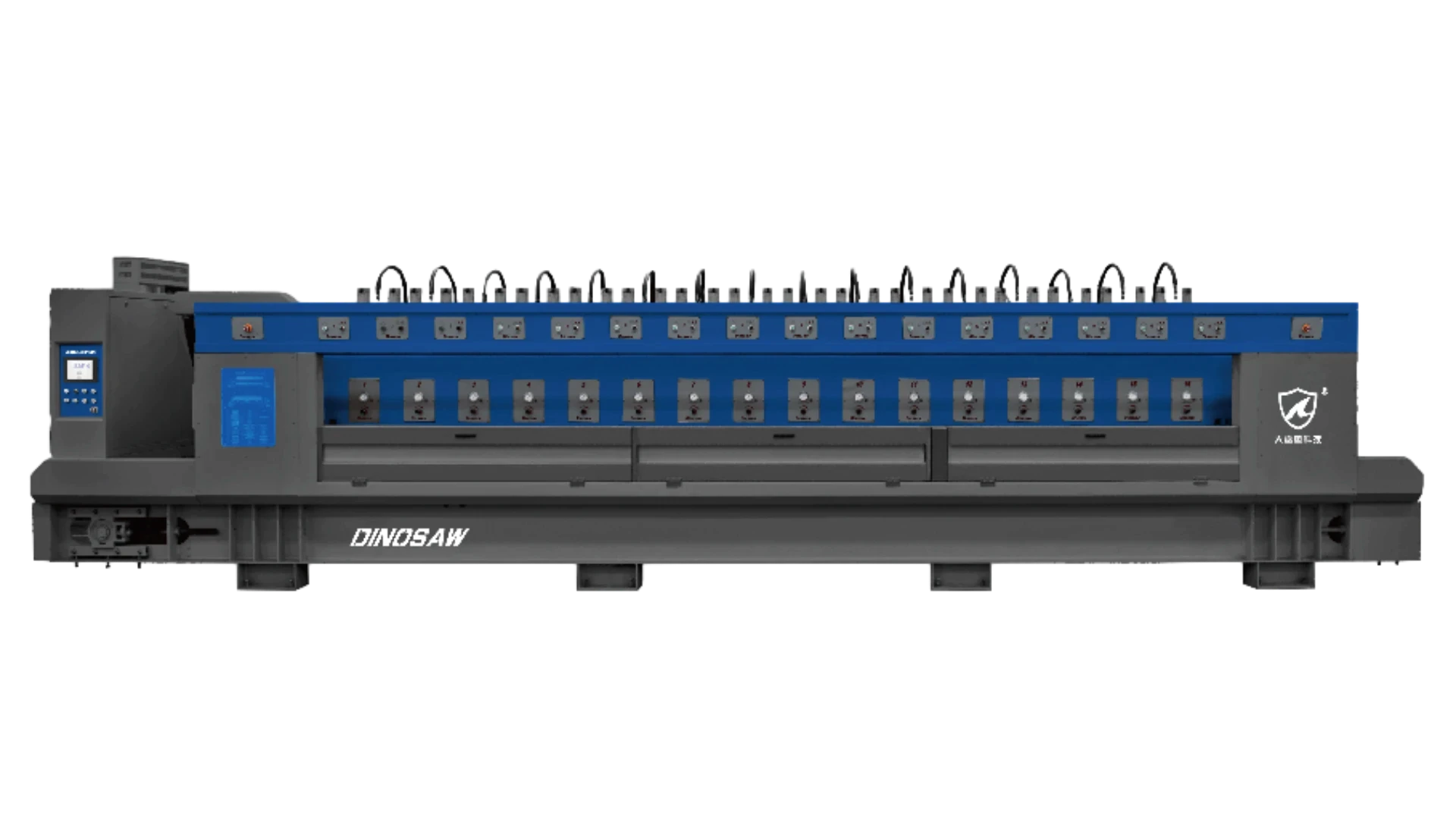

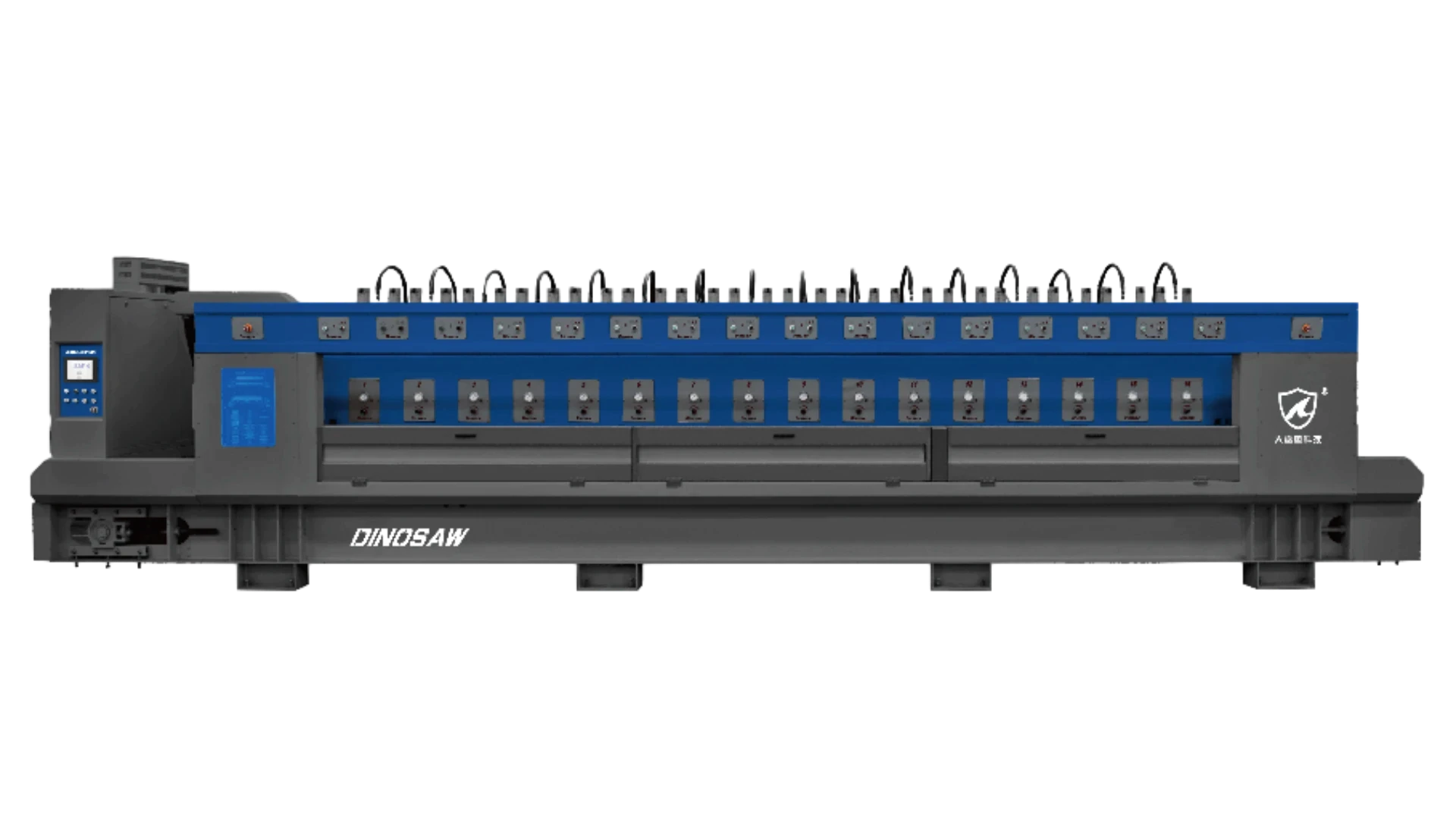

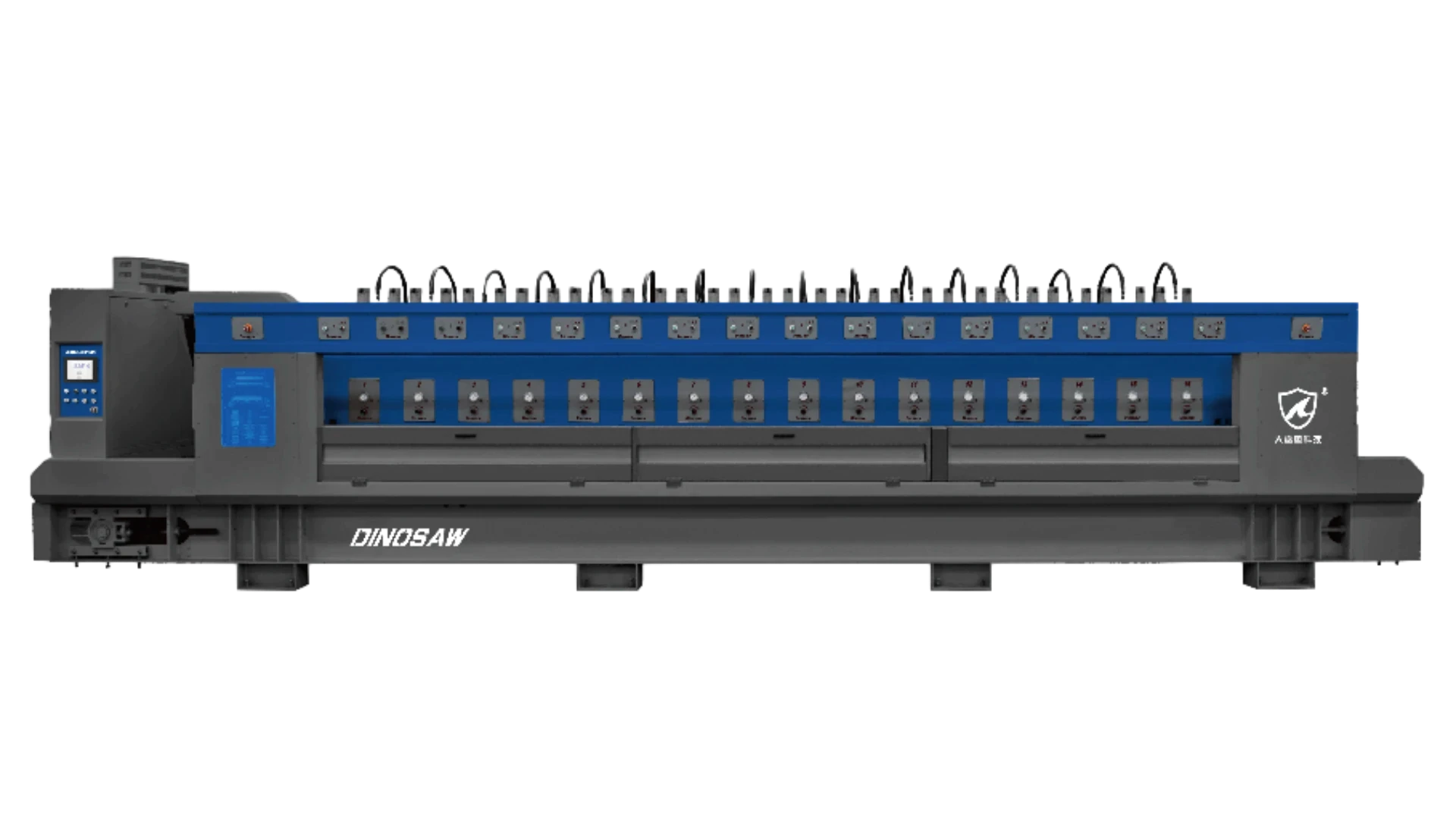

5-Axis CNC Bridge Saw

WZQJ-5N

DINOSAW 5-Axis CNC Bridge Saw achieves ±0.05mm precision cutting with DDX control system. Features straight, angled, curved, and 3D cutting capabilities, plus drilling and edge polishing. Direct CAD file import supports DXF, DWG formats. Processes granite, marble, quartz, porcelain, terrazzo, and sintered stone for vanity tops, basins, sculptures, countertops, and sinks. Integrated camera system reduces material waste by 30% through optimized nesting.

Transfoform Any Stone Into Premium Products

Granite ❯ Kitchen Sinks

Marble ❯ Bathroom Vanities

Quartz ❯ Countertops

Natural Stone ❯ Curved Furniture Elements

Natural Stone ❯ 3D Sculptures

▶ Product Demo

|

Granite's exceptional hardness and durability make it the premier choice for kitchen sinks that withstand heavy use while maintaining their beauty. |

The DINOSAW 5-axis bridge saw's powerful 18.5kW spindle precisely cuts through dense granite while maintaining ±0.05mm accuracy. Using its synchronized 5-axis movement, the machine creates perfectly rounded corners and seamless drain integrations, while the vacuum suction system securely holds the material during intricate cuts. The automatic tool compensation ensures consistent edge quality, eliminating the extensive manual finishing typically required for granite sink fabrication.

This advanced processing capability reduces production time by 65% compared to traditional methods while improving material utilization by up to 30%, dramatically increasing profitability for stone fabricators.

Granite ❯ Kitchen Sinks

Marble ❯ Bathroom Vanities

Quartz ❯ Countertops

Natural Stone ❯ Curved Furniture Elements

Natural Stone ❯ 3D Sculptures

▶ Product Demo

|

Granite's exceptional hardness and durability make it the premier choice for kitchen sinks that withstand heavy use while maintaining their beauty. |

The DINOSAW 5-axis bridge saw's powerful 18.5kW spindle precisely cuts through dense granite while maintaining ±0.05mm accuracy. Using its synchronized 5-axis movement, the machine creates perfectly rounded corners and seamless drain integrations, while the vacuum suction system securely holds the material during intricate cuts. The automatic tool compensation ensures consistent edge quality, eliminating the extensive manual finishing typically required for granite sink fabrication.

This advanced processing capability reduces production time by 65% compared to traditional methods while improving material utilization by up to 30%, dramatically increasing profitability for stone fabricators.

Consult DINOSAW Material Expert →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Elevate your bathroom renovation capabilities →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Elevate your bathroom renovation capabilities →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Elevate your bathroom renovation capabilities →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Elevate your bathroom renovation capabilities →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

Specs and options

Specifications customizable upon request.

Model | Unit | WZQJ - 5N |

|---|---|---|

Lateral X stroke | m | 3.2 |

Longitudinal Y stroke | m | 2.0 |

The Z axis saw blade vertical stroke | m | 0.45 |

Saw blade diameter | m | 0.6 |

Spindle motor capacity | kw | 18.5 |

Fixed table | m | 3.2x2.0 |

We can customize 5-axis bridge saws equipped with 800mm diameter blades, specifically designed for 3D sculpture cutting applications.

Contact DINOSAW technical team for details →

5-axis precision engineering for perfect results.

Precision. Innovation. Perfect Stone Cutting

Simple CNC Operation

Built-in graphics library supports CAD import and direct drawing for easy operation.

Higher Material Yield

Camera scanning with auto thickness measurement and layout optimization maximizes slab usage.

±0.05mm Precision Cutting

High-precision spindle combined with DDX system optimizes cutting paths for accuracy.

Inqury for Details →

Reduced Labor Costs

Vacuum suction auto material handling system minimizes manual operation requirements.

Solid & Durable

Cast beam construction with Siemens and NSK components ensures reliable durability.

Easy Installation

Integrated monoblock design allows operation after simple machine body fixing.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Stone Block Cutting Machine for Primary Processing

Rapidly transforms raw stone blocks into uniform thickness slabs for bridge saw processing. Reduces material waste by 20% while ensuring consistent dimensions for optimal CNC programming efficiency.

Streamline your stone processing workflow →

Automatic Slab Polishing Machine

Automated continuous polishing delivers mirror finishes on stone slabs, preparing smooth surfaces for bridge saw cutting operations. Increases throughput by 60% with uniform quality.

Maximize your production efficiency →

Stone Engraving Machine for Decorative Elements

Creates decorative backgrounds and stone features with 2D/3D engraving capabilities. Complements bridge saw operations for comprehensive fabrication services, 40% faster than manual methods.

Expand your decorative capabilities →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What types of stone materials can the DINOSAW 5-axis bridge saw process?

How does the 5-axis capability improve sink fabrication compared to 3-axis machines?

What is the return on investment timeline for a DINOSAW 5-axis bridge saw?

How difficult is it to learn to operate the DINOSAW 5-axis bridge saw?

What maintenance is required for the 5-axis bridge saw?

How much space and infrastructure is needed to install the DINOSAW 5-axis bridge saw?

Need more assistance? Click to contact DINOSAW →

Ready to Transform Your Stone Fabrication Capabilities?

Experience the revolutionary precision and efficiency of DINOSAW's 5-axis CNC bridge saw technology for perfect stone sinks and countertops every time.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Stone Fabrication Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

5-Axis CNC Bridge Saw

WZQJ-5N

DINOSAW 5-Axis CNC Bridge Saw achieves ±0.05mm precision cutting with DDX control system. Features straight, angled, curved, and 3D cutting capabilities, plus drilling and edge polishing. Direct CAD file import supports DXF, DWG formats. Processes granite, marble, quartz, porcelain, terrazzo, and sintered stone for vanity tops, basins, sculptures, countertops, and sinks. Integrated camera system reduces material waste by 30% through optimized nesting.

Transfoform Any Stone Into Premium Products

Granite ❯ Kitchen Sinks

Marble ❯ Bathroom Vanities

Quartz ❯ Countertops

Natural Stone ❯ Curved Furniture Elements

Natural Stone ❯ 3D Sculptures

▶ Product Demo

|

Granite's exceptional hardness and durability make it the premier choice for kitchen sinks that withstand heavy use while maintaining their beauty. |

The DINOSAW 5-axis bridge saw's powerful 18.5kW spindle precisely cuts through dense granite while maintaining ±0.05mm accuracy. Using its synchronized 5-axis movement, the machine creates perfectly rounded corners and seamless drain integrations, while the vacuum suction system securely holds the material during intricate cuts. The automatic tool compensation ensures consistent edge quality, eliminating the extensive manual finishing typically required for granite sink fabrication.

This advanced processing capability reduces production time by 65% compared to traditional methods while improving material utilization by up to 30%, dramatically increasing profitability for stone fabricators.

Granite ❯ Kitchen Sinks

Marble ❯ Bathroom Vanities

Quartz ❯ Countertops

Natural Stone ❯ Curved Furniture Elements

Natural Stone ❯ 3D Sculptures

▶ Product Demo

|

Granite's exceptional hardness and durability make it the premier choice for kitchen sinks that withstand heavy use while maintaining their beauty. |

The DINOSAW 5-axis bridge saw's powerful 18.5kW spindle precisely cuts through dense granite while maintaining ±0.05mm accuracy. Using its synchronized 5-axis movement, the machine creates perfectly rounded corners and seamless drain integrations, while the vacuum suction system securely holds the material during intricate cuts. The automatic tool compensation ensures consistent edge quality, eliminating the extensive manual finishing typically required for granite sink fabrication.

This advanced processing capability reduces production time by 65% compared to traditional methods while improving material utilization by up to 30%, dramatically increasing profitability for stone fabricators.

Consult DINOSAW Material Expert →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

High-End Kitchen Fabrication

400% ROI Through Precision & Efficiency

A premium Italian stone fabrication company struggled with complex sink integration, facing 35% material waste and lengthy production cycles. After implementing the DINOSAW 5-axis bridge saw, they achieved ±0.05mm cutting precision for complex curved sinks while reducing material waste to just 5% and decreasing production time from 4 hours to 45 minutes per unit.

Discover how to transform your kitchen fabrication business →

Luxury Bathroom Renovation

Transforming Marble Into Art

An American bathroom renovation specialist was limited by conventional equipment when creating custom marble vanities with integrated sinks, unable to achieve curved transitions and seamless edges. The DINOSAW 5-axis bridge saw's camera system and automatic slab matching technology allowed perfect marble veining alignment across complex shapes, while precision milling created smooth surface transitions

Scale your commercial project capacity →

Commercial Countertop Production

85% Faster Delivery for Large Projects

A growing commercial countertop manufacturer was losing bids due to lengthy production timelines and high costs for multiple matching countertops with integrated sinks. Implementing the DINOSAW 5-axis bridge saw with automatic programming reduced setup time by 92% for repeat pieces, while DDX control system's nesting capability maximized material utilization for large batch production.

Scale your commercial project capacity →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | WZQJ - 5N |

|---|---|---|

Lateral X stroke | m | 3.2 |

Longitudinal Y stroke | m | 2.0 |

The Z axis saw blade vertical stroke | m | 0.45 |

Saw blade diameter | m | 0.6 |

Spindle motor capacity | kw | 18.5 |

Fixed table | m | 3.2x2.0 |

We can customize 5-axis bridge saws equipped with 800mm diameter blades, specifically designed for 3D sculpture cutting applications.

Contact DINOSAW technical team for details →

5-axis precision engineering for perfect results.

Precision. Innovation. Perfect Stone Cutting

Simple CNC Operation

Built-in graphics library supports CAD import and direct drawing for easy operation.

Higher Material Yield

Camera scanning with auto thickness measurement and layout optimization maximizes slab usage.

±0.05mm Precision Cutting

High-precision spindle combined with DDX system optimizes cutting paths for accuracy.

Inqury for Details →

Simple CNC Operation

Built-in graphics library supports CAD import and direct drawing for easy operation.

Higher Material Yield

Camera scanning with auto thickness measurement and layout optimization maximizes slab usage.

±0.05mm Precision Cutting

High-precision spindle combined with DDX system optimizes cutting paths for accuracy.

Inqury for Details →

Reduced Labor Costs

Vacuum suction auto material handling system minimizes manual operation requirements.

Solid & Durable

Cast beam construction with Siemens and NSK components ensures reliable durability.

Easy Installation

Integrated monoblock design allows operation after simple machine body fixing.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Stone Block Cutting Machine for Primary Processing

Rapidly transforms raw stone blocks into uniform thickness slabs for bridge saw processing. Reduces material waste by 20% while ensuring consistent dimensions for optimal CNC programming efficiency.

Streamline your stone processing workflow →

Automatic Slab Polishing Machine

Automated continuous polishing delivers mirror finishes on stone slabs, preparing smooth surfaces for bridge saw cutting operations. Increases throughput by 60% with uniform quality.

Maximize your production efficiency →

Stone Engraving Machine for Decorative Elements

Creates decorative backgrounds and stone features with 2D/3D engraving capabilities. Complements bridge saw operations for comprehensive fabrication services, 40% faster than manual methods.

Expand your decorative capabilities →

Multi-Wire Saw Machine for Premium Stone Processing

Precision diamond wire cutting for precious marble, jade, and exotic stones into ultra-thin slabs. Minimizes material loss, maximizing yield from valuable stone blocks.

Transform precious stones into luxury surfaces →

Get a Custom Solution →

Faqs

Common Questions About 5-Axis CNC Bridge Saw for Stone Sink Fabrication

What types of stone materials can the DINOSAW 5-axis bridge saw process?

What types of stone materials can the DINOSAW 5-axis bridge saw process?

How does the 5-axis capability improve sink fabrication compared to 3-axis machines?

How does the 5-axis capability improve sink fabrication compared to 3-axis machines?

What is the return on investment timeline for a DINOSAW 5-axis bridge saw?

What is the return on investment timeline for a DINOSAW 5-axis bridge saw?

How difficult is it to learn to operate the DINOSAW 5-axis bridge saw?

How difficult is it to learn to operate the DINOSAW 5-axis bridge saw?

What Is CNC (Computer Numerical Control)? - User Guide

What maintenance is required for the 5-axis bridge saw?

What Is CNC (Computer Numerical Control)? - User Guide

How much space and infrastructure is needed to install the DINOSAW 5-axis bridge saw?

What Is CNC (Computer Numerical Control)? - User Guide

Is the control software compatible with existing digital measurement systems?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to Transform Your Stone Fabrication Capabilities?

Stone Fabrication Insights

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Stone Fabrication Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: