Why Should You Consider Chinese CNC Machines in 2025?

In today's competitive manufacturing landscape, Chinese CNC machines have emerged as powerful contenders, challenging European and American manufacturers. The global CNC market has seen significant growth, with Chinese manufacturers capturing an increasingly substantial market share over the past decade.

For businesses in metalworking, stone processing, woodworking, and manufacturing, Chinese CNC machines offer advanced technology at significantly lower prices. Many are asking: But how do they compare in quality? Are they reliable for professional use?

This analysis explores recent developments in Chinese CNC manufacturing, examining quality standards, price-performance ratios, and providing practical buying guidance for your business needs.

How Do Chinese CNC Machines Meet Quality Standards in 2025?

Continuous Innovation in Chinese Manufacturing

The perception of Chinese manufacturing has evolved dramatically. China has made substantial investments in industrial automation in recent years, transforming its capabilities from basic production to advanced precision engineering.

For CNC machines specifically, Chinese manufacturers have made remarkable strides in several key areas, including specialized equipment like CNC wire saw machines and other precision tools:

🔍 Precision Engineering | 🌟 Quality Control Systems |

|---|---|

Modern Chinese CNC machines now achieve much improved tolerances, becoming increasingly comparable to high-end Western machines. The precision capabilities have shown remarkable improvement over the past decade. | Leading Chinese manufacturers now implement rigorous quality management systems, with many achieving ISO 9001, CE, and other international certifications. Multi-stage testing has become standard practice. |

Quality Stratification in the Chinese Market

The Chinese CNC machine market is highly stratified, with significant quality variations across price points. Industry experts typically divide the market into three distinct tiers:

Market Tier | Quality Level | Price Range (vs. Western) | Characteristics | |||

|---|---|---|---|---|---|---|

High-end | Comparable to premium Western brands | 60-75% | Premium components, advanced control systems, comprehensive warranty, excellent after-sales support | |||

Mid-range | Good quality, suitable for most applications | 40-60% | Quality components, reliable performance, standard warranty, decent after-sales support | |||

Entry-level | Variable quality, requires careful selection | 25-40% | Basic components, functional performance, limited warranty, variable after-sales support | |||

The current market shows a significant shift toward mid-range and high-end machines as Chinese manufacturers upgrade their capabilities, particularly with specialized products like multi wire saw machines. Industry analysts note that the gap between top-tier Chinese CNC machines and Western counterparts has narrowed significantly, while price advantages remain substantial.

What Is the Price-Performance Ratio of Chinese CNC Machines?

The primary appeal of Chinese CNC machines lies in their competitive pricing combined with increasingly robust performance. Market analysis shows that Chinese machines typically offer savings of 30-50% compared to Western alternatives with similar specifications.This cost advantage is especially significant for small to medium enterprises investing in equipment like granite saw machines and can accelerate return on investment substantially. Manufacturers gain both immediate capital savings and long-term competitive advantages through reduced production costs.

True Cost of Ownership Factors

However, purchase price is just one component of the total cost of ownership. For a comprehensive evaluation, consider these additional factors:

⚙️Maintenance Costs | Chinese machines might require more frequent maintenance, but parts are less expensive. Typical maintenance costs average 5-10% of machine purchase price annually, compared to 3-5% for premium Western machines. | ||

|---|---|---|---|

⏰Downtime Risk | Potential downtime risk is higher for lower-tier Chinese machines but comparable for mid-to-high-end models. Recent reliability data shows just 5-10% more downtime for equivalent Chinese machines versus premium Western brands. | ||

💼After-Sales Support | This remains an area where top Western brands still hold an advantage. However, leading Chinese manufacturers like Dinosaw now offer comprehensive warranty programs for their CNC wire saw products and have expanded their global service networks, with significantly improved response times. | ||

Key Takeaway on Value

For most manufacturing operations, particularly those with tight capital constraints, Chinese CNC machines in the mid-to-high range offer the most favorable value proposition in 2025. The initial savings combined with acceptable maintenance costs result in a compelling total cost of ownership for most applications.

How Do Chinese CNC Machines Perform in Real Manufacturing Environments?

Beyond specifications and pricing, the true test of any CNC machine is its performance in real-world manufacturing environments. Here's how Chinese CNC machines are performing across different industries.

Case Study 1: Stone Processing Industry

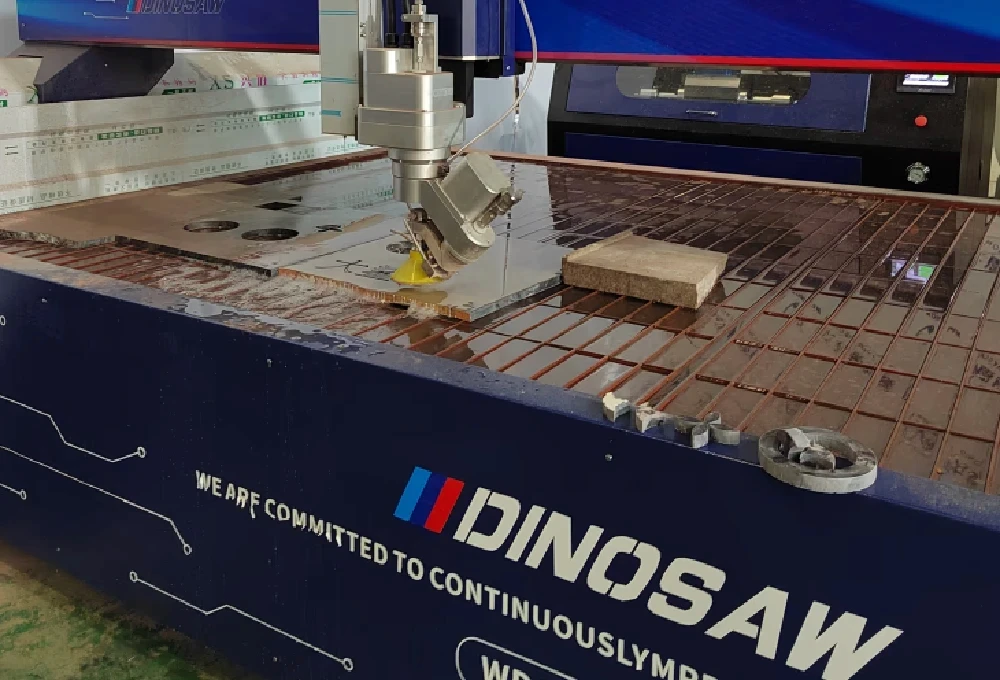

A mid-sized stone processing company in Barcelona switched from Italian stone cutting equipment to Dinosaw's 5 axis bridge saw in 2023.

According to their Production Manager: "The performance-to-price ratio exceeded our expectations. After initial skepticism, we've found the Dinosaw machine fully capable of meeting our quality standards while significantly reducing our capital investment."

Case Study 2: Custom Metal Fabrication

This Chicago-based metal fabrication shop incorporated two Chinese CNC milling centers alongside their existing American machines to handle increased production demand.

Operations Director: "While our American machines still hold a slight edge in precision and reliability, the Chinese mills deliver 95% of the performance at less than half the cost. For most of our production needs, they've proven more cost-effective."

Case Study 3: Wood Furniture Manufacturing

This high-end furniture manufacturer invested in a Chinese 5-axis CNC router for curved component production, replacing manual methods.

According to the CEO: "The capabilities of our Chinese CNC router have transformed our production capacity while maintaining our quality standards. The machine paid for itself within 10 months through increased efficiency and reduced labor costs."

Performance Patterns Across Industries

Analyzing data from manufacturing companies that integrated Chinese CNC machines between 2023-2025, including various types like marble CNC router and bridge saw systems, industry experts have identified these consistent patterns:

Performance Comparison: Chinese vs Western CNC Machines (2025)

Performance Category | Chinese CNC(High-End) | Chinese CNC(Mid-Range) | Western CNC |

|---|---|---|---|

Initial Cost | ★★★★★ | ★★★★★ | ★★ |

Precision | ★★★★ | ★★★ | ★★★★★ |

Reliability | ★★★★ | ★★★ | ★★★★★ |

Software/Interface | ★★★★ | ★★★ | ★★★★★ |

After-Sales Support | ★★★ | ★★ | ★★★★★ |

ROI/Value | ★★★★★ | ★★★★ | ★★★ |

These real-world case studies demonstrate that while Chinese CNC machines may not match premium Western brands in every category, the gap has narrowed significantly. For many businesses, especially those prioritizing cost-efficiency without sacrificing essential quality, Chinese machines represent a viable alternative.

How Do You Choose the Right Chinese CNC Machine for Your Business?

With thousands of Chinese CNC machine manufacturers in the market, choosing the right equipment requires careful evaluation. This systematic approach will help you make an informed decision:

Step 1: Identify Reputable Manufacturers

Focus on established manufacturers with proven track records. According to Global Manufacturing Directory, top-tier Chinese CNC manufacturers typically share these characteristics:

🏭 Manufacturing Experience | 🏆 Certifications & Standards |

|---|---|

Look for companies with at least 8-10 years of manufacturing history and international market presence. Companies like Dinosaw have been producing CNC machines export to over 50 countries. | Prioritize manufacturers with ISO 9001 quality management certification, CE marking for European compliance, and industry-specific certifications that indicate adherence to international standards. |

Step 2: Evaluate Machine Specifications Against Your Needs

Create a detailed requirements specification based on your production needs. Industry specialists recommend focusing on these critical parameters:

Parameter Category | What to Evaluate | Considerations for Chinese Machines | ||

|---|---|---|---|---|

Physical Dimensions | Work envelope, table size, machine footprint, weight capacity | Chinese machines often offer larger work envelopes at comparable price points, but verify measurement accuracy | ||

Performance Specs | Spindle speed, axis travel speeds, positioning accuracy, repeatability | Request actual test data rather than relying only on marketing specifications | ||

Control System | CNC controller type, software compatibility, interface language | Many Chinese machines now offer international controllers (Siemens, Fanuc) with English interfaces | ||

Step 3: Assess After-Sales Support

After-sales support remains one of the most critical factors. Based on industry experience, look for these support elements:

Warranty Coverage: Minimum 12-month warranty, with options for extension

Spare Parts Availability: Confirm that critical spare parts are stocked locally or can be shipped quickly

Technical Support Channels: Verify availability of support via phone, email, and preferably remote diagnostics

Response Times: Established SLAs for different support tiers (24/48/72 hours)

Step 4: Verify Before Purchasing

Before finalizing your purchase, take these verification steps to minimize risk:

Request Video Demonstrations: Ask for live video demonstrations showing the machine performing operations similar to your requirements

Sample Production: If possible, have the manufacturer produce sample parts based on your designs

Third-party Inspection: Consider using an independent inspection service for pre-shipment verification

Secure Payment Terms: Negotiate payment terms that provide protection, such as letters of credit or escrow services

By following this systematic approach, you can confidently select a Chinese CNC machine that meets your requirements while maximizing investment value. Industry experts emphasize that "The key to success isn't just finding the lowest price, but identifying the right manufacturer partner that provides the optimal balance of quality, performance, and support for your specific needs."

What Are the Most Common Concerns About Chinese CNC Machines?

Potential buyers often have specific concerns about Chinese CNC machines. Here, we address the most common questions based on actual user experiences and industry data.

FAQs About Chinese CNC Machines

Q: How does the precision of Chinese CNC machines compare to Western brands?

A: High-quality Chinese CNC machines now achieve precision levels increasingly comparable to Western brands. Industry testing shows that top-tier Chinese machines achieve tolerances within 0.01-0.02mm, while premium Western machines achieve 0.003-0.01mm. For most industrial applications, this difference is negligible.

Q: Are Chinese CNC machines reliable enough for 24/7 production?

A: Mid-to-high-end Chinese CNC machines are increasingly capable of sustained 24/7 operation. Manufacturing data shows mean time between failures (MTBF) for quality Chinese machines averaging 2,000-3,000 hours compared to 3,500-5,000 hours for premium Western equivalents. Proper maintenance remains essential.

Q: What about spare parts availability and service support?

A: This has historically been a weakness but has improved substantially since 2020. Leading companies like Dinosaw now maintain international service networks with regional parts depots in major markets. However, service coverage varies significantly between manufacturers, so verify specific support capabilities in your region before purchasing.

Q: Do Chinese CNC controllers have English interfaces?

A: Yes, most export-oriented Chinese CNC machines now feature fully translated English interfaces as standard. Many manufacturers increasingly incorporate international controllers from Siemens, Fanuc, or Mitsubishi, providing standardized interfaces familiar to operators worldwide.

Q: Are there intellectual property concerns when sharing designs with Chinese manufacturers?

A: While IP protection has improved in China, prudent measures are still recommended. Established manufacturers with international reputations typically respect confidentiality agreements. Legal experts recommend using specific NDAs and limiting shared information to what's necessary for machine verification.

Q: Which industries are most successfully using Chinese CNC machines?

A: Chinese CNC machines have achieved particularly strong adoption in these sectors:

Stone processing (marble, granite fabrication)

Furniture manufacturing

General metal fabrication

Sign making and engraving

Educational institutions

Small to medium job shops

Industries with extremely high precision requirements (aerospace, medical devices) still tend to favor Western or Japanese equipment, though this gap continues to narrow, even for specialized equipment like multi wire saw and stone lathe machines.

Conclusion: Are Chinese CNC Machines Worth Buying?

Chinese CNC machines have evolved dramatically over the past decade, transforming from basic, low-cost alternatives to sophisticated manufacturing equipment that can effectively compete with traditional Western and Japanese brands in most applications.

💰Value Proposition | 📈Quality Trajectory |

|---|---|

Chinese CNC machines offer 30-60% cost savings compared to Western equivalents while delivering 80-95% of the performance for most applications. This value proposition is particularly compelling for small to medium enterprises with tight capital constraints. | The quality and technological capabilities of Chinese CNC machines continue to improve rapidly. The gap between top Chinese brands and premium Western manufacturers narrows with each generation, particularly in the mid-to-high-end market segments. |

Final Assessment

For most manufacturing applications, well-selected Chinese CNC machines offer excellent value. The decision ultimately depends on your specific requirements, budget constraints, and risk tolerance.

Ready to Explore Further?

Dinosaw offers comprehensive resources to help you evaluate our range of CNC machines for stone processing and other applications:

Detailed guide to stone CNC routers for granite and marble

Best Stone CNC Machine: Types and Buying Guide for 2025

Comprehensive guide to choosing stone cutting machines for factories

For personalized assistance in selecting the right CNC machine for your specific needs, our technical experts are available for consultation:Request Expert Consultation

Industry experts have concluded, "The decision to purchase Chinese CNC equipment is no longer primarily about cost savings—it's increasingly about finding the right technological fit at a competitive price point, with leading Chinese manufacturers now firmly established as mainstream options."