Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Tailored Machines for Drilling and Engraving Tasks

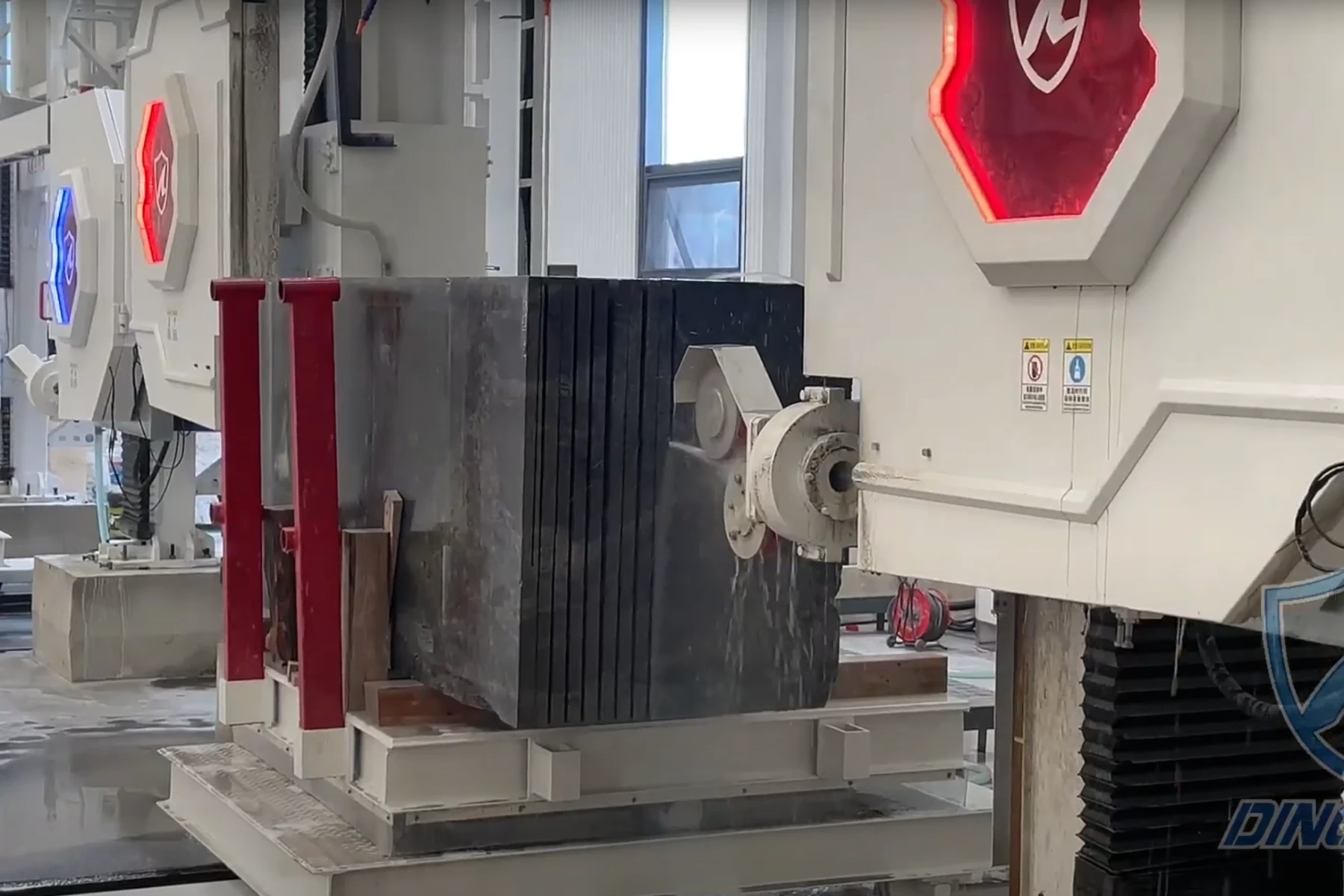

Dinosaw provides two distinct types of industrial machines for your processing needs: engraving machines for intricate carvings and drilling machines for high-efficiency hole-making. Designed to handle a wide range of materials, from natural stones to metals and composites, these machines cater to industries such as decorative art, stone manufacturing, and architectural projects.

Granite

Marble

steel

slab

quartz

Last Updated:

2025-04-15

Tailored Machines for Drilling and Engraving Tasks

Dinosaw provides two distinct types of industrial machines for your processing needs: engraving machines for intricate carvings and drilling machines for high-efficiency hole-making. Designed to handle a wide range of materials, from natural stones to metals and composites, these machines cater to industries such as decorative art, stone manufacturing, and architectural projects.

Granite

Marble

steel

slab

quartz

Last Updated:

2025-04-15

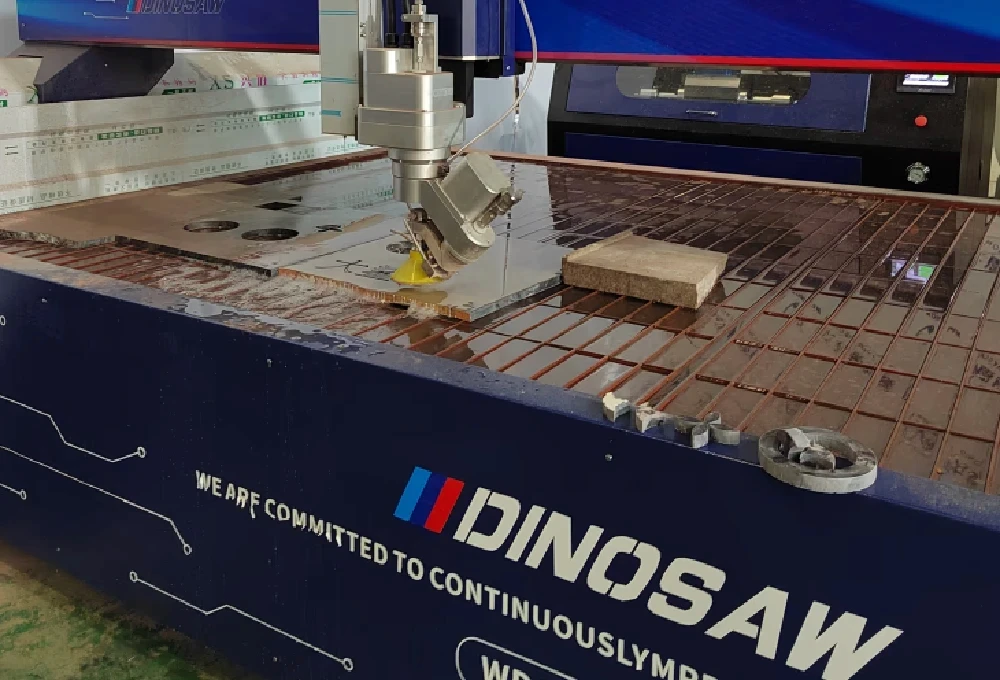

Engracving Machine

The Engraving Machine is a high-precision industrial machine designed for detailed carving and surface processing across a wide range of materials. Equipped with advanced CNC systems, these machines provide accurate and efficient solutions for decorative and industrial applications.Ideal for carving natural stones such as marble, granite, basalt, and limestone, as well as materials like acrylic, fiberglass, and composite boards, the engraving machine is perfect for creating intricate designs on tombstones, decorative panels, Roman columns, and sculptures. Its high-speed operation and multi-spindle configurations allow for increased productivity and adaptability to various projects.Dinosaw’s Engraving Machines are widely used in architectural detailing, interior and exterior decorations, and custom design projects. Built for precision, durability, and efficiency, these machines offer versatile and reliable performance, making them an essential tool for modern stone processing and decorative art production.

What are Drilling and Engraving Machines?

Drilling and engraving machines represent two distinct categories of equipment:

Engraving Machines: Designed for precision carving of intricate designs, ideal for decorative art, custom signage, and architectural embellishments.

Drilling Machines: Specializing in efficient hole-making for industrial and decorative applications, suitable for materials like stone, composites, and metals.

Dinosaw machines leverage advanced technology and robust engineering to deliver high productivity and impeccable quality.

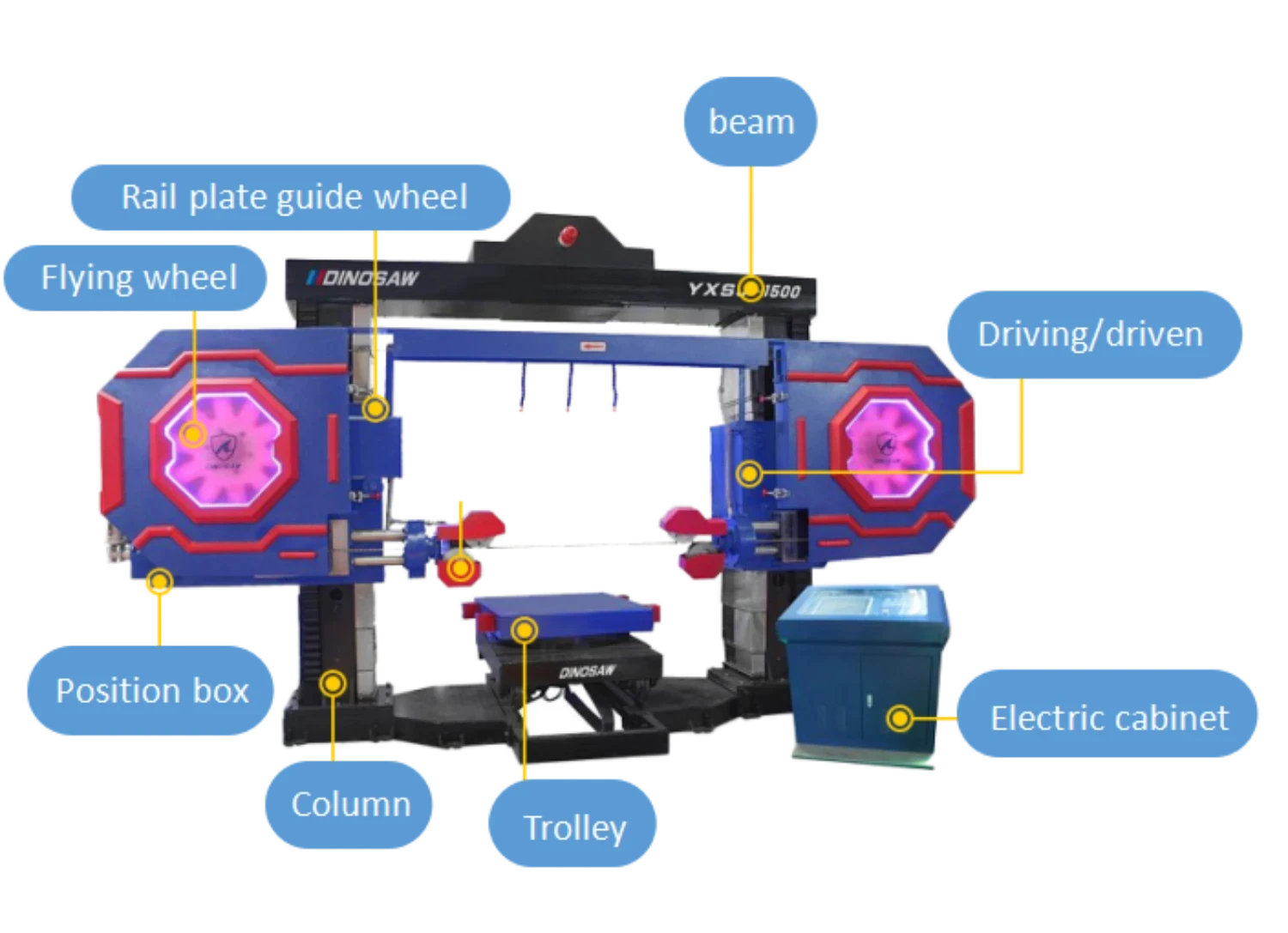

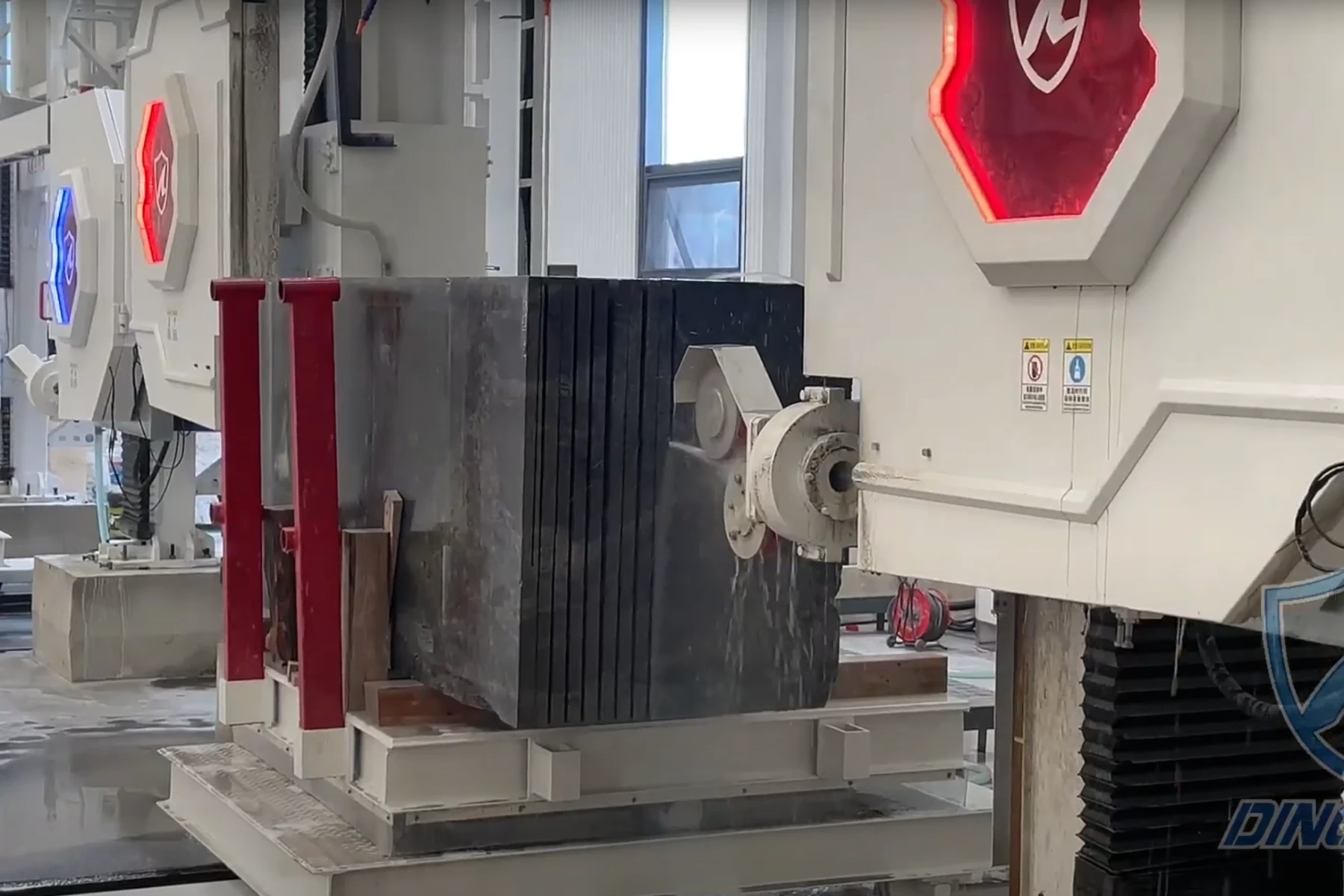

Drilling Machine

The Drilling Machine is a specialized tool designed for precision hole-making in a variety of materials. With robust construction and advanced technology, it is ideal for industrial and architectural applications that require accurate and efficient drilling.This machine is suitable for processing natural stones like marble, granite, and basalt, as well as construction materials such as concrete, ceramic tiles, and reinforced plastics. Common applications include creating holes for countertops, wall panels, architectural elements, and industrial components.Dinosaw’s Drilling Machines feature adjustable drilling sizes and depths, ensuring versatility for different project scales. From compact models for detailed tasks to gantry-style machines for large-scale projects, they cater to diverse operational needs. Reliable, efficient, and built for heavy-duty tasks, these machines are a valuable asset for modern manufacturing and construction projects.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Find Your Perfect Drilling and Engraving Machine: A Complete Buyer’s Guide

Drilling and engraving machines are essential for transforming ideas into precise, tangible results. Whether creating intricate carvings for decorative art or drilling precise holes for architectural projects, selecting the right equipment is critical. With Dinosaw’s advanced solutions, you’ll find machines tailored to meet your exact needs, ensuring efficiency, accuracy, and reliability.

This guide provides the essential insights to help you choose the ideal machine for your projects.

What Are Drilling and Engraving Machines?

Drilling and engraving machines are specialized equipment designed for high-precision processing of diverse materials. Dinosaw offers two primary machine types:

Engraving machines are ideal for intricate carving and surface detailing, commonly used for decorative and architectural applications.

Drilling machines focus on efficient and accurate hole-making, essential for industrial and construction projects.

Compatible materials include natural stones like marble and granite, artificial stones like quartz and terrazzo, building materials such as concrete and ceramic tiles, metals like aluminum and stainless steel, and specialty materials such as acrylic and fiberglass.

Types of Drilling and Engraving Machines

Engraving Machines

Designed for high-speed carving and precision detailing, these machines are ideal for creating sculptures, gravestones, architectural panels, and custom logos.

Features include advanced CNC systems for user-friendly operation, multi-spindle configurations for increased productivity, and compatibility with both hard and soft materials like marble and acrylic.

Drilling Machines

Engineered for precision hole-making, these machines cater to diverse project scales.

Gantry-style machines handle large applications like architectural elements and industrial panels, while compact drilling machines are suited for smaller projects like decorative frames and countertops.

Features include variable drilling sizes and depths, robust designs for heavy-duty tasks, and adaptability for materials ranging from reinforced plastics to ceramic tiles.

Steps to Purchasing Your Ideal Drilling or Engraving Machine

Define your needs by identifying the materials you will process and determining whether your focus is on precision engraving or high-speed drilling. Consider your production scale and whether you will produce custom items or manage industrial operations.

Research available models by exploring Dinosaw’s catalog of machines. Compare engraving models with advanced CNC systems and multi-spindle options to drilling models optimized for large or intricate projects. Pay attention to specifications like cutting dimensions, material compatibility, and maintenance requirements.

Consult with experts to review your production needs. Dinosaw’s team provides recommendations, technical details, and advice on customization options to ensure the machine aligns with your applications.

Plan your budget and ROI by evaluating upfront costs against long-term benefits like reduced waste and faster production. Include costs for shipping, installation, and operator training, and calculate the expected return on investment.

Request demonstrations to see the machine in action. Evaluate its precision, adaptability, and ease of operation, and test features like CNC programming, multi-spindle performance, or variable drilling depths.

Customize your machine with Dinosaw’s modular options. Adjust dimensions, CNC software, or components like spindles and drill heads to fit your production needs.

Arrange installation and training with Dinosaw’s support team. Schedule operator training to maximize the machine’s capabilities and discuss maintenance plans for long-term performance.

Why Choose Dinosaw Drilling and Engraving Machines?

Dinosaw machines combine advanced technology with durable engineering to deliver exceptional performance.

Key advantages include precision and versatility for over 15 material types, user-friendly CNC systems for efficient processing, modular designs tailored to specific needs, and global support for installation, training, and maintenance.

Conclusion

Choosing the right drilling or engraving machine is critical for achieving precision, efficiency, and productivity. Dinosaw’s range of customizable machines, advanced CNC systems, and expert support ensures you’ll find equipment that meets your unique requirements.

Contact Dinosaw today to explore solutions that enhance your production capabilities.

Engracving Machine

The Engraving Machine is a high-precision industrial machine designed for detailed carving and surface processing across a wide range of materials. Equipped with advanced CNC systems, these machines provide accurate and efficient solutions for decorative and industrial applications.Ideal for carving natural stones such as marble, granite, basalt, and limestone, as well as materials like acrylic, fiberglass, and composite boards, the engraving machine is perfect for creating intricate designs on tombstones, decorative panels, Roman columns, and sculptures. Its high-speed operation and multi-spindle configurations allow for increased productivity and adaptability to various projects.Dinosaw’s Engraving Machines are widely used in architectural detailing, interior and exterior decorations, and custom design projects. Built for precision, durability, and efficiency, these machines offer versatile and reliable performance, making them an essential tool for modern stone processing and decorative art production.

What are Drilling and Engraving Machines?

Drilling and engraving machines represent two distinct categories of equipment:

Engraving Machines: Designed for precision carving of intricate designs, ideal for decorative art, custom signage, and architectural embellishments.

Drilling Machines: Specializing in efficient hole-making for industrial and decorative applications, suitable for materials like stone, composites, and metals.

Dinosaw machines leverage advanced technology and robust engineering to deliver high productivity and impeccable quality.

Drilling Machine

The Drilling Machine is a specialized tool designed for precision hole-making in a variety of materials. With robust construction and advanced technology, it is ideal for industrial and architectural applications that require accurate and efficient drilling.This machine is suitable for processing natural stones like marble, granite, and basalt, as well as construction materials such as concrete, ceramic tiles, and reinforced plastics. Common applications include creating holes for countertops, wall panels, architectural elements, and industrial components.Dinosaw’s Drilling Machines feature adjustable drilling sizes and depths, ensuring versatility for different project scales. From compact models for detailed tasks to gantry-style machines for large-scale projects, they cater to diverse operational needs. Reliable, efficient, and built for heavy-duty tasks, these machines are a valuable asset for modern manufacturing and construction projects.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Find Your Perfect Drilling and Engraving Machine: A Complete Buyer’s Guide

Drilling and engraving machines are essential for transforming ideas into precise, tangible results. Whether creating intricate carvings for decorative art or drilling precise holes for architectural projects, selecting the right equipment is critical. With Dinosaw’s advanced solutions, you’ll find machines tailored to meet your exact needs, ensuring efficiency, accuracy, and reliability.

This guide provides the essential insights to help you choose the ideal machine for your projects.

What Are Drilling and Engraving Machines?

Drilling and engraving machines are specialized equipment designed for high-precision processing of diverse materials. Dinosaw offers two primary machine types:

Engraving machines are ideal for intricate carving and surface detailing, commonly used for decorative and architectural applications.

Drilling machines focus on efficient and accurate hole-making, essential for industrial and construction projects.

Compatible materials include natural stones like marble and granite, artificial stones like quartz and terrazzo, building materials such as concrete and ceramic tiles, metals like aluminum and stainless steel, and specialty materials such as acrylic and fiberglass.

Types of Drilling and Engraving Machines

Engraving Machines

Designed for high-speed carving and precision detailing, these machines are ideal for creating sculptures, gravestones, architectural panels, and custom logos.

Features include advanced CNC systems for user-friendly operation, multi-spindle configurations for increased productivity, and compatibility with both hard and soft materials like marble and acrylic.

Drilling Machines

Engineered for precision hole-making, these machines cater to diverse project scales.

Gantry-style machines handle large applications like architectural elements and industrial panels, while compact drilling machines are suited for smaller projects like decorative frames and countertops.

Features include variable drilling sizes and depths, robust designs for heavy-duty tasks, and adaptability for materials ranging from reinforced plastics to ceramic tiles.

Steps to Purchasing Your Ideal Drilling or Engraving Machine

Define your needs by identifying the materials you will process and determining whether your focus is on precision engraving or high-speed drilling. Consider your production scale and whether you will produce custom items or manage industrial operations.

Research available models by exploring Dinosaw’s catalog of machines. Compare engraving models with advanced CNC systems and multi-spindle options to drilling models optimized for large or intricate projects. Pay attention to specifications like cutting dimensions, material compatibility, and maintenance requirements.

Consult with experts to review your production needs. Dinosaw’s team provides recommendations, technical details, and advice on customization options to ensure the machine aligns with your applications.

Plan your budget and ROI by evaluating upfront costs against long-term benefits like reduced waste and faster production. Include costs for shipping, installation, and operator training, and calculate the expected return on investment.

Request demonstrations to see the machine in action. Evaluate its precision, adaptability, and ease of operation, and test features like CNC programming, multi-spindle performance, or variable drilling depths.

Customize your machine with Dinosaw’s modular options. Adjust dimensions, CNC software, or components like spindles and drill heads to fit your production needs.

Arrange installation and training with Dinosaw’s support team. Schedule operator training to maximize the machine’s capabilities and discuss maintenance plans for long-term performance.

Why Choose Dinosaw Drilling and Engraving Machines?

Dinosaw machines combine advanced technology with durable engineering to deliver exceptional performance.

Key advantages include precision and versatility for over 15 material types, user-friendly CNC systems for efficient processing, modular designs tailored to specific needs, and global support for installation, training, and maintenance.

Conclusion

Choosing the right drilling or engraving machine is critical for achieving precision, efficiency, and productivity. Dinosaw’s range of customizable machines, advanced CNC systems, and expert support ensures you’ll find equipment that meets your unique requirements.

Contact Dinosaw today to explore solutions that enhance your production capabilities.

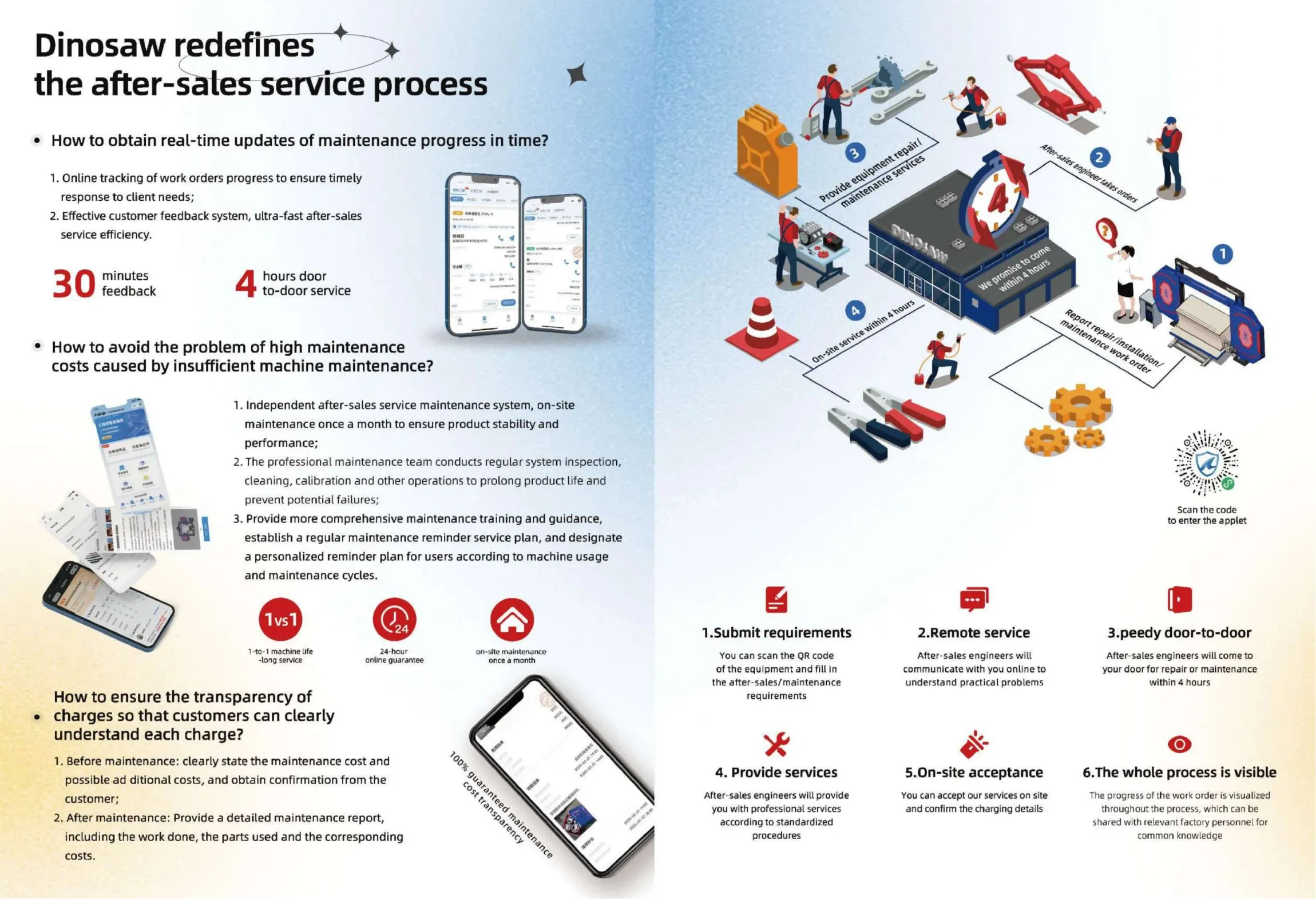

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Last Updated:

2025-01-15

Last Updated:

2025-01-15

Last Updated:

2025-04-15

Tailored Machines for Drilling and Engraving Tasks

Dinosaw provides two distinct types of industrial machines for your processing needs: engraving machines for intricate carvings and drilling machines for high-efficiency hole-making. Designed to handle a wide range of materials, from natural stones to metals and composites, these machines cater to industries such as decorative art, stone manufacturing, and architectural projects.

Granite

Marble

steel

slab

quartz

Engracving Machine

The Engraving Machine is a high-precision industrial machine designed for detailed carving and surface processing across a wide range of materials. Equipped with advanced CNC systems, these machines provide accurate and efficient solutions for decorative and industrial applications.

Ideal for carving natural stones such as marble, granite, basalt, and limestone, as well as materials like acrylic, fiberglass, and composite boards, the engraving machine is perfect for creating intricate designs on tombstones, decorative panels, Roman columns, and sculptures. Its high-speed operation and multi-spindle configurations allow for increased productivity and adaptability to various projects.

Dinosaw’s Engraving Machines are widely used in architectural detailing, interior and exterior decorations, and custom design projects. Built for precision, durability, and efficiency, these machines offer versatile and reliable performance, making them an essential tool for modern stone processing and decorative art production.

Drilling Machine

The Drilling Machine is a specialized tool designed for precision hole-making in a variety of materials. With robust construction and advanced technology, it is ideal for industrial and architectural applications that require accurate and efficient drilling.This machine is suitable for processing natural stones like marble, granite, and basalt, as well as construction materials such as concrete, ceramic tiles, and reinforced plastics. Common applications include creating holes for countertops, wall panels, architectural elements, and industrial components.Dinosaw’s Drilling Machines feature adjustable drilling sizes and depths, ensuring versatility for different project scales. From compact models for detailed tasks to gantry-style machines for large-scale projects, they cater to diverse operational needs. Reliable, efficient, and built for heavy-duty tasks, these machines are a valuable asset for modern manufacturing and construction projects.

What are Drilling and Engraving Machines?

Drilling and engraving machines represent two distinct categories of equipment:

Engraving Machines: Designed for precision carving of intricate designs, ideal for decorative art, custom signage, and architectural embellishments.

Drilling Machines: Specializing in efficient hole-making for industrial and decorative applications, suitable for materials like stone, composites, and metals.

Dinosaw machines leverage advanced technology and robust engineering to deliver high productivity and impeccable quality.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

Find Your Perfect Drilling and Engraving Machine: A Complete Buyer’s Guide

Drilling and engraving machines are essential for transforming ideas into precise, tangible results. Whether creating intricate carvings for decorative art or drilling precise holes for architectural projects, selecting the right equipment is critical. With Dinosaw’s advanced solutions, you’ll find machines tailored to meet your exact needs, ensuring efficiency, accuracy, and reliability.

This guide provides the essential insights to help you choose the ideal machine for your projects.

What Are Drilling and Engraving Machines?

Drilling and engraving machines are specialized equipment designed for high-precision processing of diverse materials. Dinosaw offers two primary machine types:

Engraving machines are ideal for intricate carving and surface detailing, commonly used for decorative and architectural applications.

Drilling machines focus on efficient and accurate hole-making, essential for industrial and construction projects.

Compatible materials include natural stones like marble and granite, artificial stones like quartz and terrazzo, building materials such as concrete and ceramic tiles, metals like aluminum and stainless steel, and specialty materials such as acrylic and fiberglass.

Types of Drilling and Engraving Machines

Engraving Machines

Designed for high-speed carving and precision detailing, these machines are ideal for creating sculptures, gravestones, architectural panels, and custom logos.

Features include advanced CNC systems for user-friendly operation, multi-spindle configurations for increased productivity, and compatibility with both hard and soft materials like marble and acrylic.

Drilling Machines

Engineered for precision hole-making, these machines cater to diverse project scales.

Gantry-style machines handle large applications like architectural elements and industrial panels, while compact drilling machines are suited for smaller projects like decorative frames and countertops.

Features include variable drilling sizes and depths, robust designs for heavy-duty tasks, and adaptability for materials ranging from reinforced plastics to ceramic tiles.

Steps to Purchasing Your Ideal Drilling or Engraving Machine

Define your needs by identifying the materials you will process and determining whether your focus is on precision engraving or high-speed drilling. Consider your production scale and whether you will produce custom items or manage industrial operations.

Research available models by exploring Dinosaw’s catalog of machines. Compare engraving models with advanced CNC systems and multi-spindle options to drilling models optimized for large or intricate projects. Pay attention to specifications like cutting dimensions, material compatibility, and maintenance requirements.

Consult with experts to review your production needs. Dinosaw’s team provides recommendations, technical details, and advice on customization options to ensure the machine aligns with your applications.

Plan your budget and ROI by evaluating upfront costs against long-term benefits like reduced waste and faster production. Include costs for shipping, installation, and operator training, and calculate the expected return on investment.

Request demonstrations to see the machine in action. Evaluate its precision, adaptability, and ease of operation, and test features like CNC programming, multi-spindle performance, or variable drilling depths.

Customize your machine with Dinosaw’s modular options. Adjust dimensions, CNC software, or components like spindles and drill heads to fit your production needs.

Arrange installation and training with Dinosaw’s support team. Schedule operator training to maximize the machine’s capabilities and discuss maintenance plans for long-term performance.

Why Choose Dinosaw Drilling and Engraving Machines?

Dinosaw machines combine advanced technology with durable engineering to deliver exceptional performance.

Key advantages include precision and versatility for over 15 material types, user-friendly CNC systems for efficient processing, modular designs tailored to specific needs, and global support for installation, training, and maintenance.

Conclusion

Choosing the right drilling or engraving machine is critical for achieving precision, efficiency, and productivity. Dinosaw’s range of customizable machines, advanced CNC systems, and expert support ensures you’ll find equipment that meets your unique requirements.

Contact Dinosaw today to explore solutions that enhance your production capabilities.

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment