Introduction: Choosing the Right Rock Cutting Saw

Selecting the best rock cutting saw directly impacts productivity and costs in mining and factory operations. Whether you’re cutting granite in quarries or shaping marble slabs in factories, the wrong equipment can lead to wasted materials, downtime, and safety risks. This guide helps you:

Compare key features of quarry saws and industrial stone cutters

Match machines to your specific materials and workloads

Calculate long-term savings from reduced maintenance and higher efficiency

Need Immediate Help?

If you already know your requirements or want expert advice on the best rock cutting saw for your project:

Explore Our Products: Browse mining saws and factory stone cutters here

Get a Custom Quote: Contact us or chat online now for free consultation and pricing

Mining Applications: High-Efficiency Rock Cutting

Quarry Scenarios and Requirements

Mining Operations

Used for rock excavation (open-pit or underground mining), tunnel construction, and ore segmentation. Must handle high-hardness rocks (e.g., granite, basalt) and complex geological conditions.

Key Needs

High cutting strength, impact resistance, stability for continuous operation, and safety features.

Quarry Rock Cutter Types and Technical Parameters

Equipment Type | Technical Features | Applicable Scenarios |

|---|---|---|

Diamond Double-Blade Saw | With belt drive, chrome-plated guide pillars, ensures stable, safe, and high-precision cuttin.Power: 118–138kW, cutting depth 850–2150mm | Marble/granite block mining |

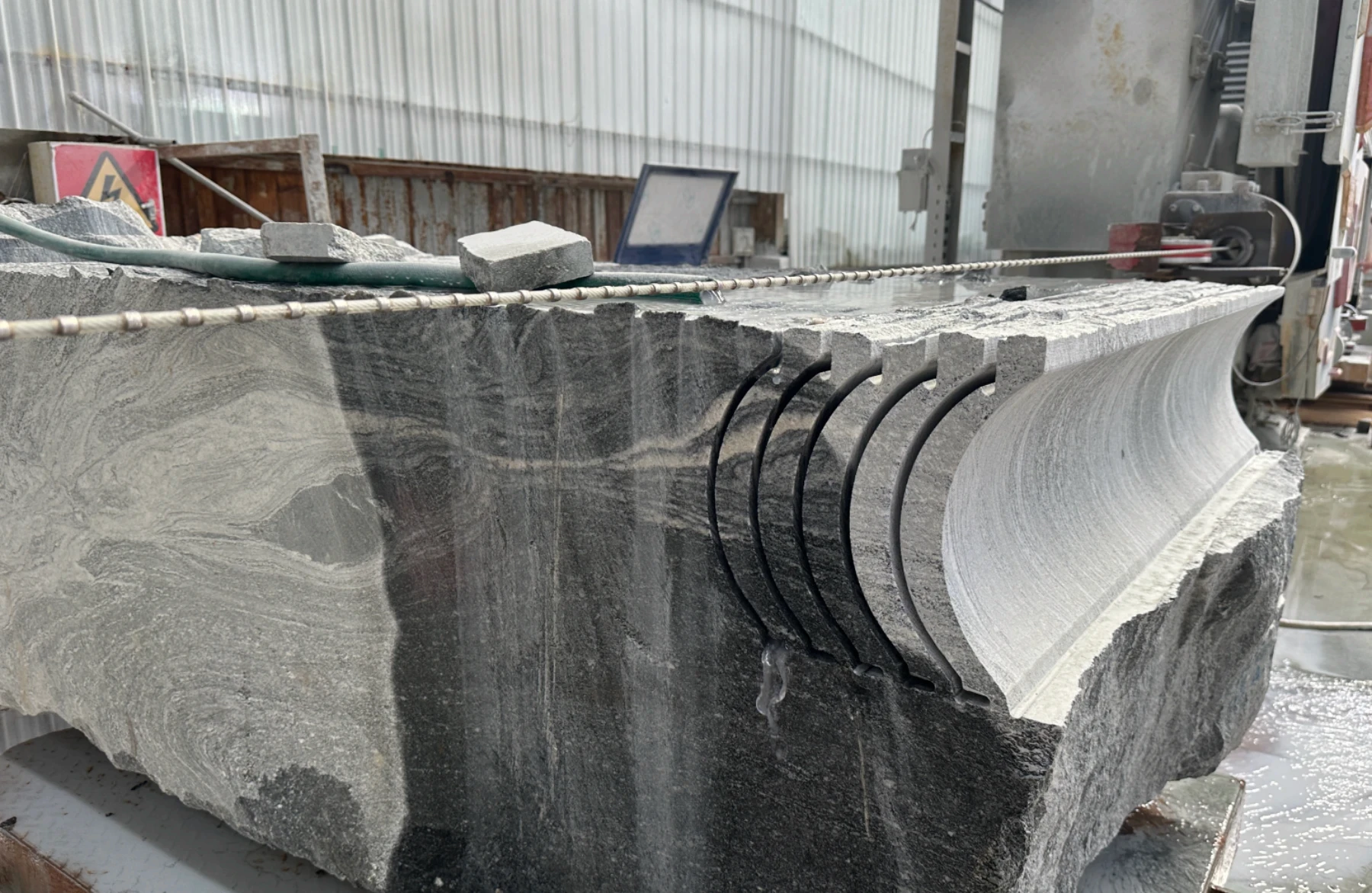

Quarrying Diamond Wire Saw | Diamond bead wire with 360° rotation, suitable for irregular rock masses.Motor power: up to 110kW | Complex terrain mining, tunnel cutting,underwater cutting |

Hydraulic Rock Saw | Compact design, compatible with excavators, remote control operation.Cutting diameter: 600mm, power: 5.5kW | Narrow spaces, auxiliary trimming |

Sandstone cutting machine | Dual-blade synchronous cutting, high precision, water-cooling system.Max. cutting depth: 520mm | Sandstone quarrying and block cutting |

Key Purchasing Criteria

Power & Torque: Match motor power to rock hardness (≥30kW recommended for granite).

Efficiency: Focus on cutting speed (33–45 m/s optimal) and feed rate.

Safety: Prioritize emergency brakes, protective covers, and auto-shutdown mechanisms.

Maintenance Costs: Opt for modular designs and easily replaceable blades (e.g., DINOSAW Mining Saw with blade life up to 2,000 hours).

Stone Factory Applications and Purchasing Considerations

Factory Scenarios and Requirements

Processing Stages: Block cutting, slab shaping, and sculpting. Requires precision (±0.1mm), low material waste, dust control, and versatility (e.g., angled or curved cuts).

Common Equipment Types and Technical Parameters

Equipment Type | Technical Features | Applicable Scenarios |

|---|---|---|

Multi-Blade Cutter | High-efficiency multi-blade cutting for mass production. Max blade diameter: 3200mm. | Standard stone slab cutting (e.g., marble, granite). |

Multi-Wire Saw | Narrow kerf width (0.5 mm), high-speed cutting at 40 m/s. | Cutting high-value stone (luxury stone) and ultra-thin slabs (thickness: 3-15mm). |

Mono-Wire Saw | CNC system for complex shapes. Cutting accuracy: ±1 mm, efficiency: 2.5 m³/h. | Landscape stone, curbs, tombstones, and irregular sculptures. |

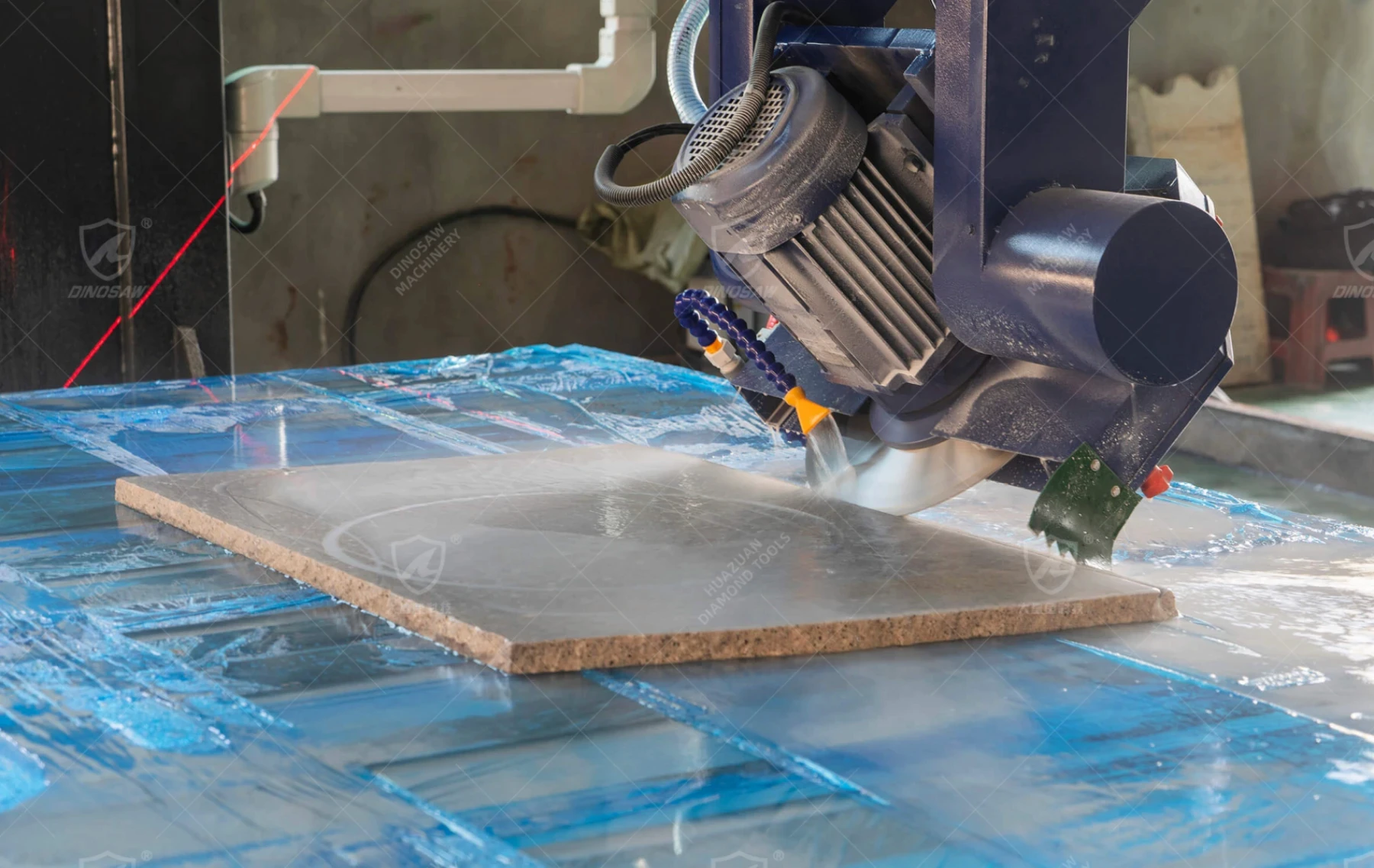

CNC Bridge Saw | Multi-axis cutting, adjustable thickness (max 700mm), rotatable worktable (3.2m × 2.0m). | Slabs, sinks, countertops, and custom architectural components. |

Waterjet Cutter | High-pressure water + abrasives, no thermal deformation. Precision: ±0.1 mm. | Intricate engravings, thin slabs (≤10mm), and artistic designs. |

Manual Cutter | Diamond blade + water cooling, 45° angle adjustment, noise <80dB. | On-site installation adjustments, small repairs, and edge polishing. |

Key Purchasing Criteria

Precision: Choose CNC models with repeat positioning accuracy ≤0.05mm.

Eco-Friendliness: Opt for water recycling systems (≥90% efficiency).

Smart Features: IoT monitoring and auto-tool changers boost productivity.

Blade Compatibility: Universal blade interfaces reduce costs (e.g., supports φ350–600mm blades).

What is the best saw for cutting rocks?

Mining Operations (High-Strength, Outdoor Use)

Granite/Basalt

Use hydraulic chain saws or diamond wire saws with diamond-embedded cables (10-12mm diameter). These tools handle massive rock blocks efficiently, using water-cooling to prevent overheating.

Sandstone/Limestone

Opt for diamond circular saws with segmented diamond blades (shock-resistant design). Ideal for open-pit mining with minimal water cooling.

Soft Rocks (e.g., Shale)

Lightweight sandstone cutting machine (dry-cut diamond blades) offer flexibility for small-scale, rapid cuts.

Factory Settings (High-Precision, Fixed Operations)

Marble/Granite

CNC bridge saws or waterjet cutters paired with continuous-rim diamond blades (soft-bond matrix) ensure smooth, precise cuts (0.1-1mm accuracy) for slabs or sculptures.

Engineered Stone (Quartz/Resin-based)

CNC stone cutting machines with ultra-thin diamond blades (10-12mm thickness) minimize vibration and cracking, coupled with dust-extraction systems.

Hard Stones (e.g., Obsidian)

Diamond wire cutters or laser cutters provide contactless precision, reducing edge chipping.

Key Selection Criteria

Stone Quarry Rock Cutting Saw

Prioritize durability and portability; tolerate moderate errors; use diesel/hydraulic-powered tools.

Stone Factory Rock Cutting Saw

Focus on precision and stability; require water-cooling and dust control; use electric-powered systems.

Universal: Diamond blades are essential. Match bond hardness to rock hardness (hard bonds for hard stones, soft bonds for soft stones).

Examples: Portable circular saws for sandstone (mining) vs. CNC bridge saws for marble (factories).

Rock Saws General Purchasing Guidelines

Compliance Certifications

Mining Equipment: Must meet GB/T 39981-2021 (explosion-proof and dust-proof certifications).

Stone Factory Equipment: Requires GB 3883.18-2009 electrical safety certification.

Lifecycle Cost Analysis

Initial Cost: Mining equipment: ~¥200,000–800,000; stone factory equipment: ~¥50,000–500,000.

Operating Costs: Daily power consumption (e.g., 30kW machine: ~¥240/day), blade replacement (¥300–2,000/blade).

Maintenance: Annual upkeep: ~5–10% of equipment price.

Vendor Evaluation

Support: Prioritize vendors offering installation, training, and troubleshooting (e.g., DINOSAW).

Warranty: Minimum 1-year warranty, 3+ years for critical components (e.g., spindles).

Key Selection Factors of Rock Cutting Machine

For Stone Mines

Prioritize durability: Look for ≥5,000-hour lifespans and MSHA/ATEX certifications

Calculate cost per cubic meter (target: ≤$2.8/m³ for granite)

For Stone Factories

Focus on precision: ≤0.5mm cutting tolerance ensures slab consistency

Check energy efficiency: ≤1.2kW·h per square meter

FAQs about Rock cutting machine

Q: What tool do you use to cut rocks?

Use a Circular saw with a diamond blade or wire saw with diamond wire. For field work, portable angle grinders with diamond blades or hydraulic rock saws are alternatives.

Q: What is the best saw blade to cut rock?

Continuous-rim diamond blades provide smooth cuts for hard stones (granite, quartz). Turbo-rim blades are faster but rougher. Avoid segmented blades—they chip brittle rocks.

Ready to Transform Your Rock Cutting Projects?

At DINOSAW, we power precision and efficiency in every cut. Whether you’re slicing through granite, shaping delicate marble, or tackling rugged mining tasks, our rock cutting saws and diamond tools are engineered to outperform.

✨ Why Choose DINOSAW?

Smart CNC Control Systems: Cut smarter, not harder—our tech ensures flawless accuracy.

Diamond-Infused Solutions: Blades and tools built to last, even in the toughest conditions.

End-to-End Support: From free ROI analysis to tailored quotes, we’re with you at every step.

📈 Boost Profit, Cut Waste🚀 Take the Next Step Today!

👉 Claim Your Free Demo: See our saws in action.

Every second saved is profit earned.

Let’s make your rock cutting faster, sharper, and smarter—contact DINOSAW now!