Last Updated:

2025-01-15

Last Updated:

2025-01-15

Discover High-Performance Diamond Tools

Diamond tools are advanced industrial tools leveraging the unparalleled hardness and durability of synthetic or natural diamonds. Key products include diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. These tools enable precise cutting, drilling, and finishing across a variety of materials, including stone, concrete, ceramics, and glass.

Granite

Marble

cement

ceramic

terrazzo

quartz

limestone

basalt

Last Updated:

2025-04-15

Discover High-Performance Diamond Tools

Diamond tools are advanced industrial tools leveraging the unparalleled hardness and durability of synthetic or natural diamonds. Key products include diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. These tools enable precise cutting, drilling, and finishing across a variety of materials, including stone, concrete, ceramics, and glass.

Granite

Marble

cement

ceramic

terrazzo

quartz

limestone

basalt

Last Updated:

2025-04-15

Last Updated:

2025-01-15

Last Updated:

2025-01-15

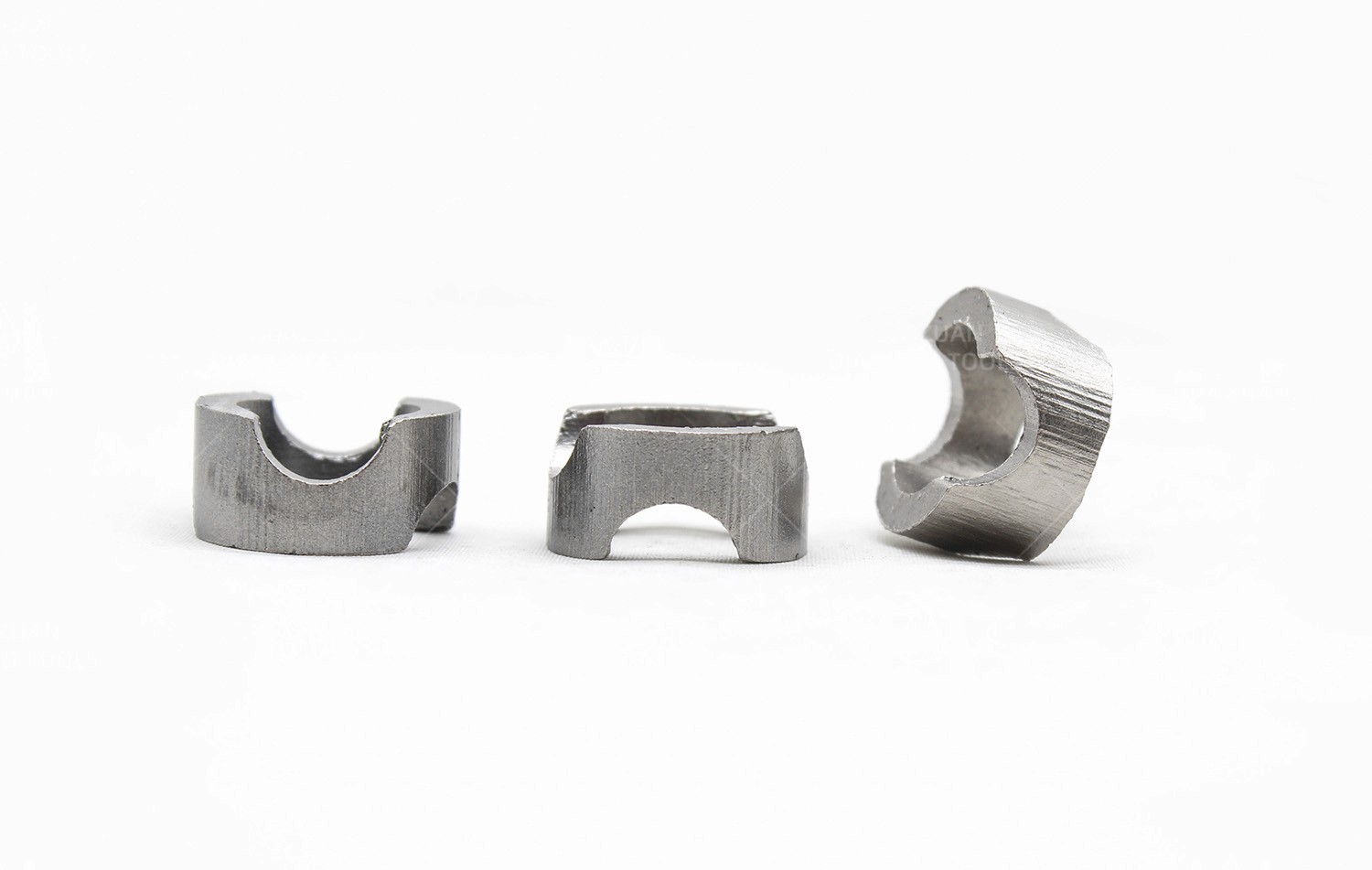

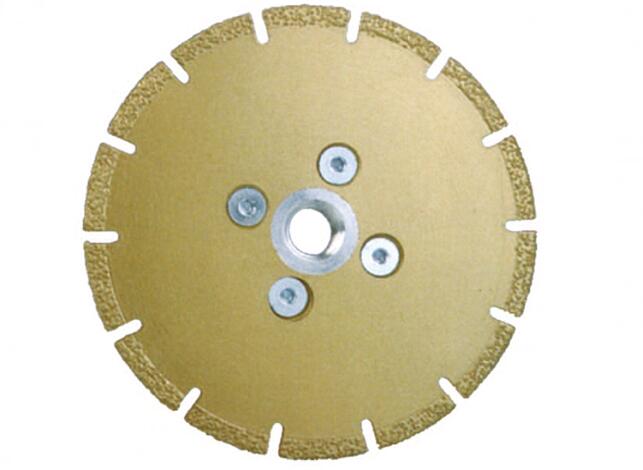

Diamond Segment

Diamond Segments are key components for tools like circular saw blades and multi-blade saws. They are made with high-quality synthetic diamonds and metal bonds, providing efficient and precise cutting of hard materials such as granite, marble, limestone, and concrete. Dinosaw’s segments are engineered for durability and high performance, ensuring smooth cutting, reduced material waste, and long tool life in various stone and construction applications.

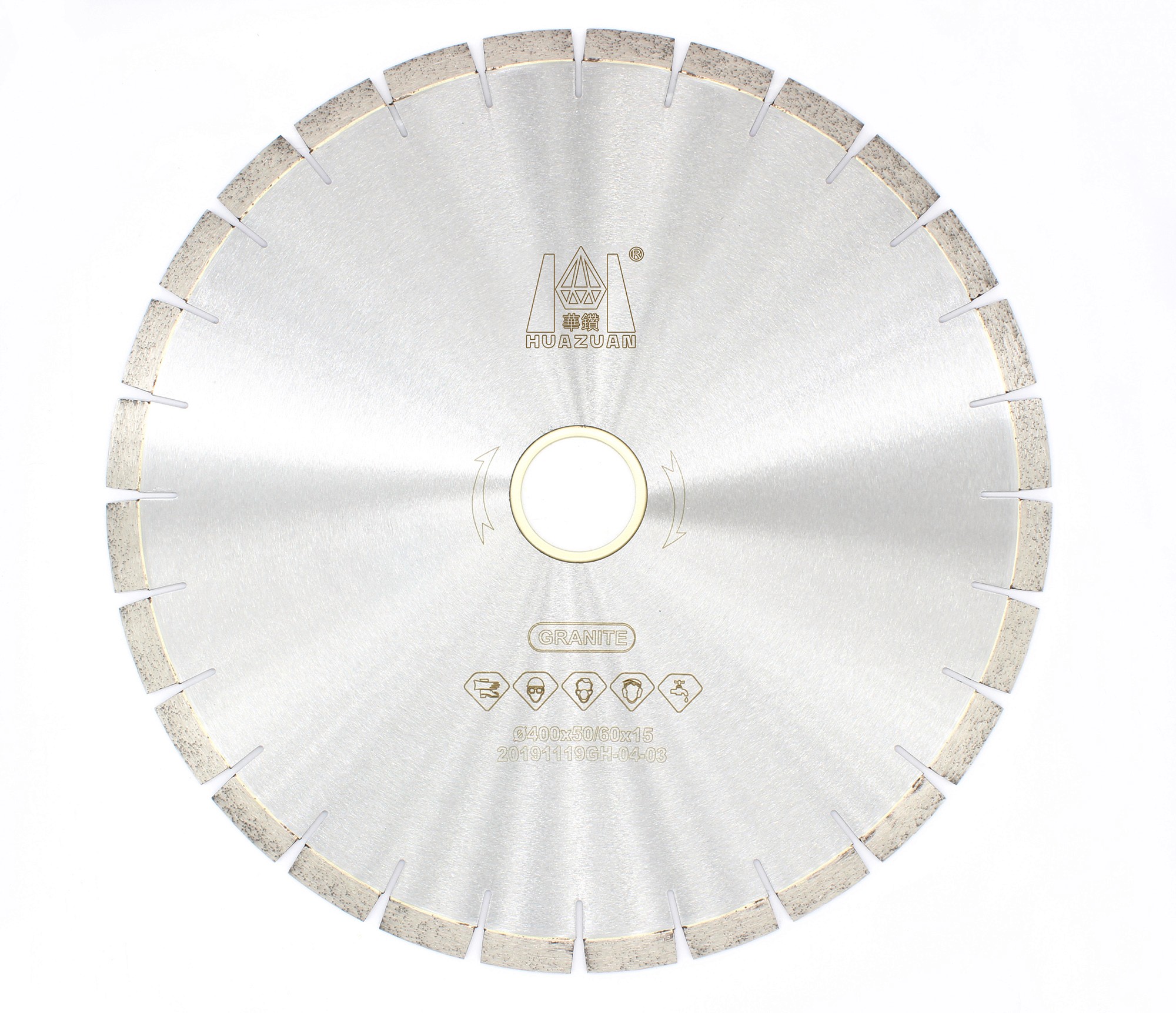

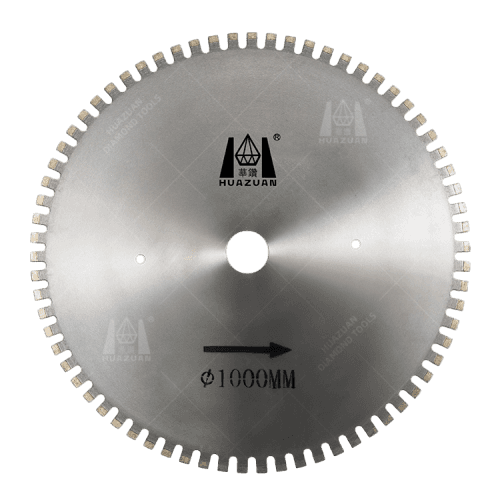

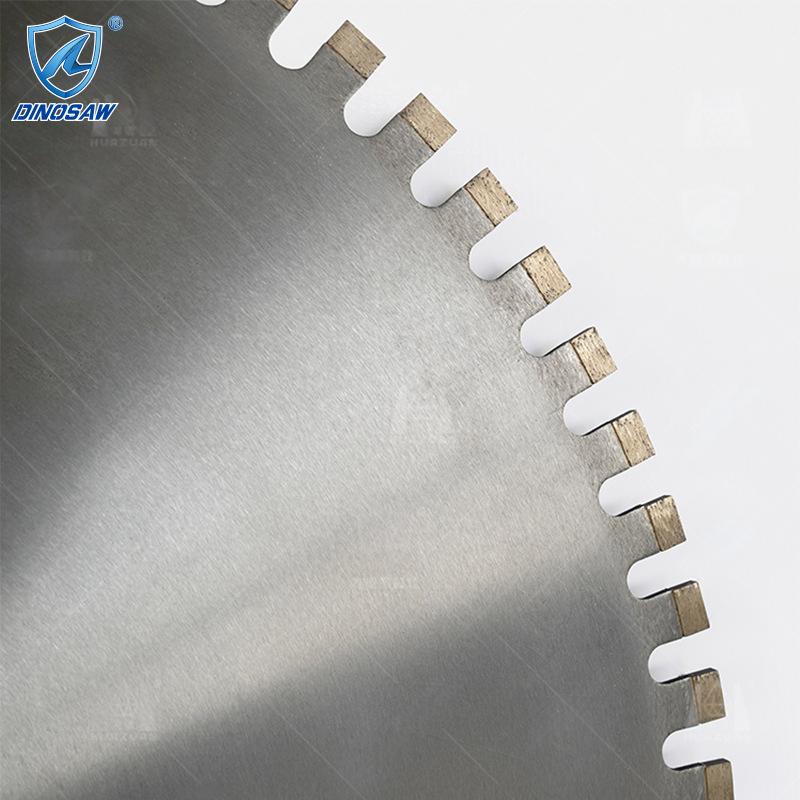

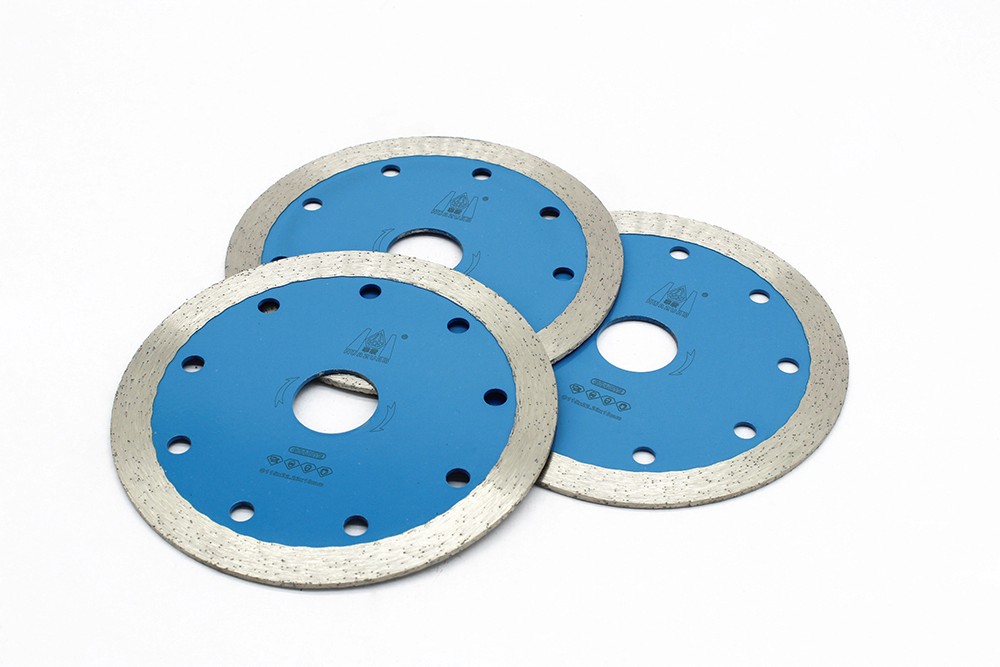

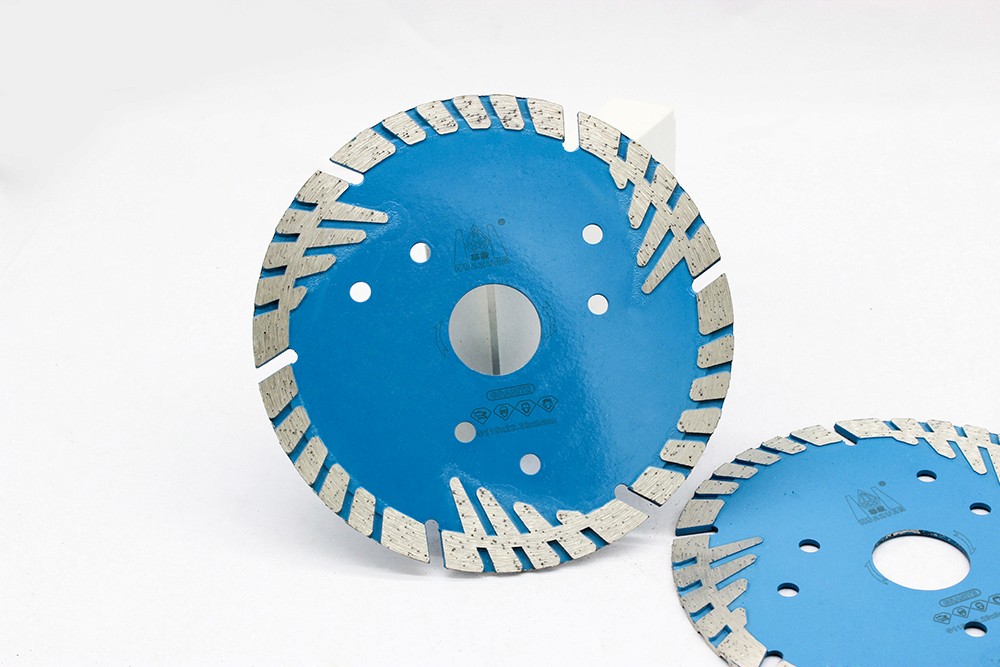

Diamond Saw Blade

Diamond Saw Blades are designed for cutting through a wide range of materials, including granite, marble, concrete, asphalt, and ceramics. With diamond-tipped segments welded to a steel core, these blades deliver fast, precise, and clean cuts. Dinosaw’s blades come in various sizes and configurations to suit both wet and dry cutting, making them a reliable choice for construction, roadwork, and stone processing projects.

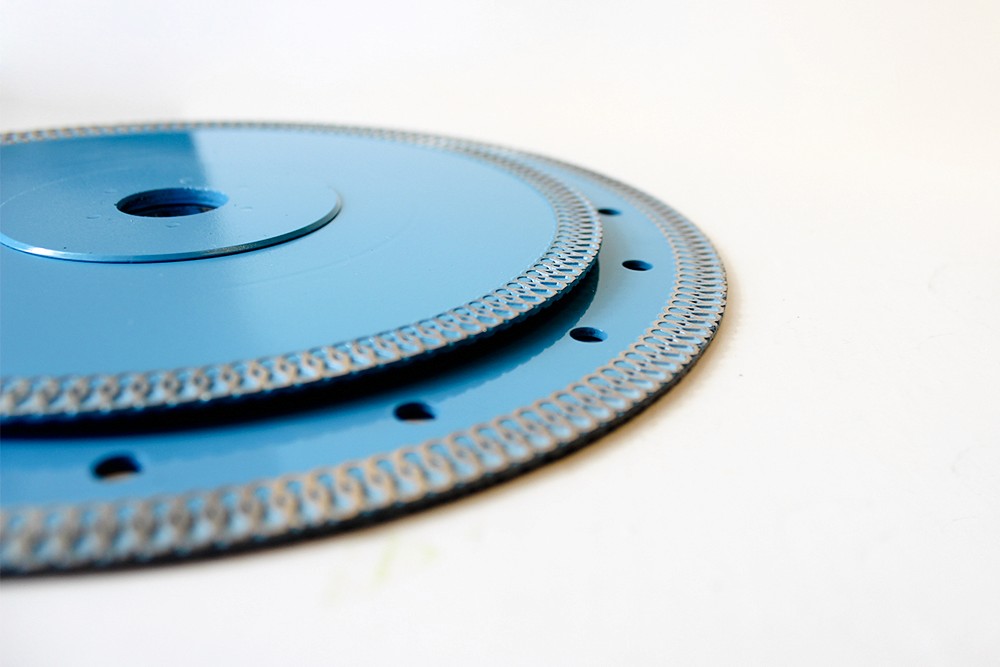

Diamond Cutting Disc

Diamond Cutting Discs are specialized for high-speed cutting of materials such as stone, concrete, ceramics, and metals. Featuring a reinforced steel body and diamond segments, they offer smooth and precise cutting performance. Dinosaw’s discs are suitable for angle grinders and other handheld machines, providing reliable solutions for fine cuts and detailed work in various industries.

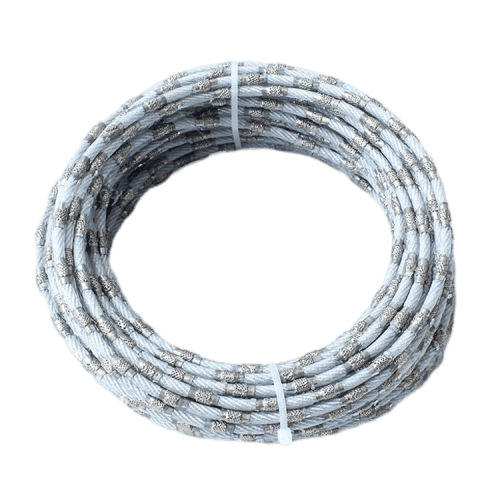

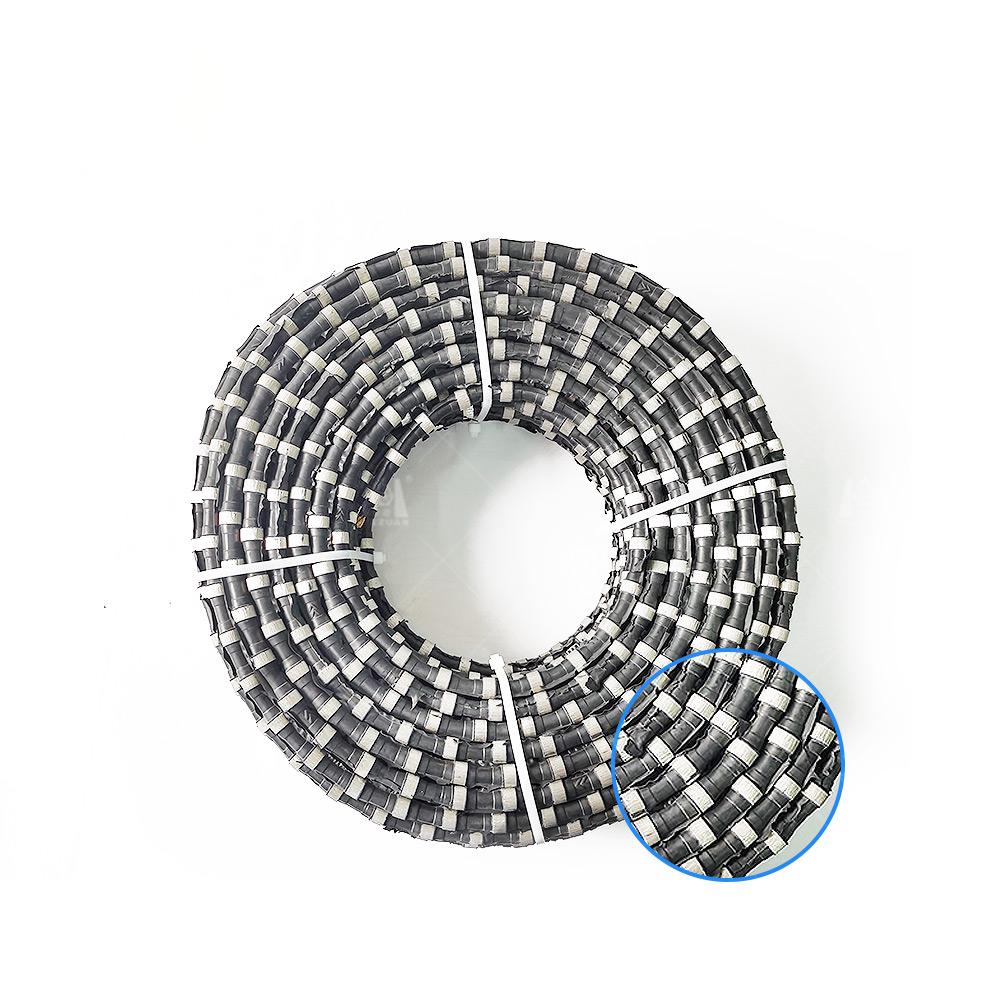

Diamond Wire Saw

Diamond Wire Saws utilize diamond-beaded wires for cutting large stone blocks, concrete structures, and metals. These tools are ideal for quarrying, shaping, and demolition tasks, offering minimal material waste and high cutting precision. Dinosaw’s wire saws are tailored for different materials and applications, ensuring efficient and flexible cutting solutions for industrial and architectural projects.

Diamond Core Drill Bit

Diamond Core Drill Bits are designed for drilling precise holes in hard materials like granite, marble, concrete, and ceramics. They feature diamond-encrusted cutting edges for smooth and efficient drilling with minimal damage to the surrounding material. Dinosaw’s core drill bits are available in various sizes and configurations, making them essential for construction, stone processing, and engineering tasks.

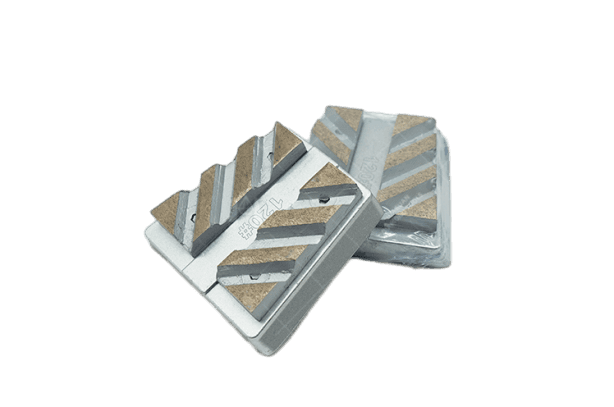

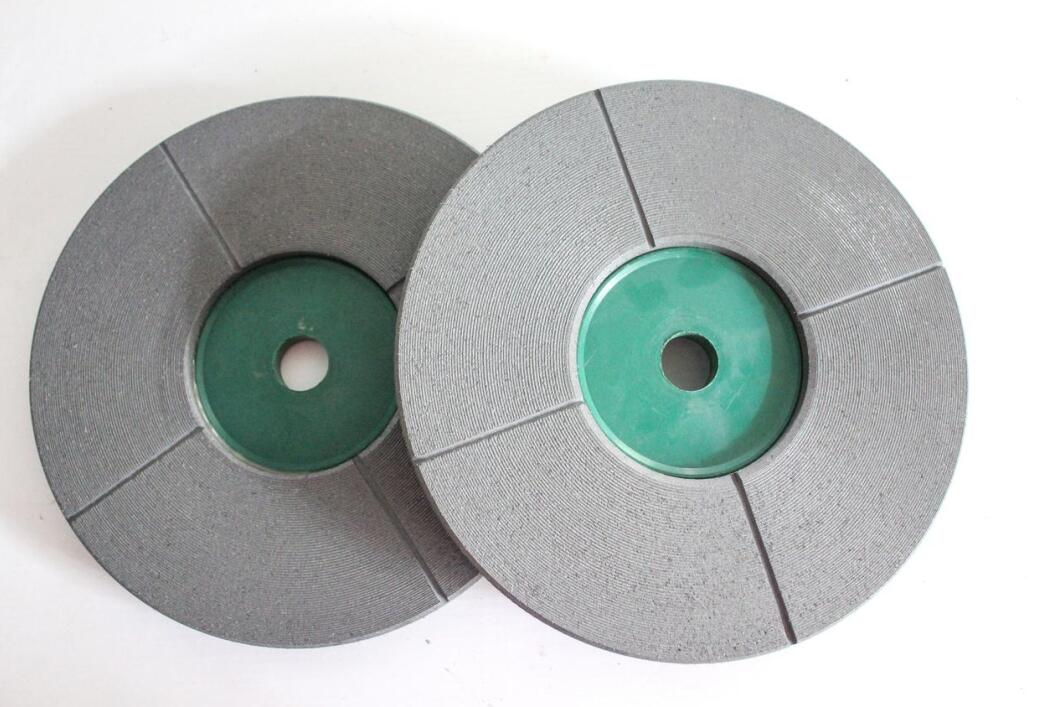

Diamond Grinding and Polishing Tools

Diamond Grinding and Polishing Tools are used for surface finishing, edge smoothing, and shape refining of materials such as stone, concrete, and ceramics. Equipped with diamond abrasives, these tools provide high efficiency and precision, delivering a polished and flawless finish. Dinosaw’s range includes grinding wheels, polishing pads, and abrasive discs, suitable for various applications in stone processing, construction, and decorative industries.

What are Diamond Tools?

Diamond tools are specialized industrial tools that incorporate diamonds for cutting, grinding, and drilling. Key categories include:

Diamond Segments: Used in saws, drills, and grinders for precision cutting and grinding.

Diamond Saw Blades: Versatile cutting tools for stone and construction materials.

Diamond Cutting Discs: Thin, durable discs for delicate cuts on ceramics and glass.

Diamond Wire Saws: Flexible tools for quarrying and shaping large stone blocks.

Diamond Core Drill Bits: High-performance bits for clean, precise drilling.

Diamond Grinding and Polishing Tools: Tools for surface leveling and finishing.

Applications: Widely used in stone processing, construction, ceramic fabrication, and glasswork.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to High-Performance Diamond Tools

Diamond tools are indispensable for cutting, drilling, grinding, and polishing hard materials. Dinosaw’s lineup includes diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. Renowned for their adaptability, precision, and durability, these tools are compatible with most machines on the market.

This guide explores the features and considerations for selecting diamond tools to meet your specific needs.

What Are Diamond Tools?

Diamond tools incorporate synthetic or natural diamonds into cutting, grinding, or drilling surfaces, leveraging their unmatched hardness to process challenging materials efficiently.

Key Categories

Diamond Segment: Essential components for saws, drills, and grinders.

Diamond Saw Blade: Versatile blades for cutting stones and construction materials.

Diamond Cutting Disc: Thin, precise tools for ceramics, glass, and tiles.

Diamond Wire Saw: Flexible tools for large-scale cutting tasks.

Diamond Core Drill Bit: High-precision tools for drilling hard materials.

Grinding and Polishing Tools: For leveling and surface finishing.

Key Advantage

Wide Compatibility: Suitable for most machines of similar types, ensuring flexibility and ease of use across brands and models.

Types of Diamond Tools

Diamond Segment

Diamond segments are integral to cutting and grinding tools, embedded with diamond particles for high performance and durability.

Key Features

Segmented, turbo, and continuous styles for diverse applications.

High-strength metal bonds ensure long-lasting performance.

Diamond Saw Blade

Diamond saw blades are high-speed tools designed for efficient and precise cutting across various materials.

Key Features

Embedded diamond particles for sharp, durable edges.

Available in different sizes and segment styles for material-specific cutting.

Diamond Cutting Disc

Diamond cutting discs are ultra-thin tools engineered for precision cutting with minimal material loss.

Key Features

Thin profiles for clean, chip-free cuts.

Durable diamond edges extend lifespan.

Diamond Wire Saw

Diamond wire saws are flexible tools designed for precision and eco-friendly large-scale cutting tasks.

Key Features

Flexible steel wires embedded with diamond beads for smooth and accurate cuts.

Reduces waste and material loss during cutting.

Diamond Core Drill Bit

Diamond core drill bits provide clean and efficient drilling through tough materials, making them indispensable in construction and manufacturing.

Key Features

Diamond-encrusted tips for superior cutting performance.

Wide range of diameters to suit various applications.

Grinding and Polishing Tools

Grinding and polishing tools enhance surface finishing, delivering uniform results for a variety of materials.

Key Features

Industrial diamonds ensure consistent grinding and polishing.

Compatible with a range of grinding and polishing machines.

Considerations for Selecting Diamond Tools

Material Compatibility

Ensure the tool matches the materials you process, such as granite, concrete, or ceramics.

Machine Compatibility

These tools are designed for universal compatibility with most machines on the market, ensuring seamless integration regardless of brand or model. Confirm machine-specific requirements like speed, power, and mounting systems.

Task Requirements

Select tools based on your operational needs: cutting, grinding, or drilling.

Tool Longevity

Opt for high-quality tools to ensure durability and reduce overall operational costs.

Efficiency

Choose tools that minimize material waste and enhance productivity.

Why Choose Dinosaw Diamond Tools?

Dinosaw’s diamond tools are trusted by professionals worldwide for their:

Precision and Durability Advanced diamond technologies ensure exceptional performance.

Universal Compatibility Designed to work seamlessly with most machines on the market.

Efficiency Reduces waste while maximizing productivity.

Reliable Quality Manufactured to rigorous industrial standards.

Comprehensive Support Expert after-sales service for uninterrupted operations.

Conclusion

Diamond tools are crucial for achieving precision and efficiency in industrial tasks. With wide compatibility and proven durability, Dinosaw’s diamond tools are an excellent choice for cutting, drilling, grinding, and polishing.

Contact Dinosaw today to explore our range of high-performance diamond tools for your industrial needs!

Diamond Segment

Diamond Segments are key components for tools like circular saw blades and multi-blade saws. They are made with high-quality synthetic diamonds and metal bonds, providing efficient and precise cutting of hard materials such as granite, marble, limestone, and concrete. Dinosaw’s segments are engineered for durability and high performance, ensuring smooth cutting, reduced material waste, and long tool life in various stone and construction applications.

Diamond Saw Blade

Diamond Saw Blades are designed for cutting through a wide range of materials, including granite, marble, concrete, asphalt, and ceramics. With diamond-tipped segments welded to a steel core, these blades deliver fast, precise, and clean cuts. Dinosaw’s blades come in various sizes and configurations to suit both wet and dry cutting, making them a reliable choice for construction, roadwork, and stone processing projects.

Diamond Cutting Disc

Diamond Cutting Discs are specialized for high-speed cutting of materials such as stone, concrete, ceramics, and metals. Featuring a reinforced steel body and diamond segments, they offer smooth and precise cutting performance. Dinosaw’s discs are suitable for angle grinders and other handheld machines, providing reliable solutions for fine cuts and detailed work in various industries.

Diamond Wire Saw

Diamond Wire Saws utilize diamond-beaded wires for cutting large stone blocks, concrete structures, and metals. These tools are ideal for quarrying, shaping, and demolition tasks, offering minimal material waste and high cutting precision. Dinosaw’s wire saws are tailored for different materials and applications, ensuring efficient and flexible cutting solutions for industrial and architectural projects.

Diamond Core Drill Bit

Diamond Core Drill Bits are designed for drilling precise holes in hard materials like granite, marble, concrete, and ceramics. They feature diamond-encrusted cutting edges for smooth and efficient drilling with minimal damage to the surrounding material. Dinosaw’s core drill bits are available in various sizes and configurations, making them essential for construction, stone processing, and engineering tasks.

Diamond Grinding and Polishing Tools

Diamond Grinding and Polishing Tools are used for surface finishing, edge smoothing, and shape refining of materials such as stone, concrete, and ceramics. Equipped with diamond abrasives, these tools provide high efficiency and precision, delivering a polished and flawless finish. Dinosaw’s range includes grinding wheels, polishing pads, and abrasive discs, suitable for various applications in stone processing, construction, and decorative industries.

What are Diamond Tools?

Diamond tools are specialized industrial tools that incorporate diamonds for cutting, grinding, and drilling. Key categories include:

Diamond Segments: Used in saws, drills, and grinders for precision cutting and grinding.

Diamond Saw Blades: Versatile cutting tools for stone and construction materials.

Diamond Cutting Discs: Thin, durable discs for delicate cuts on ceramics and glass.

Diamond Wire Saws: Flexible tools for quarrying and shaping large stone blocks.

Diamond Core Drill Bits: High-performance bits for clean, precise drilling.

Diamond Grinding and Polishing Tools: Tools for surface leveling and finishing.

Applications: Widely used in stone processing, construction, ceramic fabrication, and glasswork.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to High-Performance Diamond Tools

Diamond tools are indispensable for cutting, drilling, grinding, and polishing hard materials. Dinosaw’s lineup includes diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. Renowned for their adaptability, precision, and durability, these tools are compatible with most machines on the market.

This guide explores the features and considerations for selecting diamond tools to meet your specific needs.

What Are Diamond Tools?

Diamond tools incorporate synthetic or natural diamonds into cutting, grinding, or drilling surfaces, leveraging their unmatched hardness to process challenging materials efficiently.

Key Categories

Diamond Segment: Essential components for saws, drills, and grinders.

Diamond Saw Blade: Versatile blades for cutting stones and construction materials.

Diamond Cutting Disc: Thin, precise tools for ceramics, glass, and tiles.

Diamond Wire Saw: Flexible tools for large-scale cutting tasks.

Diamond Core Drill Bit: High-precision tools for drilling hard materials.

Grinding and Polishing Tools: For leveling and surface finishing.

Key Advantage

Wide Compatibility: Suitable for most machines of similar types, ensuring flexibility and ease of use across brands and models.

Types of Diamond Tools

Diamond Segment

Diamond segments are integral to cutting and grinding tools, embedded with diamond particles for high performance and durability.

Key Features

Segmented, turbo, and continuous styles for diverse applications.

High-strength metal bonds ensure long-lasting performance.

Diamond Saw Blade

Diamond saw blades are high-speed tools designed for efficient and precise cutting across various materials.

Key Features

Embedded diamond particles for sharp, durable edges.

Available in different sizes and segment styles for material-specific cutting.

Diamond Cutting Disc

Diamond cutting discs are ultra-thin tools engineered for precision cutting with minimal material loss.

Key Features

Thin profiles for clean, chip-free cuts.

Durable diamond edges extend lifespan.

Diamond Wire Saw

Diamond wire saws are flexible tools designed for precision and eco-friendly large-scale cutting tasks.

Key Features

Flexible steel wires embedded with diamond beads for smooth and accurate cuts.

Reduces waste and material loss during cutting.

Diamond Core Drill Bit

Diamond core drill bits provide clean and efficient drilling through tough materials, making them indispensable in construction and manufacturing.

Key Features

Diamond-encrusted tips for superior cutting performance.

Wide range of diameters to suit various applications.

Grinding and Polishing Tools

Grinding and polishing tools enhance surface finishing, delivering uniform results for a variety of materials.

Key Features

Industrial diamonds ensure consistent grinding and polishing.

Compatible with a range of grinding and polishing machines.

Considerations for Selecting Diamond Tools

Material Compatibility

Ensure the tool matches the materials you process, such as granite, concrete, or ceramics.

Machine Compatibility

These tools are designed for universal compatibility with most machines on the market, ensuring seamless integration regardless of brand or model. Confirm machine-specific requirements like speed, power, and mounting systems.

Task Requirements

Select tools based on your operational needs: cutting, grinding, or drilling.

Tool Longevity

Opt for high-quality tools to ensure durability and reduce overall operational costs.

Efficiency

Choose tools that minimize material waste and enhance productivity.

Why Choose Dinosaw Diamond Tools?

Dinosaw’s diamond tools are trusted by professionals worldwide for their:

Precision and Durability Advanced diamond technologies ensure exceptional performance.

Universal Compatibility Designed to work seamlessly with most machines on the market.

Efficiency Reduces waste while maximizing productivity.

Reliable Quality Manufactured to rigorous industrial standards.

Comprehensive Support Expert after-sales service for uninterrupted operations.

Conclusion

Diamond tools are crucial for achieving precision and efficiency in industrial tasks. With wide compatibility and proven durability, Dinosaw’s diamond tools are an excellent choice for cutting, drilling, grinding, and polishing.

Contact Dinosaw today to explore our range of high-performance diamond tools for your industrial needs!

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Last Updated:

2025-01-15

Last Updated:

2025-01-15

Last Updated:

2025-04-15

Discover High-Performance Diamond Tools

Diamond tools are advanced industrial tools leveraging the unparalleled hardness and durability of synthetic or natural diamonds. Key products include diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. These tools enable precise cutting, drilling, and finishing across a variety of materials, including stone, concrete, ceramics, and glass.

Granite

Marble

cement

ceramic

terrazzo

quartz

limestone

basalt

Diamond Segment

Diamond Segments are key components for tools like circular saw blades and multi-blade saws. They are made with high-quality synthetic diamonds and metal bonds, providing efficient and precise cutting of hard materials such as granite, marble, limestone, and concrete. Dinosaw’s segments are engineered for durability and high performance, ensuring smooth cutting, reduced material waste, and long tool life in various stone and construction applications.

Diamond Saw Blade

Diamond Saw Blades are designed for cutting through a wide range of materials, including granite, marble, concrete, asphalt, and ceramics. With diamond-tipped segments welded to a steel core, these blades deliver fast, precise, and clean cuts. Dinosaw’s blades come in various sizes and configurations to suit both wet and dry cutting, making them a reliable choice for construction, roadwork, and stone processing projects.

Diamond Cutting Disc

Diamond Cutting Discs are specialized for high-speed cutting of materials such as stone, concrete, ceramics, and metals. Featuring a reinforced steel body and diamond segments, they offer smooth and precise cutting performance. Dinosaw’s discs are suitable for angle grinders and other handheld machines, providing reliable solutions for fine cuts and detailed work in various industries.

Diamond Core Drill Bit

Diamond Core Drill Bits are designed for drilling precise holes in hard materials like granite, marble, concrete, and ceramics. They feature diamond-encrusted cutting edges for smooth and efficient drilling with minimal damage to the surrounding material. Dinosaw’s core drill bits are available in various sizes and configurations, making them essential for construction, stone processing, and engineering tasks.

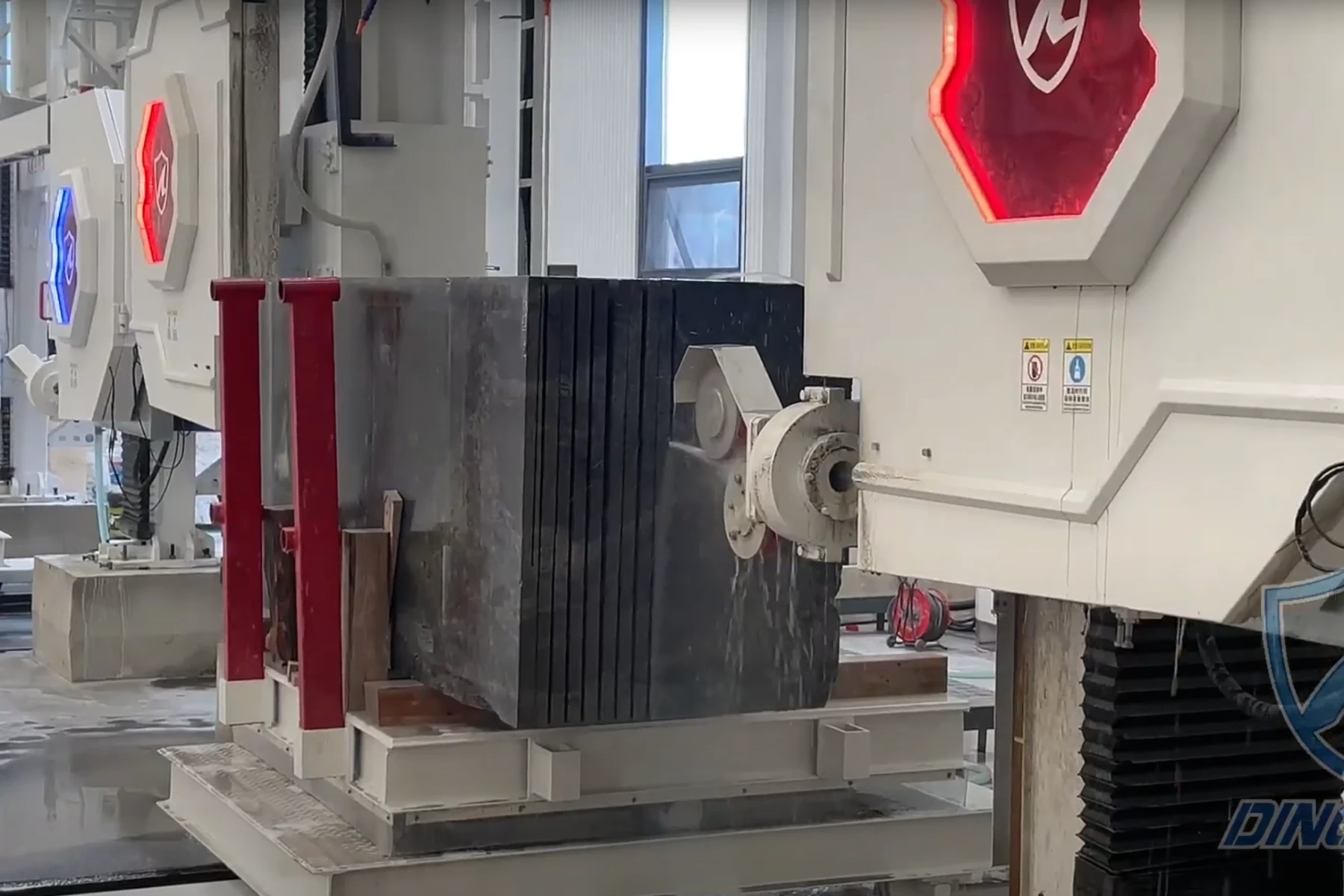

Diamond Wire Saw

Diamond Wire Saws utilize diamond-beaded wires for cutting large stone blocks, concrete structures, and metals. These tools are ideal for quarrying, shaping, and demolition tasks, offering minimal material waste and high cutting precision. Dinosaw’s wire saws are tailored for different materials and applications, ensuring efficient and flexible cutting solutions for industrial and architectural projects.

Diamond Grinding and Polishing Tools

Diamond Grinding and Polishing Tools are used for surface finishing, edge smoothing, and shape refining of materials such as stone, concrete, and ceramics. Equipped with diamond abrasives, these tools provide high efficiency and precision, delivering a polished and flawless finish. Dinosaw’s range includes grinding wheels, polishing pads, and abrasive discs, suitable for various applications in stone processing, construction, and decorative industries.

What are Diamond Tools?

Diamond tools are specialized industrial tools that incorporate diamonds for cutting, grinding, and drilling. Key categories include:

Diamond Segments: Used in saws, drills, and grinders for precision cutting and grinding.

Diamond Saw Blades: Versatile cutting tools for stone and construction materials.

Diamond Cutting Discs: Thin, durable discs for delicate cuts on ceramics and glass.

Diamond Wire Saws: Flexible tools for quarrying and shaping large stone blocks.

Diamond Core Drill Bits: High-performance bits for clean, precise drilling.

Diamond Grinding and Polishing Tools: Tools for surface leveling and finishing.

Applications: Widely used in stone processing, construction, ceramic fabrication, and glasswork.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

Your Guide to High-Performance Diamond Tools

Diamond tools are indispensable for cutting, drilling, grinding, and polishing hard materials. Dinosaw’s lineup includes diamond segments, saw blades, cutting discs, wire saws, core drill bits, and grinding and polishing tools. Renowned for their adaptability, precision, and durability, these tools are compatible with most machines on the market.

This guide explores the features and considerations for selecting diamond tools to meet your specific needs.

What Are Diamond Tools?

Diamond tools incorporate synthetic or natural diamonds into cutting, grinding, or drilling surfaces, leveraging their unmatched hardness to process challenging materials efficiently.

Key Categories

Diamond Segment: Essential components for saws, drills, and grinders.

Diamond Saw Blade: Versatile blades for cutting stones and construction materials.

Diamond Cutting Disc: Thin, precise tools for ceramics, glass, and tiles.

Diamond Wire Saw: Flexible tools for large-scale cutting tasks.

Diamond Core Drill Bit: High-precision tools for drilling hard materials.

Grinding and Polishing Tools: For leveling and surface finishing.

Key Advantage

Wide Compatibility: Suitable for most machines of similar types, ensuring flexibility and ease of use across brands and models.

Types of Diamond Tools

Diamond Segment

Diamond segments are integral to cutting and grinding tools, embedded with diamond particles for high performance and durability.

Key Features

Segmented, turbo, and continuous styles for diverse applications.

High-strength metal bonds ensure long-lasting performance.

Diamond Saw Blade

Diamond saw blades are high-speed tools designed for efficient and precise cutting across various materials.

Key Features

Embedded diamond particles for sharp, durable edges.

Available in different sizes and segment styles for material-specific cutting.

Diamond Cutting Disc

Diamond cutting discs are ultra-thin tools engineered for precision cutting with minimal material loss.

Key Features

Thin profiles for clean, chip-free cuts.

Durable diamond edges extend lifespan.

Diamond Wire Saw

Diamond wire saws are flexible tools designed for precision and eco-friendly large-scale cutting tasks.

Key Features

Flexible steel wires embedded with diamond beads for smooth and accurate cuts.

Reduces waste and material loss during cutting.

Diamond Core Drill Bit

Diamond core drill bits provide clean and efficient drilling through tough materials, making them indispensable in construction and manufacturing.

Key Features

Diamond-encrusted tips for superior cutting performance.

Wide range of diameters to suit various applications.

Grinding and Polishing Tools

Grinding and polishing tools enhance surface finishing, delivering uniform results for a variety of materials.

Key Features

Industrial diamonds ensure consistent grinding and polishing.

Compatible with a range of grinding and polishing machines.

Considerations for Selecting Diamond Tools

Material Compatibility

Ensure the tool matches the materials you process, such as granite, concrete, or ceramics.

Machine Compatibility

These tools are designed for universal compatibility with most machines on the market, ensuring seamless integration regardless of brand or model. Confirm machine-specific requirements like speed, power, and mounting systems.

Task Requirements

Select tools based on your operational needs: cutting, grinding, or drilling.

Tool Longevity

Opt for high-quality tools to ensure durability and reduce overall operational costs.

Efficiency

Choose tools that minimize material waste and enhance productivity.

Why Choose Dinosaw Diamond Tools?

Dinosaw’s diamond tools are trusted by professionals worldwide for their:

Precision and Durability Advanced diamond technologies ensure exceptional performance.

Universal Compatibility Designed to work seamlessly with most machines on the market.

Efficiency Reduces waste while maximizing productivity.

Reliable Quality Manufactured to rigorous industrial standards.

Comprehensive Support Expert after-sales service for uninterrupted operations.

Conclusion

Diamond tools are crucial for achieving precision and efficiency in industrial tasks. With wide compatibility and proven durability, Dinosaw’s diamond tools are an excellent choice for cutting, drilling, grinding, and polishing.

Contact Dinosaw today to explore our range of high-performance diamond tools for your industrial needs!

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: