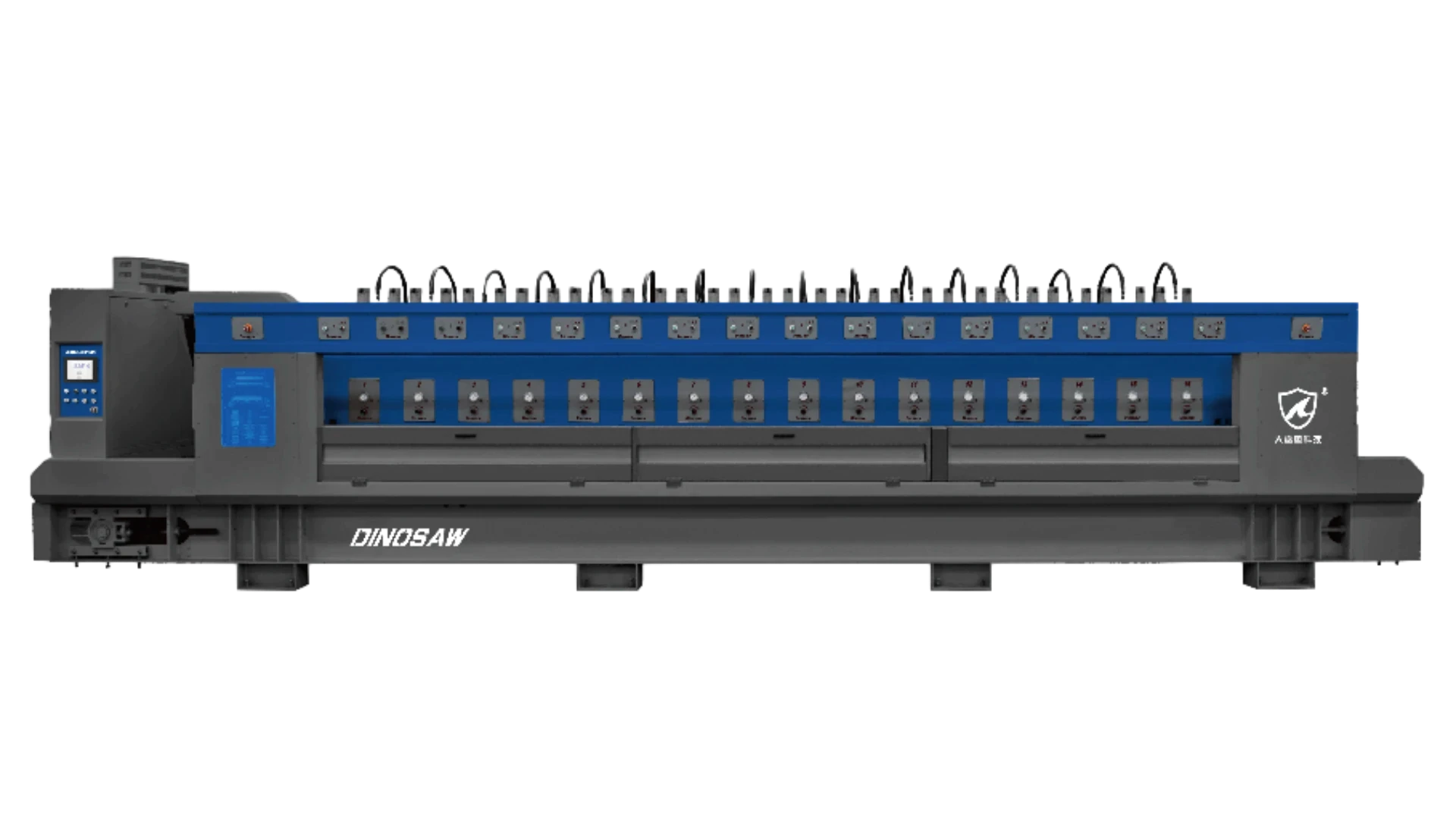

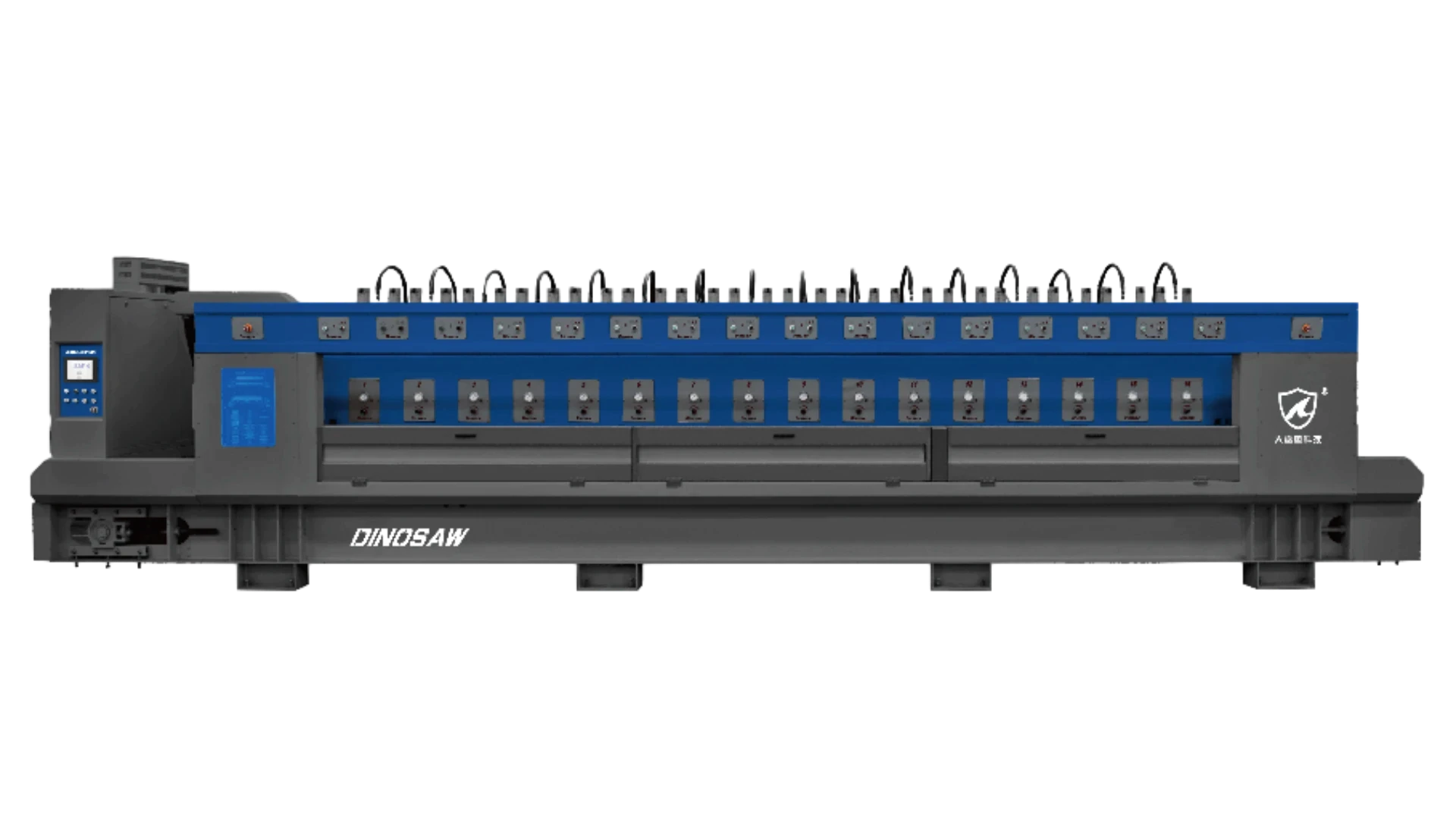

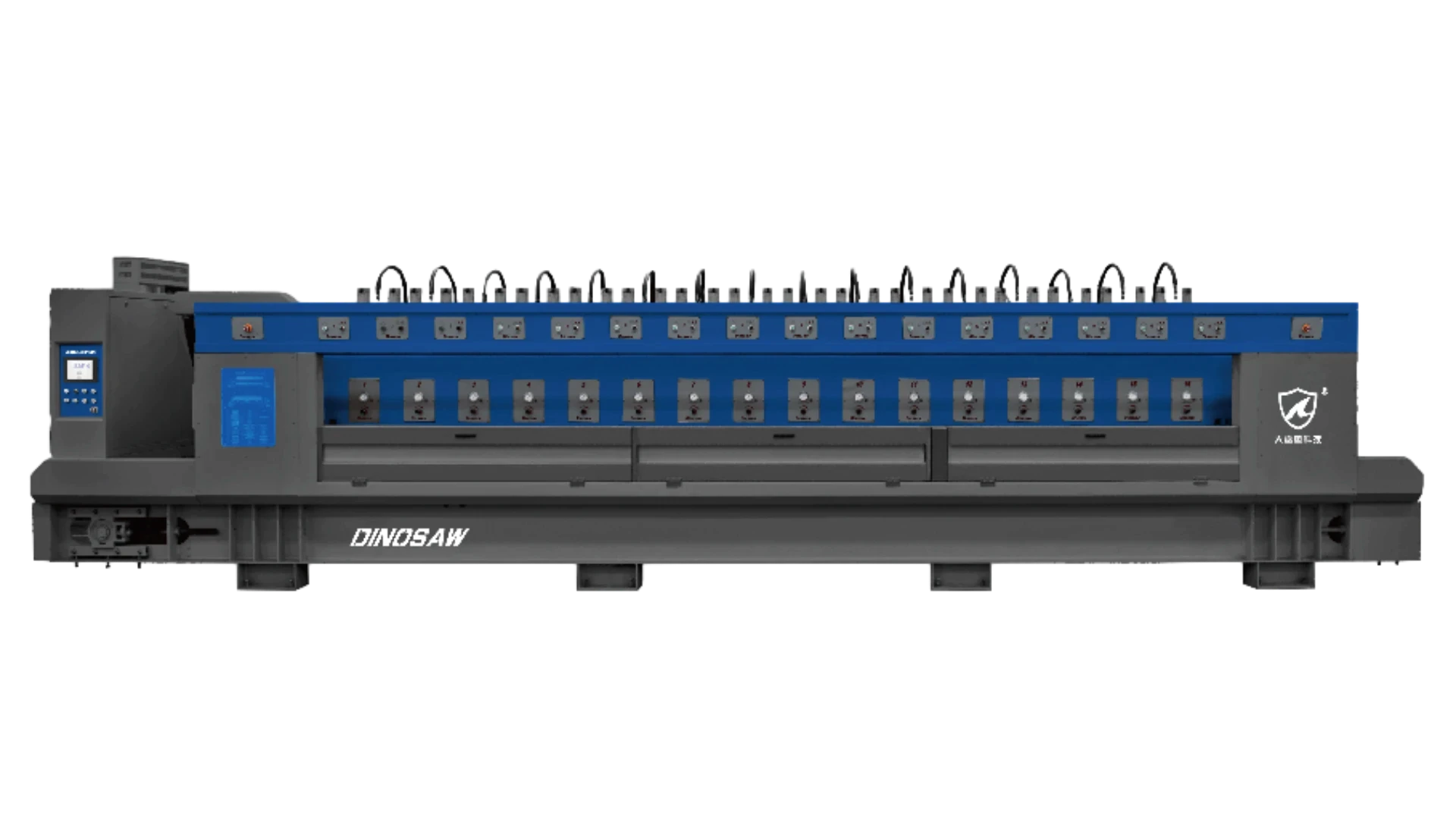

CNC Stone Bridge Saw for Precision Cutting

QSQJ-400/600/800

DINOSAW bridge saws deliver exceptional ±0.05mm precision and 25㎡/h efficiency through DDX CNC control systems, enabling high-volume stone fabrication with automated cutting, drilling, and edges operations. Perfect for processing granite, marble, engineered stone into countertops, monuments, and architectural elements. Multi-axis configurations handle straight cuts to complex curved surfaces, dramatically reducing production time while maximizing material utilization.

Granite ❯ Kitchen Countertop

Marble ❯ Bathroom Vanity Tops

Engineered Stone ❯ Commercial Surfaces

Ceramic Tile ❯ Floor Tiles

Natural Stone ❯ Monuments

▶ Product Demo

|

Granite's exceptional durability makes it the preferred choice for high-end kitchen countertops worldwide. DINOSAW bridge saws utilize diamond blades and precise CNC control to cut granite slabs with perfect edge quality, eliminating chipping and ensuring seamless joints. |

Variable cutting speeds and automated measurement systems optimize processing efficiency while maintaining consistent thickness tolerances. Professional fabricators achieve 40% faster production cycles while reducing material waste by 15% compared to traditional methods. Alt 1: CNC Bridge Saw Cutting Granite Kitchen Countertop.

Granite ❯ Kitchen Countertop

Marble ❯ Bathroom Vanity Tops

Engineered Stone ❯ Commercial Surfaces

Ceramic Tile ❯ Floor Tiles

Natural Stone ❯ Monuments

▶ Product Demo

|

Granite's exceptional durability makes it the preferred choice for high-end kitchen countertops worldwide. DINOSAW bridge saws utilize diamond blades and precise CNC control to cut granite slabs with perfect edge quality, eliminating chipping and ensuring seamless joints. |

Variable cutting speeds and automated measurement systems optimize processing efficiency while maintaining consistent thickness tolerances. Professional fabricators achieve 40% faster production cycles while reducing material waste by 15% compared to traditional methods. Alt 1: CNC Bridge Saw Cutting Granite Kitchen Countertop.

Consult DINOSAW Material Expert →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Perfect seamless fabrication →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Perfect seamless fabrication →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Perfect seamless fabrication →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Perfect seamless fabrication →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Specs and options

Specifications customizable upon request.

Model | Unit | QSQJ-400 | QSQJ-600 | QSQJ-800 |

|---|---|---|---|---|

Max.diameter of blade | mm | 400 | 600 | 800 |

Main motor power | KW | 15 | 18.5 | 22 |

Table dimensions (LxW) | mm | 3200x2000 | 3200x2000 | 3200x2000 |

Table tilting degree | n° | 0 - 85° | 0 - 85° | 0 - 85° |

Table rotating degree | n° | 90° / 360° | 90° / 360° | 90° / 360° |

Max. cutting size (LxWxH) | mm | 3200x2000x80 | 3200x2000x180 | 3200x2000x280 |

Overall dimensions (LxWxH) | mm | 6000x5000x3000 | 6000x5000x3200 | 6000x5000x3400 |

Water consumption | m³/h | 3 | 3 | 3 |

Approximate Weight | t | 5 | 5.3 | 5.5 |

Contact DINOSAW technical team for details →

Bridge design maximizes processing efficiency

Bridge Excellence for Stone Fabrication

Superior Stone Precision

±0.05mm accuracy via precision motors, bearings, DDX CNC system

Maximum Cutting Efficiency

25㎡/h speed via 18.5kw high-performance main motor

Easy Automation Operation

CNC system with CAD import and one-click processing

Inqury for Details →

Reduced Material Waste

Camera imaging enables automatic layout optimization to maximize stone utilization

Automated Workpiece Handling

Automated suction cup workpiece positioning system eliminates labor-intensive material movement

Stable and Durable

Siemens, NSK brand components with cast iron bridge beam provide exceptional structural durability

Reduced Energy Costs

Advanced motor control and standby modes optimize power consumption for up to 40% energy savings

Quick Setup & Installation

One-piece frame structure design enables quick deployment with plug-and-play connectivity

Multi-Language Support

6+ UN languages default configuration with custom language support for international usability

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Double-blade Circular Saw for Quarry Mining

Specialized dual-blade cutting system designed for efficient stone extraction in quarries. Features adjustable blade positions and powerful motors for cutting hard stone blocks. Reduces material waste while maximizing extraction efficiency. Ideal for large-scale quarry operations and initial stone processing.

Maximize quarry production efficiency →

Stone Block Cutting Machine for Slab Production

High-capacity block cutting technology for transforming raw stone blocks into precision slabs. Processes multiple blocks simultaneously with adjustable thickness settings. Delivers consistent slab thickness with minimal material loss. Essential for stone fabricators requiring high-volume slab production.

Optimize your stone block processing →

Continuous Polishing Machine for Production Lines

Automated conveyor-based polishing system for efficient surface finishing of stone slabs. Features multiple polishing heads with progressive grit sequences for superior surface quality. Eliminates manual handling while ensuring consistent finish across large production runs. Prepares slabs for subsequent cutting and engraving processes.

Streamline your surface finishing process →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What materials can a CNC bridge saw cut effectively?

How does bridge saw accuracy compare to traditional cutting methods?

What axis configuration should I choose for my applications?

How much space does a bridge saw installation require?

What maintenance is required for optimal performance?

How user-friendly is the software interface?

What production efficiency improvements can I expect?

What safety features are included with DINOSAW bridge saws?

Can bridge saws handle custom or irregular shapes?

Need more assistance? Click to contact DINOSAW →

Ready to revolutionize your stone processing?

Transform efficiency and precision with DINOSAW CNC bridge saw technology today

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Stone Processing: CNC Bridge Saw Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CNC Stone Bridge Saw for Precision Cutting

QSQJ-400/600/800

DINOSAW bridge saws deliver exceptional ±0.05mm precision and 25㎡/h efficiency through DDX CNC control systems, enabling high-volume stone fabrication with automated cutting, drilling, and edges operations. Perfect for processing granite, marble, engineered stone into countertops, monuments, and architectural elements. Multi-axis configurations handle straight cuts to complex curved surfaces, dramatically reducing production time while maximizing material utilization.

Granite ❯ Kitchen Countertop

Marble ❯ Bathroom Vanity Tops

Engineered Stone ❯ Commercial Surfaces

Ceramic Tile ❯ Floor Tiles

Natural Stone ❯ Monuments

▶ Product Demo

|

Granite's exceptional durability makes it the preferred choice for high-end kitchen countertops worldwide. DINOSAW bridge saws utilize diamond blades and precise CNC control to cut granite slabs with perfect edge quality, eliminating chipping and ensuring seamless joints. |

Variable cutting speeds and automated measurement systems optimize processing efficiency while maintaining consistent thickness tolerances. Professional fabricators achieve 40% faster production cycles while reducing material waste by 15% compared to traditional methods. Alt 1: CNC Bridge Saw Cutting Granite Kitchen Countertop.

Granite ❯ Kitchen Countertop

Marble ❯ Bathroom Vanity Tops

Engineered Stone ❯ Commercial Surfaces

Ceramic Tile ❯ Floor Tiles

Natural Stone ❯ Monuments

▶ Product Demo

|

Granite's exceptional durability makes it the preferred choice for high-end kitchen countertops worldwide. DINOSAW bridge saws utilize diamond blades and precise CNC control to cut granite slabs with perfect edge quality, eliminating chipping and ensuring seamless joints. |

Variable cutting speeds and automated measurement systems optimize processing efficiency while maintaining consistent thickness tolerances. Professional fabricators achieve 40% faster production cycles while reducing material waste by 15% compared to traditional methods. Alt 1: CNC Bridge Saw Cutting Granite Kitchen Countertop.

Consult DINOSAW Material Expert →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Kitchen Countertop Fabrication

Transforming Production Efficiency for Custom Designs

A leading countertop fabricator increased daily output by 65% after implementing DINOSAW 4+1 axis bridge saw.

The integrated cutting, drilling, and edge finishing eliminated workflow bottlenecks while reducing labor costs by 30%.

Supercharge your countertop production →

Sink & Integrated Vanity Fabrication

Seamless 5-Axis Precision for Complex Cutouts

Advanced 5-axis systems create flawless sink cutouts and integrated vanity tops without visible joints.

Automated tool changes handle drilling, profiling, and edge finishing in single setups, eliminating manual assembly steps.

Transform architectural projects →

Architectural Cladding Projects

Meeting Demanding Specifications on Schedule

Architectural projects require precise dimensional tolerances and surface finishes. DINOSAW 5-axis systems process complex geometries for curtain walls and decorative panels, ensuring perfect fit during installation.

Transform architectural projects →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | QSQJ-400 | QSQJ-600 | QSQJ-800 |

|---|---|---|---|---|

Max.diameter of blade | mm | 400 | 600 | 800 |

Main motor power | KW | 15 | 18.5 | 22 |

Table dimensions (LxW) | mm | 3200x2000 | 3200x2000 | 3200x2000 |

Table tilting degree | n° | 0 - 85° | 0 - 85° | 0 - 85° |

Table rotating degree | n° | 90° / 360° | 90° / 360° | 90° / 360° |

Max. cutting size (LxWxH) | mm | 3200x2000x80 | 3200x2000x180 | 3200x2000x280 |

Overall dimensions (LxWxH) | mm | 6000x5000x3000 | 6000x5000x3200 | 6000x5000x3400 |

Water consumption | m³/h | 3 | 3 | 3 |

Approximate Weight | t | 5 | 5.3 | 5.5 |

Contact DINOSAW technical team for details →

Bridge design maximizes processing efficiency

Bridge Excellence for Stone Fabrication

Superior Stone Precision

±0.05mm accuracy via precision motors, bearings, DDX CNC system

Maximum Cutting Efficiency

25㎡/h speed via 18.5kw high-performance main motor

Easy Automation Operation

CNC system with CAD import and one-click processing

Inqury for Details →

Superior Stone Precision

±0.05mm accuracy via precision motors, bearings, DDX CNC system

Maximum Cutting Efficiency

25㎡/h speed via 18.5kw high-performance main motor

Easy Automation Operation

CNC system with CAD import and one-click processing

Inqury for Details →

Reduced Material Waste

Camera imaging enables automatic layout optimization to maximize stone utilization

Automated Workpiece Handling

Automated suction cup workpiece positioning system eliminates labor-intensive material movement

Stable and Durable

Siemens, NSK brand components with cast iron bridge beam provide exceptional structural durability

Reduced Energy Costs

Advanced motor control and standby modes optimize power consumption for up to 40% energy savings

Quick Setup & Installation

One-piece frame structure design enables quick deployment with plug-and-play connectivity

Multi-Language Support

6+ UN languages default configuration with custom language support for international usability

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Double-blade Circular Saw for Quarry Mining

Specialized dual-blade cutting system designed for efficient stone extraction in quarries. Features adjustable blade positions and powerful motors for cutting hard stone blocks. Reduces material waste while maximizing extraction efficiency. Ideal for large-scale quarry operations and initial stone processing.

Maximize quarry production efficiency →

Stone Block Cutting Machine for Slab Production

High-capacity block cutting technology for transforming raw stone blocks into precision slabs. Processes multiple blocks simultaneously with adjustable thickness settings. Delivers consistent slab thickness with minimal material loss. Essential for stone fabricators requiring high-volume slab production.

Optimize your stone block processing →

Continuous Polishing Machine for Production Lines

Automated conveyor-based polishing system for efficient surface finishing of stone slabs. Features multiple polishing heads with progressive grit sequences for superior surface quality. Eliminates manual handling while ensuring consistent finish across large production runs. Prepares slabs for subsequent cutting and engraving processes.

Streamline your surface finishing process →

CNC Stone Engraving Machine for Surface Decoration

Precision CNC system for creating detailed patterns, text, and images on stone surfaces. Processes decorative panels, tombstones, and architectural elements with exceptional detail accuracy. Multi-tool capabilities handle various engraving depths and textures in a single setup. Perfect for custom decoration requirements.

Create stunning stone surface designs →

Get a Custom Solution →

Faqs

Common Questions About DINOSAW Bridge Saw Machines

What materials can a CNC bridge saw cut effectively?

What materials can a CNC bridge saw cut effectively?

How does bridge saw accuracy compare to traditional cutting methods?

How does bridge saw accuracy compare to traditional cutting methods?

What axis configuration should I choose for my applications?

What axis configuration should I choose for my applications?

How much space does a bridge saw installation require?

How much space does a bridge saw installation require?

What Is CNC (Computer Numerical Control)? - User Guide

What maintenance is required for optimal performance?

What Is CNC (Computer Numerical Control)? - User Guide

How user-friendly is the software interface?

What Is CNC (Computer Numerical Control)? - User Guide

What production efficiency improvements can I expect?

What Is CNC (Computer Numerical Control)? - User Guide

What safety features are included with DINOSAW bridge saws?

What Is CNC (Computer Numerical Control)? - User Guide

Can bridge saws handle custom or irregular shapes?

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to revolutionize your stone processing?

Master Stone Processing: CNC Bridge Saw Insights

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Master Stone Processing: CNC Bridge Saw Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: