Introduction: Why This Granite Bridge Saw Guide Matters

Choosing the right granite bridge saw saves time, money, and materials. This guide helps Stone manufacturers:

Avoid buying machines that don’t fit your stone workshop needs

Compare 5-axis, 4+1-axis,3-axis,CNC, and PLC models bridge saw

Find trusted suppliers with fast local service

Key Features of Top Stone Bridge Saw

When comparing different bridge saw cutting machines, the following key features should be given priority:

Beam and Overall Structure

Pay attention to whether the beam and the whole cutting machine structure are made of castings or weldments. Generally speaking, castings are more robust and durable than weldments.

PLC or CNC System

The choice between a PLC (Programmable Logic Controller) and a CNC (Computer Numerical Control) system affects the ease of operation and the diversity of functions. A CNC machine usually offers more complex and precise control capabilities, while a PLC machine may be more user - friendly for basic operations.

Total Machine Power

The power of the bridge cutting machine is crucial. Machines with higher power can drive the saw blade to cut harder stones more effectively, improving the cutting efficiency and quality.

Accessories

The quality of accessories such as motors, frequency converters, and bearings is of great importance. It's recommended to choose machines with accessories from well - known brands, as they are more stable and reliable, ensuring the long - term stable operation of the machine.

Stable and Standardized Identification

Clear and standardized identification on parts like the electrical control box and operation panel is very helpful for later maintenance. It allows technicians to quickly locate and solve problems, reducing downtime.

Brand Reputation

A trustworthy brand not only provides better pre - sale solutions but also offers more comprehensive after - sale services, including installation, maintenance, and spare parts supply. This can give you more peace of mind in the long - term use of the stone cutting machine.

Compare Models of Bridge Saw for Stone Cutting

Function Modules for Granite Bridge Saws

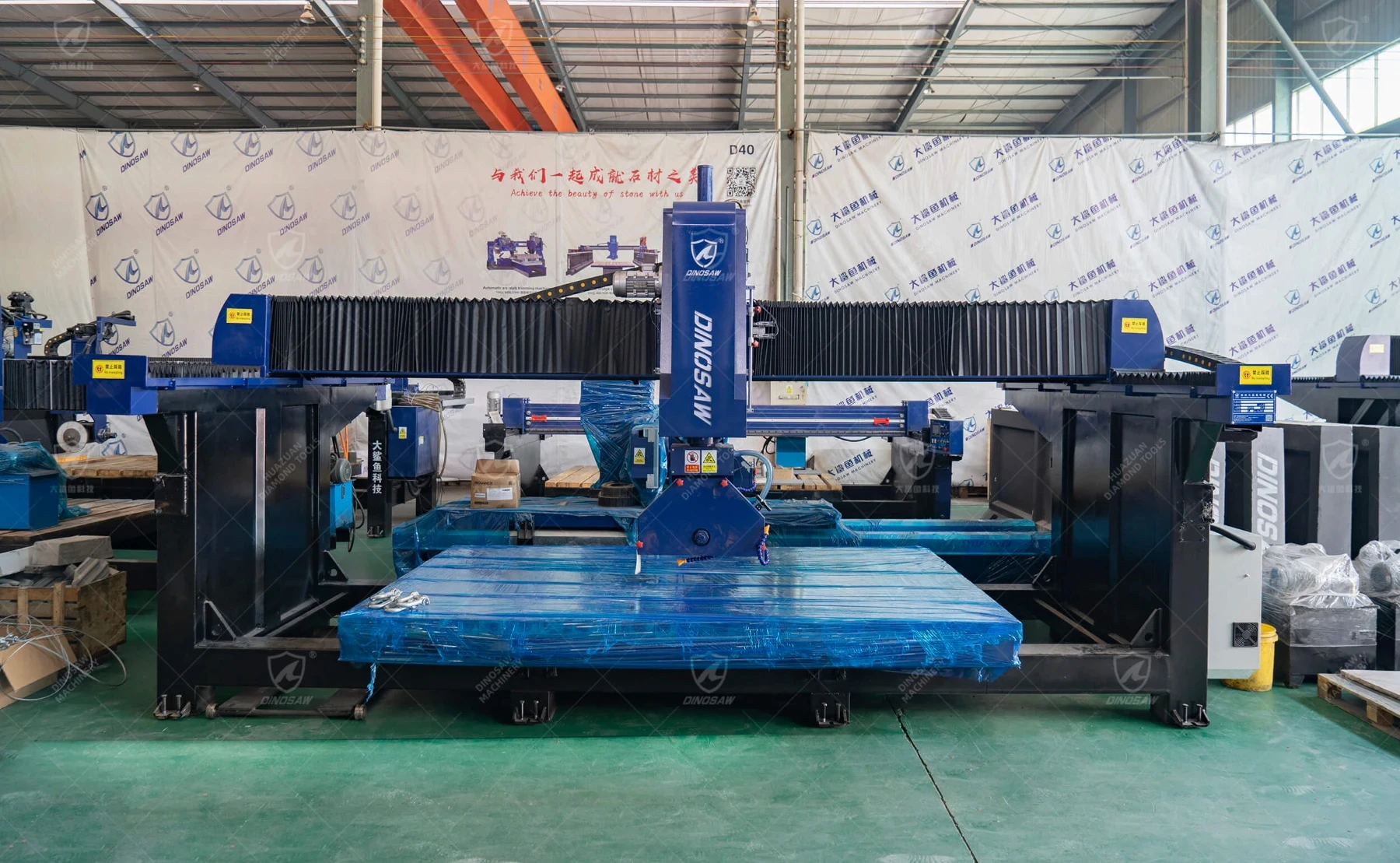

Integrated vs. Non - integrated Machines

Integrated Machines

These are designed for easy installation. They are a one - piece unit, which means that the setup process is relatively simple and quick. For example, in a small countertop shop with limited space and technical personnel, an integrated machine can be up and running in a short period of time. It's like having a ready - to - use appliance that just needs to be plugged in and some basic adjustments made.

Non - integrated Machines

Although they are heavier, their solid fixation and more stable operation make them suitable for heavy - duty granite cutting tasks. In a large - scale construction project where precision and stability are of utmost importance, such as cutting large granite slabs for building facades, non - integrated machines can provide a more reliable performance. They are like a sturdy workbench that can withstand a lot of pressure and vibration.

Axis Options

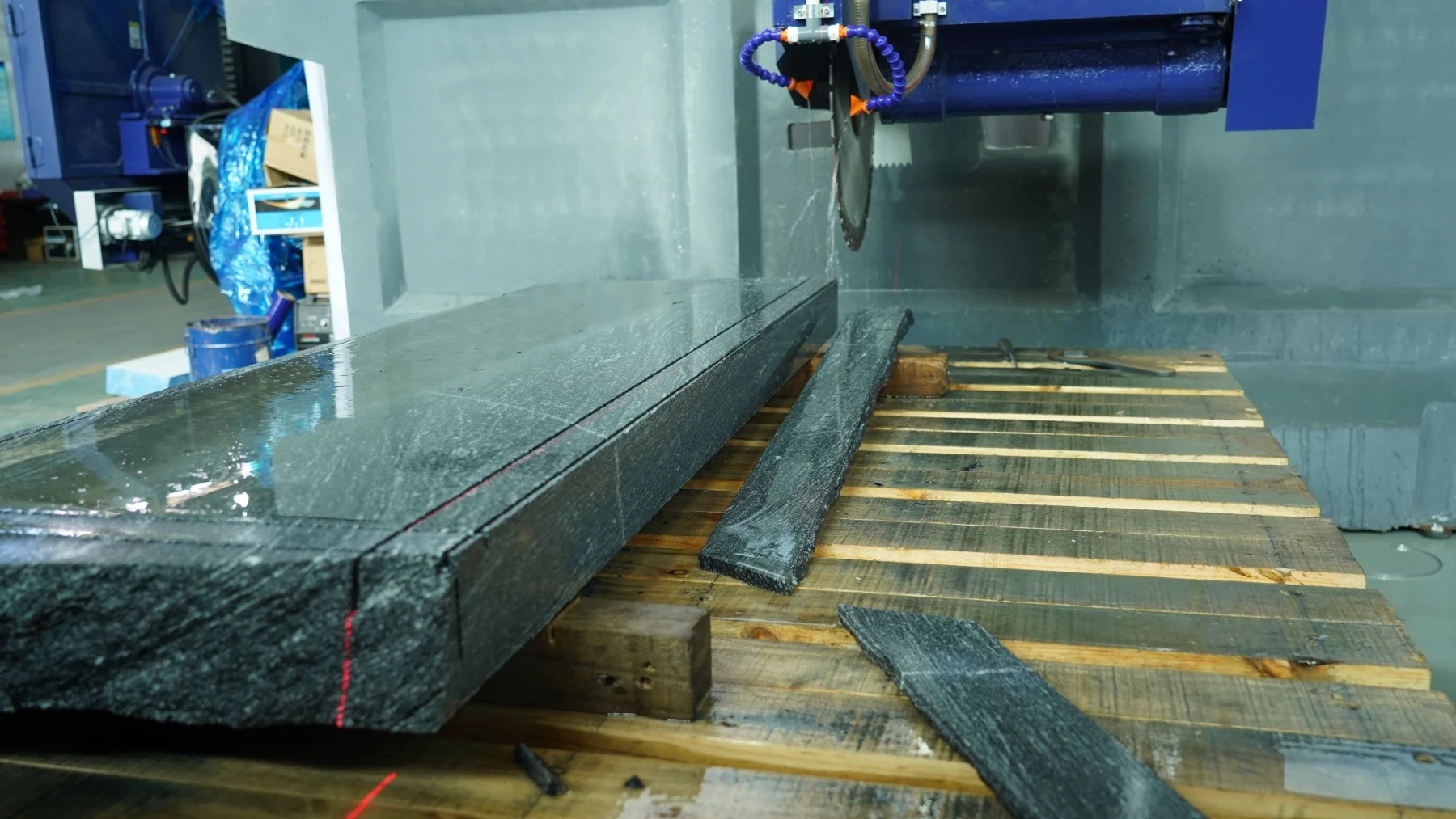

3 - axis Bridge Saw

They have the basic functions of cutting in three directions (X, Y, Z). For some simple granite cutting tasks, like cutting standard - sized granite slabs for countertops, a 3 - axis machine is sufficient. It's like a basic tool that can get the job done for common tasks.

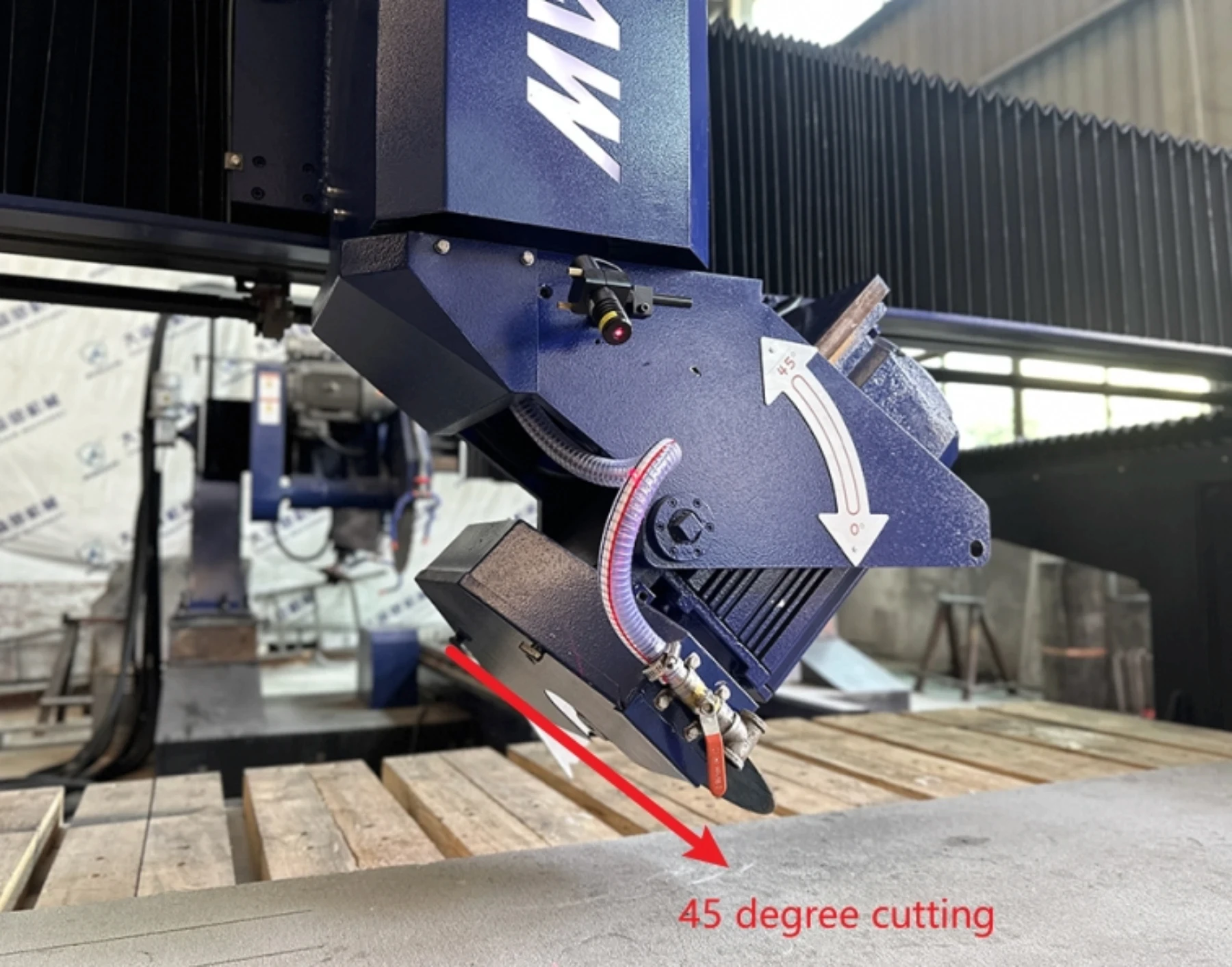

4 - axis Bridge Saw

With an additional axis, they can perform more complex cutting operations. For example, when cutting granite with a certain degree of curvature or beveling, the 4th axis allows the saw to move in a more precise and versatile way. It's like adding an extra arm to a tool that enables it to reach and work in more difficult - to - access areas.

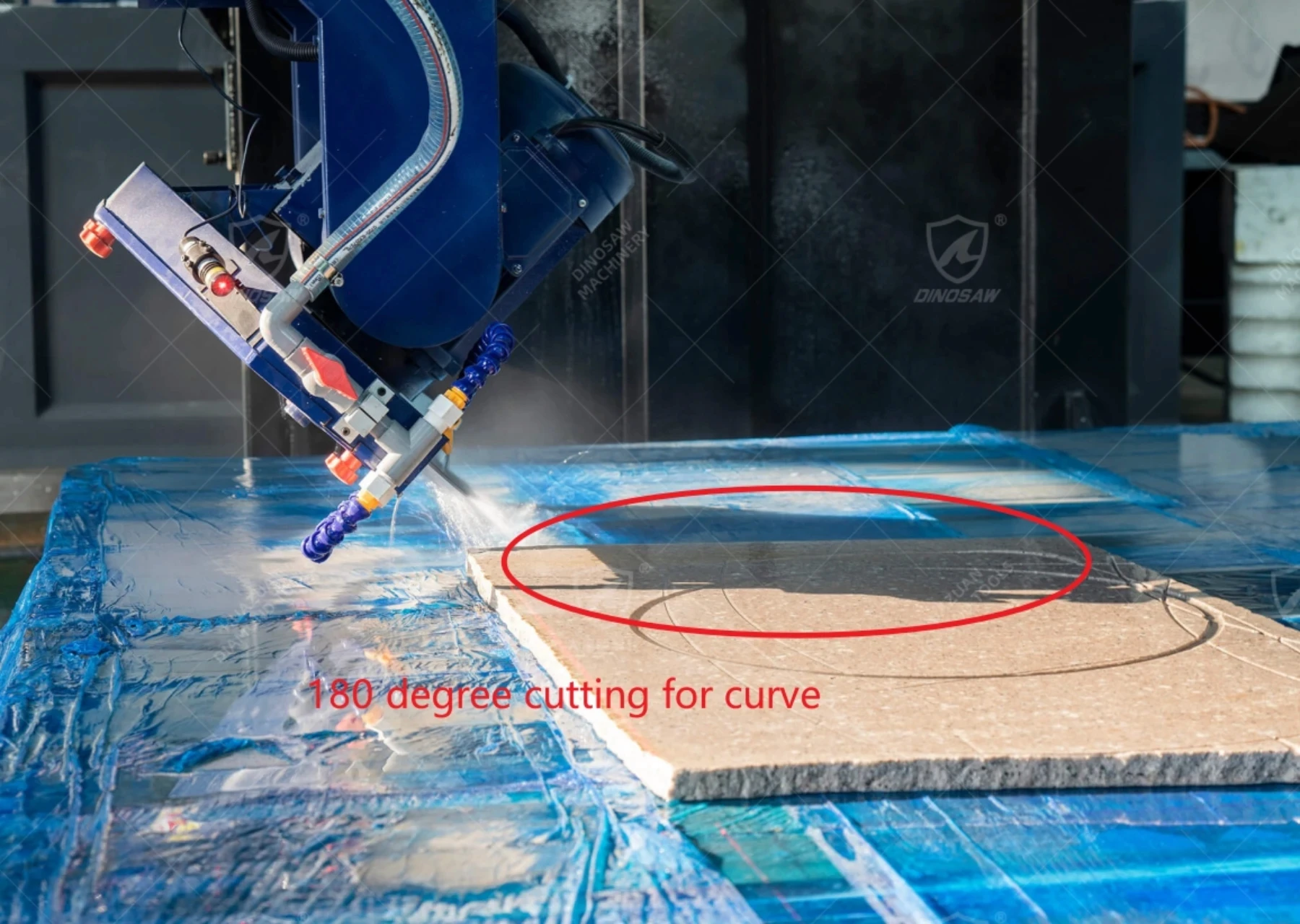

5 - axis Bridge Saw

These advanced stone cutting saws offer even more flexibility and precision. They can handle highly complex granite cutting tasks, such as creating 3D granite sculptures or cutting granite with multiple angles and curves. It's like a highly skilled artisan with multiple tools and skills, able to create intricate works of art.

4 + 1 - axis Bridge Saw

The "1" here refers to an additional milling cutter. This is useful when there is a need to not only cut but also to mill or shape the granite in a specific way. For instance, in the production of granite moldings, the milling cutter can create precise edges and profiles. It's like having a combination of a saw and a carving tool in one machine.

Size Variations

Small - sized Machines

They can accommodate saw blades with a maximum diameter of 800mm. These are suitable for cutting small - sized granite pieces, such as granite samples or small decorative granite items. It's like a compact tool that is perfect for handling small - scale projects.

Medium - sized Machines

With a maximum saw blade diameter of 1600mm, they can handle medium - sized granite cutting tasks. For example, in a countertop shop that produces a variety of countertop sizes, a medium - sized machine can cut granite slabs of different sizes to meet the diverse customer demands. It's like a versatile tool that can handle a wider range of tasks than the small - sized one.

Large - sized Machines

These machines can take saw blades with a diameter of up to 3200mm. They are mainly used in large - scale granite processing factories or construction sites where huge granite slabs need to be cut. It's like a giant tool that can handle the biggest and most demanding cutting jobs.

Additional Functions

Worktable Rotation and Flipping : This function is very helpful in handling granite slabs. For example, when loading and unloading heavy granite slabs, the rotation and flipping of the worktable can make the process much easier. It's like having a movable platform that can be adjusted to different angles and positions to facilitate the handling of heavy materials.

Different Regular Requirements of Stone Factory

For Countertop Shops

If a countertop shop mainly needs to cut standard - sized granite slabs and perform 45 - degree chamfering, a 3 - axis machine may be enough. For example, a small local countertop shop that focuses on producing simple granite countertops for kitchens and bathrooms can use a 3 - axis machine to cut the granite to the required size and then use a separate chamfering tool for the 45 - degree edge finishing. The worktable rotation and flipping function can also be useful for loading and unloading the granite slabs easily.

However, if the shop wants to offer more complex designs, such as curved countertops or countertops with special edge profiles, a 4 - axis or 4 + 1 - axis stone cutter would be more suitable. The additional axis (or axes) can help create the desired curves and profiles, and the milling cutter (in the case of a 4 + 1 - axis machine) can be used to shape the edges in a more precise way.

For Construction Projects

In a construction project that involves cutting granite for building facades, a non - integrated machine with a larger size and more axes is usually required. For example, a high - rise building project that uses granite cladding may need a 5 - axis machine to cut the granite slabs into the exact size and shape required for the facade design. The worktable rotation and flipping function can help in handling the large and heavy granite slabs during the cutting process.

If the construction project also includes some on - site cutting and finishing of granite, such as cutting granite for steps or paving stones, a smaller - sized machine with a 3 - axis or 4 - axis system may be more convenient. It can be easily transported to the construction site and used for the specific cutting tasks.

Cost - Saving Tips for Granite Bridge Cutter Buyers

Negotiate Diamond Blade Replacements or Discounts

When placing bulk orders for bridge saws, try to negotiate with the supplier for free blade replacements or discounted blades. For example, if you are a large - scale granite processing factory that needs to purchase multiple bridge saws at once, you can ask the supplier to include a certain number of free blades or offer a lower price for the blades. This can significantly reduce your long - term operating costs, as blades are a major consumable item in the cutting process.

Choose Energy - Efficient Models

Opt for energy - efficient bridge saw models. Take DINOSAW's bridge saws as an example. They are equipped with permanent magnet motors and frequency converters, which can save more than 20 % of energy. By using such energy - saving models, you can reduce your electricity costs over the lifespan of the machine. For a medium - sized countertop shop that uses the bridge saw for 8 hours a day, this energy - saving feature can lead to substantial cost savings in the long run.

Step-by-Step Buying Checklist for CNC Bridge Saw

Compare Prices and Features

Start by comparing the prices and features of different bridge saw models. Look for the best value for your money and consider the long-term cost of ownership, including maintenance and spare parts.

Measure Workshop Space

Check the available space in your workshop to ensure the bridge saw will fit. Consider the machine's dimensions and the space needed for operation and maintenance.

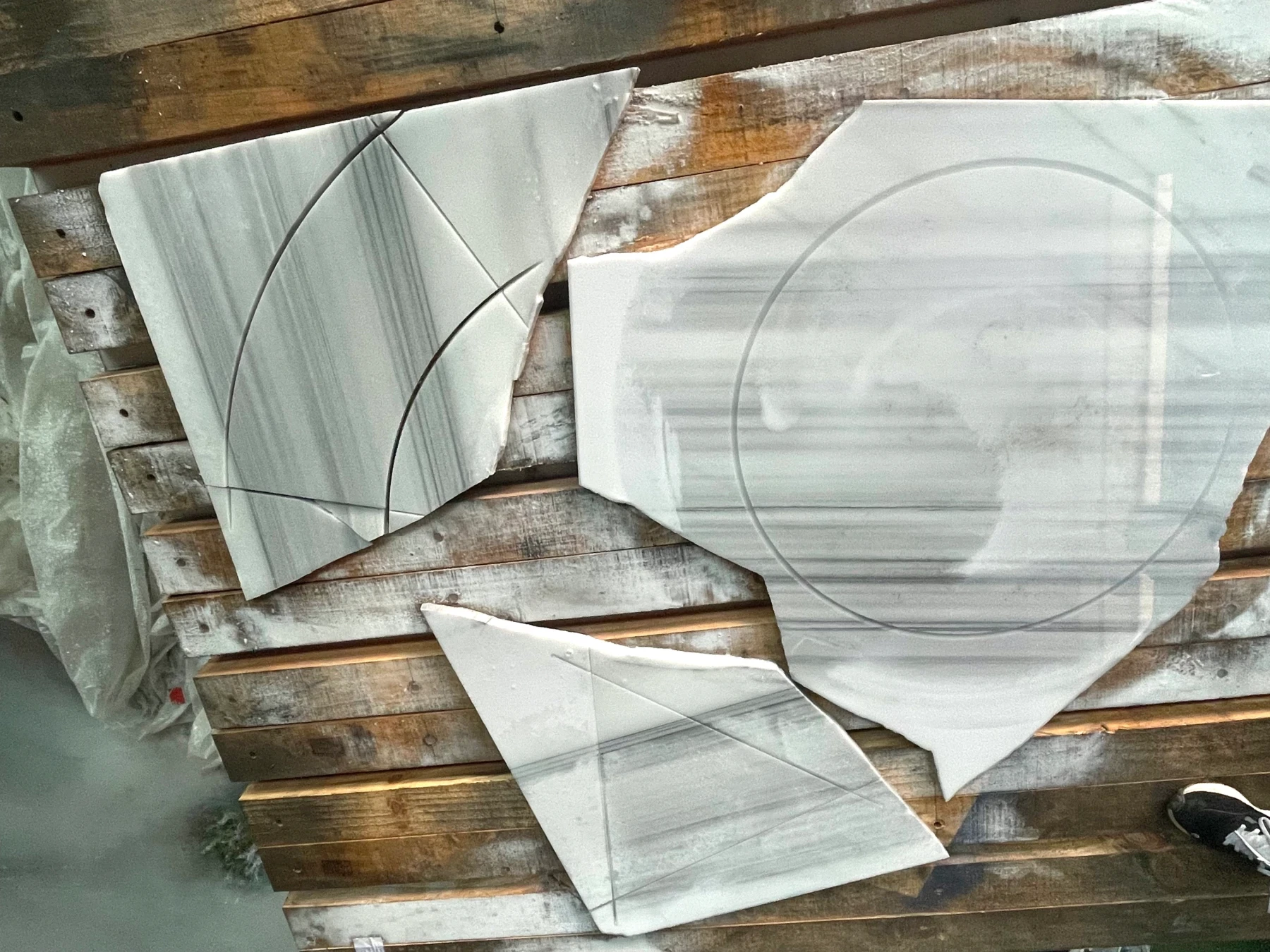

Test Cut Samples

Test the bridge saw with your specific granite type to see how it performs. This will help you determine if the machine can handle your cutting needs.

Verify Warranty

Make sure the warranty covers blade motors. Check the terms and conditions to understand what is included and for how long.

Ask for Installation Support

Inquire about installation support. Find out if the supplier provides on-site installation and what the cost is. Also, ask about training for your staff.

Review Safety Features

Ensure the bridge saw has necessary safety features such as emergency stop buttons, safety guards, and dust collection systems.

Check Maintenance Requirements

Understand the maintenance requirements of the bridge saw. This includes regular maintenance tasks and the availability of spare parts.

Consider After-sales Service

Evaluate the after-sales service provided by the supplier. This includes technical support, repair services, and the response time for any issues.

FAQs About Granite Bridge Saws

What is the best blade for cutting granite stone?

Diamond blades are best for cutting granite. Choose one with the right grit size and bond for your needs.

How to polish granite after cutting?

Polish granite with a polishing pad or diamond disc. Start with coarse grit and move to finer grit. Keep it wet.

What machines are used to cut granite?

Bridge saws, CNC routers, waterjet cutters, and manual stone slab edge cutting machines are used.

Is it better to cut granite wet or dry?

Wet cutting is better to reduce dust and keep the blade cool. Dry cutting is an option if necessary.

How do you cut granite without chipping?

Use a sharp blade, cut slowly, and use a lubricant. Avoid too much pressure.

Conclusion: Start Your Granite Cutting Business Confidently

Now that you know what to look for, why not choose DINOSAW? We offer a wide range of high - quality granite bridge saws with excellent features and competitive prices. Our machines are designed with safety and efficiency in mind. Plus, we provide great after - sales service to support you every step of the way.

Contact DINOSAW or chat with us online for the perfect bridge saw for your business. Don't miss out on the opportunity to upgrade your cutting equipment with DINOSAW!