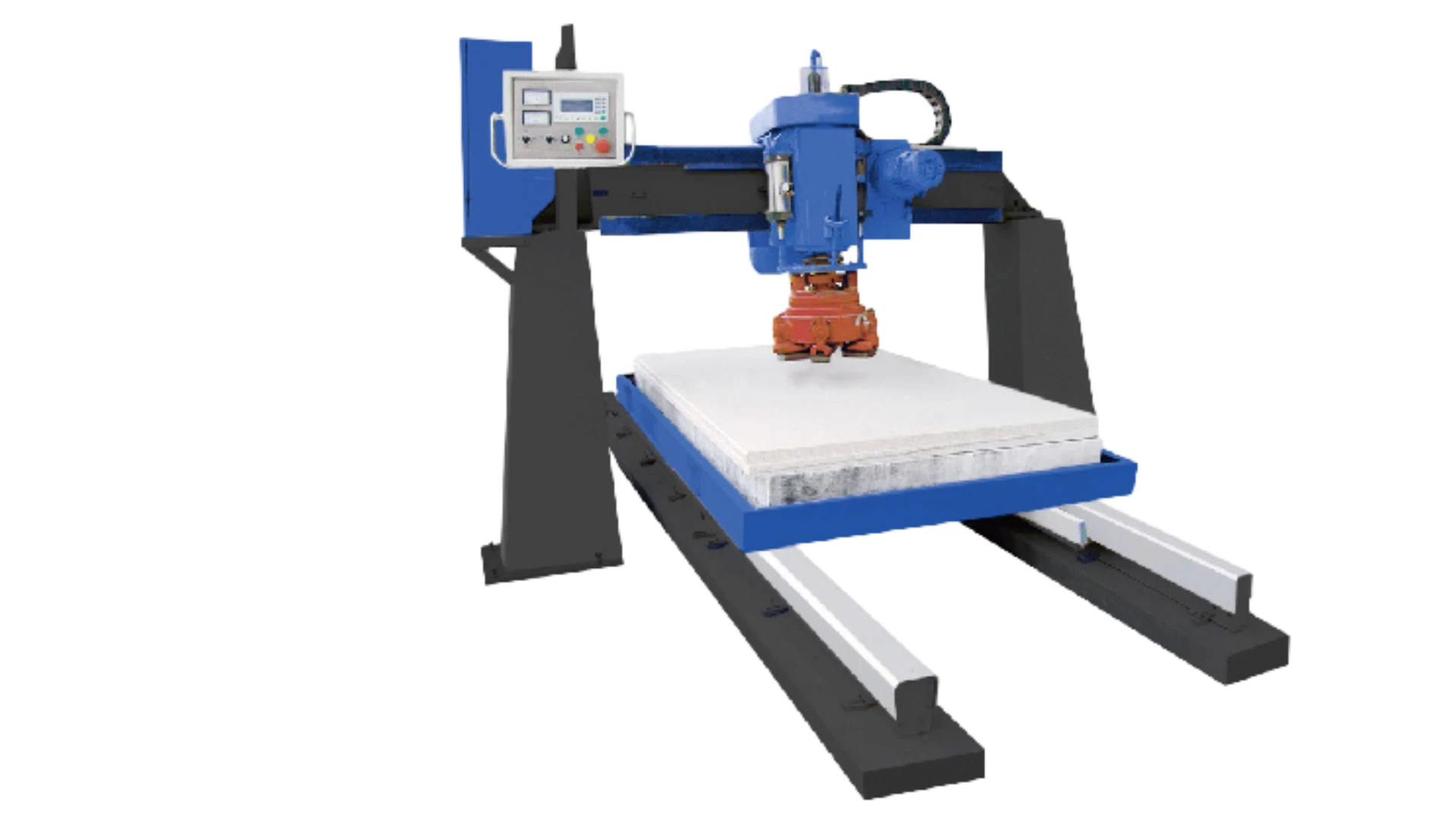

4+1 Axis Bridge Saw Cutting Machine

DSQJ-400

The 4+1 Axis Bridge Saw integrates an engraving spindle for precision hole cutting and edge milling. Designed for sink and countertop fabrication with horizontal, vertical, rotational, and 45-degree bevel cutting capabilities including straight cuts, curved cuts, drilling operations. Perfect for granite, marble, quartz, sintered stone, and porcelain processing. The CNC system supports CAD import with one-click operation for automated continuous cutting, batch processing.

Compatible Materials & Products

Granite ❯ Kitchen Countertrtops

Marble ❯ Bathroom Vanities

Quartrtz ❯ Countertops

Ceramics ❯ Washstand

|

Granite countertops represent the pinnacle of kitchen elegance and durability. |

Our 4+1 axis bridge saw utilizes precision cuttingtechnology to create flawless sink cutouts andedge profiles. The multi-angle cutting capability ensures perfect 45-degree bevels while the integrated spindle enables precise faucet hole drilling and radius corner finishing.

This technology delivers professional-grade kitchen installations with reduced waste and faster turnaround times.

Granite ❯ Kitchen Countertrtops

Marble ❯ Bathroom Vanities

Quartrtz ❯ Countertops

Ceramics ❯ Washstand

|

Granite countertops represent the pinnacle of kitchen elegance and durability. |

Our 4+1 axis bridge saw utilizes precision cuttingtechnology to create flawless sink cutouts andedge profiles. The multi-angle cutting capability ensures perfect 45-degree bevels while the integrated spindle enables precise faucet hole drilling and radius corner finishing.

This technology delivers professional-grade kitchen installations with reduced waste and faster turnaround times.

Consult DINOSAW Material Expert →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Elevate architectural stone processing →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Elevate architectural stone processing →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Elevate architectural stone processing →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Elevate architectural stone processing →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Specs and options

Specifications customizable upon request.

Model | Unit | DSQJ-400 |

|---|---|---|

Blade diameter | mm | 250 - 400 |

Max.cutting size | m | 3.2x2.0x0.5 |

Worktable dimension | m | 3.2x2.0 |

Blade rotate degree | / | 0 - 360 |

Blade tilt degree | / | 0 - 45 |

Worktable tilting degree | / | 0 - 85 |

Worktable rotating degree | / | optional |

Main motor | kw | 15 |

Spindle motor | kw | 7.5 |

Total motor | kw | 24.5 |

Water consumption | m³/h | 3.5 |

Weight | t | 3.7 |

Overall dimensions | m | 5.0x3.0x2.7 |

Contact DINOSAW technical team for details →

4+1 axis technology delivers complete countertop fabrication solutions in single setup

Sink Cutting. Edge Milling. Automated Excellence.

Faster Production Speed

18.5kW high-power main motor cuts through materials 30% faster than standard machines

Streamlined Workflow

CNC system with CAD import enables one-click operation for automated batch processing

Complete Sink Fabrication

Integrated milling spindle performs precise hole cutting and edge profiling in single setup

Inqury for Details →

Reduced Maintenance Costs

Dust-proof and waterproof design minimizes maintenance requirements and downtime

Maximum Durability

Cast iron head and heavy-duty beam construction ensure stable, vibration-free cutting

Instant Setup & Operation

One-piece frame design allows immediate operation after installation

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Engraving Machine

Adds textures, lettering, and decorative patterns to cut stone pieces. Enables complete memorial stone production workflow with reduced handling time and consistent quality.

Complete memorial stone production line →

Stone Block Cutting Machine

Perfect upstream solution for initial slab preparation before precision cutting. The block cutting machine efficiently cuts large stone blocks into manageable slabs, feeding directly into the bridge saw workflow. This combination maximizes material utilization while maintaining consistent slab thickness for optimal bridge saw performance.

Optimize your stone processing chain →

Stone Polishing Machine

Automated polishing ensures consistent surface quality while reducing manual labor. When paired with the bridge saw, this creates a complete fabrication line from rough cutting to final polish, ideal for high-end countertop and architectural applications.

Achieve premium surface finishes →

Get a Custom Solution

Faqs

Common Questions About DINOSAW Diamond Wire Saw Cutting Machines

What materials can the 4+1 axis bridge saw cut?

How accurate is the cutting precision?

What is the maximum slab size the machine can handle?

How much water does the cutting process consume?

What training is required to operate the machine?

What maintenance schedule should be followed?

What's the difference between 4+1 axis and 5-axis bridge saws?

Does the machine support CAD file import and automated cutting?

Can the machine be customized for specific applications?

Need more assistance? Click to contact DINOSAW →

Ready to revolutionize your stone cutting?

Experience precision, efficiency, and quality with DINOSAW 4+1 Axis Bridge Saw technology.

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Deepen Your Knowledge: Stone Cutting Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

4+1 Axis Bridge Saw Cutting Machine

DSQJ-400

The 4+1 Axis Bridge Saw integrates an engraving spindle for precision hole cutting and edge milling. Designed for sink and countertop fabrication with horizontal, vertical, rotational, and 45-degree bevel cutting capabilities including straight cuts, curved cuts, drilling operations. Perfect for granite, marble, quartz, sintered stone, and porcelain processing. The CNC system supports CAD import with one-click operation for automated continuous cutting, batch processing.

Compatible Materials & Products

Granite ❯ Kitchen Countertrtops

Marble ❯ Bathroom Vanities

Quartrtz ❯ Countertops

Ceramics ❯ Washstand

|

Granite countertops represent the pinnacle of kitchen elegance and durability. |

Our 4+1 axis bridge saw utilizes precision cuttingtechnology to create flawless sink cutouts andedge profiles. The multi-angle cutting capability ensures perfect 45-degree bevels while the integrated spindle enables precise faucet hole drilling and radius corner finishing.

This technology delivers professional-grade kitchen installations with reduced waste and faster turnaround times.

Granite ❯ Kitchen Countertrtops

Marble ❯ Bathroom Vanities

Quartrtz ❯ Countertops

Ceramics ❯ Washstand

|

Granite countertops represent the pinnacle of kitchen elegance and durability. |

Our 4+1 axis bridge saw utilizes precision cuttingtechnology to create flawless sink cutouts andedge profiles. The multi-angle cutting capability ensures perfect 45-degree bevels while the integrated spindle enables precise faucet hole drilling and radius corner finishing.

This technology delivers professional-grade kitchen installations with reduced waste and faster turnaround times.

Consult DINOSAW Material Expert →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Kitchen Countertrtop Production

Maximizing Fabrication Efficiency

A leading countertop manufacturer integrated our 4+1 axis bridge saw into their production line, achieving 30% faster turnaround times for custom kitchen installations. The automated sink cutting feature eliminated manual template work, while precision edge profiling reduced finishing time.

Transform your countertop production →

Architectural Stone Fabrication

Precision Cutting for Complex Designs

An architectural firm utilized our bridge saw for a luxury hotel project requiring intricate marble wall panels. The

4-axis positioning system enabled complex angle cuts with ±0.1mm accuracy. Camera-guided cutting reduced

material waste by 15% while ensuring consistent quality across 500+ panels.

Perfect luxury bathroom fabrication →

Custom Bathroom Vanities

Premium Quality for Luxury Bathrooms

A premium bathroom specialist leveraged our machine's integrated spindle for creating seamless basin formations in marble vanities. The wet cutting system preserved marble's natural patterns while the tilting worktable simplified handling of heavy slabs. This resulted in 40% reduction in labor costs and zero material cracking.

Perfect luxury bathroom fabrication →

Specs and options

Specifications customizable upon request.

Contact DINOSAW technical team for details

Model | Unit | DSQJ-400 |

|---|---|---|

Blade diameter | mm | 250 - 400 |

Max.cutting size | m | 3.2x2.0x0.5 |

Worktable dimension | m | 3.2x2.0 |

Blade rotate degree | / | 0 - 360 |

Blade tilt degree | / | 0 - 45 |

Worktable tilting degree | / | 0 - 85 |

Worktable rotating degree | / | optional |

Main motor | kw | 15 |

Spindle motor | kw | 7.5 |

Total motor | kw | 24.5 |

Water consumption | m³/h | 3.5 |

Weight | t | 3.7 |

Overall dimensions | m | 5.0x3.0x2.7 |

Contact DINOSAW technical team for details →

4+1 axis technology delivers complete countertop fabrication solutions in single setup

Sink Cutting. Edge Milling. Automated Excellence.

Faster Production Speed

18.5kW high-power main motor cuts through materials 30% faster than standard machines

Streamlined Workflow

CNC system with CAD import enables one-click operation for automated batch processing

Complete Sink Fabrication

Integrated milling spindle performs precise hole cutting and edge profiling in single setup

Inqury for Details →

Faster Production Speed

18.5kW high-power main motor cuts through materials 30% faster than standard machines

Streamlined Workflow

CNC system with CAD import enables one-click operation for automated batch processing

Complete Sink Fabrication

Integrated milling spindle performs precise hole cutting and edge profiling in single setup

Inqury for Details →

Reduced Maintenance Costs

Dust-proof and waterproof design minimizes maintenance requirements and downtime

Maximum Durability

Cast iron head and heavy-duty beam construction ensure stable, vibration-free cutting

Instant Setup & Operation

One-piece frame design allows immediate operation after installation

Complete Production Solutions

&

Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

CNC Stone Engraving Machine

Adds textures, lettering, and decorative patterns to cut stone pieces. Enables complete memorial stone production workflow with reduced handling time and consistent quality.

Complete memorial stone production line →

Stone Block Cutting Machine

Perfect upstream solution for initial slab preparation before precision cutting. The block cutting machine efficiently cuts large stone blocks into manageable slabs, feeding directly into the bridge saw workflow. This combination maximizes material utilization while maintaining consistent slab thickness for optimal bridge saw performance.

Optimize your stone processing chain →

Stone Polishing Machine

Automated polishing ensures consistent surface quality while reducing manual labor. When paired with the bridge saw, this creates a complete fabrication line from rough cutting to final polish, ideal for high-end countertop and architectural applications.

Achieve premium surface finishes →

Get a Custom Solution →

Faqs

Common Questions About 4+1 Axis Bridge Saw Cutting Machine

What materials can the 4+1 axis bridge saw cut?

What materials can the 4+1 axis bridge saw cut?

How accurate is the cutting precision?

How accurate is the cutting precision?

What is the maximum slab size the machine can handle?

What is the maximum slab size the machine can handle?

How much water does the cutting process consume?

How much water does the cutting process consume?

What Is CNC (Computer Numerical Control)? - User Guide

What training is required to operate the machine?

What Is CNC (Computer Numerical Control)? - User Guide

What maintenance schedule should be followed?

What Is CNC (Computer Numerical Control)? - User Guide

What's the difference between 4+1 axis and 5-axis bridge saws?

What Is CNC (Computer Numerical Control)? - User Guide

Does the machine support CAD file import and automated cutting?

What Is CNC (Computer Numerical Control)? - User Guide

Can the machine be customized for specific applications?

What Is CNC (Computer Numerical Control)? - User Guide

Need more assistance? Contact DINOSAW →

Ready to revolutionize your stone cutting?

Deepen Your Knowledge: Stone Cutting Insights

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

Get A Quote

DINOSAW: Trustworthy Bridge Saw Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Related Reading

Deepen Your Knowledge: Stone Cutting Insights

Get specifications, case studies, applications, technical information, and latest developments for DINOSAW industry machines.

Other Machines or Tools

Are you looking for more new information machines or tools?

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: