Open Hours:

8:30am-20:30pm

Whatsapp:

Last Updated:

2025-04-15

The Best Wire Saw Machines for Cutting Hard Materials

Are you looking for wire saw machines, such as CNC mono wire saw machines or multi-wire saw machines? Dinosaw offers equipment suitable for cutting concrete, metals, and stones like granite, marble, sandstone, and jade. Whether for construction projects or new material processing, our machines deliver efficient and precise solutions to meet your needs.

Granite

Marble

luxurystone

concrete

carbon fiber

resin

graphite

rubber

Last Updated:

2025-04-15

The Best Wire Saw Machines for Cutting Hard Materials

Are you looking for wire saw machines, such as CNC mono wire saw machines or multi-wire saw machines? Dinosaw offers equipment suitable for cutting concrete, metals, and stones like granite, marble, sandstone, and jade. Whether for construction projects or new material processing, our machines deliver efficient and precise solutions to meet your needs.

Granite

Marble

luxurystone

concrete

carbon fiber

resin

graphite

rubber

The best Wire Saw Machines for cutting hard materials

Are you looking for wire saw machines, such as CNC mono wire saw machines or multi-wire saw machines? Dinosaw offers equipment suitable for cutting concrete, metals, and stones like granite, marble, sandstone, and jade. Whether for construction projects or new material processing, our machines deliver efficient and precise solutions to meet your needs.

Granite

Marble

luxurystone

concrete

carbon fiber

resin

graphite

rubber

Last Updated:

2025-04-15

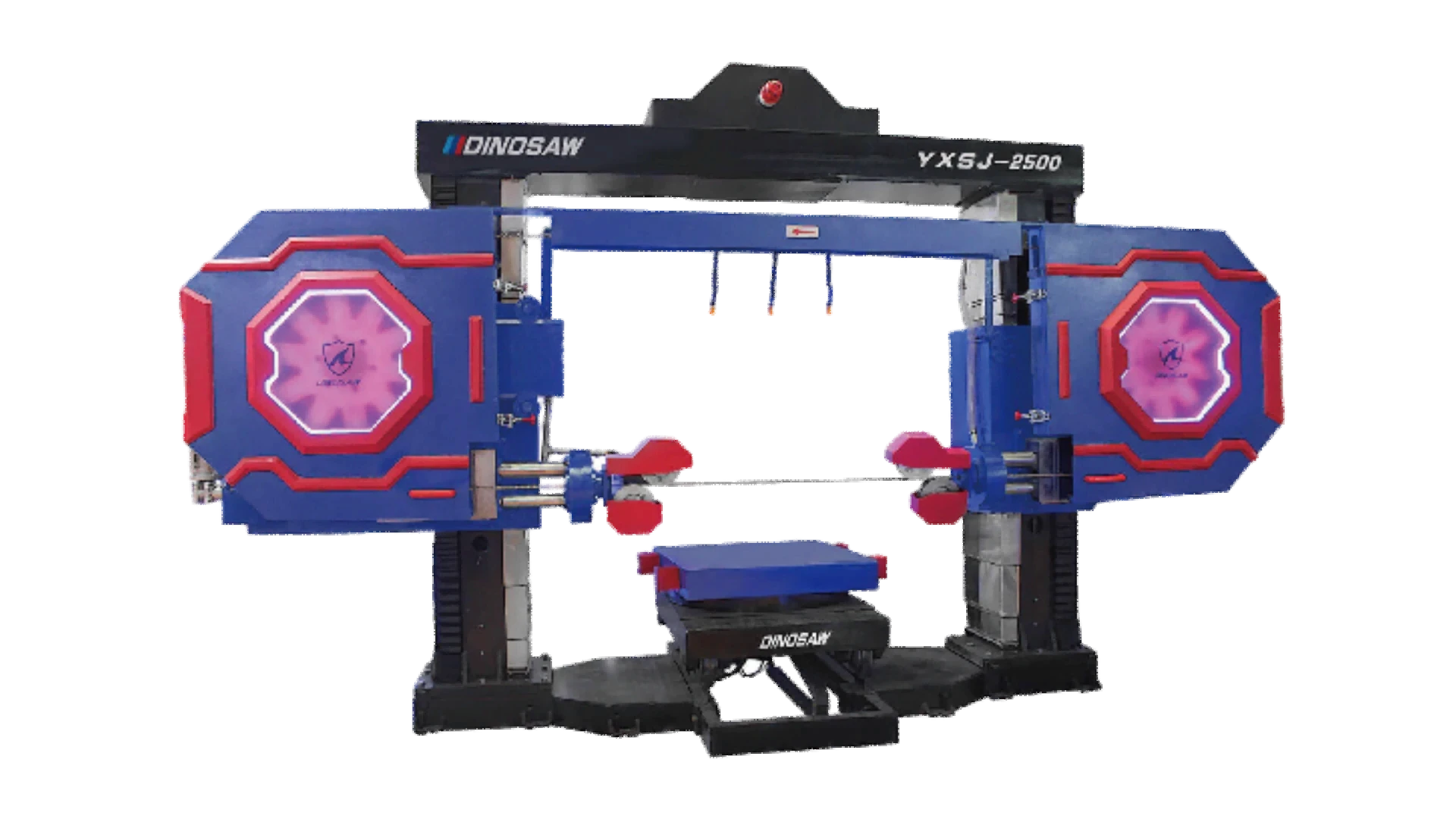

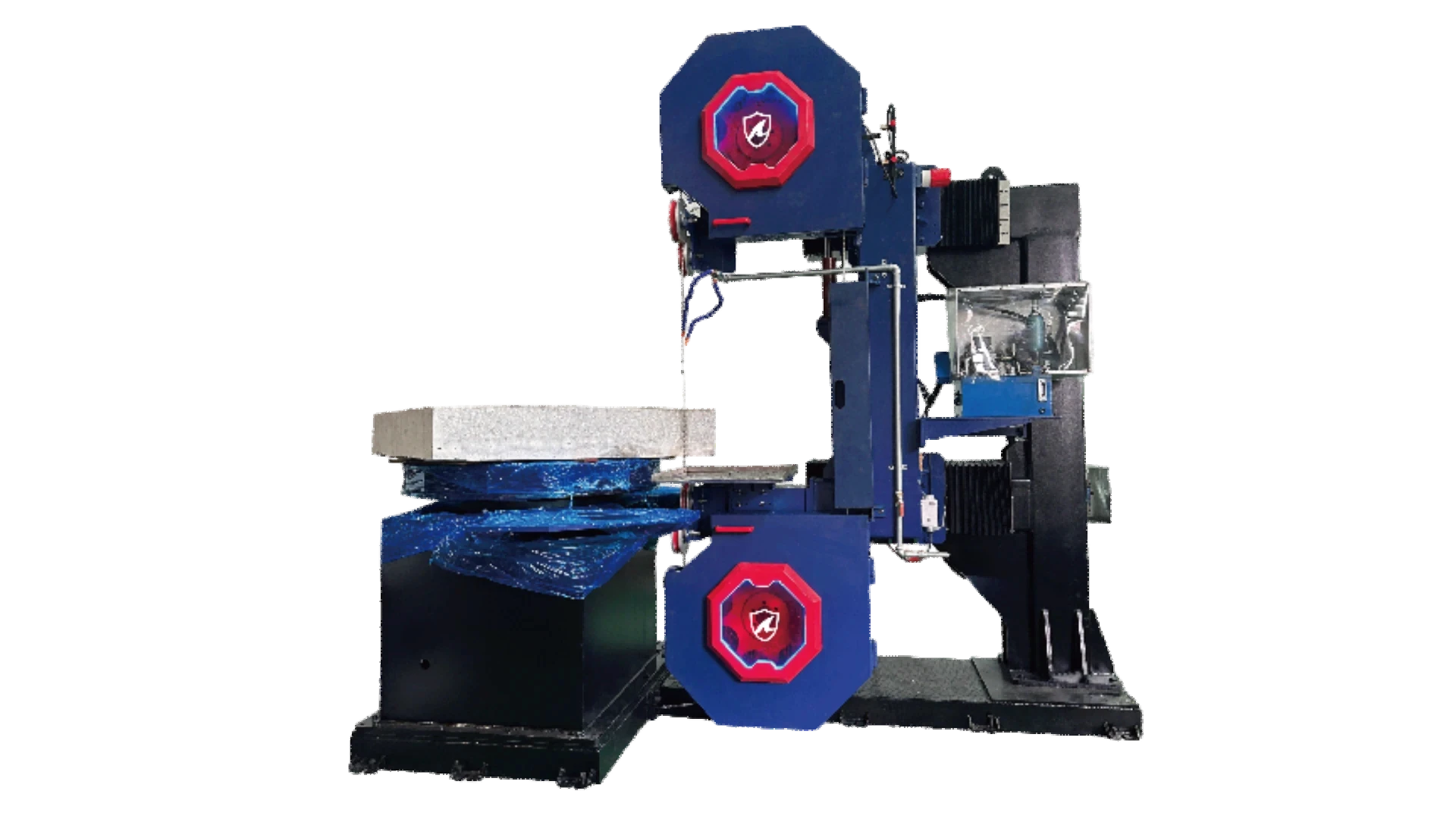

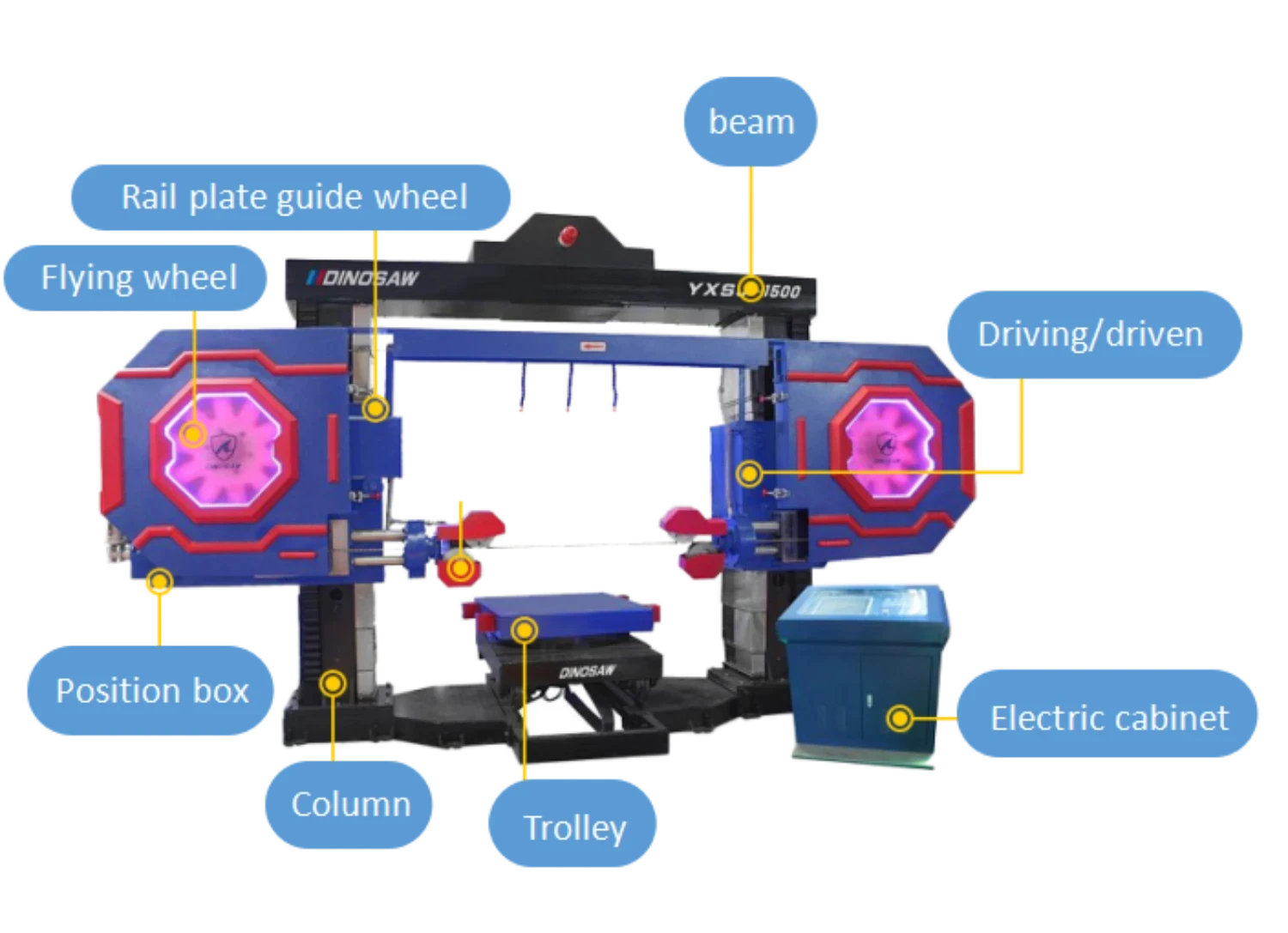

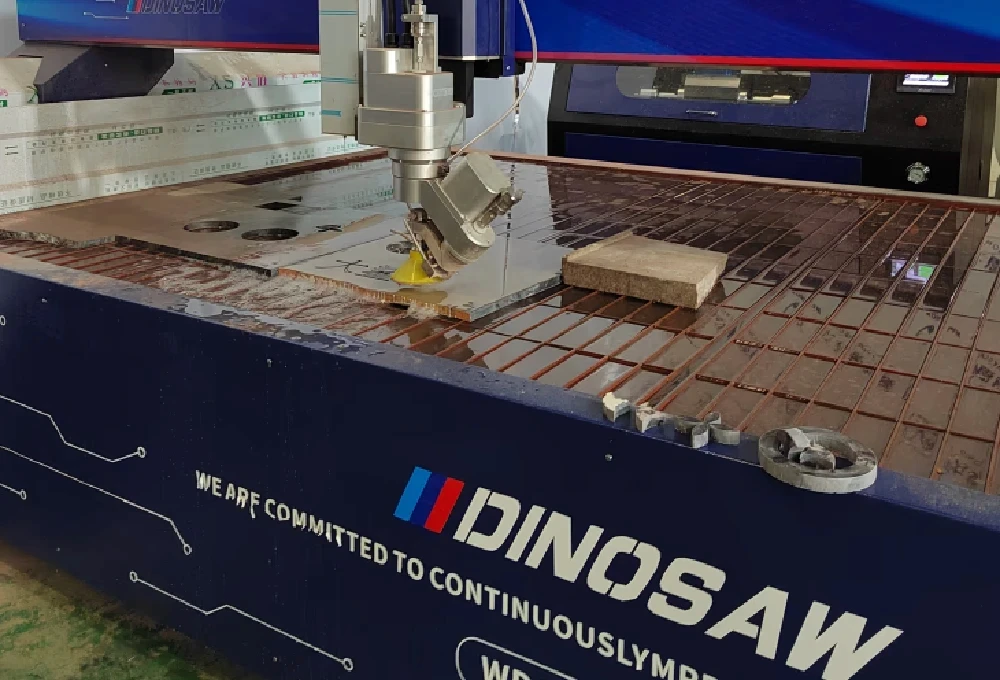

CNC Mono Wire Saw Machine

The CNC mono saw machine is a highly efficient cutting tool specifically designed for precision processing. It is composed of a diamond wire saw, a cast iron frame, a driving flywheel (to drive the wire saw for cutting), servo control, hydraulic tensioning, a worktable, and a CNC control system.

The machine operates by driving the diamond wire through the flywheel to achieve friction-based cutting. The CNC control system automatically adjusts the wire tension, ensuring smooth and accurate cutting. This system, combined with hydraulic tensioning, enhances operational efficiency and safety.

Ideal for cutting stone blocks, concrete, graphite, and various stones such as granite, marble, jade, and travertine, this machine is widely used in architectural materials, engineering components, and high-end stone processing. Its advantages include smooth cutting surfaces, minimal material waste, and suitability for small to medium-scale processing projects requiring high precision.

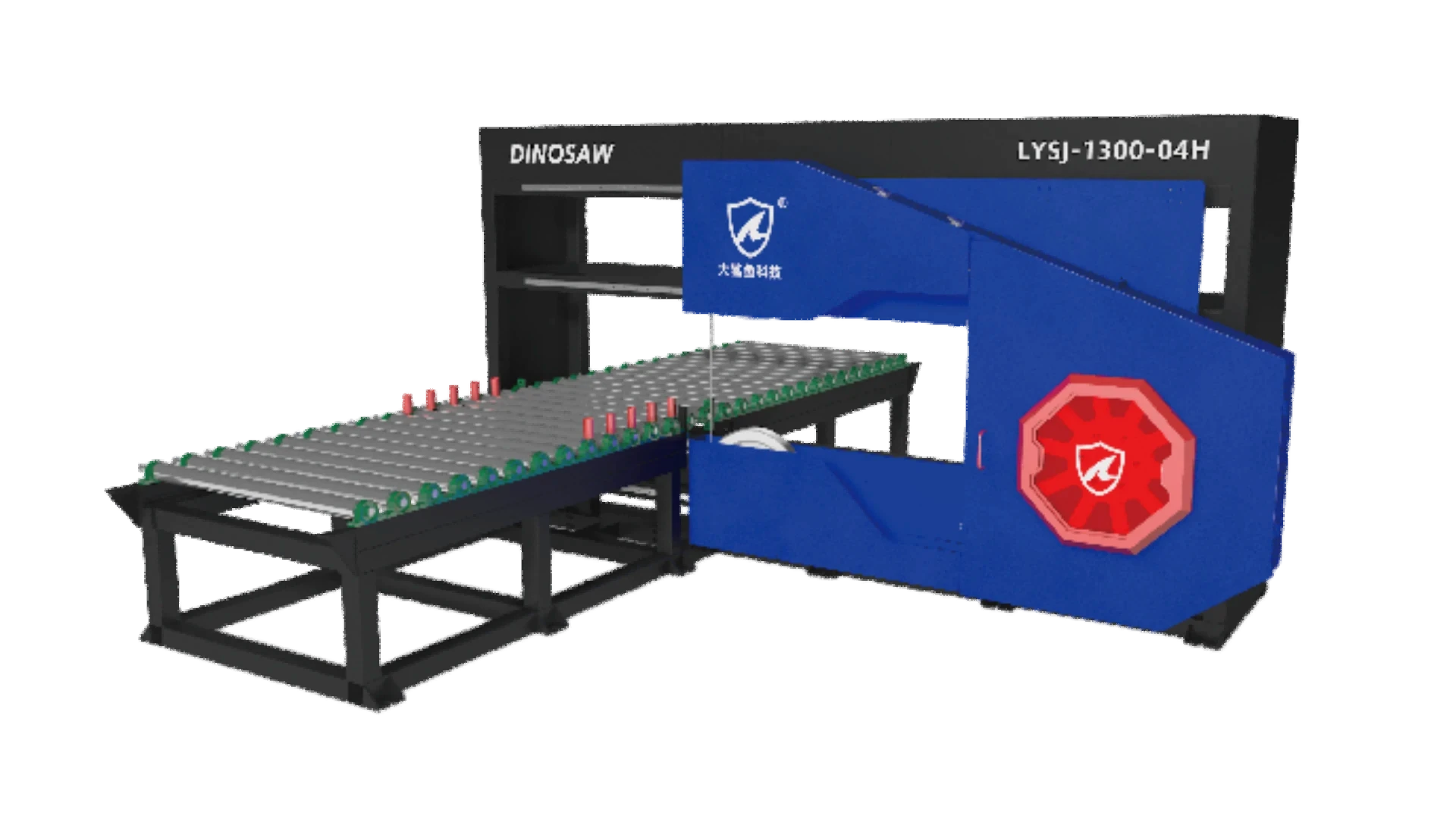

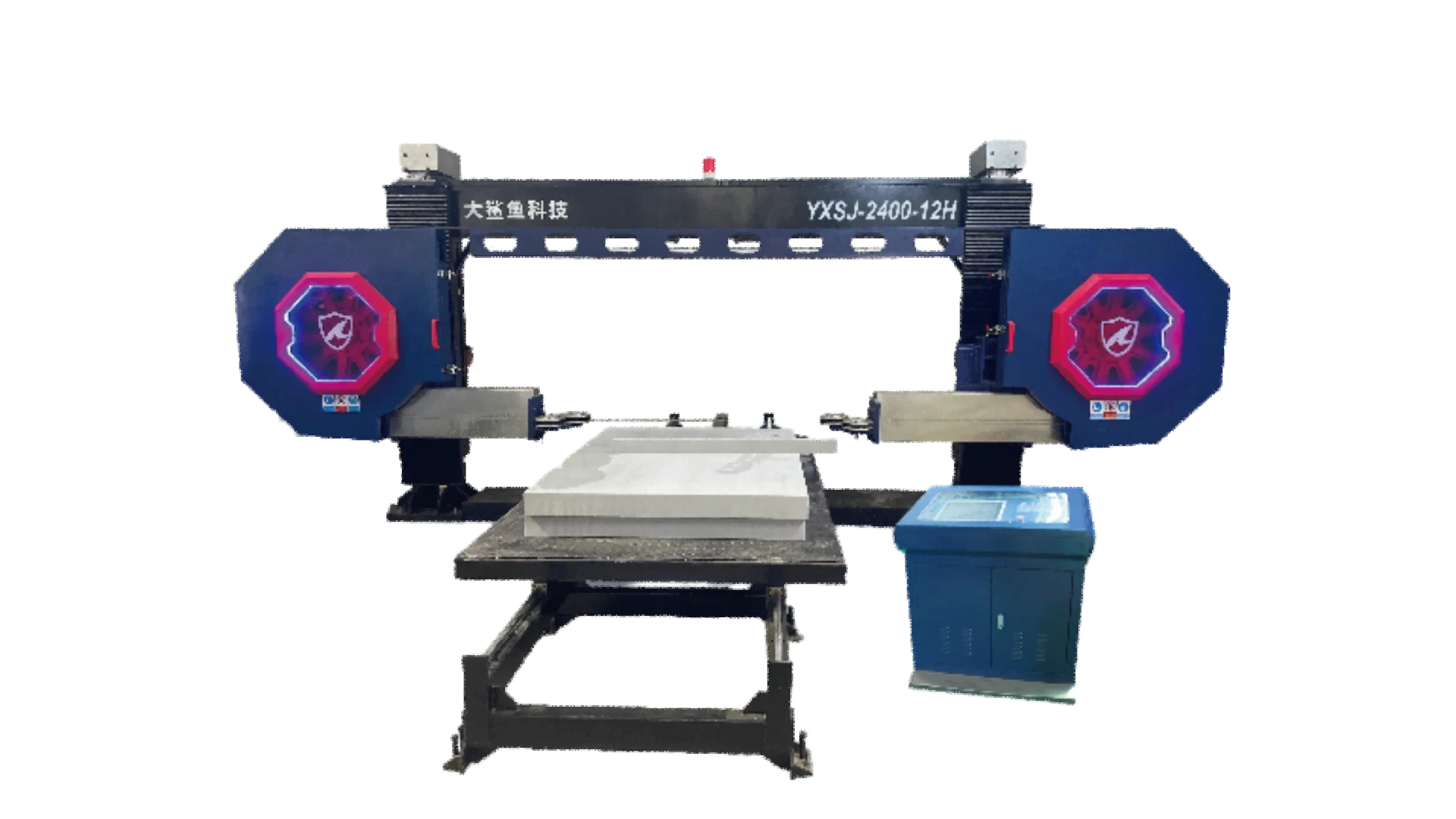

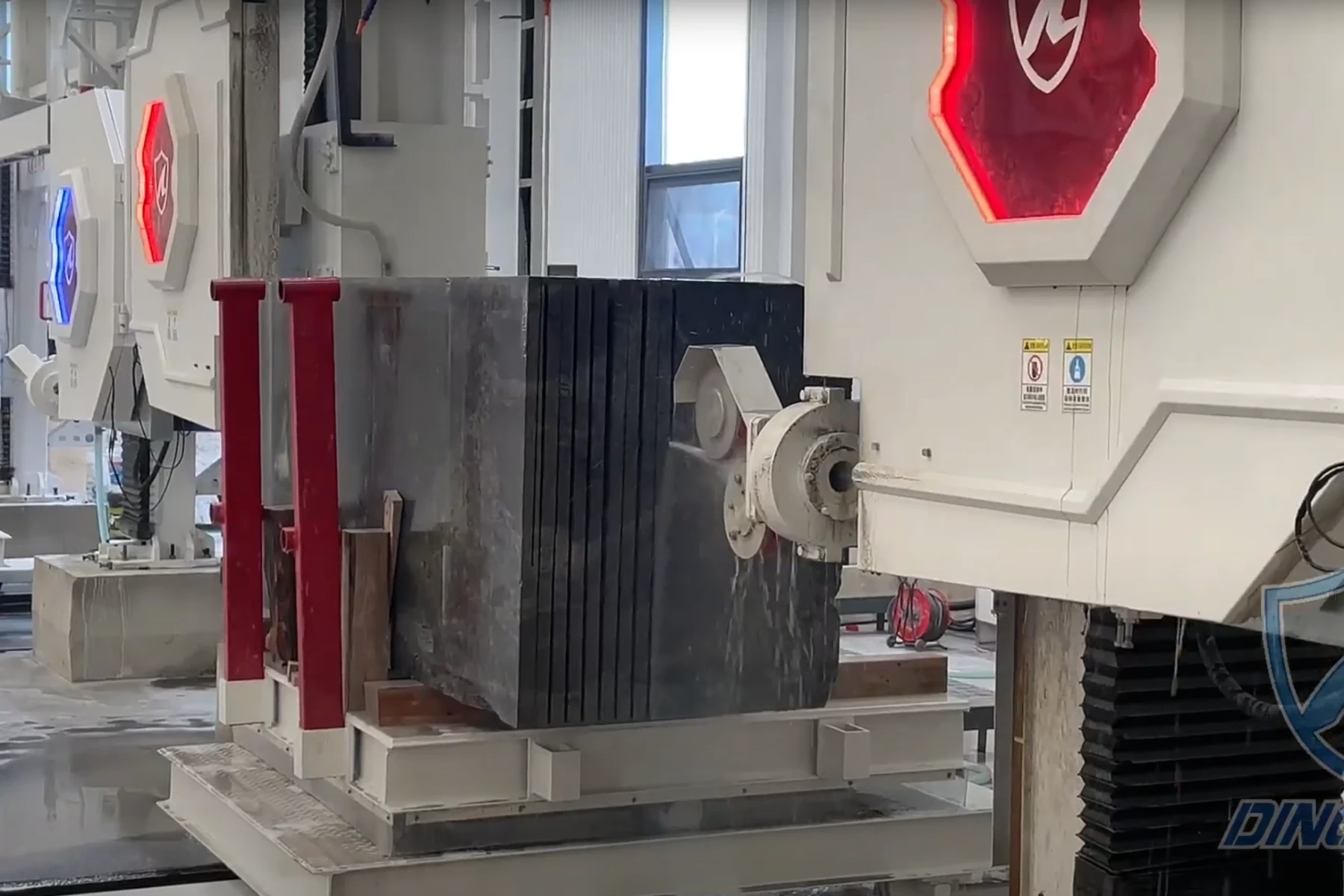

CNC Multi-Wire Saw Machine

The multi-wire saw machine is a highly efficient cutting device designed for large-scale stone processing, especially for cutting granite and marble slabs in batches. It features multiple diamond wires, a durable frame structure, synchronized pulleys, and a high-power motor to handle continuous high-intensity workloads.

The core technology lies in its synchronized wire control system, ensuring consistent thickness and high-quality surfaces across multiple slabs. It is ideal for processing granite, marble, sandstone, travertine, and other hard stones, making it the preferred choice for stone factories focused on mass production.

Compared to traditional cutting tools, the multi-wire saw machine offers higher material utilization, easy operation, and reduced maintenance costs, providing a cost-effective and efficient solution for high-volume stone cutting.

What is a Wire Saw Machine?

A wire saw machine is a high-efficiency cutting tool designed to process hard materials using diamond wires. Depending on the application, it can be classified into CNC single-wire saw machines and multi-wire saw machines.

The CNC mono-wire saw machine is tailored for small-scale and high-precision projects, such as tombstones, decorative stone pieces, and concrete cutting. The multi-wire saw machine is ideal for mass production, enabling efficient cutting of granite, marble, sandstone, and other stones.

Whether for construction, stone processing, or new material manufacturing, wire saw machines offer a highly efficient, low-waste cutting solution, making them indispensable for modern manufacturing industries.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

The Ultimate Guide to Choosing the Right Wire Saw Machine

Wire saw machines have become indispensable in industries like construction, stone processing, and metal fabrication. With their high precision, small kerf, and ability to cut a variety of shapes and angles, wire saws offer superior performance compared to traditional blade-based systems. Understanding the machine’s capabilities and materials it can handle is key to making the right choice.

What Is a Wire Saw Machine?

A wire saw machine uses diamond-coated wires to cut through a broad range of materials with unparalleled accuracy. Compared to blade saws, wire saws provide higher precision, smaller kerf, flexible cutting options, and superior material preservation.

Wire saws excel in processing natural stones like marble, granite, and limestone; building materials like concrete and ceramic tiles; metals including stainless steel and aluminum; and specialty materials such as graphite and carbon fiber.

Benefits of Wire Saw Machines

Wire saw machines offer significant advantages through their material versatility, enabling them to handle delicate marble and tough metals with equal efficiency. The smaller kerf minimizes material loss while enhancing reusability by preserving offcuts for future use. With precision cuts and reduced scrap, they provide a cost-effective solution for various industries.

Types of Wire Saw Machines

CNC Wire Saw Machines are designed for intricate work, such as architectural elements and decorative shapes, while handling a range of materials from lightweight limestone to dense basalt or metals. Equipped with intuitive CNC interfaces, they offer adaptability for various applications.

CNC Multi-Wire Saw Machines are best suited for large-scale production, excelling in high-volume slab cutting. These machines are capable of processing multiple slabs simultaneously, delivering consistent, precise results for materials like granite and quartzite. Modular designs and customization options cater to diverse production needs.

Wire saw machines are further categorized based on material types, specific processing requirements, and size, ensuring a perfect fit for different operational demands.

Factors to Consider When Choosing a Wire Saw Machine

Material compatibility is critical when selecting a wire saw machine. Assess whether it can handle your primary materials, such as marble or aluminum. The scale of production is another key factor, with multi-wire machines being ideal for high-volume needs, while single-wire models are better for precision work. Precision requirements, available workspace, and ease of operation should also guide your decision.

Why Choose Dinosaw Wire Saw Machines?

Dinosaw machines are built with advanced technology to ensure precision, efficiency, and durability. Their broad material compatibility allows processing of over 20 types of materials, while user-friendly CNC systems simplify operation. Customizable options and advanced cutting technology reduce waste and ensure consistent output. With a global presence in over 100 countries, Dinosaw is trusted by industries worldwide for its reliability and performance.

Steps to Purchasing Your Ideal Wire Saw Machine

Identifying your operational needs, including materials and production goals, is the first step. Exploring Dinosaw’s range of wire saw machines helps you find the model best suited to your requirements. Consulting with experts ensures personalized recommendations, and evaluating customization options aligns the machine with your operational goals. Proper installation and training complete the process, maximizing your machine’s efficiency.

Conclusion

Dinosaw wire saw machines deliver unparalleled precision, versatility, and reliability for a wide range of materials and applications. Whether you need to process intricate marble profiles or large granite slabs, Dinosaw provides the perfect balance of performance and efficiency to meet your production needs.

Contact Dinosaw today to discover the ideal wire saw machine for your operations.

CNC Mono Wire Saw Machine

The CNC mono saw machine is a highly efficient cutting tool specifically designed for precision processing. It is composed of a diamond wire saw, a cast iron frame, a driving flywheel (to drive the wire saw for cutting), servo control, hydraulic tensioning, a worktable, and a CNC control system.

The machine operates by driving the diamond wire through the flywheel to achieve friction-based cutting. The CNC control system automatically adjusts the wire tension, ensuring smooth and accurate cutting. This system, combined with hydraulic tensioning, enhances operational efficiency and safety.

Ideal for cutting stone blocks, concrete, graphite, and various stones such as granite, marble, jade, and travertine, this machine is widely used in architectural materials, engineering components, and high-end stone processing. Its advantages include smooth cutting surfaces, minimal material waste, and suitability for small to medium-scale processing projects requiring high precision.

CNC Multi-Wire Saw Machine

The multi-wire saw machine is a highly efficient cutting device designed for large-scale stone processing, especially for cutting granite and marble slabs in batches. It features multiple diamond wires, a durable frame structure, synchronized pulleys, and a high-power motor to handle continuous high-intensity workloads.

The core technology lies in its synchronized wire control system, ensuring consistent thickness and high-quality surfaces across multiple slabs. It is ideal for processing granite, marble, sandstone, travertine, and other hard stones, making it the preferred choice for stone factories focused on mass production.

Compared to traditional cutting tools, the multi-wire saw machine offers higher material utilization, easy operation, and reduced maintenance costs, providing a cost-effective and efficient solution for high-volume stone cutting.

What is a Wire Saw Machine?

A wire saw machine is a high-efficiency cutting tool designed to process hard materials using diamond wires. Depending on the application, it can be classified into CNC single-wire saw machines and multi-wire saw machines.

The CNC mono-wire saw machine is tailored for small-scale and high-precision projects, such as tombstones, decorative stone pieces, and concrete cutting. The multi-wire saw machine is ideal for mass production, enabling efficient cutting of granite, marble, sandstone, and other stones.

Whether for construction, stone processing, or new material manufacturing, wire saw machines offer a highly efficient, low-waste cutting solution, making them indispensable for modern manufacturing industries.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

The Ultimate Guide to Choosing the Right Wire Saw Machine

Wire saw machines have become indispensable in industries like construction, stone processing, and metal fabrication. With their high precision, small kerf, and ability to cut a variety of shapes and angles, wire saws offer superior performance compared to traditional blade-based systems. Understanding the machine’s capabilities and materials it can handle is key to making the right choice.

What Is a Wire Saw Machine?

A wire saw machine uses diamond-coated wires to cut through a broad range of materials with unparalleled accuracy. Compared to blade saws, wire saws provide higher precision, smaller kerf, flexible cutting options, and superior material preservation.

Wire saws excel in processing natural stones like marble, granite, and limestone; building materials like concrete and ceramic tiles; metals including stainless steel and aluminum; and specialty materials such as graphite and carbon fiber.

Benefits of Wire Saw Machines

Wire saw machines offer significant advantages through their material versatility, enabling them to handle delicate marble and tough metals with equal efficiency. The smaller kerf minimizes material loss while enhancing reusability by preserving offcuts for future use. With precision cuts and reduced scrap, they provide a cost-effective solution for various industries.

Types of Wire Saw Machines

CNC Wire Saw Machines are designed for intricate work, such as architectural elements and decorative shapes, while handling a range of materials from lightweight limestone to dense basalt or metals. Equipped with intuitive CNC interfaces, they offer adaptability for various applications.

CNC Multi-Wire Saw Machines are best suited for large-scale production, excelling in high-volume slab cutting. These machines are capable of processing multiple slabs simultaneously, delivering consistent, precise results for materials like granite and quartzite. Modular designs and customization options cater to diverse production needs.

Wire saw machines are further categorized based on material types, specific processing requirements, and size, ensuring a perfect fit for different operational demands.

Factors to Consider When Choosing a Wire Saw Machine

Material compatibility is critical when selecting a wire saw machine. Assess whether it can handle your primary materials, such as marble or aluminum. The scale of production is another key factor, with multi-wire machines being ideal for high-volume needs, while single-wire models are better for precision work. Precision requirements, available workspace, and ease of operation should also guide your decision.

Why Choose Dinosaw Wire Saw Machines?

Dinosaw machines are built with advanced technology to ensure precision, efficiency, and durability. Their broad material compatibility allows processing of over 20 types of materials, while user-friendly CNC systems simplify operation. Customizable options and advanced cutting technology reduce waste and ensure consistent output. With a global presence in over 100 countries, Dinosaw is trusted by industries worldwide for its reliability and performance.

Steps to Purchasing Your Ideal Wire Saw Machine

Identifying your operational needs, including materials and production goals, is the first step. Exploring Dinosaw’s range of wire saw machines helps you find the model best suited to your requirements. Consulting with experts ensures personalized recommendations, and evaluating customization options aligns the machine with your operational goals. Proper installation and training complete the process, maximizing your machine’s efficiency.

Conclusion

Dinosaw wire saw machines deliver unparalleled precision, versatility, and reliability for a wide range of materials and applications. Whether you need to process intricate marble profiles or large granite slabs, Dinosaw provides the perfect balance of performance and efficiency to meet your production needs.

Contact Dinosaw today to discover the ideal wire saw machine for your operations.

CNC Mono Wire Saw Machine

The CNC mono saw machine is a highly efficient cutting tool specifically designed for precision processing. It is composed of a diamond wire saw, a cast iron frame, a driving flywheel (to drive the wire saw for cutting), servo control, hydraulic tensioning, a worktable, and a CNC control system.

The machine operates by driving the diamond wire through the flywheel to achieve friction-based cutting. The CNC control system automatically adjusts the wire tension, ensuring smooth and accurate cutting. This system, combined with hydraulic tensioning, enhances operational efficiency and safety.

Ideal for cutting stone blocks, concrete, graphite, and various stones such as granite, marble, jade, and travertine, this machine is widely used in architectural materials, engineering components, and high-end stone processing. Its advantages include smooth cutting surfaces, minimal material waste, and suitability for small to medium-scale processing projects requiring high precision.

CNC Multi-Wire Saw Machine

The multi-wire saw machine is a highly efficient cutting device designed for large-scale stone processing, especially for cutting granite and marble slabs in batches. It features multiple diamond wires, a durable frame structure, synchronized pulleys, and a high-power motor to handle continuous high-intensity workloads.

The core technology lies in its synchronized wire control system, ensuring consistent thickness and high-quality surfaces across multiple slabs. It is ideal for processing granite, marble, sandstone, travertine, and other hard stones, making it the preferred choice for stone factories focused on mass production.

Compared to traditional cutting tools, the multi-wire saw machine offers higher material utilization, easy operation, and reduced maintenance costs, providing a cost-effective and efficient solution for high-volume stone cutting.

What is a Wire Saw Machine?

A wire saw machine is a high-efficiency cutting tool designed to process hard materials using diamond wires. Depending on the application, it can be classified into CNC single-wire saw machines and multi-wire saw machines.

The CNC mono-wire saw machine is tailored for small-scale and high-precision projects, such as tombstones, decorative stone pieces, and concrete cutting. The multi-wire saw machine is ideal for mass production, enabling efficient cutting of granite, marble, sandstone, and other stones.

Whether for construction, stone processing, or new material manufacturing, wire saw machines offer a highly efficient, low-waste cutting solution, making them indispensable for modern manufacturing industries.

The Ultimate Guide to Choosing the Right Wire Saw Machine

Wire saw machines have become indispensable in industries like construction, stone processing, and metal fabrication. With their high precision, small kerf, and ability to cut a variety of shapes and angles, wire saws offer superior performance compared to traditional blade-based systems. Understanding the machine’s capabilities and materials it can handle is key to making the right choice.

What Is a Wire Saw Machine?

A wire saw machine uses diamond-coated wires to cut through a broad range of materials with unparalleled accuracy. Compared to blade saws, wire saws provide higher precision, smaller kerf, flexible cutting options, and superior material preservation.

Wire saws excel in processing natural stones like marble, granite, and limestone; building materials like concrete and ceramic tiles; metals including stainless steel and aluminum; and specialty materials such as graphite and carbon fiber.

Benefits of Wire Saw Machines

Wire saw machines offer significant advantages through their material versatility, enabling them to handle delicate marble and tough metals with equal efficiency. The smaller kerf minimizes material loss while enhancing reusability by preserving offcuts for future use. With precision cuts and reduced scrap, they provide a cost-effective solution for various industries.

Types of Wire Saw Machines

CNC Wire Saw Machines are designed for intricate work, such as architectural elements and decorative shapes, while handling a range of materials from lightweight limestone to dense basalt or metals. Equipped with intuitive CNC interfaces, they offer adaptability for various applications.

CNC Multi-Wire Saw Machines are best suited for large-scale production, excelling in high-volume slab cutting. These machines are capable of processing multiple slabs simultaneously, delivering consistent, precise results for materials like granite and quartzite. Modular designs and customization options cater to diverse production needs.

Wire saw machines are further categorized based on material types, specific processing requirements, and size, ensuring a perfect fit for different operational demands.

Factors to Consider When Choosing a Wire Saw Machine

Material compatibility is critical when selecting a wire saw machine. Assess whether it can handle your primary materials, such as marble or aluminum. The scale of production is another key factor, with multi-wire machines being ideal for high-volume needs, while single-wire models are better for precision work. Precision requirements, available workspace, and ease of operation should also guide your decision.

Why Choose Dinosaw Wire Saw Machines?

Dinosaw machines are built with advanced technology to ensure precision, efficiency, and durability. Their broad material compatibility allows processing of over 20 types of materials, while user-friendly CNC systems simplify operation. Customizable options and advanced cutting technology reduce waste and ensure consistent output. With a global presence in over 100 countries, Dinosaw is trusted by industries worldwide for its reliability and performance.

Steps to Purchasing Your Ideal Wire Saw Machine

Identifying your operational needs, including materials and production goals, is the first step. Exploring Dinosaw’s range of wire saw machines helps you find the model best suited to your requirements. Consulting with experts ensures personalized recommendations, and evaluating customization options aligns the machine with your operational goals. Proper installation and training complete the process, maximizing your machine’s efficiency.

Conclusion

Dinosaw wire saw machines deliver unparalleled precision, versatility, and reliability for a wide range of materials and applications. Whether you need to process intricate marble profiles or large granite slabs, Dinosaw provides the perfect balance of performance and efficiency to meet your production needs.

Contact Dinosaw today to discover the ideal wire saw machine for your operations.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment