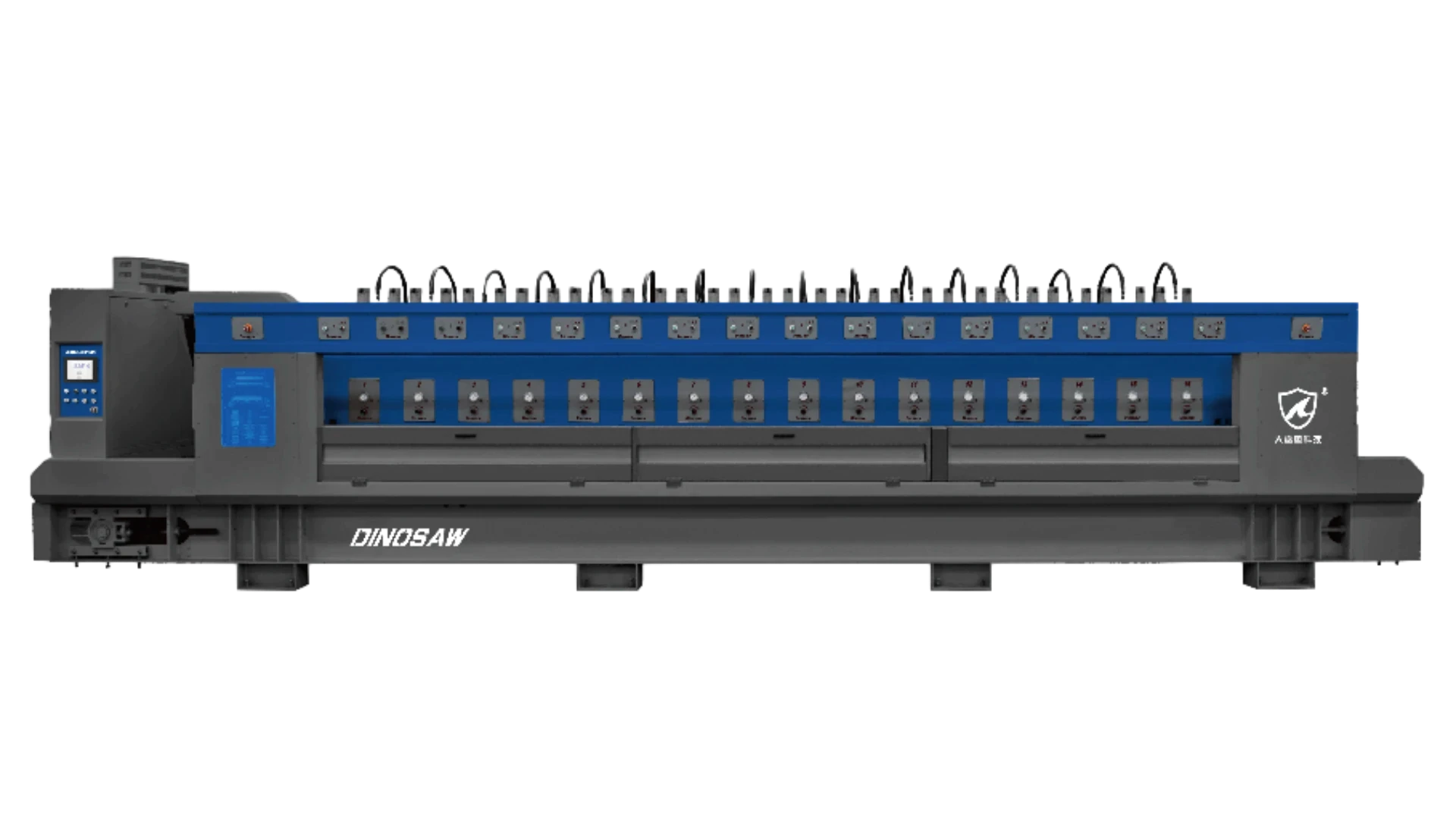

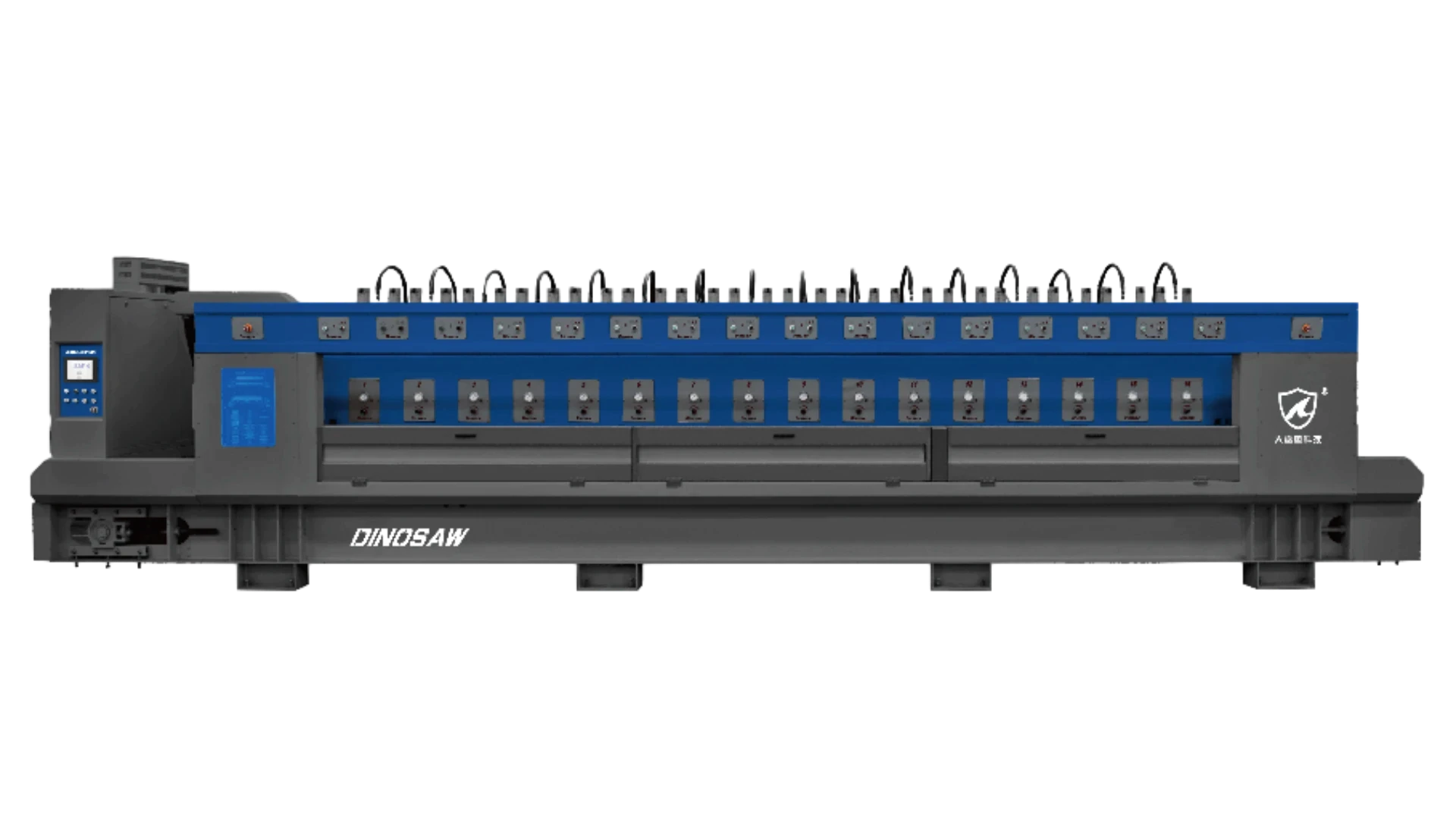

Heavy-Duty Stone Block Cutting Machine for Natural Stone

LMDQ-2200/2500/2800/3000

DINOSAW stone cutting machine combines high speed (10m/min) and deep cutting capability (1350mm) with multi-blade technology, perfect for efficient cutting of granite, marble, limestone, cement, and other blocks. It precisely cuts (±0.2mm) stone blocks into slabs and strips of specified thickness without requiring a trolley system, making it the ideal equipment for block processing.

Compatible Materials & Products

▶ Product Demo

Granite ❯ Block Cutting

Marble ❯ Batch Slab Cutting

Limestone ❯ Block Cutting

Sandstone ❯ Batch Slab Cutting

Quartzite ❯ Block Cutting

▶ Product Demo

Granite ❯ Block Cutting

Marble ❯ Batch Slab Cutting

Limestone ❯ Block Cutting

Sandstone ❯ Batch Slab Cutting

Quartzite ❯ Block Cutting

Consult DINOSAW Material Expert →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Perfect your countertop fabrication →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Perfect your countertop fabrication →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Perfect your countertop fabrication →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Perfect your countertop fabrication →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Specs and options

Specifications customizable upon request.

Model | Unit | LMDQ-2200 | LMDQ-2500 | LMDQ-2800 | LMDQ-3000 |

|---|---|---|---|---|---|

Max. diameter of blade | mm | Φ2200 | Φ2500 | Φ2800 | Φ3000 |

Max. No. of blades | pc | 9 | 9 | 1(5) | 1(5) |

Recommended Blade Combination | mm | Φ2200 Φ2000 | Φ2500 Φ2200 | Φ2800 | Φ3000 |

Main motor power | KW | 45 | 45/55 | 55 | 75 |

Max. Cutting size (L x W x H) | mm | 4000 x 2200 x 950 | 3700 x 2200 x 1100 | 3500 x 2200 x 1300 | 3500 x 2200 x 1350 |

Overall dimensions (L x W x H) | mm | 7500 x 4000 x 7000 | 7500 x 4000 x 7000 | 7500 x 4000 x 7000 | 8000 x 4000 x 7000 |

Water consumption | m³/h | 15 | 15 | 15 | 15 |

Approximate Weight | t | 11 | 11 | 12 | 13 |

Contact DINOSAW technical team for details →

Professional stone block cutting equipment delivering consistent processing with multi-blade efficiency.

Block Processing Ready. Precision Cutting. Proven Results.

High-Speed Multi-Blade Cutting

55kW main motor, heavy-duty spindle and multi-blade system achieve 120㎡/h cutting with high efficiency.

±0.2mm Cutting Precision

Hydraulic lift provides ±0.2mm precision, gear rack and PLC system ensures consistent slabs.

40% Longer Equipment Lifespan

Cast bridge structure with large-diameter guide columns and reinforced beams ensures durability.

Inqury for Details →

20% Energy Savings

Permanent magnet motor technology optimizes power consumption while maintaining cutting performance.

Front & Rear Loading Convenience

Front and rear loading options with conveyor cart configuration streamline material handling.

Motor Overload Protection

Flexible coupling with belt protection prevents motor damage from excessive cutting loads.

Maintenance Reduction

Automatic lubrication system reduces manual maintenance and equipment failures significantly.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Quarry Wire Saw Machine for Block Extraction

Upstream solution for initial block extraction from quarry faces. Cuts raw granite and marble blocks to optimal dimensions for subsequent block cutting operations. Maximizes material utilization in quarry-to-slab workflow integration while reducing extraction waste.

Optimize your quarry extraction process →

Automatic Polishing Machine for Slab Finishing

Downstream processing equipment for achieving smooth or mirror-finish surfaces on cut slabs. Automated polishing heads deliver consistent surface quality for background walls, tabletops, and materials ready for secondary processing. Completes the block-to-finished-slab workflow efficiently.

Complete your stone finishing line →

CNC Bridge Saw for Precision Secondary Processing

Advanced secondary cutting solution for beveling, arc cutting, drilling, and milling operations on initially cut slabs. Enables precision fabrication of countertops, sinks, and tabletops with complex shapes and openings. Perfect for high-value applications requiring detailed finishing work.

Perfect your precision fabrication →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What materials can the stone block cutting machine process?

What is the cutting accuracy of the stone block cutter?

What maintenance requirements should I expect?

What daily output can I expect from this machine?

What training and support do you provide?

Can the machine handle custom cutting projects?

Need more assistance? Click to contact DINOSAW →

Ready to Transform Your Stone Production?

Achieve 200% efficiency gains with DINOSAW precision cutting technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Stone Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Stone Cutting Knowledge & Solutions

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

Heavy-Duty Stone Block Cutting Machine for Natural Stone

LMDQ-2200/2500/2800/3000

DINOSAW stone cutting machine combines high speed (10m/min) and deep cutting capability (1350mm) with multi-blade technology, perfect for efficient cutting of granite, marble, limestone, cement, and other blocks. It precisely cuts (±0.2mm) stone blocks into slabs and strips of specified thickness without requiring a trolley system, making it the ideal equipment for block processing.

Compatible Materials & Products

▶ Product Demo

Granite ❯ Block Cutting

Marble ❯ Batch Slab Cutting

Limestone ❯ Block Cutting

Sandstone ❯ Batch Slab Cutting

Quartzite ❯ Block Cutting

▶ Product Demo

Granite ❯ Block Cutting

Marble ❯ Batch Slab Cutting

Limestone ❯ Block Cutting

Sandstone ❯ Batch Slab Cutting

Quartzite ❯ Block Cutting

Consult DINOSAW Material Expert →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Memorial Stone Processing

Enhancing Granite Fabricator Efficiency

A leading memorial stone fabricator increased production capacity by 200% after implementing our cutting system. The ±0.2mm precision eliminated costly rework while multi-blade configuration reduced processing time.

Supercharge your granite memorial production →

Commercial Kitchen Projects

Precision Cutting for Flawless Installations

High-end restaurant chain reduced installation delays by 40% using our precision cutting technology. Consistent 2cm thickness eliminated field modifications while servo drive efficiency reduced operating costs by 30% during peak periods.

Project completion accelerated from 6 weeks to 4 weeks while maintaining premium quality standards.

Scale your architectural stone production →

Architectural Stone Supply

Scaling Production for Major Construction

Construction material supplier met aggressive deadlines by processing up to 450㎡ daily with our multi-blade system for 1.5cm slabs. Cast bridge stability maintained quality standards across extended continuous operation for luxury hotel facade installation.

Scale your architectural stone production →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | LMDQ-2200 | LMDQ-2500 | LMDQ-2800 | LMDQ-3000 |

|---|---|---|---|---|---|

Max. diameter of blade | mm | Φ2200 | Φ2500 | Φ2800 | Φ3000 |

Max. No. of blades | pc | 9 | 9 | 1(5) | 1(5) |

Recommended Blade Combination | mm | Φ2200 Φ2000 | Φ2500 Φ2200 | Φ2800 | Φ3000 |

Main motor power | KW | 45 | 45/55 | 55 | 75 |

Max. Cutting size (L x W x H) | mm | 4000 x 2200 x 950 | 3700 x 2200 x 1100 | 3500 x 2200 x 1300 | 3500 x 2200 x 1350 |

Overall dimensions (L x W x H) | mm | 7500 x 4000 x 7000 | 7500 x 4000 x 7000 | 7500 x 4000 x 7000 | 8000 x 4000 x 7000 |

Water consumption | m³/h | 15 | 15 | 15 | 15 |

Approximate Weight | t | 11 | 11 | 12 | 13 |

Contact DINOSAW technical team for details →

Professional stone block cutting equipment delivering consistent processing with multi-blade efficiency.

Block Processing Ready. Precision Cutting. Proven Results.

High-Speed Multi-Blade Cutting

55kW main motor, heavy-duty spindle and multi-blade system achieve 120㎡/h cutting with high efficiency.

±0.2mm Cutting Precision

Hydraulic lift provides ±0.2mm precision, gear rack and PLC system ensures consistent slabs.

40% Longer Equipment Lifespan

Cast bridge structure with large-diameter guide columns and reinforced beams ensures durability.

Inqury for Details →

High-Speed Multi-Blade Cutting

55kW main motor, heavy-duty spindle and multi-blade system achieve 120㎡/h cutting with high efficiency.

±0.2mm Cutting Precision

Hydraulic lift provides ±0.2mm precision, gear rack and PLC system ensures consistent slabs.

40% Longer Equipment Lifespan

Cast bridge structure with large-diameter guide columns and reinforced beams ensures durability.

Inqury for Details →

20% Energy Savings

Permanent magnet motor technology optimizes power consumption while maintaining cutting performance.

Front & Rear Loading Convenience

Front and rear loading options with conveyor cart configuration streamline material handling.

Motor Overload Protection

Flexible coupling with belt protection prevents motor damage from excessive cutting loads.

Maintenance Reduction

Automatic lubrication system reduces manual maintenance and equipment failures significantly.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Quarry Wire Saw Machine for Block Extraction

Upstream solution for initial block extraction from quarry faces. Cuts raw granite and marble blocks to optimal dimensions for subsequent block cutting operations. Maximizes material utilization in quarry-to-slab workflow integration while reducing extraction waste.

Optimize your quarry extraction process →

Automatic Polishing Machine for Slab Finishing

Downstream processing equipment for achieving smooth or mirror-finish surfaces on cut slabs. Automated polishing heads deliver consistent surface quality for background walls, tabletops, and materials ready for secondary processing. Completes the block-to-finished-slab workflow efficiently.

Complete your stone finishing line →

CNC Bridge Saw for Precision Secondary Processing

Advanced secondary cutting solution for beveling, arc cutting, drilling, and milling operations on initially cut slabs. Enables precision fabrication of countertops, sinks, and tabletops with complex shapes and openings. Perfect for high-value applications requiring detailed finishing work.

Perfect your precision fabrication →

Get a Custom Solution →

Faqs

Common Questions About Heavy-Duty Stone Block Cutting Machines

What materials can the stone block cutting machine process?

What materials can the stone block cutting machine process?

What is the cutting accuracy of the stone block cutter?

What is the cutting accuracy of the stone block cutter?

What maintenance requirements should I expect?

What maintenance requirements should I expect?

What daily output can I expect from this machine?

What daily output can I expect from this machine?

What Is CNC (Computer Numerical Control)? - User Guide

What training and support do you provide?

What Is CNC (Computer Numerical Control)? - User Guide

Can the machine handle custom cutting projects?

What Is CNC (Computer Numerical Control)? - User Guide

What are the power requirements and energy consumption?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to Transform Your Stone Production?

Expand Your Stone Cutting Knowledge & Solutions

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Stone Cutting Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Stone Cutting Knowledge & Solutions

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: