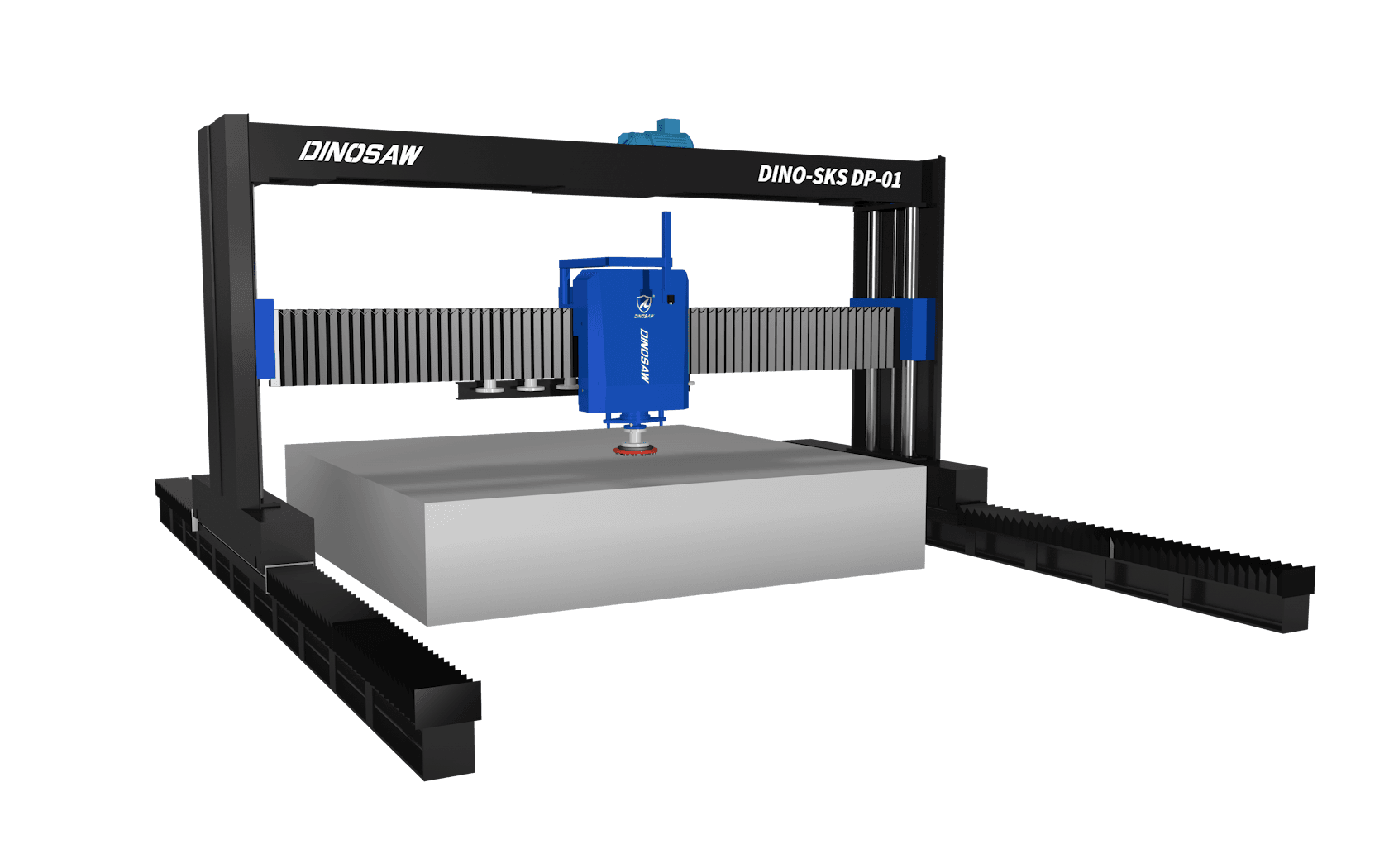

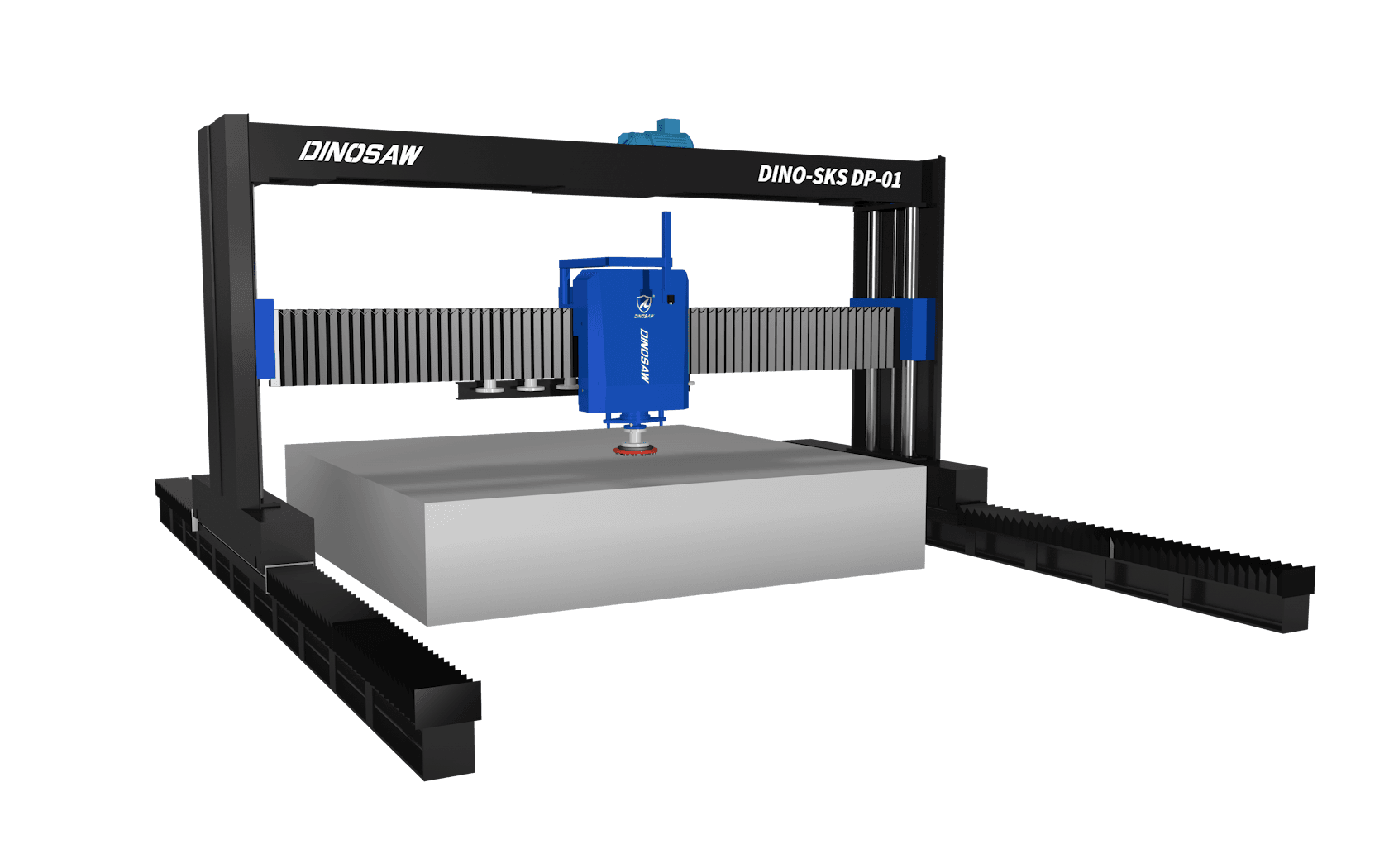

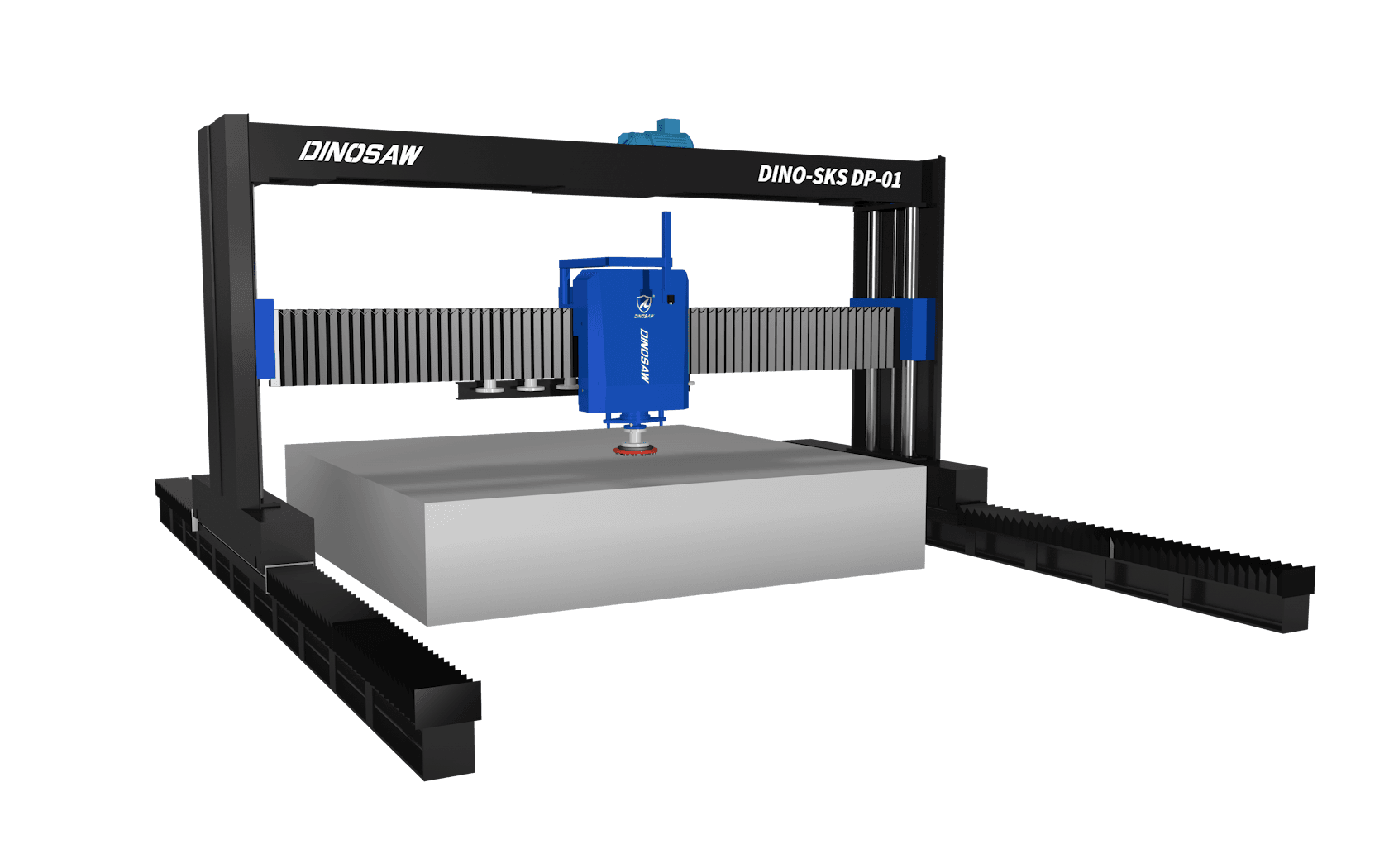

CNC Diamond Wire Saw Cutting Machine for Tombstone

YXSJ-1500/2400

DINOSAW CNC Diamond Wire Saw Cutting Machine cuts tombstones with precision. The CNC system performs vertical cutting, 45° beveling, curves, and profile shaping. This machine processes granite, marble, basalt, limestone and other natural stones for tombstones and memorials. Multiple stone slabs placed side by side can be cut simultaneously with a single diamond wire, increasing output by 900%. Diamond wire creates smooth cuts with minimal kerf loss for intricate designs and clean edges.

Compatible Materials & Products

Granite ❯ Tombstones & Monuments

Marble ❯ Memorial Sculptures

Basalt ❯ Modern Memorial Stones

Limestone ❯ Carved Memorial Tablets

▶ Product Demo

|

|

|

|

|

Granite's exceptional durability makes it the premier choice for lasting memorial stones and monuments. DINOSAW's CNC diamond wire saw employs multiple tension-controlled wires with diamond-embedded beads to cut through dense granite with precision and efficiency. The multi-wire design allows simultaneous cutting of multiple slabs, reducing production time by up to 40% while maintaining consistent dimensions and smooth surfaces for high-quality tombstones.

Granite ❯ Tombstones & Monuments

Marble ❯ Memorial Sculptures

Basalt ❯ Modern Memorial Stones

Limestone ❯ Carved Memorial Tablets

▶ Product Demo

|

|

|

|

|

Granite's exceptional durability makes it the premier choice for lasting memorial stones and monuments. DINOSAW's CNC diamond wire saw employs multiple tension-controlled wires with diamond-embedded beads to cut through dense granite with precision and efficiency. The multi-wire design allows simultaneous cutting of multiple slabs, reducing production time by up to 40% while maintaining consistent dimensions and smooth surfaces for high-quality tombstones.

Consult DINOSAW Material Expert →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Unlock new design possibilities for memorial stones →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Unlock new design possibilities for memorial stones →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Unlock new design possibilities for memorial stones →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Unlock new design possibilities for memorial stones →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Specs and options

Specifications customizable upon request.

Model | YXSJ-1500-9H | YXSJ-2400-13H |

|---|---|---|

Max working dimensions | 1.5x1.5x0.8m | 2.5x2.4x1.2m |

Wire diameter | 7.6-11.5mm | 7.6-11.5mm |

Main motor power | 11kw | 15-30kw |

Worktable size | 2.5x1.4m | 2.5x1.4m |

Overall dimensions | 5.7x3.5x2.5m | 7.0x6.5x2.5m |

Approximate weight | 3.8t | 5t |

Contact DINOSAW technical team for details →

Engineering excellence meets masterful stone craftsmanship in a machine designed for perfect memorial stonework

Precision Cutting that Transforms Stone into Art

Batch Processing Capability

Multiple materials arranged in parallel, capable of cutting up to 9 tombstones at once.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

20% Energy Savings

High-efficiency permanent magnet synchronous moto.

Remote Operation

OTA technology for remote updates and maintenance support.

Versatile Cutting

Multi-axis control enables linear, curved & custom cuts for tombstones, monuments & crosses.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Engraving Machine for Tombstones

Our CNC Stone Engraving Machine transforms cut tombstone blanks into personalized memorials. It creates detailed inscriptions, decorative elements, and portraits with diamond-tipped tools. Combined with the wire saw, you establish a complete memorial stone production line from rough block to finished monument.

Complete your memorial stone production line →

Automatic Stone Polishing Machine for Monuments

Our Automatic Stone Polishing Machine delivers mirror like finishes to memorial stones after wire saw cutting. It processes flat surfaces, beveled edges, and curved profiles with consistent quality. Programmable sequences adjust pressure and speed by stone type, ensuring optimal results without operator intervention.

Achieve flawless monument finishes →

Multi-function Stone Bridge Saw for Pre-cutting

Our Multi-function Stone Bridge Saw quickly divides large stone blocks into manageable sizes before wire saw precision cutting. Its powerful blade handles rough cutting tasks, allowing the wire saw to focus on precision work. This upstream solution increases overall production capacity when working with your wire saw.

Streamline your memorial stone production →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

How does a diamond wire saw compare to traditional bridge saws?

What tombstone materials can this machine process?

How many tombstones can be cut simultaneously?

How is the diamond wire maintained and how often is replacement needed?

How easy is it to operate this machine?

What is the return on investment period?

Need more assistance? Click to contact DINOSAW →

Transform Your Memorial Stone Production Today

Elevate quality, increase efficiency, and expand design possibilities with DINOSAW's precision CNC wire saw technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expert Insights: Memorial Stone Processing

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC Diamond Wire Saw Cutting Machine for Tombstone

YXSJ-1500/2400

DINOSAW CNC Diamond Wire Saw Cutting Machine cuts tombstones with precision. The CNC system performs vertical cutting, 45° beveling, curves, and profile shaping. This machine processes granite, marble, basalt, limestone and other natural stones for tombstones and memorials. Multiple stone slabs placed side by side can be cut simultaneously with a single diamond wire, increasing output by 900%. Diamond wire creates smooth cuts with minimal kerf loss for intricate designs and clean edges.

Compatible Materials & Products

Granite ❯ Tombstones & Monuments

Marble ❯ Memorial Sculptures

Basalt ❯ Modern Memorial Stones

Limestone ❯ Carved Memorial Tablets

▶ Product Demo

|

|

|

|

|

Granite's exceptional durability makes it the premier choice for lasting memorial stones and monuments. DINOSAW's CNC diamond wire saw employs multiple tension-controlled wires with diamond-embedded beads to cut through dense granite with precision and efficiency. The multi-wire design allows simultaneous cutting of multiple slabs, reducing production time by up to 40% while maintaining consistent dimensions and smooth surfaces for high-quality tombstones.

Granite ❯ Tombstones & Monuments

Marble ❯ Memorial Sculptures

Basalt ❯ Modern Memorial Stones

Limestone ❯ Carved Memorial Tablets

▶ Product Demo

|

|

|

|

|

Granite's exceptional durability makes it the premier choice for lasting memorial stones and monuments. DINOSAW's CNC diamond wire saw employs multiple tension-controlled wires with diamond-embedded beads to cut through dense granite with precision and efficiency. The multi-wire design allows simultaneous cutting of multiple slabs, reducing production time by up to 40% while maintaining consistent dimensions and smooth surfaces for high-quality tombstones.

Consult DINOSAW Material Expert →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Granite Memorial Production

Transforming Production Efficiency for Memorial Fabricators

A leading memorial stone fabricator in the USA installed two DINOSAW CNC Diamond Wire Saw machines to replace their aging bridge saws. Within three months, their production capacity increased by 38% while material waste decreased by 22%. The multi-wire technology allowed them to cut multiple tombstone slabs simultaneously, dramatically reducing processing time.

Their precision cutting operations now deliver consistent thickness across all stones with perfect edge quality, eliminating the need for extensive edge work and finishing. The automated CNC operations also reduced their labor needs by 35%, allowing them to reallocate skilled workers to more valuable custom design and engraving tasks.

Revolutionize your memorial stone production →

Custom Memorial Design

Expanding Creative Possibilities in Memorial Stonework

A boutique memorial studio in Europe specialized in custom-designed monuments faced challenges creating complex curves and unique shapes. After implementing DINOSAW's Diamond Wire Saw technology, they achieved unprecedented design flexibility with the ability to cut intricate profiles and curved sections with perfect precision.

The CNC control system allowed them to import designs directly from CAD software, translating artistic concepts into precise cutting paths without manual interpretation errors. This new capability expanded their portfolio to include signature memorial designs with flowing curves and organic shapes that were previously impossible to produce efficiently.

Discover sustainable memorial stone processing →

Memorial Stone Recycling

Sustainability and Cost Efficiency in Stone Processing

A memorial services company specializing in stone recycling and repurposing implemented DINOSAW's CNC Diamond Wire Saw to precisely cut and reshape existing memorial stones. The minimal kerf width of the diamond wire technology allowed them to maximize material recovery from older monuments, cutting thin slabs with minimal waste.

Their sustainable approach reduced raw material costs by 45% while providing an environmentally responsible service to their community. The precision and versatility of the wire saw enabled them to transform reclaimed stone into new memorial products with the same quality and finish as those made from virgin materials.

Discover sustainable memorial stone processing →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | YXSJ-1500-9H | YXSJ-2400-13H |

|---|---|---|

Max working dimensions | 1.5x1.5x0.8m | 2.5x2.4x1.2m |

Wire diameter | 7.6-11.5mm | 7.6-11.5mm |

Main motor power | 11kw | 15-30kw |

Worktable size | 2.5x1.4m | 2.5x1.4m |

Overall dimensions | 5.7x3.5x2.5m | 7.0x6.5x2.5m |

Approximate weight | 3.8t | 5t |

Contact DINOSAW technical team for details →

Engineering excellence meets masterful stone craftsmanship in a machine designed for perfect memorial stonework

Precision Cutting that Transforms Stone into Art

Batch Processing Capability

Multiple materials arranged in parallel, capable of cutting up to 9 tombstones at once.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

Inqury for Details →

Batch Processing Capability

Multiple materials arranged in parallel, capable of cutting up to 9 tombstones at once.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Reduced Labor Costs

Smooth cutting surface eliminates the need for secondary polishing processes.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

±1mm Precision Cutting

Servo motor with hydraulic tensioning maintains constant wire saw pressure.

20% Energy Savings

High-efficiency permanent magnet synchronous moto.

Remote Operation

OTA technology for remote updates and maintenance support.

Versatile Cutting

Multi-axis control enables linear, curved & custom cuts for tombstones, monuments & crosses.

Robust Construction

Cast iron columns with Siemens and NSK components ensure durability.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Engraving Machine for Tombstones

Our CNC Stone Engraving Machine transforms cut tombstone blanks into personalized memorials. It creates detailed inscriptions, decorative elements, and portraits with diamond-tipped tools. Combined with the wire saw, you establish a complete memorial stone production line from rough block to finished monument.

Complete your memorial stone production line →

Automatic Stone Polishing Machine for Monuments

Our Automatic Stone Polishing Machine delivers mirror like finishes to memorial stones after wire saw cutting. It processes flat surfaces, beveled edges, and curved profiles with consistent quality. Programmable sequences adjust pressure and speed by stone type, ensuring optimal results without operator intervention.

Achieve flawless monument finishes →

Multi-function Stone Bridge Saw for Pre-cutting

Our Multi-function Stone Bridge Saw quickly divides large stone blocks into manageable sizes before wire saw precision cutting. Its powerful blade handles rough cutting tasks, allowing the wire saw to focus on precision work. This upstream solution increases overall production capacity when working with your wire saw.

Streamline your memorial stone production →

Get a Custom Solution →

Faqs

Key Questions About CNC Diamond Wire Saw for Tombstone Cutting

How does a diamond wire saw compare to traditional bridge saws?

How does a diamond wire saw compare to traditional bridge saws?

What tombstone materials can this machine process?

What tombstone materials can this machine process?

How many tombstones can be cut simultaneously?

How many tombstones can be cut simultaneously?

How is the diamond wire maintained and how often is replacement needed?

How is the diamond wire maintained and how often is replacement needed?

What Is CNC (Computer Numerical Control)? - User Guide

How easy is it to operate this machine?

What Is CNC (Computer Numerical Control)? - User Guide

What is the return on investment period?

What Is CNC (Computer Numerical Control)? - User Guide

Can this machine create curved designs for custom memorials?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Transform Your Memorial Stone Production Today

Expert Insights: Memorial Stone Processing

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Expert Insights: Memorial Stone Processing

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: