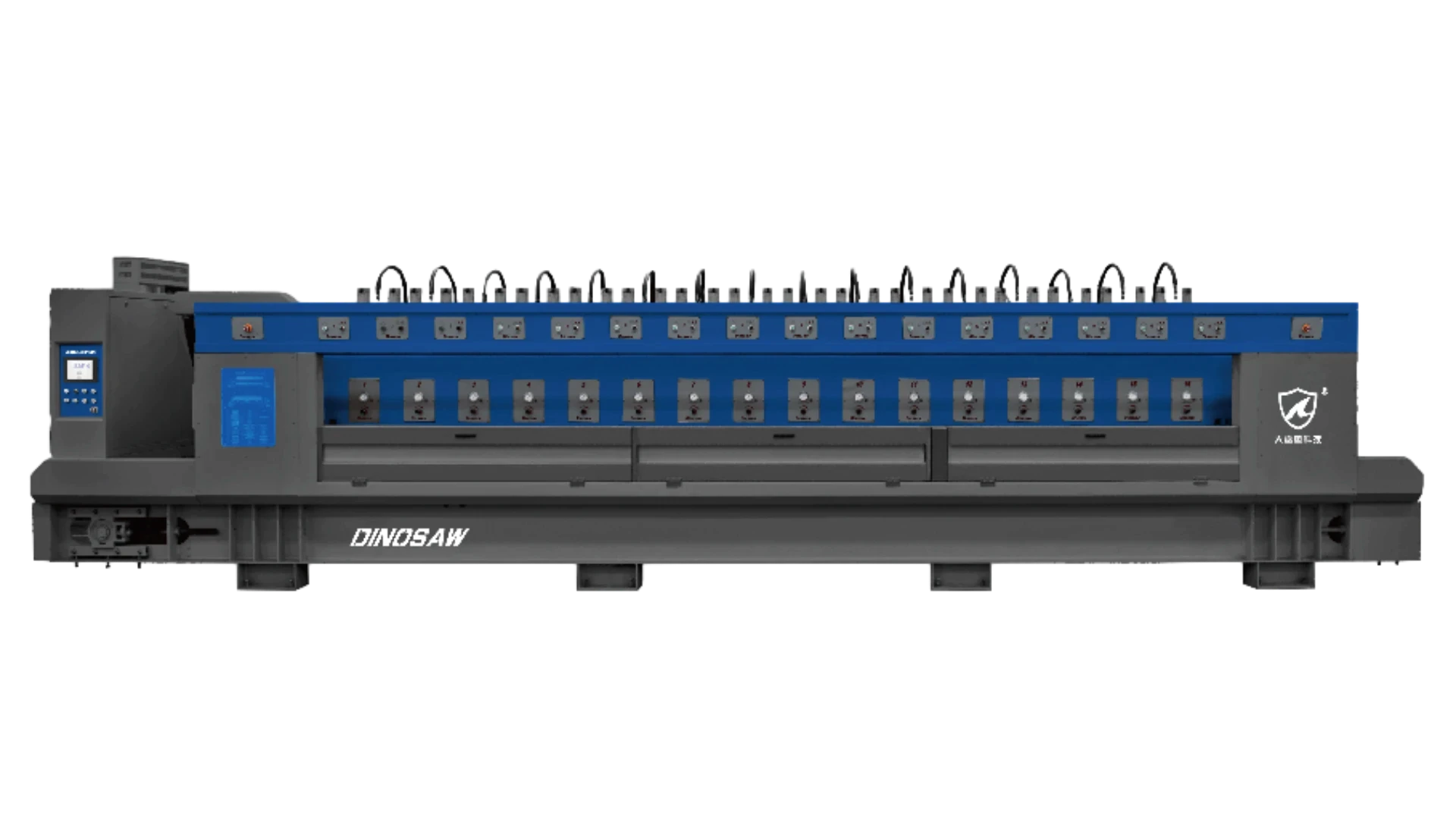

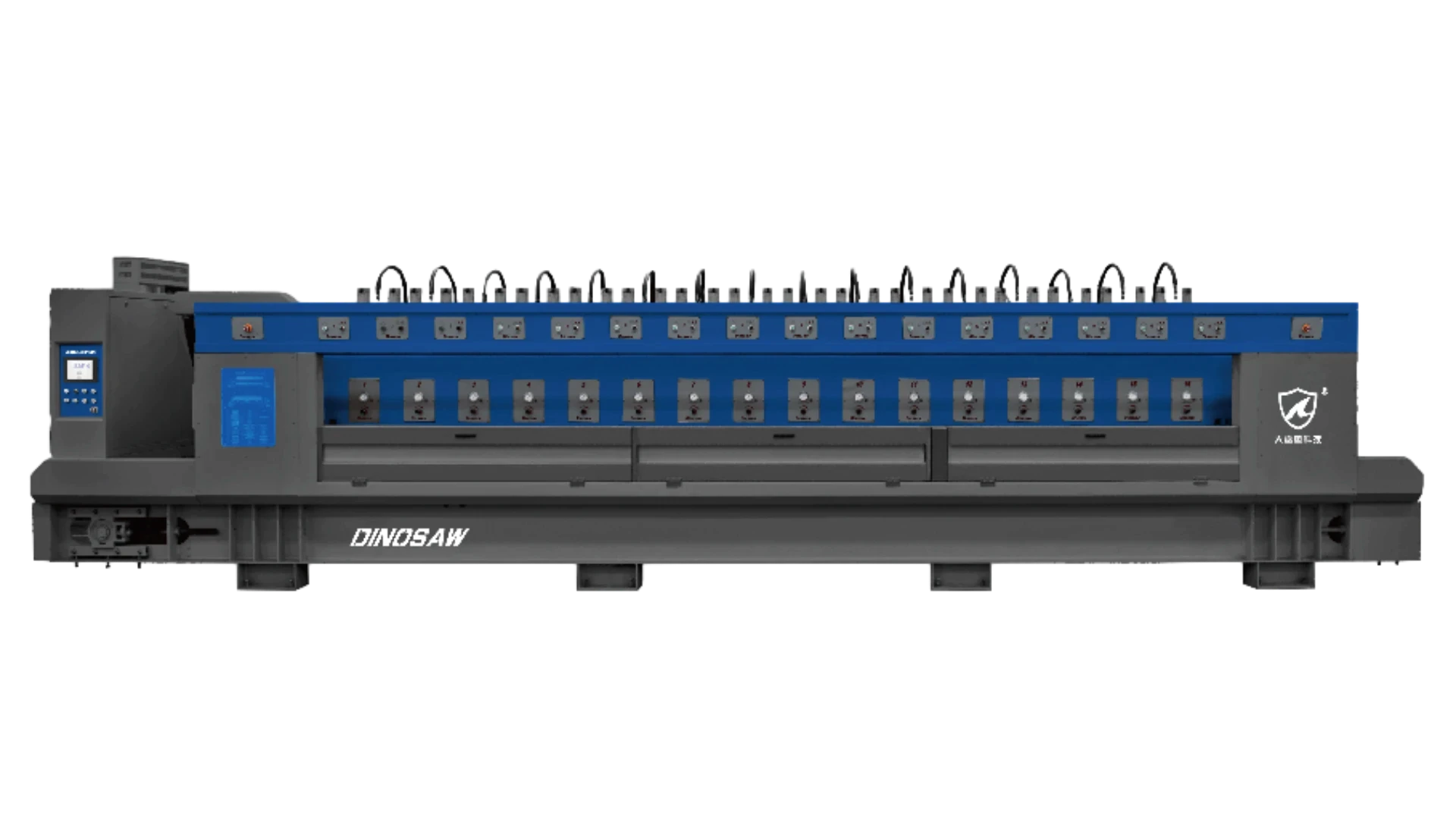

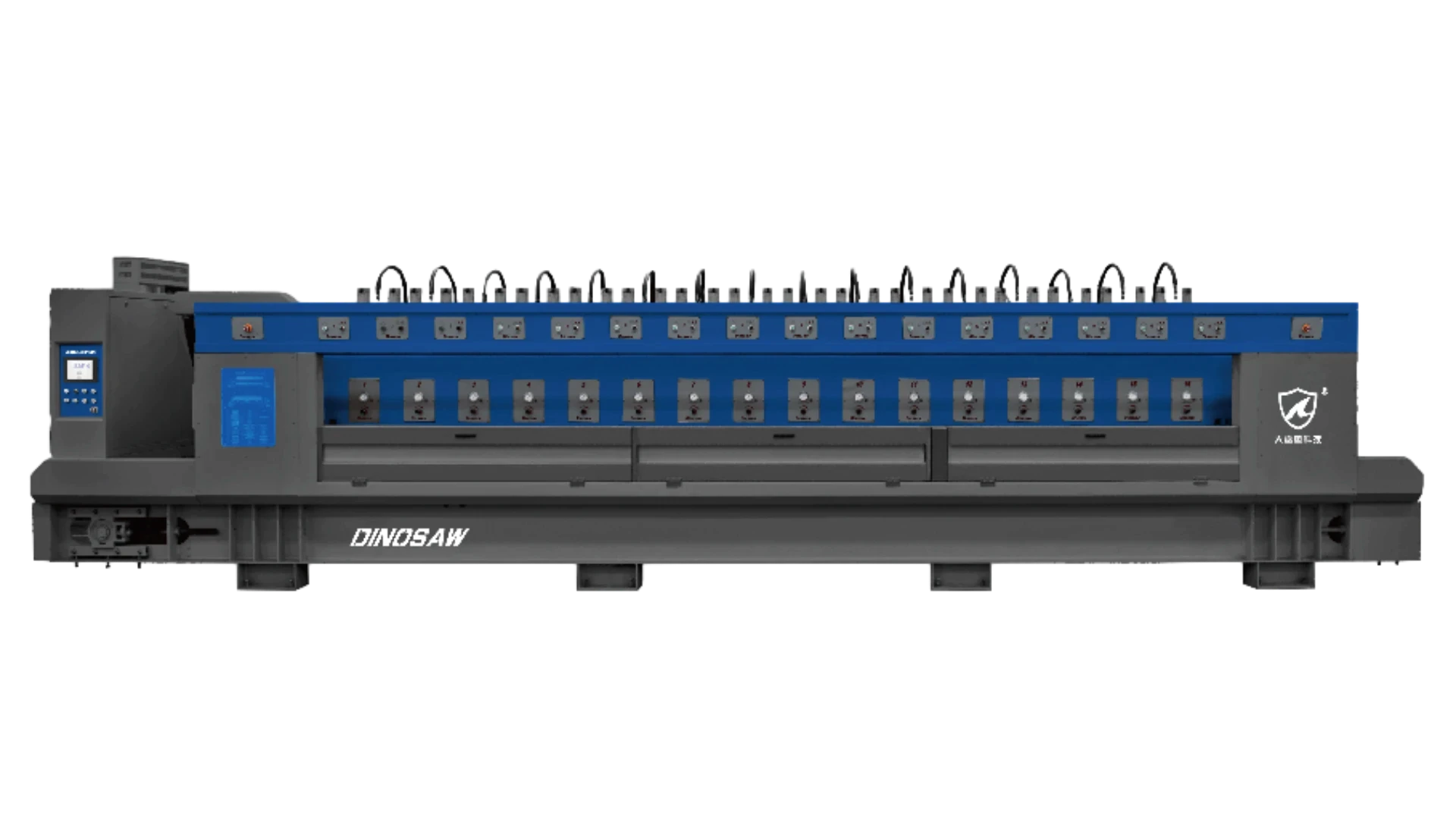

Stone Block Cutting Wire Saw Machine

XBSJ-3000/3500/4000

DINOSAW Stone Block Cutting Wire Saw Machine delivers 1-2mm precision cutting for blocks up to 4000mm, surpassing traditional blade saws. It enables vertical squaring, slab cutting, and horizontal splitting while preserving material integrity, as all cut parts remain usable. Effectively processes granite, marble, limestone, bluestone, graphite, concrete, and metal. Features wire breaking protection and AI-optimized cutting speed for maximum efficiency and safety.

Versatile Stone Cutting: Materials & Products

DINOSAW block squaring diamond wire saw machine precisely and efficiently processes various materials, producing perfectly squared blocks ready for further processing.

Granite ❯ Precision Block Squaring

Marble ❯ Clean-Edge Slabs

Concrete ❯ Large Pipe Batch Cutting

Graphite ❯ Large Block Division

Quartz Glass ❯ Precision Optical Components

▶ Product Demo

|

Granite Block cutting with DINOSAW squaring wire saw machine |

|

Granite splitting with DINOSAW stone block wire saw cutting machine |

|

DINOSAW diamond wire saw machine cutting granite block |

Quarries and fabricators need precise squaring for monuments and architectural applications. Our diamond wire saw achieves perfect 90° angles, minimizing material waste.

The hydraulic tension control system automatically adjusts wire tension when cutting dense granite, maintaining consistent cutting speed and preventing wire deviation. Surface roughness below Ra 3.2 allows direct processing with minimal finish work.

Stone fabricators save 30% in block processing time compared to traditional cutting methods, significantly reducing diamond wire consumption.

Granite ❯ Precision Block Squaring

Marble ❯ Clean-Edge Slabs

Concrete ❯ Large Pipe Batch Cutting

Graphite ❯ Large Block Division

Quartz Glass ❯ Precision Optical Components

▶ Product Demo

|

Granite Block cutting with DINOSAW squaring wire saw machine |

|

Granite splitting with DINOSAW stone block wire saw cutting machine |

|

DINOSAW diamond wire saw machine cutting granite block |

Quarries and fabricators need precise squaring for monuments and architectural applications. Our diamond wire saw achieves perfect 90° angles, minimizing material waste.

The hydraulic tension control system automatically adjusts wire tension when cutting dense granite, maintaining consistent cutting speed and preventing wire deviation. Surface roughness below Ra 3.2 allows direct processing with minimal finish work.

Stone fabricators save 30% in block processing time compared to traditional cutting methods, significantly reducing diamond wire consumption.

Consult DINOSAW Material Expert →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Enhance your fabrication workflow →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Enhance your fabrication workflow →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Enhance your fabrication workflow →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Enhance your fabrication workflow →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Specs and options

Specifications customizable upon request.

Model | Unit | XBSJ-3000-25H | XBSJ-3500-25H | XBSJ-4000-25H | XBSJ-5000-25H |

|---|---|---|---|---|---|

Max working dimensions | m | 3.0x3.0x2.0 | 3.5x3.5x2.0 | 4.0x4.x2.3 | 5x3.3x2.3 |

Wire diameter | mm | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 |

Worktable size | mm | 2.0x2.0 | 2.0x2.0 | 2.0x2.0 | / |

Table rotating degree(Option) | n° | 360° | 360° | 360° | / |

Main motor power | kw | 15 | 15 | 15 | 15 |

Water consumption | m³/h | 5 | 6 | 6 | 6 |

Overall dimensions | m | 7.7x8.2x5.1 | 7.7x8.7x5.1 | 7.7x9.2x5.4 | 7.7x9.2x5.4 |

Approximate weight | t | 10.8 | 11.5 | 12 | 16.5 |

*Can be customized as per requirement

Contact DINOSAW technical team for details →

Diamond innovation meets engineering excellence.

Cut Large. Cut Precise. Cut Any Material.

Extra-Large Size Cutting

Four-pulley structure enables cutting up to 5×2.4m dimensions.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 2㎡/h cutting speed for marble.

Automatic Continuous Processing

PLC-controlled automatic slab segmentation enables continuous batch cutting of materials.

Inqury for Details →

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Remote Operation

OTA technology for remote updates and maintenance support.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches.

Reduced Maintenance

Dust/water-resistant design with automatic lubrication system.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Quarry Wire Saw Machine

Combine with DINOSAW quarry wire saw for complete stone extraction and processing. Extract raw blocks directly from quarry faces, then square them for maximum value.

Link: Explore Efficient Quarry Solutions →

Automatic Stone Grinding Machine

Pair with DINOSAW automatic grinding equipment for complete stone processing. Create finished architectural elements from raw blocks with seamless transition from cutting to surface finishing.

Link: Discover Automated Surface Processing →

Stone Engraving Machine

Complete your workflow with DINOSAW CNC engraving technology. Add custom designs, text, and patterns after squaring and cutting for versatile decorative options in architectural applications.

Link: Enhance Stone Product Value →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What is the maximum cutting size of the block squaring machine?

Can this wire saw machine cut curved or custom shapes?

Is the diamond wire easy to break during operation?

How difficult is it to operate the block squaring wire saw machine?

What is the load capacity of the trolley system?

Does the machine have remote diagnostics capabilities?

Can the machine cut materials other than stone?

Need more assistance? Click to contact DINOSAW →

Transform Your Stone Processing Capabilities Today

Join industry leaders worldwide who rely on DINOSAW block squaring technology to maximize precision, efficiency, and profitability. Our diamond wire saw solutions are engineered to deliver exceptional results across all materials with unmatched reliability.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Deepen Your Knowledge: Stone Cutting & Processing Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

Stone Block Cutting Wire Saw Machine

XBSJ-3000/3500/4000

DINOSAW Stone Block Cutting Wire Saw Machine delivers 1-2mm precision cutting for blocks up to 4000mm, surpassing traditional blade saws. It enables vertical squaring, slab cutting, and horizontal splitting while preserving material integrity, as all cut parts remain usable. Effectively processes granite, marble, limestone, bluestone, graphite, concrete, and metal. Features wire breaking protection and AI-optimized cutting speed for maximum efficiency and safety.

Versatile Stone Cutting: Materials & Products

DINOSAW block squaring diamond wire saw machine precisely and efficiently processes various materials, producing perfectly squared blocks ready for further processing.

Granite ❯ Precision Block Squaring

Marble ❯ Clean-Edge Slabs

Concrete ❯ Large Pipe Batch Cutting

Graphite ❯ Large Block Division

Quartz Glass ❯ Precision Optical Components

▶ Product Demo

|

Granite Block cutting with DINOSAW squaring wire saw machine |

|

Granite splitting with DINOSAW stone block wire saw cutting machine |

|

DINOSAW diamond wire saw machine cutting granite block |

Quarries and fabricators need precise squaring for monuments and architectural applications. Our diamond wire saw achieves perfect 90° angles, minimizing material waste.

The hydraulic tension control system automatically adjusts wire tension when cutting dense granite, maintaining consistent cutting speed and preventing wire deviation. Surface roughness below Ra 3.2 allows direct processing with minimal finish work.

Stone fabricators save 30% in block processing time compared to traditional cutting methods, significantly reducing diamond wire consumption.

Granite ❯ Precision Block Squaring

Marble ❯ Clean-Edge Slabs

Concrete ❯ Large Pipe Batch Cutting

Graphite ❯ Large Block Division

Quartz Glass ❯ Precision Optical Components

▶ Product Demo

|

Granite Block cutting with DINOSAW squaring wire saw machine |

|

Granite splitting with DINOSAW stone block wire saw cutting machine |

|

DINOSAW diamond wire saw machine cutting granite block |

Quarries and fabricators need precise squaring for monuments and architectural applications. Our diamond wire saw achieves perfect 90° angles, minimizing material waste.

The hydraulic tension control system automatically adjusts wire tension when cutting dense granite, maintaining consistent cutting speed and preventing wire deviation. Surface roughness below Ra 3.2 allows direct processing with minimal finish work.

Stone fabricators save 30% in block processing time compared to traditional cutting methods, significantly reducing diamond wire consumption.

Consult DINOSAW Material Expert →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Stone Fabrication Facilities

Maximizing Quarried Block Value Through Precise Squaring

DINOSAW wire saw processes quarried stone blocks up to 5×2.4m - significantly larger than traditional blade systems.

This outstanding capacity combined with ±1mm precision increases block value by up to 40% as properly squared blocks command higher market prices.

The hydraulic tensioning system maintains consistent cutting even with varying stone properties, reducing processing time by 30%.

Link Button: Optimize your quarry block production →

Specialty Materials Processing

Streamlining Production with Automated Block Splitting

Stone fabricators need efficiency to stay competitive. DINOSAW's wire saw features PLC-controlled automatic slab cutting system that eliminates manual positioning and alignment.

Continuous batch processing capabilities allow operators to set parameters once and process multiple pieces without intervention, achieving 1.5-2.0㎡/hour cutting speed while maintaining consistent quality.

Built-in 4G connectivity enables remote diagnostics, resolving most issues without waiting for on-site service and minimizing production downtime.

Link Button: Explore technical materials processing →

Industrial Metal Recycling

Precision Cutting for High-Value Technical Materials

Industries processing specialty materials such as graphite blocks, natural stone varieties, and quartz glass need high precision cutting.

DINOSAW offers customized configurations including dust collection systems and dry-cutting options specifically designed for each material type and application requirements.

Adjustable parameters optimize settings for each material, while the enclosed cutting area prevents contamination. These specialized configurations ensure material integrity and exceptional dimensional accuracy required for aerospace, electronics, and nuclear applications.

Link Button: Explore technical materials processing →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | XBSJ-3000-25H | XBSJ-3500-25H | XBSJ-4000-25H | XBSJ-5000-25H |

|---|---|---|---|---|---|

Max working dimensions | m | 3.0x3.0x2.0 | 3.5x3.5x2.0 | 4.0x4.x2.3 | 5x3.3x2.3 |

Wire diameter | mm | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 | 7.6 - 11.5 |

Worktable size | mm | 2.0x2.0 | 2.0x2.0 | 2.0x2.0 | / |

Table rotating degree(Option) | n° | 360° | 360° | 360° | / |

Main motor power | kw | 15 | 15 | 15 | 15 |

Water consumption | m³/h | 5 | 6 | 6 | 6 |

Overall dimensions | m | 7.7x8.2x5.1 | 7.7x8.7x5.1 | 7.7x9.2x5.4 | 7.7x9.2x5.4 |

Approximate weight | t | 10.8 | 11.5 | 12 | 16.5 |

*Can be customized as per requirement

Contact DINOSAW technical team for details →

Diamond innovation meets engineering excellence.

Cut Large. Cut Precise. Cut Any Material.

Extra-Large Size Cutting

Four-pulley structure enables cutting up to 5×2.4m dimensions.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 2㎡/h cutting speed for marble.

Automatic Continuous Processing

PLC-controlled automatic slab segmentation enables continuous batch cutting of materials.

Inqury for Details →

Extra-Large Size Cutting

Four-pulley structure enables cutting up to 5×2.4m dimensions.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 2㎡/h cutting speed for marble.

Automatic Continuous Processing

PLC-controlled automatic slab segmentation enables continuous batch cutting of materials.

Inqury for Details →

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

Remote Operation

OTA technology for remote updates and maintenance support.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches.

Reduced Maintenance

Dust/water-resistant design with automatic lubrication system.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Quarry Wire Saw Machine

Combine with DINOSAW quarry wire saw for complete stone extraction and processing. Extract raw blocks directly from quarry faces, then square them for maximum value.

Link: Explore Efficient Quarry Solutions →

Automatic Stone Grinding Machine

Pair with DINOSAW automatic grinding equipment for complete stone processing. Create finished architectural elements from raw blocks with seamless transition from cutting to surface finishing.

Link: Discover Automated Surface Processing →

Stone Engraving Machine

Complete your workflow with DINOSAW CNC engraving technology. Add custom designs, text, and patterns after squaring and cutting for versatile decorative options in architectural applications.

Link: Enhance Stone Product Value →

Get a Custom Solution →

Faqs

Answered: DINOSAW Block Squaring Diamond Wire Saw Machine

What is the maximum cutting size of the block squaring machine?

What is the maximum cutting size of the block squaring machine?

Can this wire saw machine cut curved or custom shapes?

Can this wire saw machine cut curved or custom shapes?

Is the diamond wire easy to break during operation?

Is the diamond wire easy to break during operation?

How difficult is it to operate the block squaring wire saw machine?

How difficult is it to operate the block squaring wire saw machine?

What Is CNC (Computer Numerical Control)? - User Guide

What is the load capacity of the trolley system?

What Is CNC (Computer Numerical Control)? - User Guide

Does the machine have remote diagnostics capabilities?

What Is CNC (Computer Numerical Control)? - User Guide

What warranty is provided with the machine?

What Is CNC (Computer Numerical Control)? - User Guide

Can the machine cut materials other than stone?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Transform Your Stone Processing Capabilities Today

Deepen Your Knowledge: Stone Cutting & Processing Insights

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Deepen Your Knowledge: Stone Cutting & Processing Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: