Last Updated:

2025-01-15

Last Updated:

2025-01-15

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Professional Stone Quarrying Equipment

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Last Updated:

2025-04-15

Professional Stone Quarrying Equipment

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Last Updated:

2025-04-15

Mining And Quarrying Machinery Types

DINOSAW offers four primary categories of mining and quarrying equipment, each designed for specific extraction and processing requirements in professional stone quarrying operations:

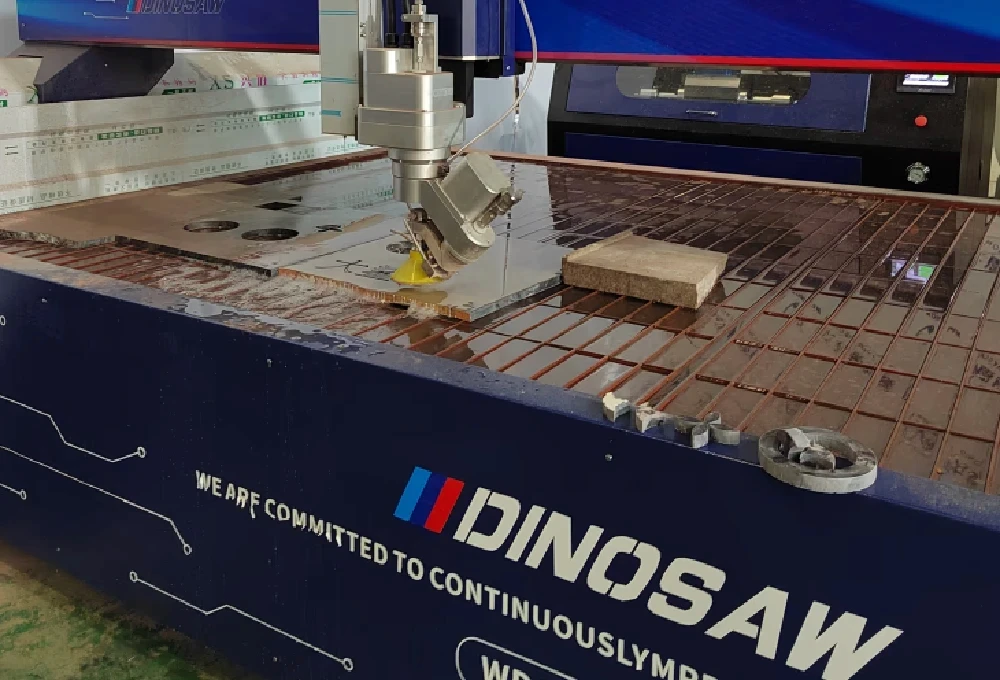

Quarry Wire Saw Machines: Advanced diamond wire technology delivers precise block separation with minimal waste, ideal for extracting large dimension stones from quarry faces

Portable Trimming Wire Saw Machines: Compact, modular design for on-site trimming and shaping, perfect for special environment operations and mobile projects requiring flexibility

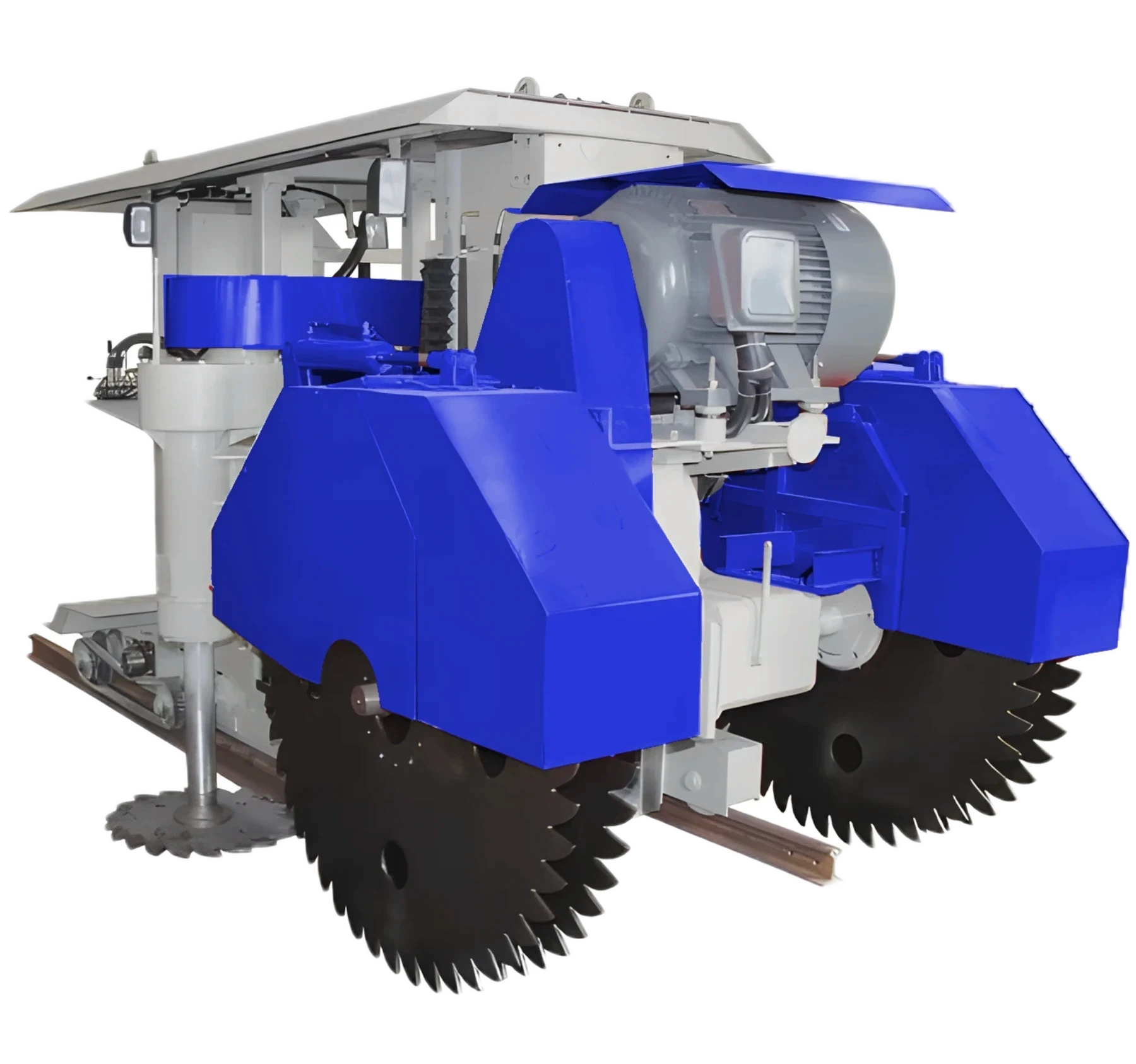

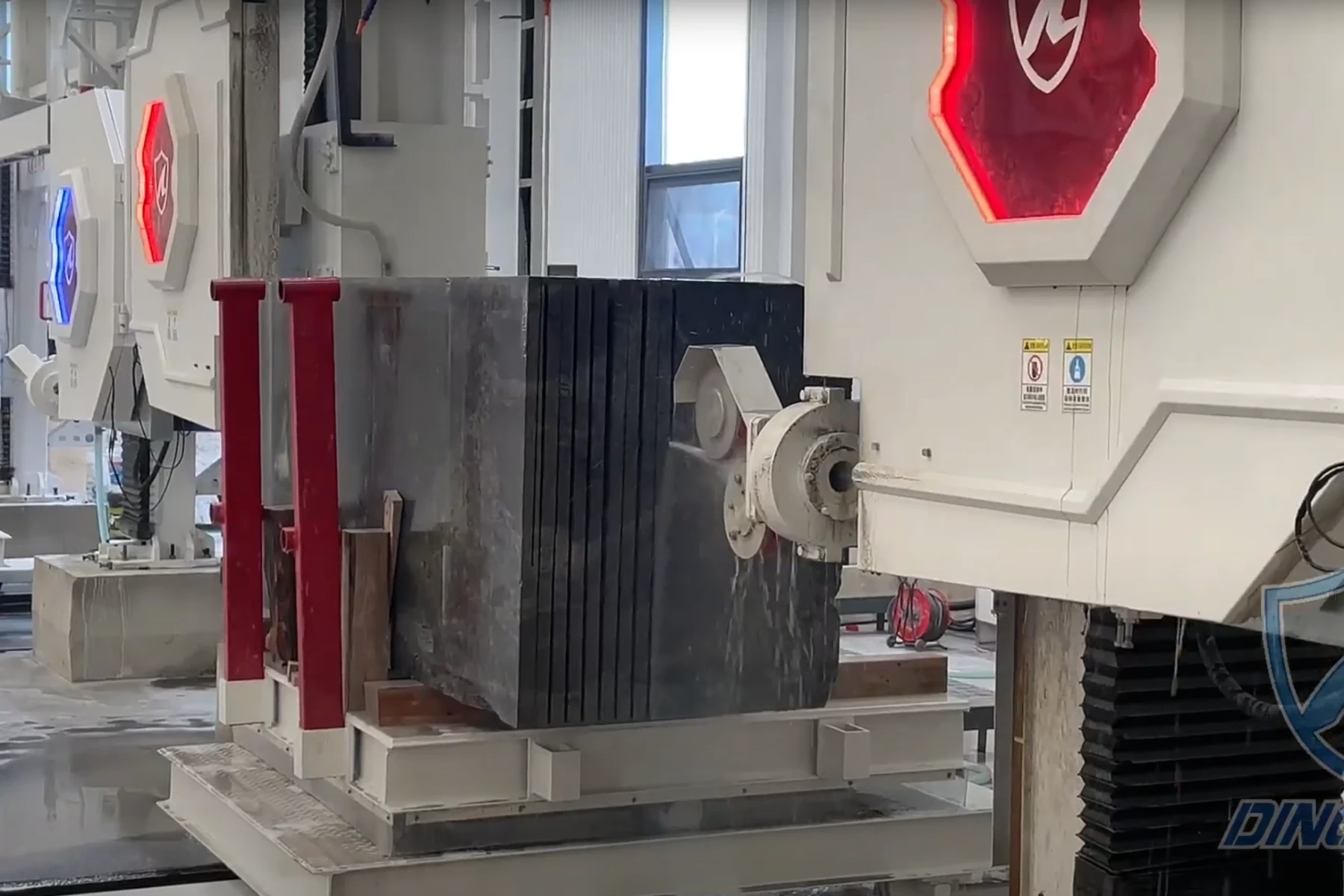

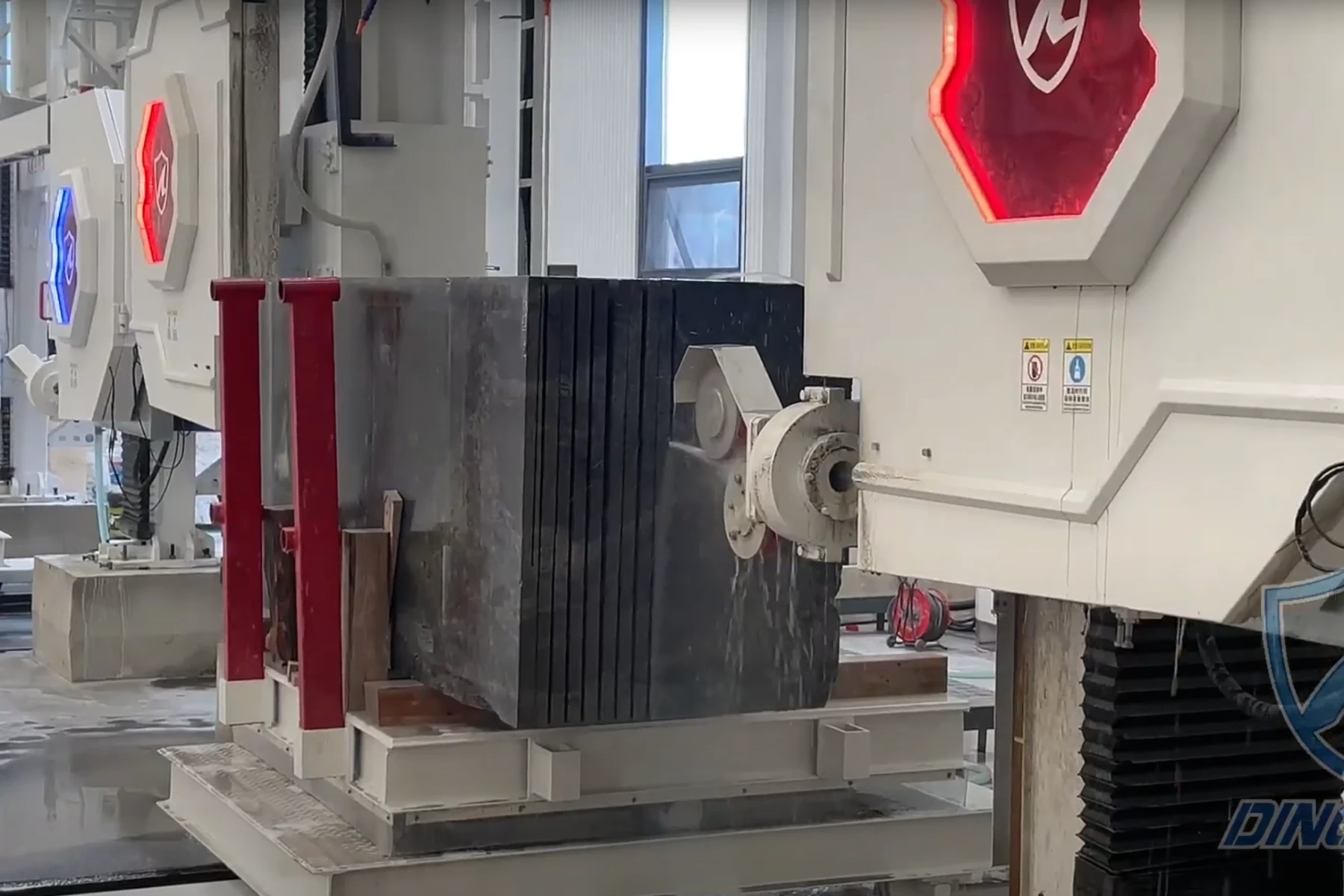

Double Blade Cutter Stone Quarrying Machines: Heavy-duty equipment for dimensional stone cutting with superior accuracy and efficient operation for processing blocks into commercial sizes

Sandstone Cutting Machines for Quarrying: Specialized equipment designed specifically for efficient cutting of softer stone materials with maximum precision and reliability

What is Mining and Quarry Machine?

Mining and Quarry Machines are specialized equipment designed for extracting dimensional stone from quarries and processing raw blocks into commercial products. These machines utilize advanced technologies to efficiently separate stone blocks from natural deposits while maintaining the material's structural integrity and commercial value.

Modern quarrying equipment combines precision engineering with powerful cutting mechanisms, allowing operators to extract stone with minimal waste and environmental impact. The advanced machinery enhances extraction efficiency, reduces labor requirements, and maximizes material yield through precision cutting technology. These systems adapt to diverse quarrying environments and stone types while improving workplace safety through automated operations.

From large-scale quarry extraction to precision block cutting, modern quarrying equipment enables efficient processing of marble, granite, limestone, sandstone, basalt, quartzite, and other natural stones. DINOSAW offers comprehensive quarrying solutions that address the entire extraction workflow, significantly impacting operational productivity, product quality, and overall profitability of quarrying operations.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to Advanced Quarrying Machines

Quarrying operations require efficient and reliable equipment to extract natural stones like marble, granite, and sandstone. Dinosaw’s lineup of quarry wire saw machines, double blade quarrying machines, and chainsaws is designed to meet the demands of modern quarries, offering advanced technology and superior performance.

This guide highlights the features and advantages of these machines, helping you select the best solution for your quarrying needs.

What Are Quarrying Machines?

Quarrying machines are specialized tools used to extract large stone blocks from quarries efficiently and safely. These machines utilize advanced cutting technologies to improve productivity, minimize material waste, and streamline operations.

Primary Types of Quarrying Machines

Quarry wire saw machines are precision tools for cutting large stone blocks.

Double blade quarrying machines offer high-efficiency vertical cutting capabilities.

Chainsaws provide versatile solutions for flexible quarrying tasks.

Materials Processed

Quarrying machines are designed for natural stones, including marble, granite, sandstone, limestone, quartzite, and basalt.

Types of Quarrying Machines

Quarry Wire Saw Machines

Wire saw machines utilize diamond-coated wires for high-precision and large-scale quarrying.

Key Features

Diamond wire technology enables smooth, precise cuts with minimal waste.

Automatic tension control reduces vibration and enhances cutting efficiency.

Eco-friendly operation produces low noise and minimal dust.

Advantages

Handles deep cuts with exceptional precision.

Adapts to various quarry layouts and terrains.

Provides excellent block recovery rates and smooth surfaces.

Double Blade Quarrying Machines

Double blade machines are designed for efficient vertical cutting in stone quarries.

Key Features

Large blade configurations facilitate cutting of both soft and hard stones.

Automated speed control enhances cutting accuracy.

User-friendly designs simplify operation and reduce fatigue.

Advantages

Delivers high cutting efficiency and cost-effectiveness.

Perfect for quarries requiring vertical cutting.

Minimizes manual labor and operational expenses.

Chainsaws

Chainsaws offer unmatched versatility, particularly in challenging quarrying terrains.

Key Features

Wear-resistant chains ensure durability in various conditions.

360-degree cutting capabilities handle both vertical and horizontal cuts with precision.

Compact and portable designs enable easy transport and operation in confined spaces.

Advantages

Ideal for intricate quarrying and shaping tasks.

Performs well with softer stones like limestone and sandstone.

Provides high recovery rates and smooth cutting surfaces.

Sandstone Cutting Machines

Key Features

Specialized cutting mechanisms for softer materials

precision control systems for dimensional accuracy

durable components for reliable operation.

Advantages

Optimized for sandstone and similar materials

reduced material waste

consistent cutting quality.

Steps to Choosing the Right Quarrying Machine

Define your quarrying needs by identifying the type of stone in your quarry, such as marble or granite, and determining your operational focus, whether it’s block extraction, vertical cutting, or edge shaping.

Compare machine features and capabilities to match your needs. Quarry wire saw machines are ideal for precision block cutting, double blade machines excel in vertical cutting, and chainsaws provide flexibility for irregular terrains.

Consult with Dinosaw experts to discuss geological conditions, material types, and production goals. Receive tailored advice on configurations and features.

Evaluate operational efficiency by analyzing investment costs versus benefits like improved recovery rates and reduced labor. Consider maintenance and energy consumption for sustainable operations.

Test and install the machine by requesting demonstrations and scheduling professional installation and training to optimize usage.

Why Choose Dinosaw Quarrying Machines?

Dinosaw quarrying machines are trusted for their advanced cutting technologies, versatile applications, and durable construction. With diamond wire, large blades, and durable chains, they deliver precision and efficiency in various quarrying environments. Eco-friendly solutions, including low noise and minimal dust, align with modern sustainability goals. Comprehensive global support ensures smooth operations and expert training.

Conclusion

Selecting the right quarrying machine is crucial for optimizing productivity and achieving high-quality results. Dinosaw’s quarry wire saw machines, double blade quarrying machines, and chainsaws combine advanced technology, reliability, and efficiency to handle diverse quarrying tasks.

Contact Dinosaw today to find the perfect solution for your quarrying operations!

Mining And Quarrying Machinery Types

DINOSAW offers four primary categories of mining and quarrying equipment, each designed for specific extraction and processing requirements in professional stone quarrying operations:

Quarry Wire Saw Machines: Advanced diamond wire technology delivers precise block separation with minimal waste, ideal for extracting large dimension stones from quarry faces

Portable Trimming Wire Saw Machines: Compact, modular design for on-site trimming and shaping, perfect for special environment operations and mobile projects requiring flexibility

Double Blade Cutter Stone Quarrying Machines: Heavy-duty equipment for dimensional stone cutting with superior accuracy and efficient operation for processing blocks into commercial sizes

Sandstone Cutting Machines for Quarrying: Specialized equipment designed specifically for efficient cutting of softer stone materials with maximum precision and reliability

What is Mining and Quarry Machine?

Mining and Quarry Machines are specialized equipment designed for extracting dimensional stone from quarries and processing raw blocks into commercial products. These machines utilize advanced technologies to efficiently separate stone blocks from natural deposits while maintaining the material's structural integrity and commercial value.

Modern quarrying equipment combines precision engineering with powerful cutting mechanisms, allowing operators to extract stone with minimal waste and environmental impact. The advanced machinery enhances extraction efficiency, reduces labor requirements, and maximizes material yield through precision cutting technology. These systems adapt to diverse quarrying environments and stone types while improving workplace safety through automated operations.

From large-scale quarry extraction to precision block cutting, modern quarrying equipment enables efficient processing of marble, granite, limestone, sandstone, basalt, quartzite, and other natural stones. DINOSAW offers comprehensive quarrying solutions that address the entire extraction workflow, significantly impacting operational productivity, product quality, and overall profitability of quarrying operations.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to Advanced Quarrying Machines

Quarrying operations require efficient and reliable equipment to extract natural stones like marble, granite, and sandstone. Dinosaw’s lineup of quarry wire saw machines, double blade quarrying machines, and chainsaws is designed to meet the demands of modern quarries, offering advanced technology and superior performance.

This guide highlights the features and advantages of these machines, helping you select the best solution for your quarrying needs.

What Are Quarrying Machines?

Quarrying machines are specialized tools used to extract large stone blocks from quarries efficiently and safely. These machines utilize advanced cutting technologies to improve productivity, minimize material waste, and streamline operations.

Primary Types of Quarrying Machines

Quarry wire saw machines are precision tools for cutting large stone blocks.

Double blade quarrying machines offer high-efficiency vertical cutting capabilities.

Chainsaws provide versatile solutions for flexible quarrying tasks.

Materials Processed

Quarrying machines are designed for natural stones, including marble, granite, sandstone, limestone, quartzite, and basalt.

Types of Quarrying Machines

Quarry Wire Saw Machines

Wire saw machines utilize diamond-coated wires for high-precision and large-scale quarrying.

Key Features

Diamond wire technology enables smooth, precise cuts with minimal waste.

Automatic tension control reduces vibration and enhances cutting efficiency.

Eco-friendly operation produces low noise and minimal dust.

Advantages

Handles deep cuts with exceptional precision.

Adapts to various quarry layouts and terrains.

Provides excellent block recovery rates and smooth surfaces.

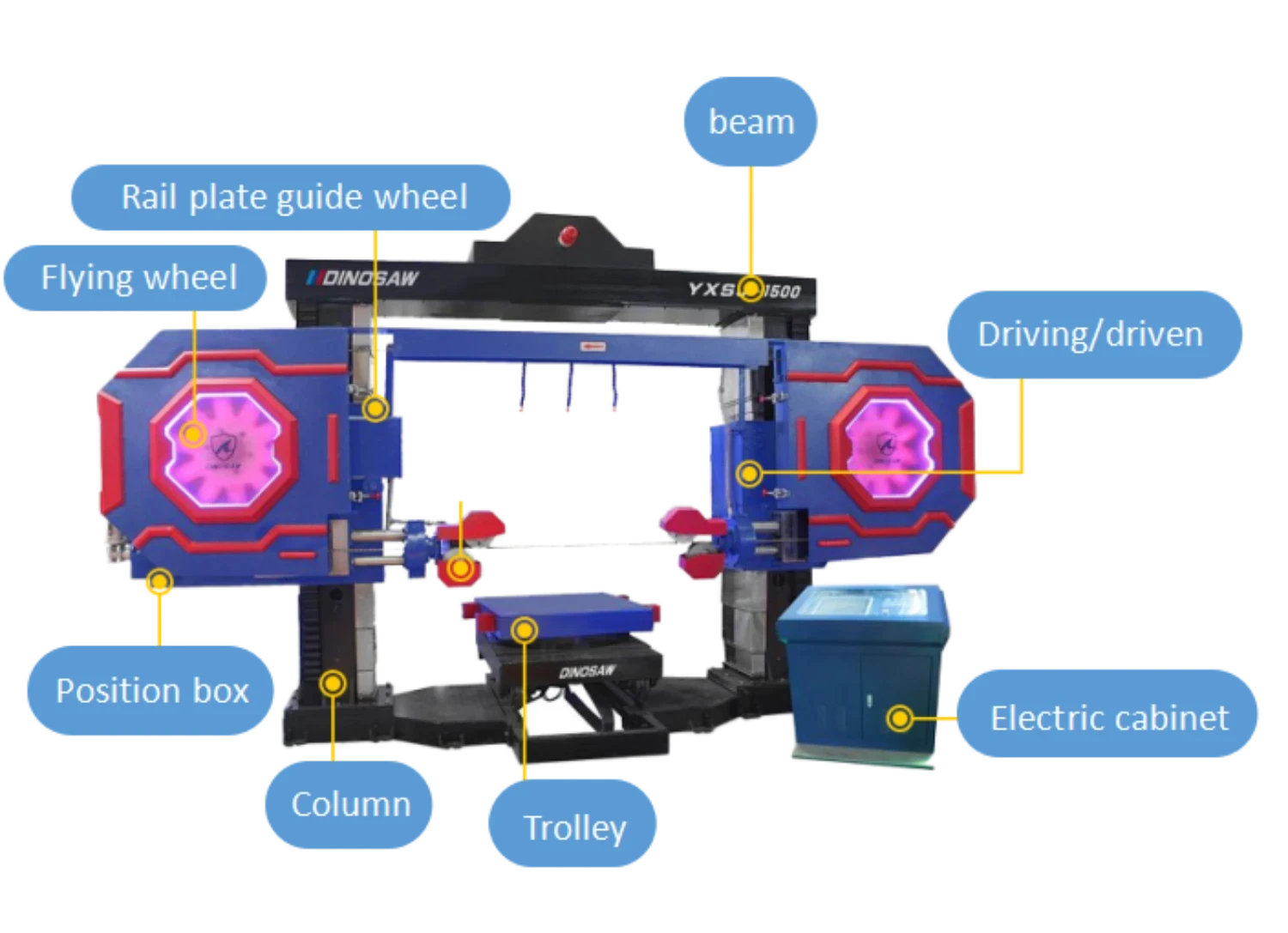

Double Blade Quarrying Machines

Double blade machines are designed for efficient vertical cutting in stone quarries.

Key Features

Large blade configurations facilitate cutting of both soft and hard stones.

Automated speed control enhances cutting accuracy.

User-friendly designs simplify operation and reduce fatigue.

Advantages

Delivers high cutting efficiency and cost-effectiveness.

Perfect for quarries requiring vertical cutting.

Minimizes manual labor and operational expenses.

Chainsaws

Chainsaws offer unmatched versatility, particularly in challenging quarrying terrains.

Key Features

Wear-resistant chains ensure durability in various conditions.

360-degree cutting capabilities handle both vertical and horizontal cuts with precision.

Compact and portable designs enable easy transport and operation in confined spaces.

Advantages

Ideal for intricate quarrying and shaping tasks.

Performs well with softer stones like limestone and sandstone.

Provides high recovery rates and smooth cutting surfaces.

Sandstone Cutting Machines

Key Features

Specialized cutting mechanisms for softer materials

precision control systems for dimensional accuracy

durable components for reliable operation.

Advantages

Optimized for sandstone and similar materials

reduced material waste

consistent cutting quality.

Steps to Choosing the Right Quarrying Machine

Define your quarrying needs by identifying the type of stone in your quarry, such as marble or granite, and determining your operational focus, whether it’s block extraction, vertical cutting, or edge shaping.

Compare machine features and capabilities to match your needs. Quarry wire saw machines are ideal for precision block cutting, double blade machines excel in vertical cutting, and chainsaws provide flexibility for irregular terrains.

Consult with Dinosaw experts to discuss geological conditions, material types, and production goals. Receive tailored advice on configurations and features.

Evaluate operational efficiency by analyzing investment costs versus benefits like improved recovery rates and reduced labor. Consider maintenance and energy consumption for sustainable operations.

Test and install the machine by requesting demonstrations and scheduling professional installation and training to optimize usage.

Why Choose Dinosaw Quarrying Machines?

Dinosaw quarrying machines are trusted for their advanced cutting technologies, versatile applications, and durable construction. With diamond wire, large blades, and durable chains, they deliver precision and efficiency in various quarrying environments. Eco-friendly solutions, including low noise and minimal dust, align with modern sustainability goals. Comprehensive global support ensures smooth operations and expert training.

Conclusion

Selecting the right quarrying machine is crucial for optimizing productivity and achieving high-quality results. Dinosaw’s quarry wire saw machines, double blade quarrying machines, and chainsaws combine advanced technology, reliability, and efficiency to handle diverse quarrying tasks.

Contact Dinosaw today to find the perfect solution for your quarrying operations!

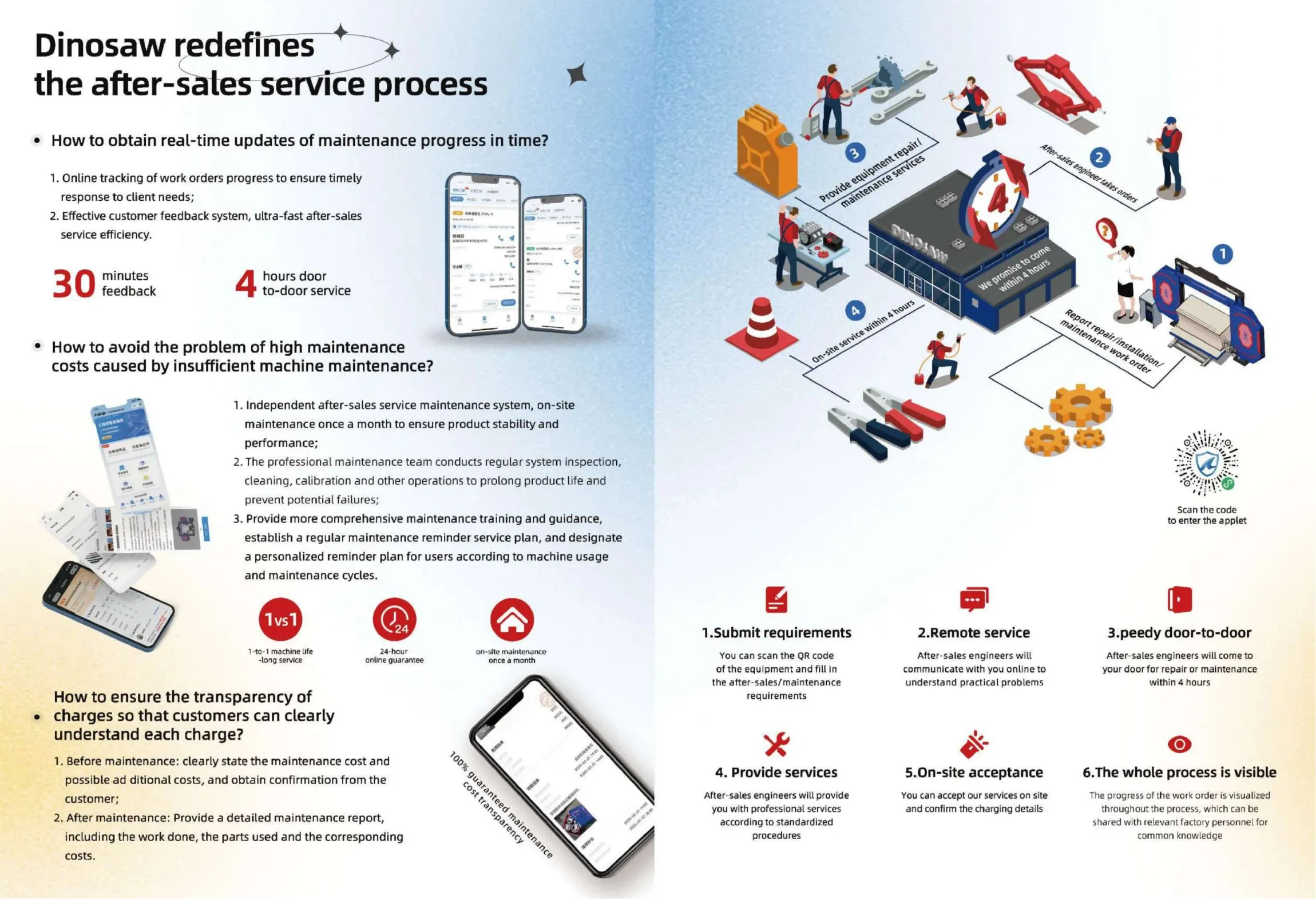

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Last Updated:

2025-04-15

Professional Stone Quarrying Equipment & Mining Machinery

DINOSAW delivers high-performance mining and quarrying machinery engineered for precision stone extraction. Our comprehensive range includes quarrying wire saws, circular saws, block cutting machines and chain saws that maximize efficiency while minimizing waste for marble, granite, sandstone, and limestone quarrying operations.

Granite

Marble

sandstone

basalt

shale

Mining And Quarrying Machinery Types

DINOSAW offers four primary categories of mining and quarrying equipment, each designed for specific extraction and processing requirements in professional stone quarrying operations:

Quarry Wire Saw Machines: Advanced diamond wire technology delivers precise block separation with minimal waste, ideal for extracting large dimension stones from quarry faces

Portable Trimming Wire Saw Machines: Compact, modular design for on-site trimming and shaping, perfect for special environment operations and mobile projects requiring flexibility

Double Blade Cutter Stone Quarrying Machines: Heavy-duty equipment for dimensional stone cutting with superior accuracy and efficient operation for processing blocks into commercial sizes

Sandstone Cutting Machines for Quarrying: Specialized equipment designed specifically for efficient cutting of softer stone materials with maximum precision and reliability

What is Mining and Quarry Machine?

Mining and Quarry Machines are specialized equipment designed for extracting dimensional stone from quarries and processing raw blocks into commercial products. These machines utilize advanced technologies to efficiently separate stone blocks from natural deposits while maintaining the material's structural integrity and commercial value.

Modern quarrying equipment combines precision engineering with powerful cutting mechanisms, allowing operators to extract stone with minimal waste and environmental impact. The advanced machinery enhances extraction efficiency, reduces labor requirements, and maximizes material yield through precision cutting technology. These systems adapt to diverse quarrying environments and stone types while improving workplace safety through automated operations.

From large-scale quarry extraction to precision block cutting, modern quarrying equipment enables efficient processing of marble, granite, limestone, sandstone, basalt, quartzite, and other natural stones. DINOSAW offers comprehensive quarrying solutions that address the entire extraction workflow, significantly impacting operational productivity, product quality, and overall profitability of quarrying operations.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

Your Guide to Advanced Quarrying Machines

Quarrying operations require efficient and reliable equipment to extract natural stones like marble, granite, and sandstone. Dinosaw’s lineup of quarry wire saw machines, double blade quarrying machines, and chainsaws is designed to meet the demands of modern quarries, offering advanced technology and superior performance.

This guide highlights the features and advantages of these machines, helping you select the best solution for your quarrying needs.

What Are Quarrying Machines?

Quarrying machines are specialized tools used to extract large stone blocks from quarries efficiently and safely. These machines utilize advanced cutting technologies to improve productivity, minimize material waste, and streamline operations.

Primary Types of Quarrying Machines

Quarry wire saw machines are precision tools for cutting large stone blocks.

Double blade quarrying machines offer high-efficiency vertical cutting capabilities.

Chainsaws provide versatile solutions for flexible quarrying tasks.

Materials Processed

Quarrying machines are designed for natural stones, including marble, granite, sandstone, limestone, quartzite, and basalt.

Types of Quarrying Machines

Quarry Wire Saw Machines

Wire saw machines utilize diamond-coated wires for high-precision and large-scale quarrying.

Key Features

Diamond wire technology enables smooth, precise cuts with minimal waste.

Automatic tension control reduces vibration and enhances cutting efficiency.

Eco-friendly operation produces low noise and minimal dust.

Advantages

Handles deep cuts with exceptional precision.

Adapts to various quarry layouts and terrains.

Provides excellent block recovery rates and smooth surfaces.

Double Blade Quarrying Machines

Double blade machines are designed for efficient vertical cutting in stone quarries.

Key Features

Large blade configurations facilitate cutting of both soft and hard stones.

Automated speed control enhances cutting accuracy.

User-friendly designs simplify operation and reduce fatigue.

Advantages

Delivers high cutting efficiency and cost-effectiveness.

Perfect for quarries requiring vertical cutting.

Minimizes manual labor and operational expenses.

Chainsaws

Chainsaws offer unmatched versatility, particularly in challenging quarrying terrains.

Key Features

Wear-resistant chains ensure durability in various conditions.

360-degree cutting capabilities handle both vertical and horizontal cuts with precision.

Compact and portable designs enable easy transport and operation in confined spaces.

Advantages

Ideal for intricate quarrying and shaping tasks.

Performs well with softer stones like limestone and sandstone.

Provides high recovery rates and smooth cutting surfaces.

Sandstone Cutting Machines

Key Features

Specialized cutting mechanisms for softer materials

precision control systems for dimensional accuracy

durable components for reliable operation.

Advantages

Optimized for sandstone and similar materials

reduced material waste

consistent cutting quality.

Steps to Choosing the Right Quarrying Machine

Define your quarrying needs by identifying the type of stone in your quarry, such as marble or granite, and determining your operational focus, whether it’s block extraction, vertical cutting, or edge shaping.

Compare machine features and capabilities to match your needs. Quarry wire saw machines are ideal for precision block cutting, double blade machines excel in vertical cutting, and chainsaws provide flexibility for irregular terrains.

Consult with Dinosaw experts to discuss geological conditions, material types, and production goals. Receive tailored advice on configurations and features.

Evaluate operational efficiency by analyzing investment costs versus benefits like improved recovery rates and reduced labor. Consider maintenance and energy consumption for sustainable operations.

Test and install the machine by requesting demonstrations and scheduling professional installation and training to optimize usage.

Why Choose Dinosaw Quarrying Machines?

Dinosaw quarrying machines are trusted for their advanced cutting technologies, versatile applications, and durable construction. With diamond wire, large blades, and durable chains, they deliver precision and efficiency in various quarrying environments. Eco-friendly solutions, including low noise and minimal dust, align with modern sustainability goals. Comprehensive global support ensures smooth operations and expert training.

Conclusion

Selecting the right quarrying machine is crucial for optimizing productivity and achieving high-quality results. Dinosaw’s quarry wire saw machines, double blade quarrying machines, and chainsaws combine advanced technology, reliability, and efficiency to handle diverse quarrying tasks.

Contact Dinosaw today to find the perfect solution for your quarrying operations!

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment