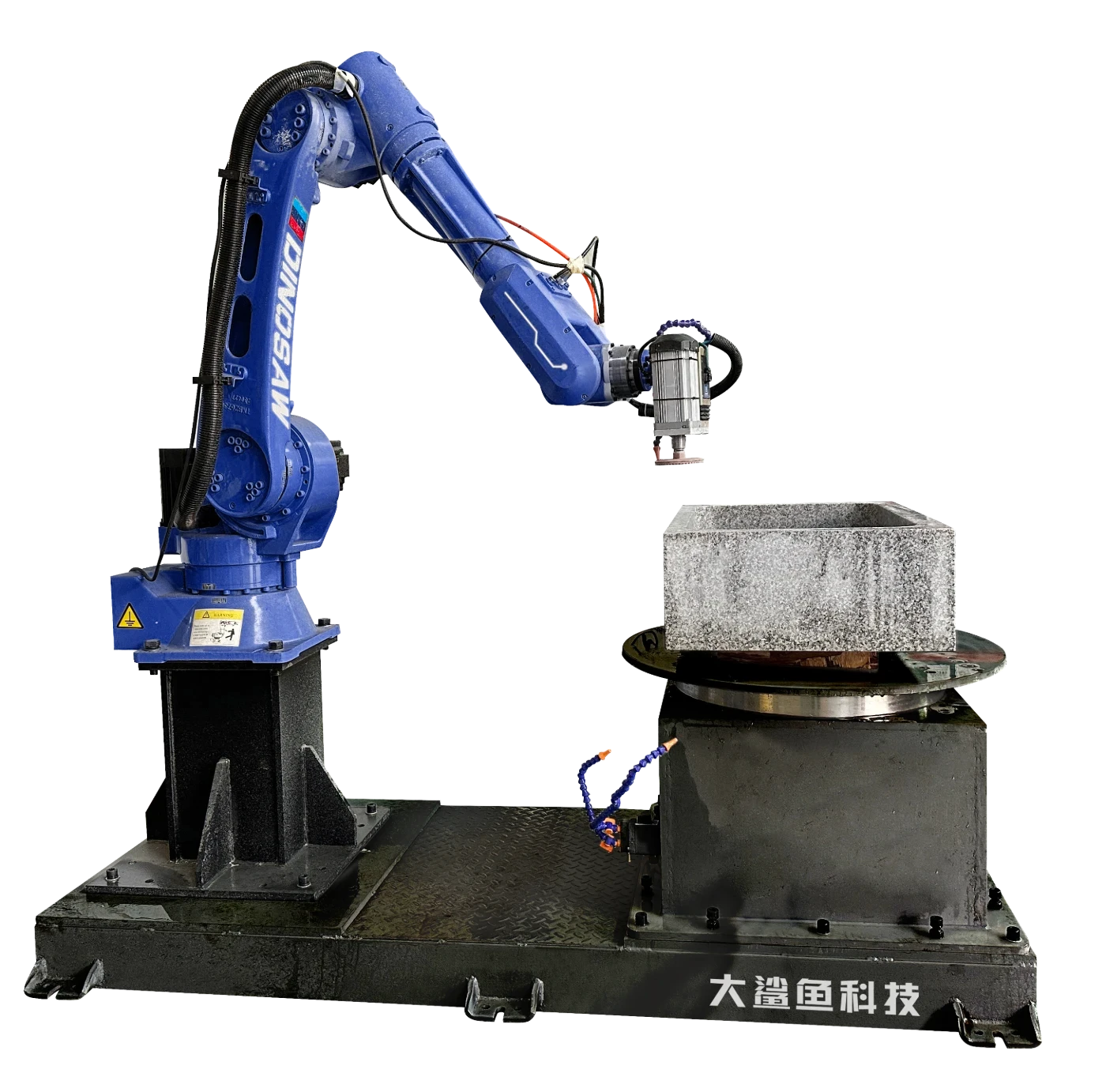

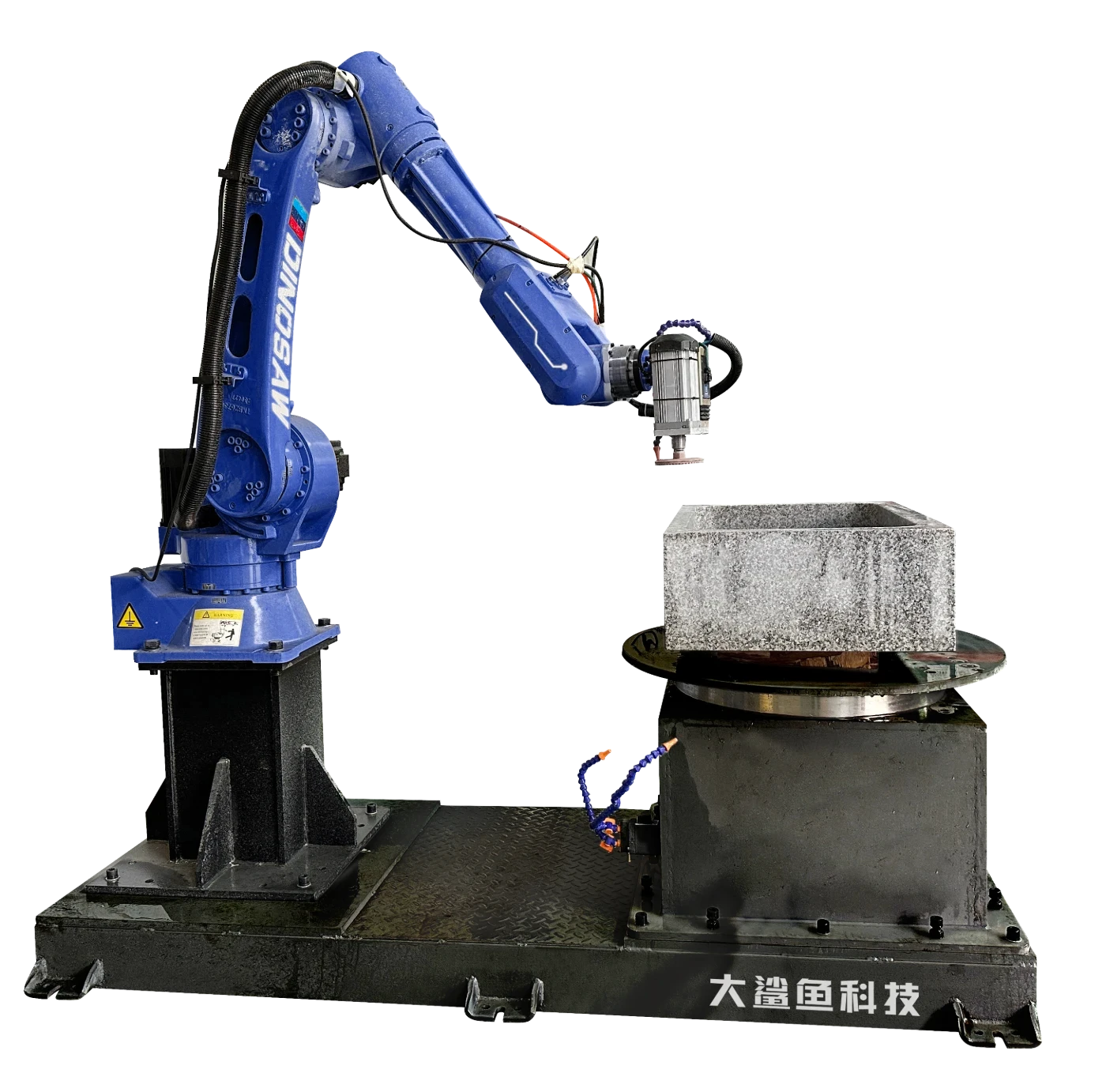

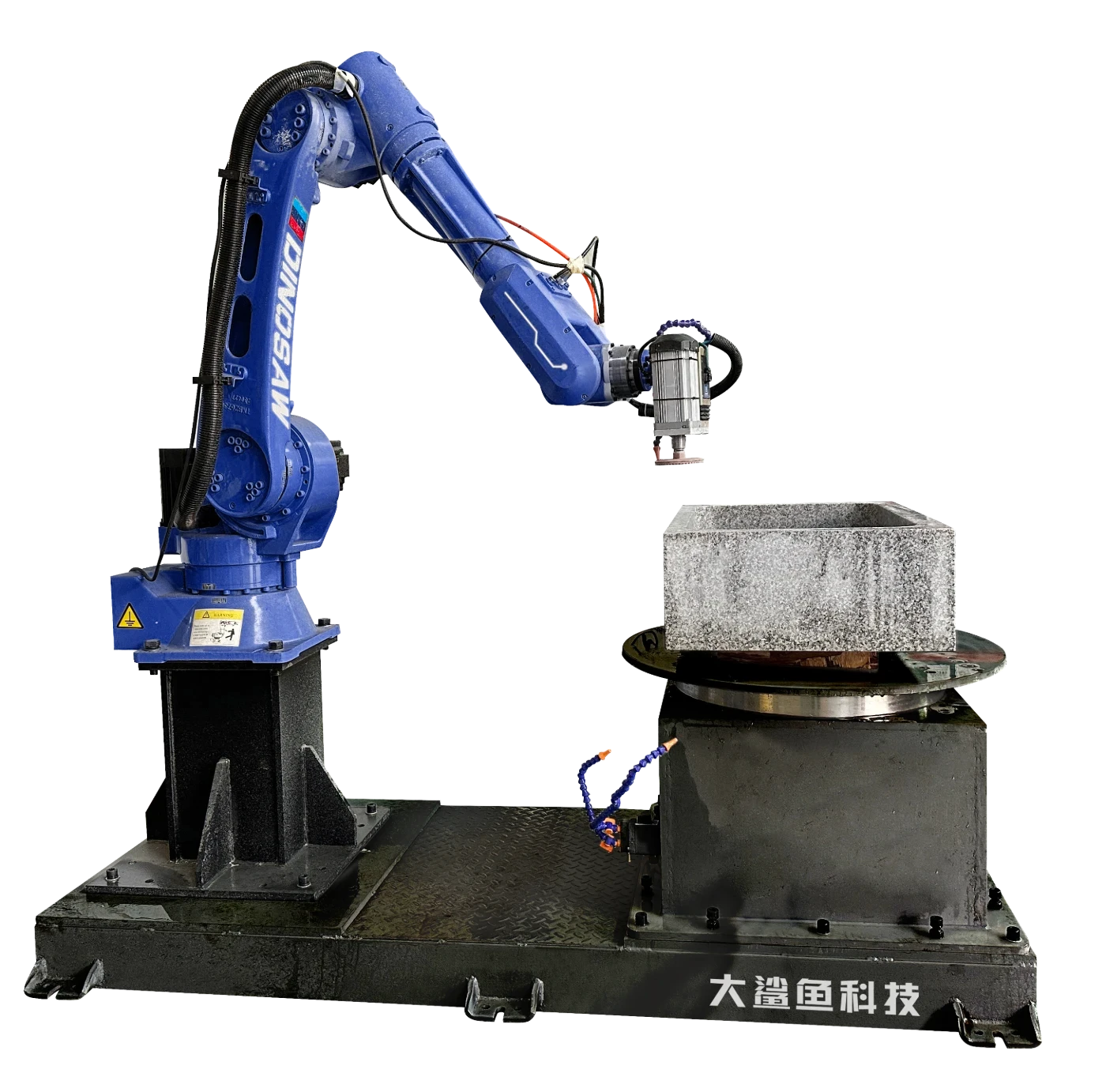

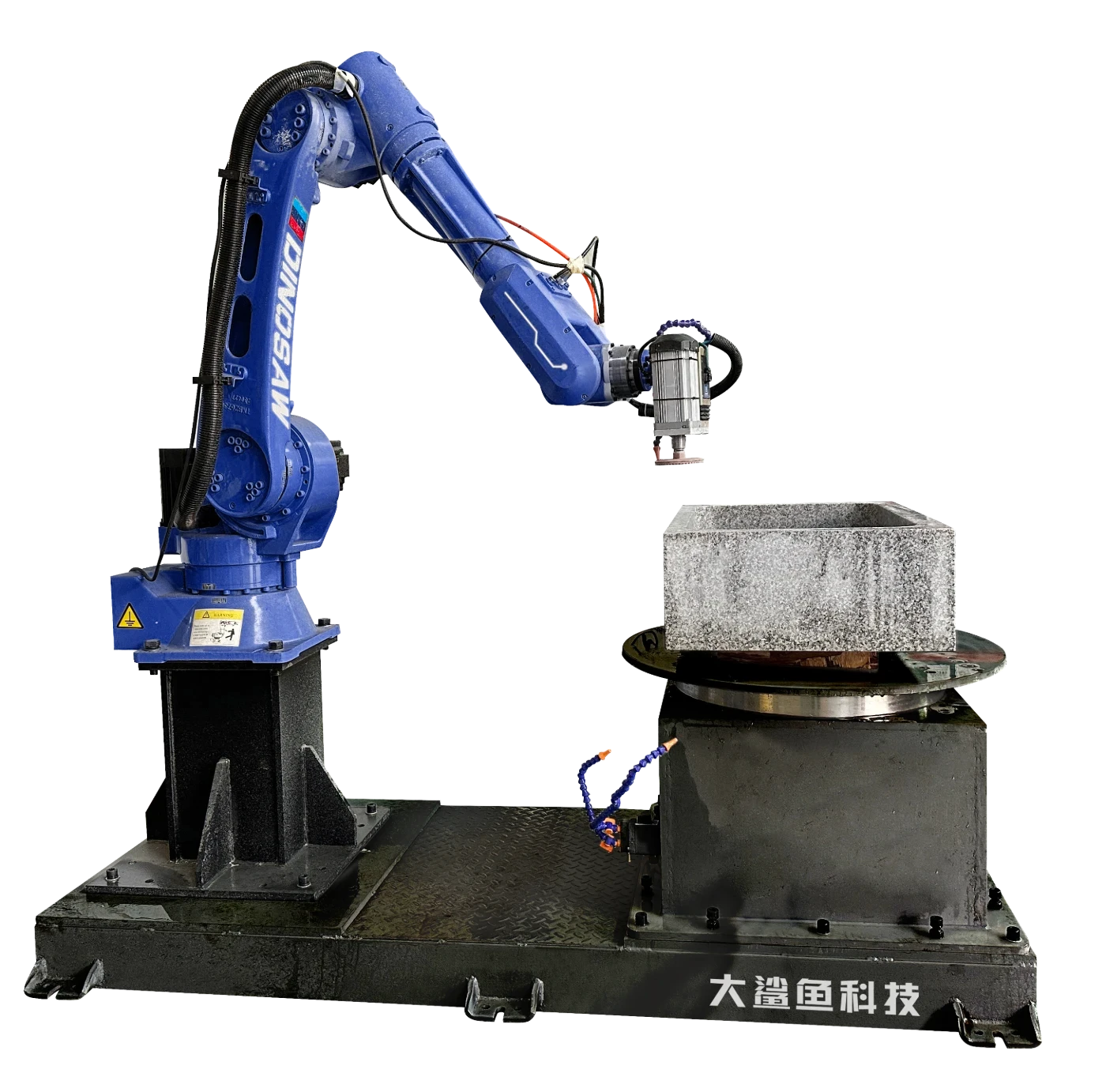

6 Axis Robot Arm for Stone Polishing & Grinding

JXS3670

DINOSAW 6 axis robot arm delivers precise stone polishing and grinding with. Features 6-axis complete mobility for complex surface finishing, edge polishing, and sculptural detailing.This automated stone polishing robot processes diverse materials including granite, marble, limestone, sandstone, quartz, slate, travertine, and engineered stone. Applications span tombstones, kitchen countertops, bathroom vanities, sculptures, and decorative elements across all stone fabrication projects.

Compatible Materials & Products

▶ Product Demo

Granite ❯ Tombstones & Memorials

Marble ❯ Countertops

Quartz ❯ Bathroom Sinks & Basins

Natural Stone ❯ Artistic Sculptures

▶ Product Demo

Granite ❯ Tombstones & Memorials

Marble ❯ Countertops

Quartz ❯ Bathroom Sinks & Basins

Natural Stone ❯ Artistic Sculptures

Consult DINOSAW Material Expert →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Elevate your countertop quality standards →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Elevate your countertop quality standards →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Elevate your countertop quality standards →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Elevate your countertop quality standards →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Specs and options

Specifications customizable upon request.

Equipment model | JXS3670 |

|---|---|

Max working radius | 1721MM |

axis 1 speed | 187°/s |

Axis 2 speed | 148°/s |

axis 3 speed | 169°/s |

axis 4 speed | 234°/s |

axis 5 speed | 225°/s |

axis 6 speed | 225°/s |

max operation area axis 1 | ±160° |

max operation area axis 2 | 150° ~ -90° |

max operation area axis 3 | 80° ~ -100° |

max operation area axis 4 | ±150° |

max operation area axis 5 | ±110° |

max operation area axis 6 | ±300° |

protective specification | IP54 |

position repeat accuracy | ±0.05° |

working temperature | 0~45°C |

Contact DINOSAW technical team for details →

Advanced robotics meets stone craftsmanship excellence

Precision. Automation. Profitability.

Reduce Labor Costs

24/7 automated operation , eliminating skilled labor shortages

Easy Operation & Quick Training

Import design drawings for automatic processing, ordinary workers can operate quickly

Handle Complex Workpiece

6-axis grinding system reaches any angle and position of workpieces

Inqury for Details →

Achieve Consistent Quality Results

CNC system combined with polishing process library ensures identical finishing procedures on every product.

Multi-Purpose Machine Flexibility

Compatible with all grinding tools for tombstones, countertops, and sculptures

Low Maintenance Design

IP54 dust and water protection rating reduces maintenance requirements and failure rates significantly.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Wire Saw for Sculpture Shape Cutting

Wire saw cuts precise sculpture shapes, then 6 axis robot arm provides final polishing. Ideal workflow for artistic stone production requiring geometric accuracy and smooth surfaces.

Perfect your artistic sculpture production →

7-Axis Engraving Robot for Detailed Carving

6 axis robot arm polishes surfaces first, then 7-axis engraving robot adds detailed carving. Complete workflow for sculptures, monuments, and tombstones.

Enhance your memorial carving capabilities →

5-Axis Bridge Saw for Countertop & Sink Cutting

Bridge saw cuts countertops and sink openings to finished dimensions, then 6 axis robot arm provides final polishing. One-stop solution for kitchen and bathroom fabrication.

Streamline your countertop production →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What types of stone materials can the 6 axis robot arm process?

How accurate is the positioning system for detailed polishing work?

What maintenance requirements does the robotic polishing system have?

How does the adaptive force control technology work?

Need more assistance? Click to contact DINOSAW →

Ready to Automate Your Stone Polishing Operations?

Transform your production with DINOSAW 6 axis robot arm technology and achieve superior results.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Industry Robot Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Stone Automation Knowledge

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

6 Axis Robot Arm for Stone Polishing & Grinding

JXS3670

DINOSAW 6 axis robot arm delivers precise stone polishing and grinding with. Features 6-axis complete mobility for complex surface finishing, edge polishing, and sculptural detailing.This automated stone polishing robot processes diverse materials including granite, marble, limestone, sandstone, quartz, slate, travertine, and engineered stone. Applications span tombstones, kitchen countertops, bathroom vanities, sculptures, and decorative elements across all stone fabrication projects.

Compatible Materials & Products

▶ Product Demo

Granite ❯ Tombstones & Memorials

Marble ❯ Countertops

Quartz ❯ Bathroom Sinks & Basins

Natural Stone ❯ Artistic Sculptures

▶ Product Demo

Granite ❯ Tombstones & Memorials

Marble ❯ Countertops

Quartz ❯ Bathroom Sinks & Basins

Natural Stone ❯ Artistic Sculptures

Consult DINOSAW Material Expert →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Memorial Manufacturing

Transforming Granite Memorial Production Efficienc

A leading memorial manufacturer increased production capacity by 400% after implementing DINOSAW 6 axis robot arms. The automated system eliminated inconsistent hand-polishing results while reducing skilled labor requirements from 8 operators to 2 supervisors.

The robotic precision enabled intricate engraving details previously impossible with manual methods.

Revolutionize your memorial production line →

Luxury Kitchen Fabrication

Achieving Premium Edge Finishing Excellence

High-end kitchen fabricator reduced countertop rejection to 1% using robotic edge polishing. Consistent pressure control eliminated the scratches and uneven surfaces common with manual grinding operations.

The 6 axis flexibility enabled complex waterfall edge profiles and seamless corner transitions, opening new premium market opportunities.

Scale your artistic production capabilities →

Artistic Stone Carving

Scaling Handcrafted Quality for Mass Production

Renowned sculpture studio automated finishing processes to meet growing demand for architectural decorative elements. The robotic system replicated master craftsman techniques with identical quality across 500+ pieces monthly.

Production costs decreased 45% while maintaining artistic authenticity. Artists now focus on creative design rather than repetitive finishing work.

Scale your artistic production capabilities →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Equipment model | JXS3670 |

|---|---|

Max working radius | 1721MM |

axis 1 speed | 187°/s |

Axis 2 speed | 148°/s |

axis 3 speed | 169°/s |

axis 4 speed | 234°/s |

axis 5 speed | 225°/s |

axis 6 speed | 225°/s |

max operation area axis 1 | ±160° |

max operation area axis 2 | 150° ~ -90° |

max operation area axis 3 | 80° ~ -100° |

max operation area axis 4 | ±150° |

max operation area axis 5 | ±110° |

max operation area axis 6 | ±300° |

protective specification | IP54 |

position repeat accuracy | ±0.05° |

working temperature | 0~45°C |

Contact DINOSAW technical team for details →

Advanced robotics meets stone craftsmanship excellence

Precision. Automation. Profitability.

Reduce Labor Costs

24/7 automated operation , eliminating skilled labor shortages

Easy Operation & Quick Training

Import design drawings for automatic processing, ordinary workers can operate quickly

Handle Complex Workpiece

6-axis grinding system reaches any angle and position of workpieces

Inqury for Details →

Reduce Labor Costs

24/7 automated operation , eliminating skilled labor shortages

Easy Operation & Quick Training

Import design drawings for automatic processing, ordinary workers can operate quickly

Handle Complex Workpiece

6-axis grinding system reaches any angle and position of workpieces

Inqury for Details →

Achieve Consistent Quality Results

CNC system combined with polishing process library ensures identical finishing procedures on every product.

Multi-Purpose Machine Flexibility

Compatible with all grinding tools for tombstones, countertops, and sculptures

Low Maintenance Design

IP54 dust and water protection rating reduces maintenance requirements and failure rates significantly.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Wire Saw for Sculpture Shape Cutting

Wire saw cuts precise sculpture shapes, then 6 axis robot arm provides final polishing. Ideal workflow for artistic stone production requiring geometric accuracy and smooth surfaces.

Perfect your artistic sculpture production →

7-Axis Engraving Robot for Detailed Carving

6 axis robot arm polishes surfaces first, then 7-axis engraving robot adds detailed carving. Complete workflow for sculptures, monuments, and tombstones.

Enhance your memorial carving capabilities →

5-Axis Bridge Saw for Countertop & Sink Cutting

Bridge saw cuts countertops and sink openings to finished dimensions, then 6 axis robot arm provides final polishing. One-stop solution for kitchen and bathroom fabrication.

Streamline your countertop production →

Get a Custom Solution →

Faqs

Common Questions About 6 Axis Robot Arm for Stone Polishing

What types of stone materials can the 6 axis robot arm process?

What types of stone materials can the 6 axis robot arm process?

How accurate is the positioning system for detailed polishing work?

How accurate is the positioning system for detailed polishing work?

What maintenance requirements does the robotic polishing system have?

What maintenance requirements does the robotic polishing system have?

How does the adaptive force control technology work?

How does the adaptive force control technology work?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to Automate Your Stone Polishing Operations?

Expand Your Stone Automation Knowledge

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Industry Robot Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expand Your Stone Automation Knowledge

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: