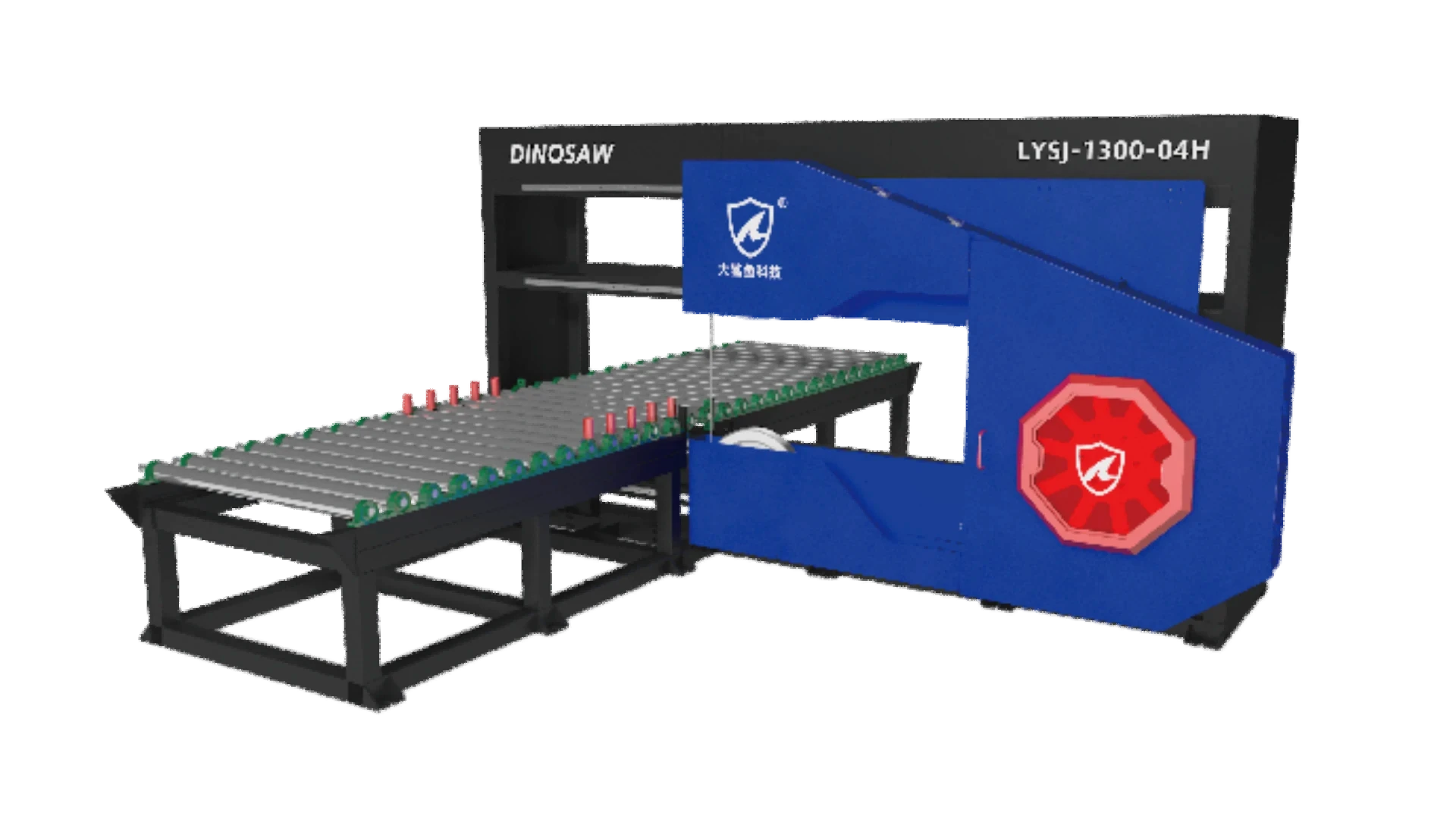

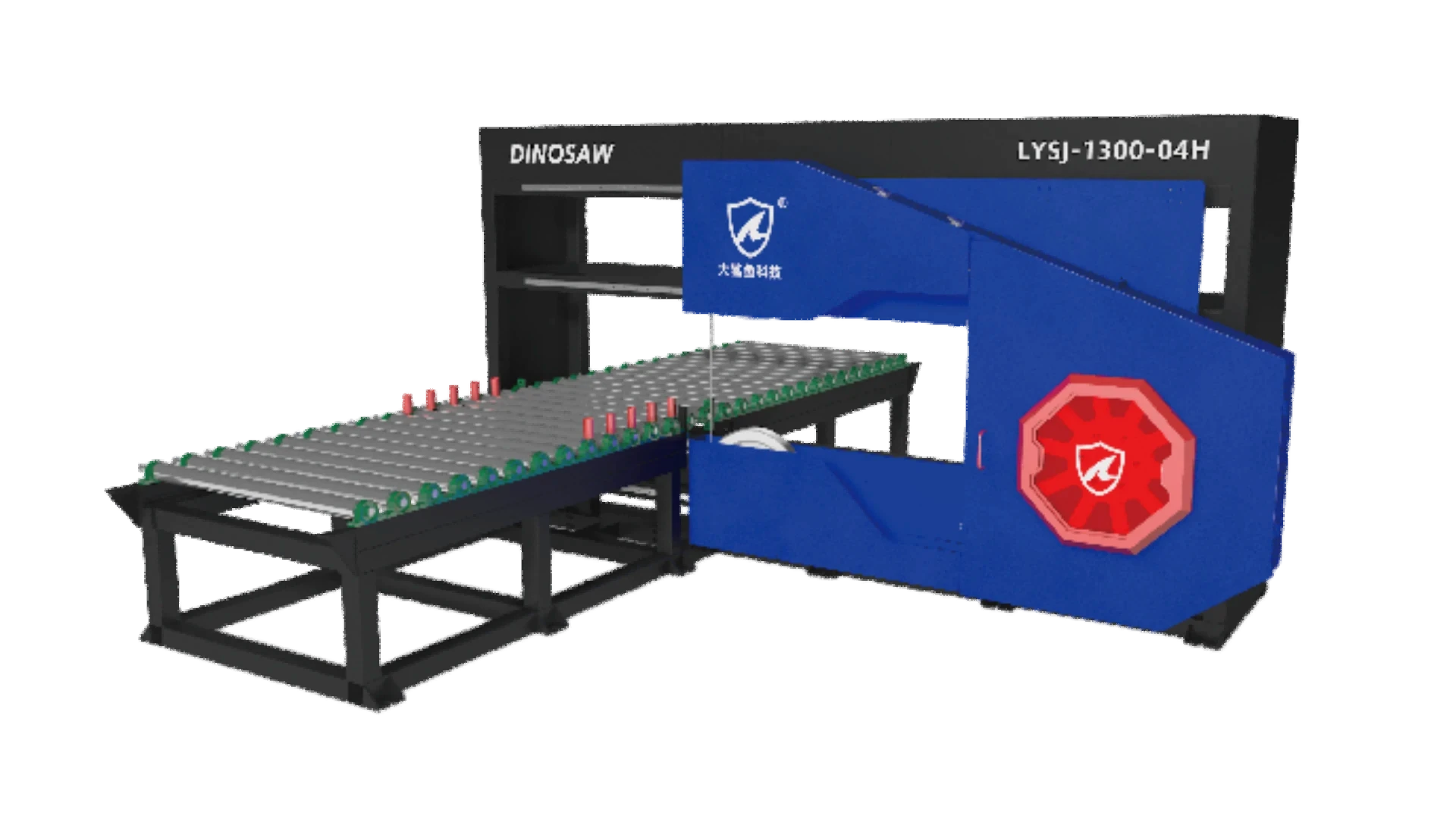

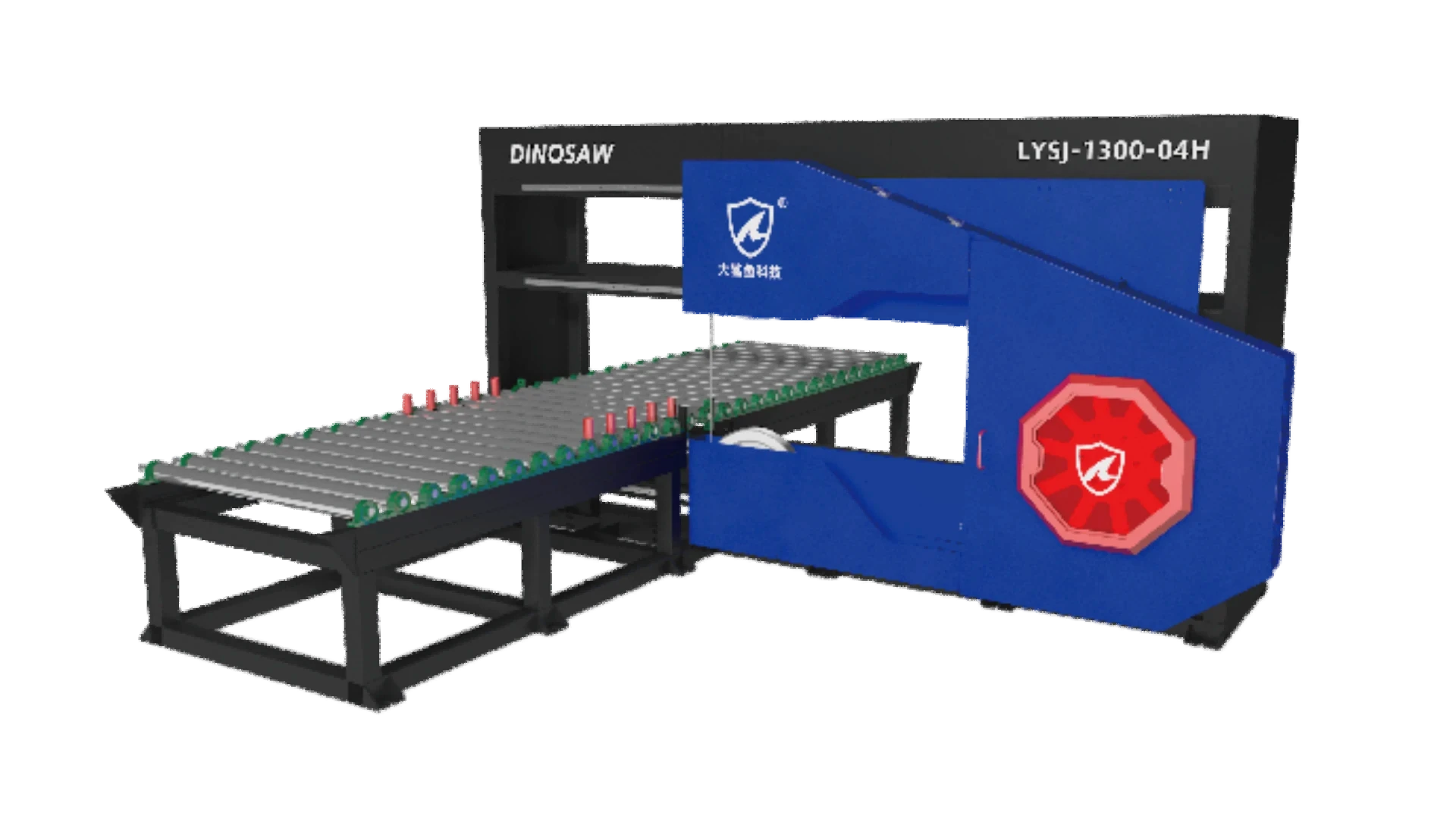

Diamond Wire Saw Cutting Machine for Kerbstone

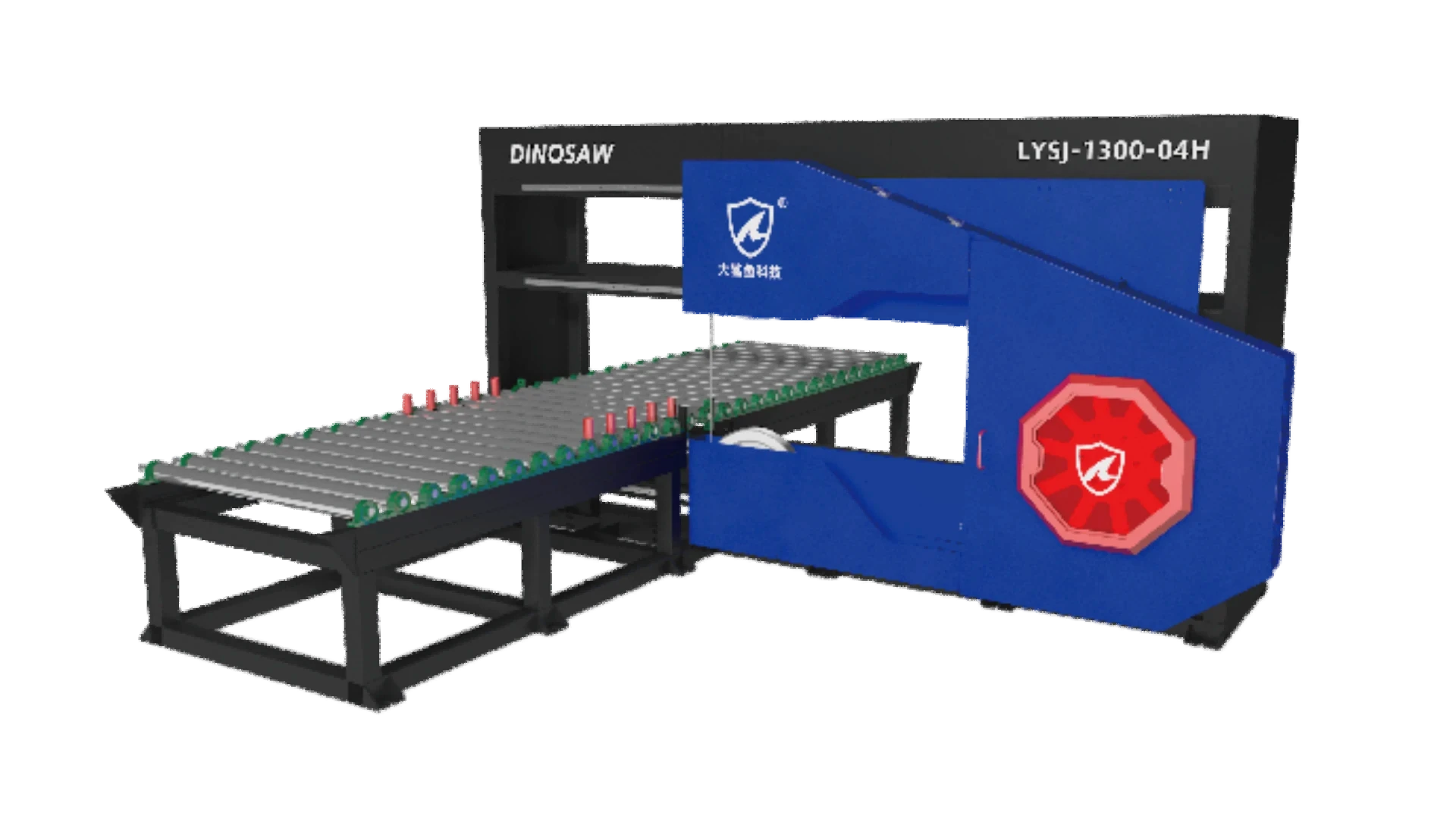

LYSJ-1300-04H

DINOSAW automated kerbstone diamond wire saw cutting machine delivers precise curved and straight cuts with ±1mm accuracy. Featuring conveyor belt system, CNC control, and industrial-grade components for efficient batch production of stone products. Perfect for processing granite, concrete, and basalt into curved kerbstones, irregular tombstones, and decorative stone pieces. Achieve superior edge quality with minimal waste and 40% higher productivity compared to traditional cutting methods.

Compatible Materials & Products

Specifications customizable upon request. Contact DINOSAW technical team for details

▶ Product Demo

Granite ❯ Curved Kerbstones

Granite ❯ Tombstones

Granite ❯ Stone Crosses

Concrete ❯ Kerbstones

▶ Product Demo

Granite ❯ Curved Kerbstones

Granite ❯ Tombstones

Granite ❯ Stone Crosses

Concrete ❯ Kerbstones

Consult DINOSAW Material Expert →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Transform landscape stone production →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Transform landscape stone production →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Transform landscape stone production →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Transform landscape stone production →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Specs and options

Specifications customizable upon request.

Model | Unit | LYSJ-1300-04H |

|---|---|---|

Max. cutting size | m | 1.2x2.4x0.4 |

Wire diameter | mm | 8.8 - 11.0 |

Main motor power | kw | 7.5 - 15 |

Overall dimensions | m | 5.2x5.0x2.5 |

Approximate weight | t | 4.5t |

Contact DINOSAW technical team for details →

DINOSAW kerbstone wire saw delivers precision curved cuts, eliminating mold costs and enabling automated production.

Shape Any Curve, Cut Any Stone

Smooth Surface without Secondary Polishing

Constant tension system ensures ±1mm precision wire saw cutting.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Assembly Line Processing

Equipped with conveyor system for automatic loading/unloading, enabling continuous production.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Remote Operation

OTA technology for remote updates and maintenance support.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

Robust Construction

Cast iron framer with Siemens and NSK components ensure durability.

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches.

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Bridge Saw Cutting Machine

Quickly prepares stone slabs with precise dimensions for kerbstone production. Reduces preparation time by 40% and material waste by 25% through automated cutting sequences

Enhancement of slate cutting efficiency →

CNC Stone Engraving Machine

Creates detailed engravings and patterns on tombstones and decorative pieces. Precision CNC system ensures consistent quality across multiple products with accurate depth control.

Realization of fine stone engraving →

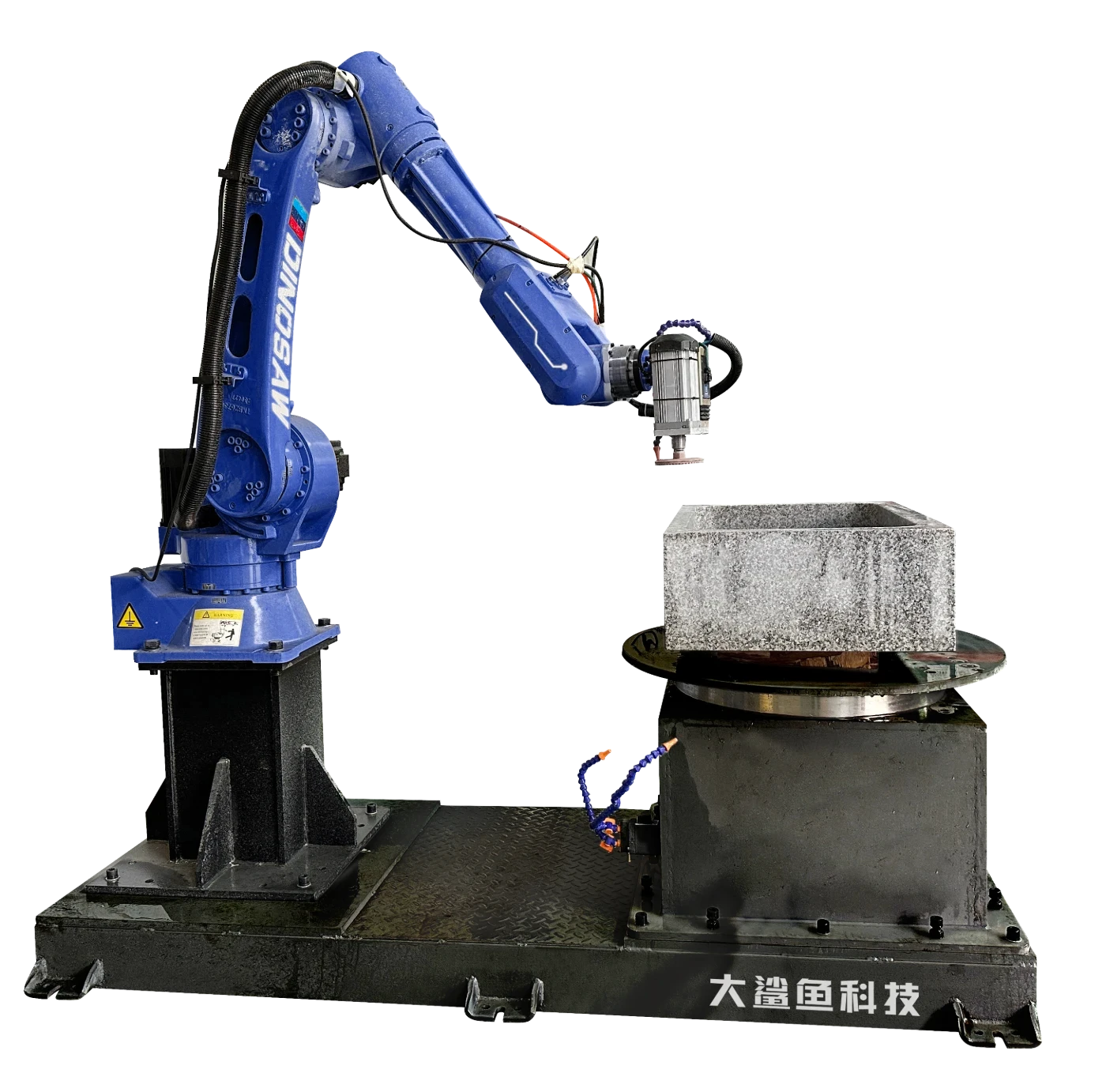

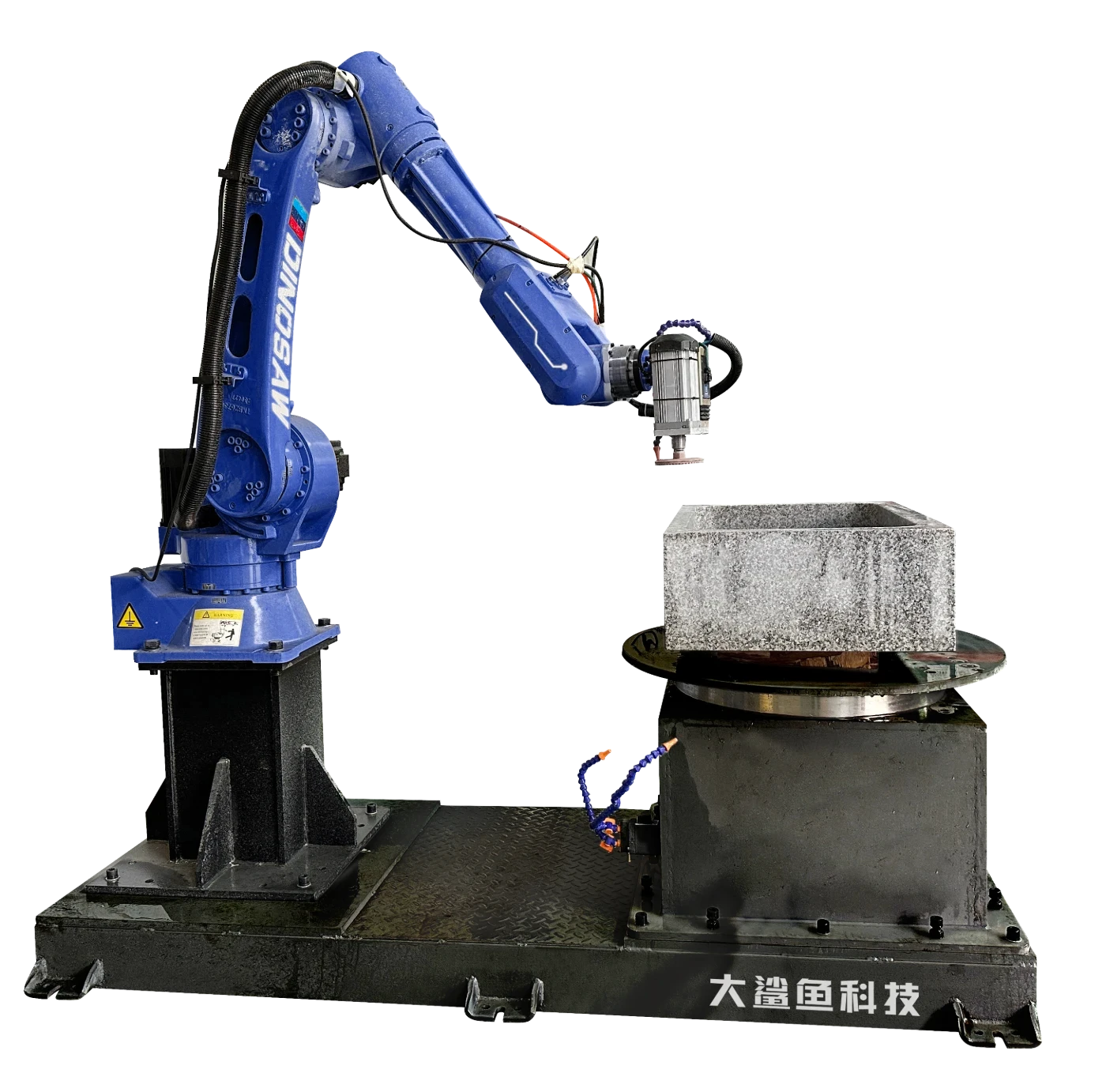

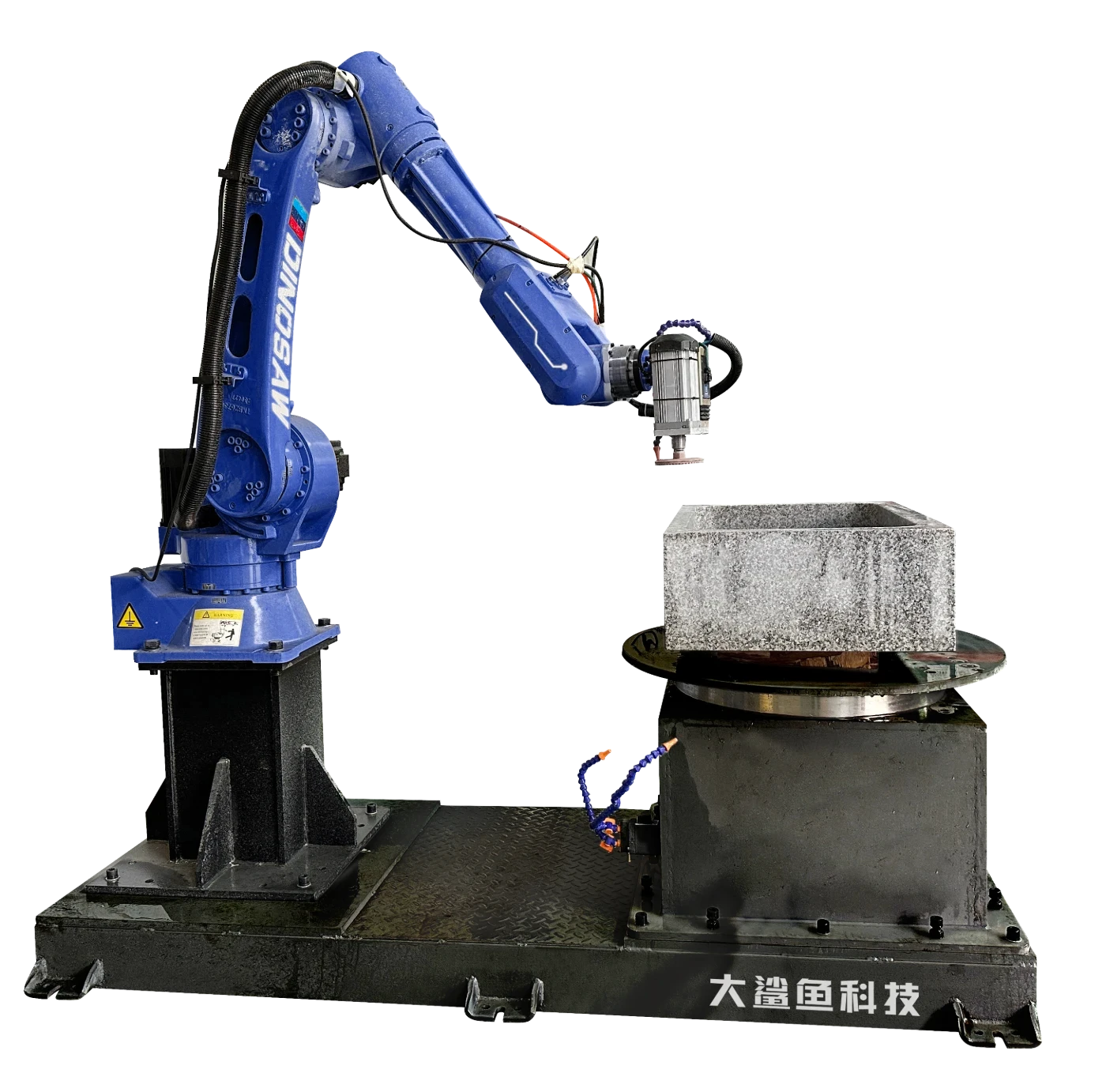

Robotic Polishing System

Handles both flat and curved edge polishing with 6-axis movement. Adapts to any surface geometry while maintaining consistent pressure and finish quality, boosting productivity by 65%.

Realization of efficient batch polishing →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What is the advantage of a diamond wire saw over traditional cutting methods for kerbstones?

Can this machine cut multiple kerbstones simultaneously?

What maintenance is required for the kerbstone wire saw machine?

How complex can the cutting shapes be for kerbstones?

What is the production capacity for standard curved kerbstones?

Need more assistance? Click to contact DINOSAW →

Transform Your Kerbstone Production Today

Join leading stone fabricators worldwide who have increased productivity and precision while reducing costs with DINOSAW diamond wire saw technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Explore these resources to learn more about diamond wire saw technology and maximize your kerbstone production efficiency.

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

Diamond Wire Saw Cutting Machine for Kerbstone

LYSJ-1300-04H

DINOSAW automated kerbstone diamond wire saw cutting machine delivers precise curved and straight cuts with ±1mm accuracy. Featuring conveyor belt system, CNC control, and industrial-grade components for efficient batch production of stone products. Perfect for processing granite, concrete, and basalt into curved kerbstones, irregular tombstones, and decorative stone pieces. Achieve superior edge quality with minimal waste and 40% higher productivity compared to traditional cutting methods.

Compatible Materials & Products

Specifications customizable upon request. Contact DINOSAW technical team for details

▶ Product Demo

Granite ❯ Curved Kerbstones

Granite ❯ Tombstones

Granite ❯ Stone Crosses

Concrete ❯ Kerbstones

▶ Product Demo

Granite ❯ Curved Kerbstones

Granite ❯ Tombstones

Granite ❯ Stone Crosses

Concrete ❯ Kerbstones

Consult DINOSAW Material Expert →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Municipal Road Construction

Accelerating Urban Infrastructure Development

City infrastructure projects require precise curved kerbstones under tight deadlines. Our automated conveyor system processes up to 100 units daily with ±1mm precision. European municipalities report 35% faster project completion and 28% cost reduction compared to traditional methods.

Enhance memorial stone production capabilities →

Memorial Stone Processing

Crafting Complex Memorial Stonework with Precision

Memorial stone fabricators require exceptional precision for custom monuments. Our diamond wire technology creates intricate curves with minimal waste. Clients report 45% fewer rejected pieces, 30% less finishing work, and achieve complex designs impossible with conventional cutting methods.

Revolutionize architectural stone fabrication →

Landscape Architecture

Elevating Outdoor Spaces with Custom Stone Elements

Landscape architects increasingly specify curved stone elements for premium outdoor spaces. Our machine creates precise, consistent pieces for garden borders and decorative elements. The conveyor system ensures efficient batch production, enabling businesses to fulfill large contracts with consistent quality.

Revolutionize architectural stone fabrication →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | LYSJ-1300-04H |

|---|---|---|

Max. cutting size | m | 1.2x2.4x0.4 |

Wire diameter | mm | 8.8 - 11.0 |

Main motor power | kw | 7.5 - 15 |

Overall dimensions | m | 5.2x5.0x2.5 |

Approximate weight | t | 4.5t |

Contact DINOSAW technical team for details →

DINOSAW kerbstone wire saw delivers precision curved cuts, eliminating mold costs and enabling automated production.

Shape Any Curve, Cut Any Stone

Smooth Surface without Secondary Polishing

Constant tension system ensures ±1mm precision wire saw cutting.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Assembly Line Processing

Equipped with conveyor system for automatic loading/unloading, enabling continuous production.

Inqury for Details →

Smooth Surface without Secondary Polishing

Constant tension system ensures ±1mm precision wire saw cutting.

Double Cutting Efficiency

Industrial permanent magnet motor achieves 1.5㎡/h cutting speed for granite.

Assembly Line Processing

Equipped with conveyor system for automatic loading/unloading, enabling continuous production.

Inqury for Details →

5-Minute Quick Operation

Self-developed CNC control system, no programming required.

20% Energy Savings

High-efficiency permanent magnet synchronous motor.

Remote Operation

OTA technology for remote updates and maintenance support.

Versatile Cutting

Multi-axis control enables straight, curved, and custom-shaped cuts.

Robust Construction

Cast iron framer with Siemens and NSK components ensure durability.

Comprehensive Safety Protection

Software alerts + hardware safeguards with protective covers and limit switches.

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Bridge Saw Cutting Machine

Quickly prepares stone slabs with precise dimensions for kerbstone production. Reduces preparation time by 40% and material waste by 25% through automated cutting sequences

Enhancement of slate cutting efficiency →

CNC Stone Engraving Machine

Creates detailed engravings and patterns on tombstones and decorative pieces. Precision CNC system ensures consistent quality across multiple products with accurate depth control.

Realization of fine stone engraving →

Robotic Polishing System

Handles both flat and curved edge polishing with 6-axis movement. Adapts to any surface geometry while maintaining consistent pressure and finish quality, boosting productivity by 65%.

Realization of efficient batch polishing →

Get a Custom Solution →

Faqs

Your Questions Answered: DINOSAW Kerbstone Diamond Wire Saw Machine

What is the advantage of a diamond wire saw over traditional cutting methods for kerbstones?

What is the advantage of a diamond wire saw over traditional cutting methods for kerbstones?

Can this machine cut multiple kerbstones simultaneously?

Can this machine cut multiple kerbstones simultaneously?

What maintenance is required for the kerbstone wire saw machine?

What maintenance is required for the kerbstone wire saw machine?

How complex can the cutting shapes be for kerbstones?

How complex can the cutting shapes be for kerbstones?

What Is CNC (Computer Numerical Control)? - User Guide

What is the production capacity for standard curved kerbstones?

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Transform Your Kerbstone Production Today

Explore these resources to learn more about diamond wire saw technology and maximize your kerbstone production efficiency.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Wire Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Explore these resources to learn more about diamond wire saw technology and maximize your kerbstone production efficiency.

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: