Last Updated:

2025-01-15

Last Updated:

2025-01-15

Explore High-Performance Industry Machines

Dinosaw provides a range of other industry machines to meet varied processing requirements. From high-precision waterjet cutting to efficient stone splitting and CNC machining, our equipment is designed to optimize production and improve efficiency for industries such as manufacturing, stone processing, and construction.

carbon steel

acrylic

glass

fiberglass

travertine

slate

Last Updated:

2025-04-15

Explore High-Performance Industry Machines

Dinosaw provides a range of other industry machines to meet varied processing requirements. From high-precision waterjet cutting to efficient stone splitting and CNC machining, our equipment is designed to optimize production and improve efficiency for industries such as manufacturing, stone processing, and construction.

carbon steel

acrylic

glass

fiberglass

travertine

slate

Last Updated:

2025-04-15

Machining Center

The Automatic Polishing Machine is a versatile and high-performance machine designed for polishing both flat surfaces and edges. It supports a wide range of materials, including granite, marble, quartz, limestone, porcelain, glass, and metals like stainless steel and aluminum.Equipped with advanced multi-head configurations and automated control systems, this machine can handle surface polishing tasks for slabs, countertops, and wall panels, as well as edge polishing for trims, borders, and steps. Additionally, it is capable of shaping and polishing curved surfaces, such as arc panels, and removing rust from metal surfaces, ensuring smooth finishes and enhanced material quality.Widely used in stone processing factories, metal workshops, and glassworks, the Automatic Polishing Machine delivers consistent, high-quality results while reducing labor costs and increasing productivity. Its adaptability and precision make it an essential choice for businesses seeking reliable solutions for surface and edge finishing.

What are Other Industry Machines?

Other Industrial Machines encompass specialized equipment for various industrial needs:Waterjet Cutting Machines: High-precision tools for cutting metals, stones, and composites.Thicknessing Machines: Ensure uniform material thickness for engineered products.Machining Centers: Multifunctional CNC machines for precision parts.Assembly Line Equipment: Automates workflows for enhanced efficiency.Hydraulic Stone Splitters: Splits large stones into smaller blocks for processing.

Applications Include:Custom stone processing, metal fabrication, production automation, and architectural stonework.

These machines integrate advanced technology to enhance productivity, reduce waste, and meet the demands of modern industries.

Other Machine

The Manual Polishing Machine is a compact and portable machine ideal for smaller-scale polishing tasks. Designed for natural stones such as granite, marble, and limestone, it is capable of polishing surfaces, edges, and shaping edges for decorative applications.This machine is commonly used for polishing countertops, edge trims, and custom designs. Its flexibility and user-friendly operation make it suitable for small workshops or on-site projects requiring fine adjustments and customization.While limited to stone materials, the Manual Polishing Machine provides an affordable and efficient solution for achieving high-quality finishes. Its reliability and versatility make it a practical tool for professionals in the stone processing industry.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to Selecting High-Performance Industry Machines

Industrial machines play a vital role in streamlining production across diverse industries and materials. Dinosaw’s lineup of waterjet cutting machines, thicknessing machines, stone machining centers, assembly line equipment, and hydraulic stone splitters delivers cutting-edge technology and exceptional versatility for a variety of applications.

This guide provides an in-depth overview of these machines, helping you choose the best solution for your production needs.

What Are Industrial Machines?

Industrial machines are specialized tools engineered to handle complex processes like cutting, shaping, and assembling materials with precision and efficiency. Dinosaw’s machines are designed for processing natural stones, artificial composites, metals, and advanced building materials.

Key Categories

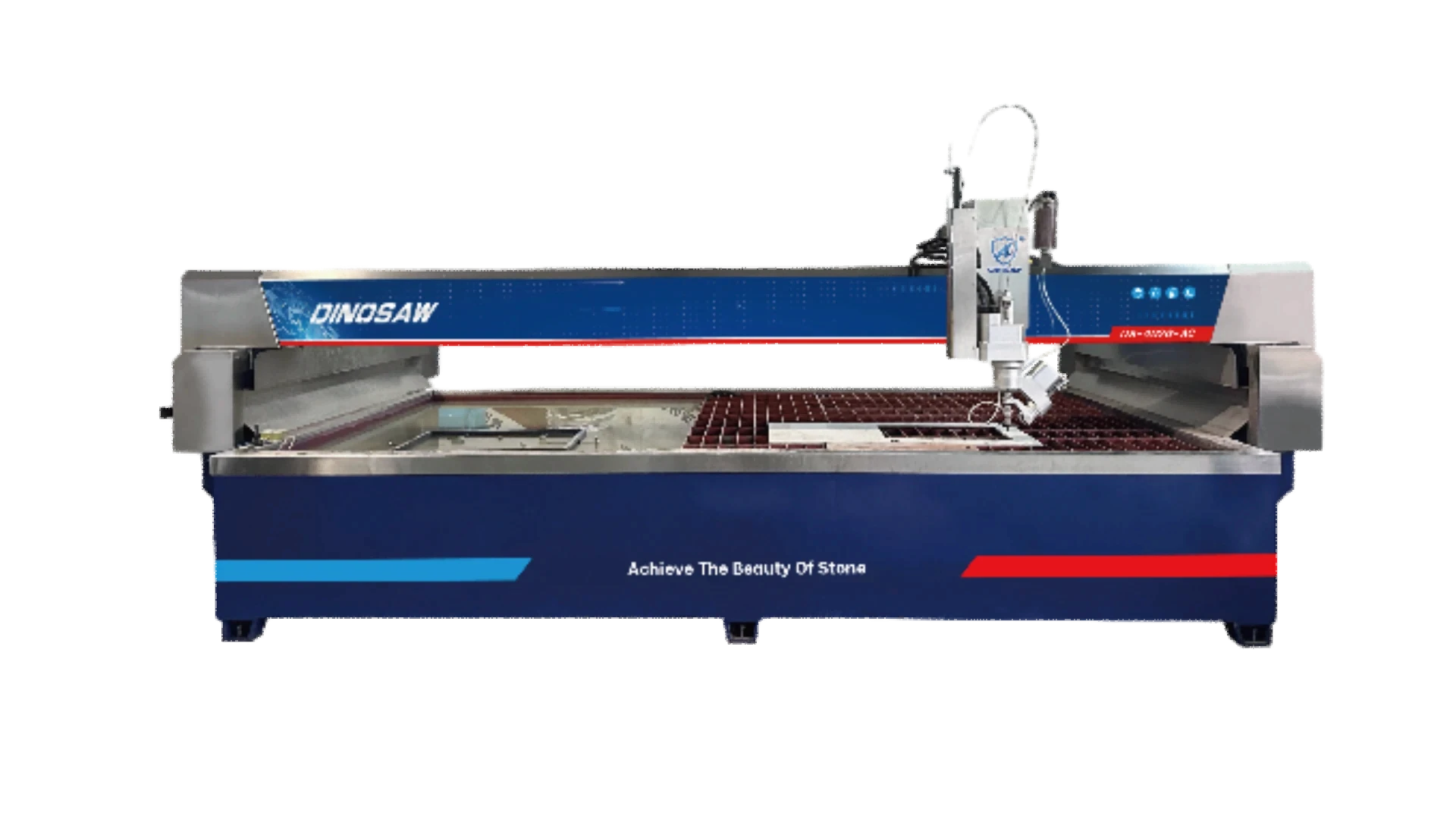

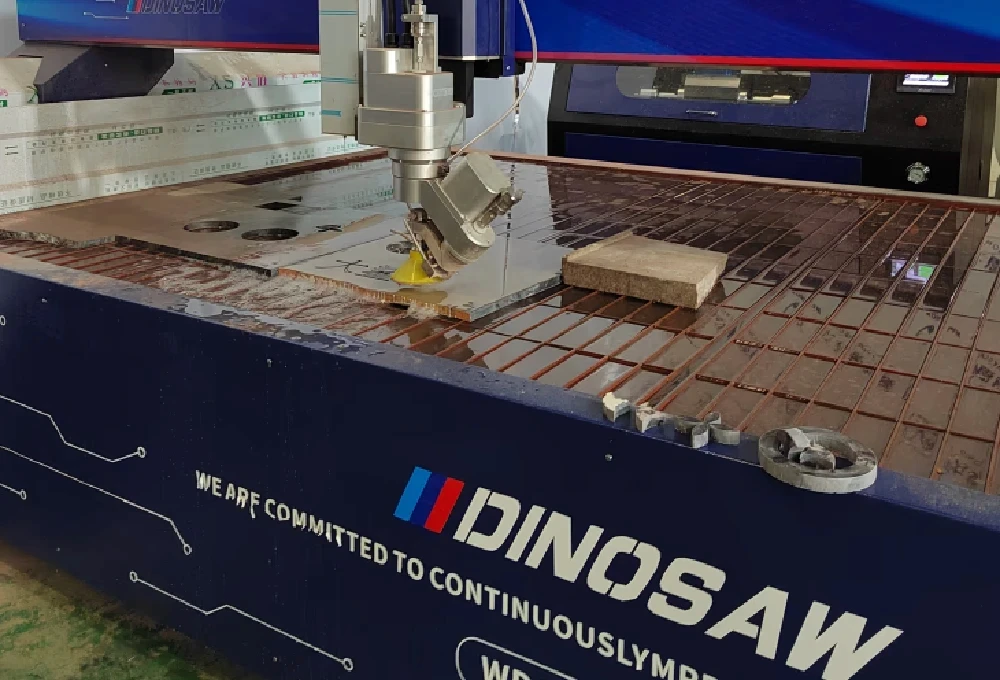

Waterjet cutting machines provide precise and versatile cutting for hard and composite materials.

Thicknessing machines ensure uniform thickness for stone slabs and panels.

Stone machining centers specialize in fabricating stone countertops and surfaces.

Assembly line equipment automates production workflows to enhance efficiency.

Hydraulic stone splitters break large stones into manageable blocks.

Materials Processed

Industrial machines handle materials like marble, granite, sintered stone, concrete, ceramics, steel, aluminum, fiberglass, and more.

Types of Industrial Machines

Waterjet Cutting Machines

Waterjet cutting machines use high-pressure water streams, often mixed with abrasives, for precise cuts.

Key Features

Non-thermal cutting prevents material deformation.

CNC systems enable intricate designs with high accuracy.

Compatible with hard and delicate materials.

Applications

Cutting architectural stone panels and metal components.

Fabricating decorative elements for interiors and exteriors.

Thicknessing Machines

Thicknessing machines calibrate stone slabs and sheets to uniform thicknesses, ensuring precision for further processing.

Key Features

Automatic feeding systems for consistent operation.

Adjustable settings for diverse thickness requirements.

Applications

Calibrating slabs for countertops, flooring, and cladding panels.

Stone Machining Centers

Stone machining centers are CNC-controlled systems for fabricating natural and engineered stones.

Key Features

Multi-functional capabilities for cutting, drilling, and milling.

High-speed precision for complex designs.

Applications

Fabricating countertops, detailed carvings, and custom stone surfaces.

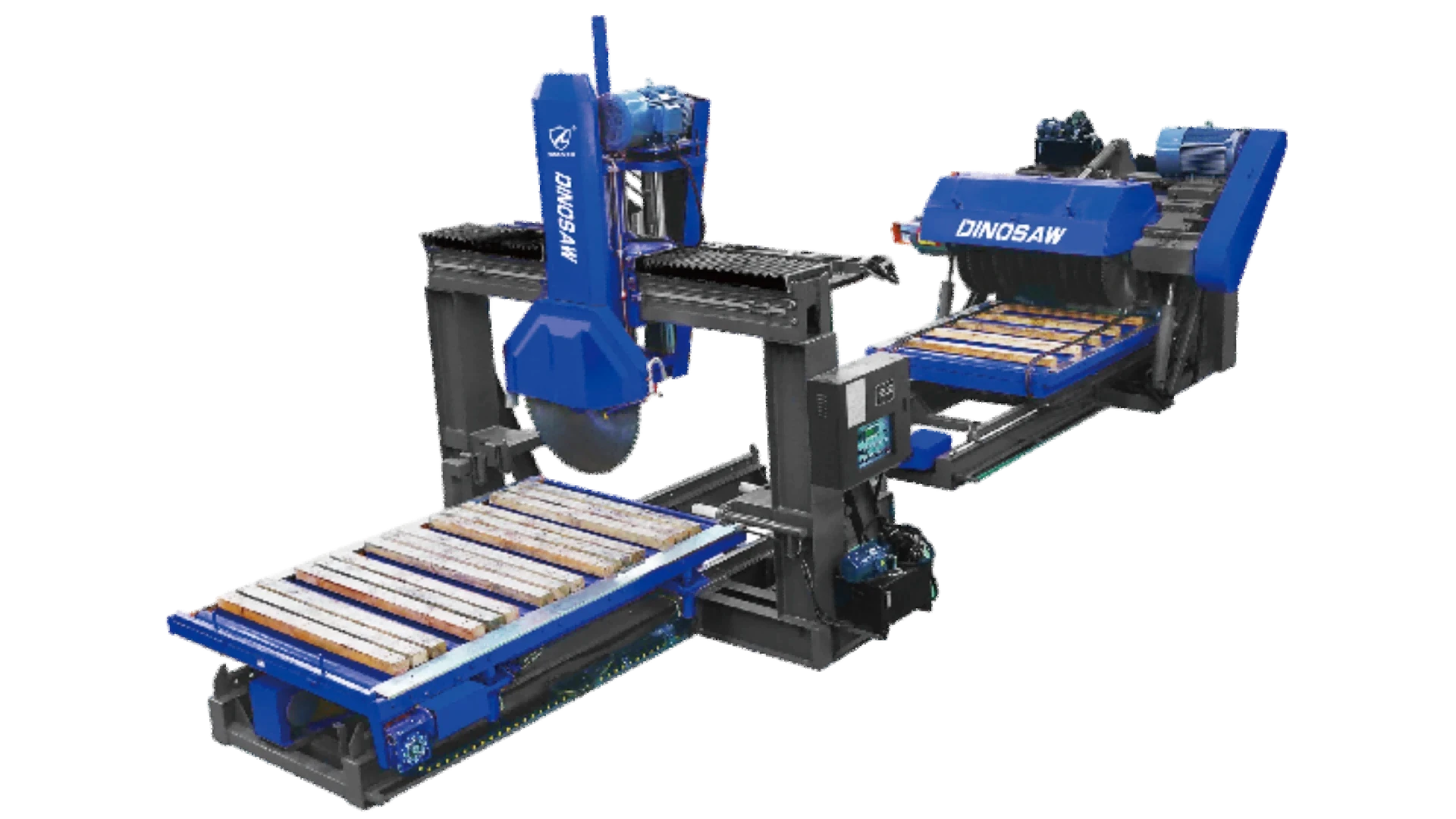

Assembly Line Equipment

Assembly line equipment automates production processes to reduce manual intervention and increase output.

Key Features

Fully automated systems for seamless material flow.

Configurable layouts for specific production needs.

Applications

High-volume slab processing and modular manufacturing.

Hydraulic Stone Splitters

Hydraulic stone splitters use high pressure to break large stones into smaller blocks.

Key Features

Durable designs for demanding quarry or factory settings.

High-pressure systems for effective splitting.

Applications

Producing paving stones, cladding materials, and monuments.

Steps to Choosing the Right Industrial Machine

Define your needs by identifying the materials you process and the production goals you aim to achieve, such as cutting, calibrating, or shaping.

Compare machine features and capabilities to match your requirements. Waterjet cutting machines are ideal for precision tasks, thicknessing machines ensure uniformity, and stone machining centers handle detailed fabrication.

Consult Dinosaw experts to share your specific requirements and explore customization options.

Evaluate ROI by analyzing cost savings from reduced material waste and increased efficiency. Consider the long-term benefits of energy efficiency and machine durability.

Test and install the selected machine to ensure compatibility with your operations. Schedule professional installation and training for seamless integration.

Why Choose Dinosaw Industrial Machines?

Dinosaw machines combine innovative technology with robust engineering for unmatched precision, versatility, and durability. Designed to reduce waste, increase production capacity, and handle demanding industrial environments, Dinosaw machines also come with comprehensive global support, including after-sales services and operator training.

Conclusion

Choosing the right industrial machine is essential for optimizing production and achieving superior results. Dinosaw’s range of high-performance machines, from waterjet cutting systems to hydraulic stone splitters, ensures you’ll find the perfect solution for your needs.

Contact Dinosaw today to explore our advanced industrial machines and enhance your production capabilities!

Machining Center

The Automatic Polishing Machine is a versatile and high-performance machine designed for polishing both flat surfaces and edges. It supports a wide range of materials, including granite, marble, quartz, limestone, porcelain, glass, and metals like stainless steel and aluminum.Equipped with advanced multi-head configurations and automated control systems, this machine can handle surface polishing tasks for slabs, countertops, and wall panels, as well as edge polishing for trims, borders, and steps. Additionally, it is capable of shaping and polishing curved surfaces, such as arc panels, and removing rust from metal surfaces, ensuring smooth finishes and enhanced material quality.Widely used in stone processing factories, metal workshops, and glassworks, the Automatic Polishing Machine delivers consistent, high-quality results while reducing labor costs and increasing productivity. Its adaptability and precision make it an essential choice for businesses seeking reliable solutions for surface and edge finishing.

What are Other Industry Machines?

Other Industrial Machines encompass specialized equipment for various industrial needs:Waterjet Cutting Machines: High-precision tools for cutting metals, stones, and composites.Thicknessing Machines: Ensure uniform material thickness for engineered products.Machining Centers: Multifunctional CNC machines for precision parts.Assembly Line Equipment: Automates workflows for enhanced efficiency.Hydraulic Stone Splitters: Splits large stones into smaller blocks for processing.

Applications Include:Custom stone processing, metal fabrication, production automation, and architectural stonework.

These machines integrate advanced technology to enhance productivity, reduce waste, and meet the demands of modern industries.

Other Machine

The Manual Polishing Machine is a compact and portable machine ideal for smaller-scale polishing tasks. Designed for natural stones such as granite, marble, and limestone, it is capable of polishing surfaces, edges, and shaping edges for decorative applications.This machine is commonly used for polishing countertops, edge trims, and custom designs. Its flexibility and user-friendly operation make it suitable for small workshops or on-site projects requiring fine adjustments and customization.While limited to stone materials, the Manual Polishing Machine provides an affordable and efficient solution for achieving high-quality finishes. Its reliability and versatility make it a practical tool for professionals in the stone processing industry.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Your Guide to Selecting High-Performance Industry Machines

Industrial machines play a vital role in streamlining production across diverse industries and materials. Dinosaw’s lineup of waterjet cutting machines, thicknessing machines, stone machining centers, assembly line equipment, and hydraulic stone splitters delivers cutting-edge technology and exceptional versatility for a variety of applications.

This guide provides an in-depth overview of these machines, helping you choose the best solution for your production needs.

What Are Industrial Machines?

Industrial machines are specialized tools engineered to handle complex processes like cutting, shaping, and assembling materials with precision and efficiency. Dinosaw’s machines are designed for processing natural stones, artificial composites, metals, and advanced building materials.

Key Categories

Waterjet cutting machines provide precise and versatile cutting for hard and composite materials.

Thicknessing machines ensure uniform thickness for stone slabs and panels.

Stone machining centers specialize in fabricating stone countertops and surfaces.

Assembly line equipment automates production workflows to enhance efficiency.

Hydraulic stone splitters break large stones into manageable blocks.

Materials Processed

Industrial machines handle materials like marble, granite, sintered stone, concrete, ceramics, steel, aluminum, fiberglass, and more.

Types of Industrial Machines

Waterjet Cutting Machines

Waterjet cutting machines use high-pressure water streams, often mixed with abrasives, for precise cuts.

Key Features

Non-thermal cutting prevents material deformation.

CNC systems enable intricate designs with high accuracy.

Compatible with hard and delicate materials.

Applications

Cutting architectural stone panels and metal components.

Fabricating decorative elements for interiors and exteriors.

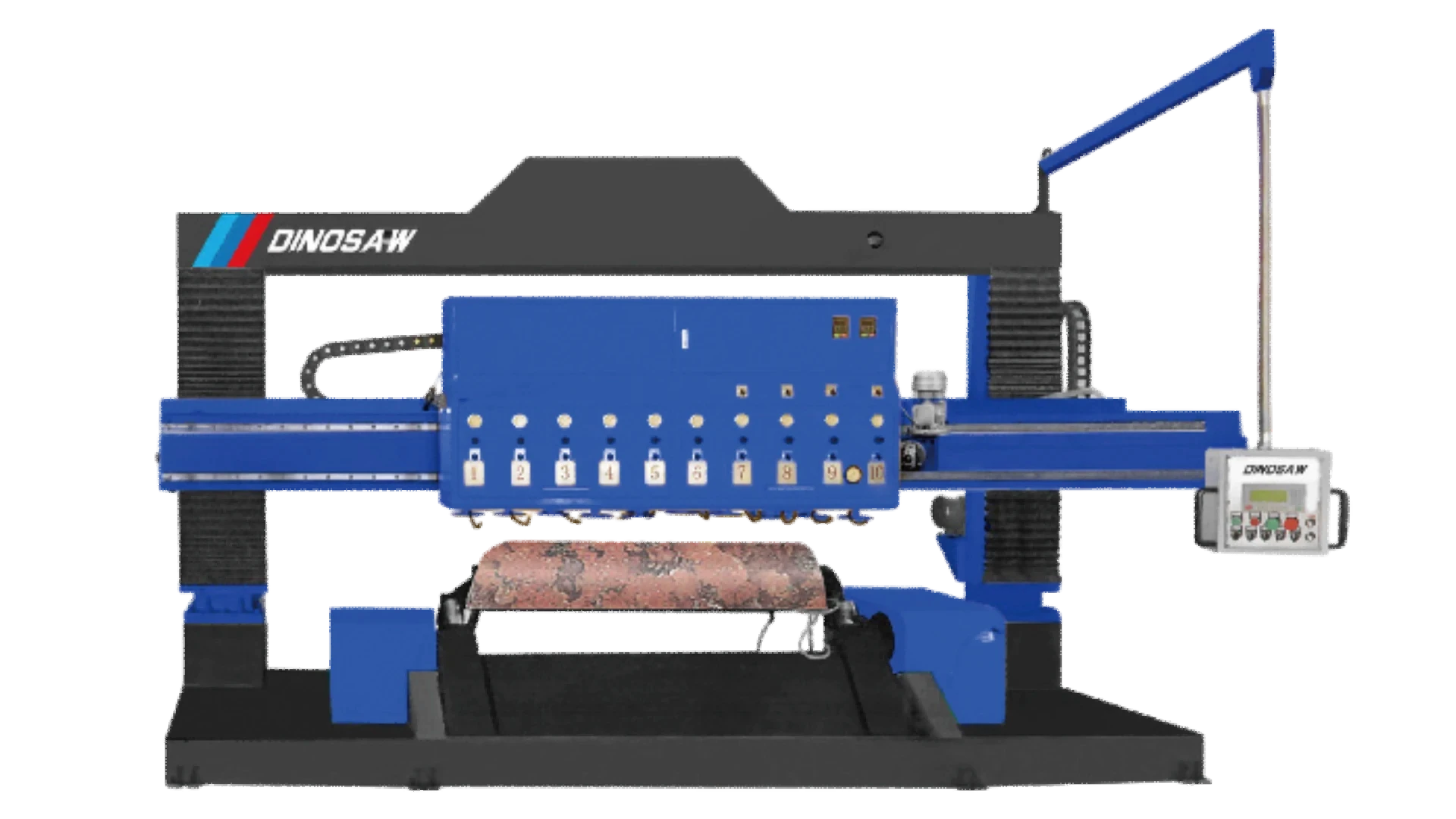

Thicknessing Machines

Thicknessing machines calibrate stone slabs and sheets to uniform thicknesses, ensuring precision for further processing.

Key Features

Automatic feeding systems for consistent operation.

Adjustable settings for diverse thickness requirements.

Applications

Calibrating slabs for countertops, flooring, and cladding panels.

Stone Machining Centers

Stone machining centers are CNC-controlled systems for fabricating natural and engineered stones.

Key Features

Multi-functional capabilities for cutting, drilling, and milling.

High-speed precision for complex designs.

Applications

Fabricating countertops, detailed carvings, and custom stone surfaces.

Assembly Line Equipment

Assembly line equipment automates production processes to reduce manual intervention and increase output.

Key Features

Fully automated systems for seamless material flow.

Configurable layouts for specific production needs.

Applications

High-volume slab processing and modular manufacturing.

Hydraulic Stone Splitters

Hydraulic stone splitters use high pressure to break large stones into smaller blocks.

Key Features

Durable designs for demanding quarry or factory settings.

High-pressure systems for effective splitting.

Applications

Producing paving stones, cladding materials, and monuments.

Steps to Choosing the Right Industrial Machine

Define your needs by identifying the materials you process and the production goals you aim to achieve, such as cutting, calibrating, or shaping.

Compare machine features and capabilities to match your requirements. Waterjet cutting machines are ideal for precision tasks, thicknessing machines ensure uniformity, and stone machining centers handle detailed fabrication.

Consult Dinosaw experts to share your specific requirements and explore customization options.

Evaluate ROI by analyzing cost savings from reduced material waste and increased efficiency. Consider the long-term benefits of energy efficiency and machine durability.

Test and install the selected machine to ensure compatibility with your operations. Schedule professional installation and training for seamless integration.

Why Choose Dinosaw Industrial Machines?

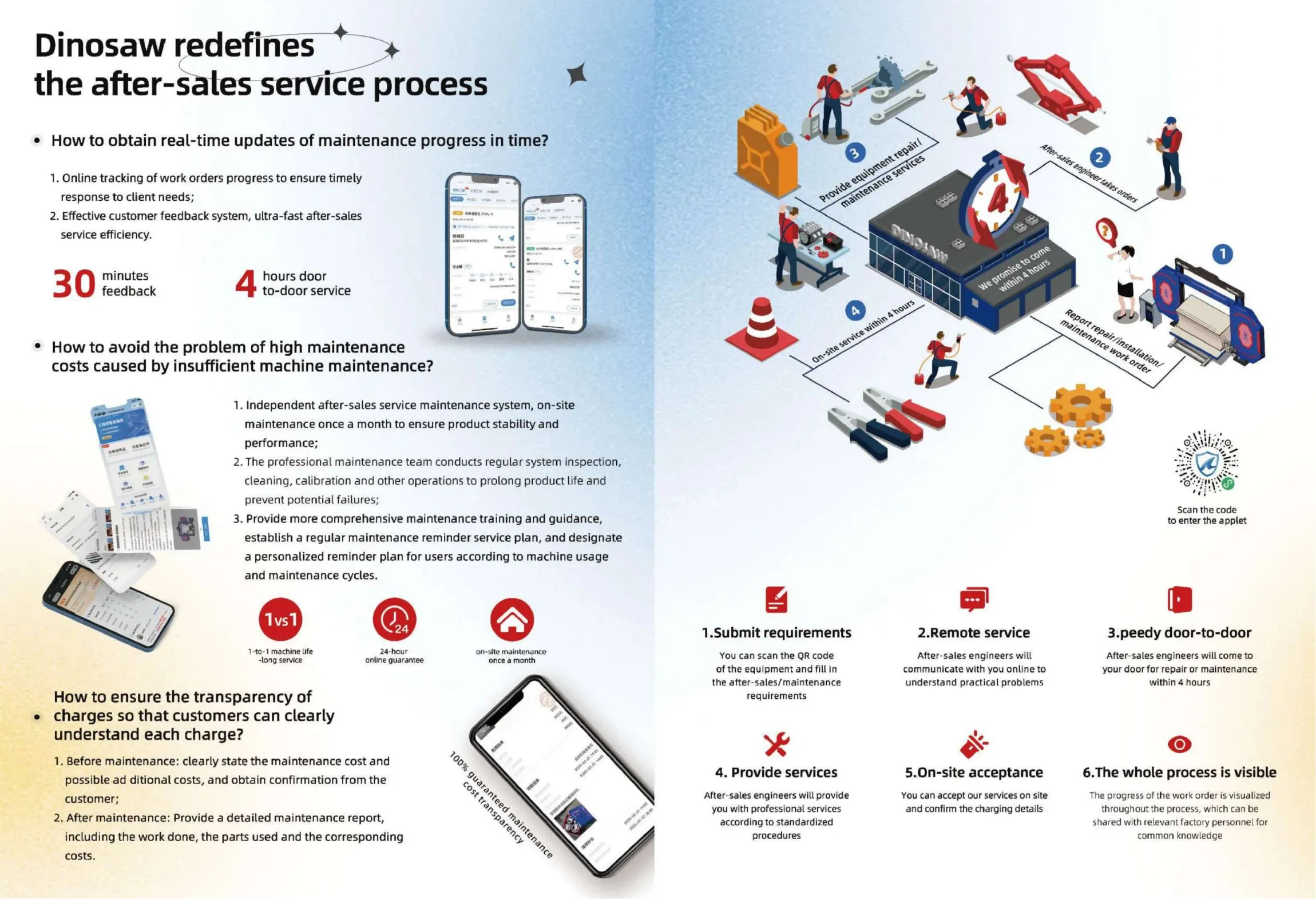

Dinosaw machines combine innovative technology with robust engineering for unmatched precision, versatility, and durability. Designed to reduce waste, increase production capacity, and handle demanding industrial environments, Dinosaw machines also come with comprehensive global support, including after-sales services and operator training.

Conclusion

Choosing the right industrial machine is essential for optimizing production and achieving superior results. Dinosaw’s range of high-performance machines, from waterjet cutting systems to hydraulic stone splitters, ensures you’ll find the perfect solution for your needs.

Contact Dinosaw today to explore our advanced industrial machines and enhance your production capabilities!

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Last Updated:

2025-04-15

Explore High-Performance Industry Machines

Dinosaw provides a range of other industry machines to meet varied processing requirements. From high-precision waterjet cutting to efficient stone splitting and CNC machining, our equipment is designed to optimize production and improve efficiency for industries such as manufacturing, stone processing, and construction.

carbon steel

acrylic

glass

fiberglass

travertine

slate

Machining Center

The Automatic Polishing Machine is a versatile and high-performance machine designed for polishing both flat surfaces and edges. It supports a wide range of materials, including granite, marble, quartz, limestone, porcelain, glass, and metals like stainless steel and aluminum.

Equipped with advanced multi-head configurations and automated control systems, this machine can handle surface polishing tasks for slabs, countertops, and wall panels, as well as edge polishing for trims, borders, and steps. Additionally, it is capable of shaping and polishing curved surfaces, such as arc panels, and removing rust from metal surfaces, ensuring smooth finishes and enhanced material quality.

Widely used in stone processing factories, metal workshops, and glassworks, the Automatic Polishing Machine delivers consistent, high-quality results while reducing labor costs and increasing productivity. Its adaptability and precision make it an essential choice for businesses seeking reliable solutions for surface and edge finishing.

Other Machine

The Manual Polishing Machine is a compact and portable machine ideal for smaller-scale polishing tasks. Designed for natural stones such as granite, marble, and limestone, it is capable of polishing surfaces, edges, and shaping edges for decorative applications.

This machine is commonly used for polishing countertops, edge trims, and custom designs. Its flexibility and user-friendly operation make it suitable for small workshops or on-site projects requiring fine adjustments and customization.

While limited to stone materials, the Manual Polishing Machine provides an affordable and efficient solution for achieving high-quality finishes. Its reliability and versatility make it a practical tool for professionals in the stone processing industry.

What are Other Industry Machines?

Other Industrial Machines encompass specialized equipment for various industrial needs:Waterjet Cutting Machines: High-precision tools for cutting metals, stones, and composites.Thicknessing Machines: Ensure uniform material thickness for engineered products.Machining Centers: Multifunctional CNC machines for precision parts.Assembly Line Equipment: Automates workflows for enhanced efficiency.Hydraulic Stone Splitters: Splits large stones into smaller blocks for processing.

Applications Include:Custom stone processing, metal fabrication, production automation, and architectural stonework.

These machines integrate advanced technology to enhance productivity, reduce waste, and meet the demands of modern industries.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

Your Guide to Selecting High-Performance Industry Machines

Industrial machines play a vital role in streamlining production across diverse industries and materials. Dinosaw’s lineup of waterjet cutting machines, thicknessing machines, stone machining centers, assembly line equipment, and hydraulic stone splitters delivers cutting-edge technology and exceptional versatility for a variety of applications.

This guide provides an in-depth overview of these machines, helping you choose the best solution for your production needs.

What Are Industrial Machines?

Industrial machines are specialized tools engineered to handle complex processes like cutting, shaping, and assembling materials with precision and efficiency. Dinosaw’s machines are designed for processing natural stones, artificial composites, metals, and advanced building materials.

Key Categories

Waterjet cutting machines provide precise and versatile cutting for hard and composite materials.

Thicknessing machines ensure uniform thickness for stone slabs and panels.

Stone machining centers specialize in fabricating stone countertops and surfaces.

Assembly line equipment automates production workflows to enhance efficiency.

Hydraulic stone splitters break large stones into manageable blocks.

Materials Processed

Industrial machines handle materials like marble, granite, sintered stone, concrete, ceramics, steel, aluminum, fiberglass, and more.

Types of Industrial Machines

Waterjet Cutting Machines

Waterjet cutting machines use high-pressure water streams, often mixed with abrasives, for precise cuts.

Key Features

Non-thermal cutting prevents material deformation.

CNC systems enable intricate designs with high accuracy.

Compatible with hard and delicate materials.

Applications

Cutting architectural stone panels and metal components.

Fabricating decorative elements for interiors and exteriors.

Thicknessing Machines

Thicknessing machines calibrate stone slabs and sheets to uniform thicknesses, ensuring precision for further processing.

Key Features

Automatic feeding systems for consistent operation.

Adjustable settings for diverse thickness requirements.

Applications

Calibrating slabs for countertops, flooring, and cladding panels.

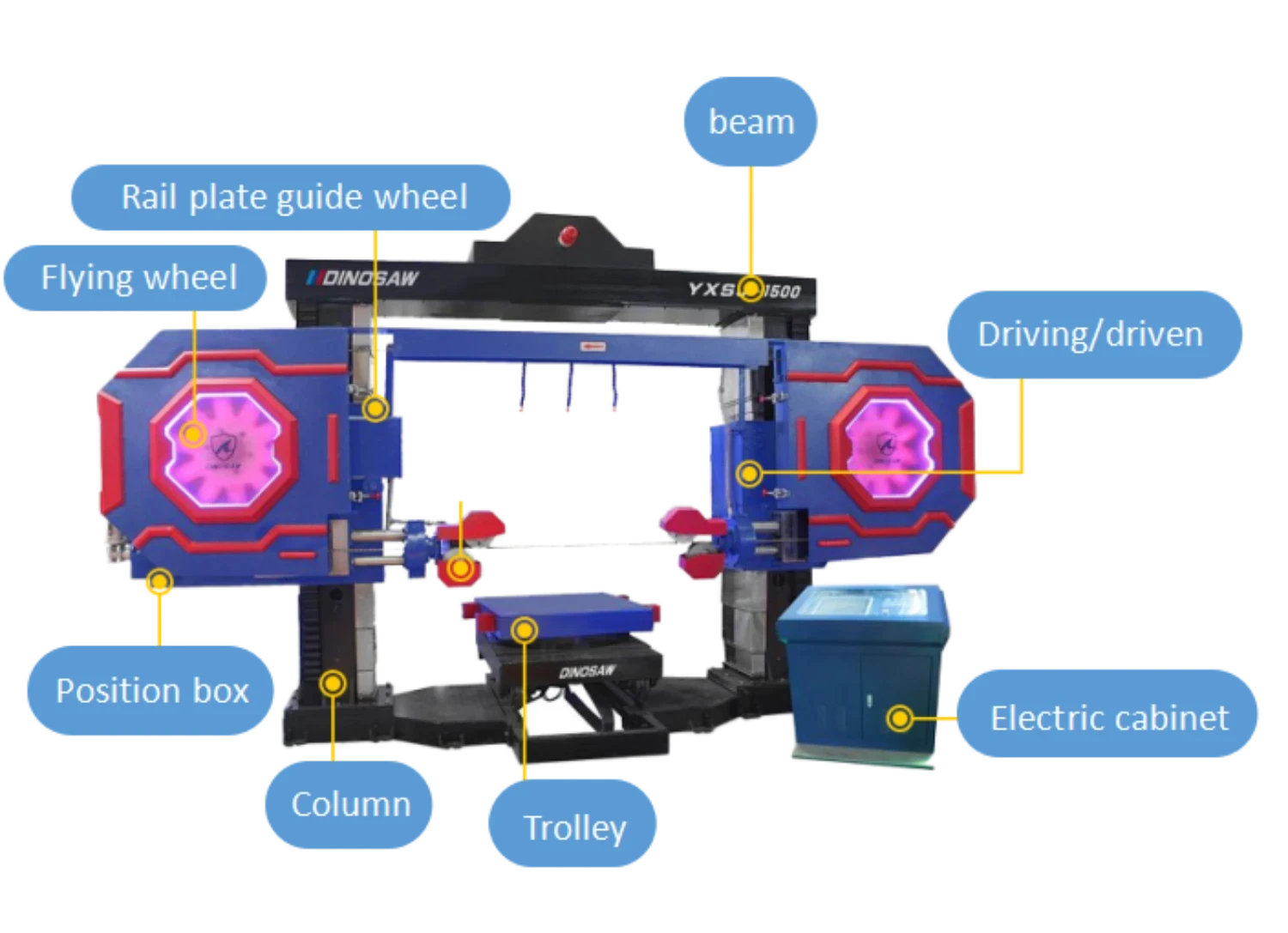

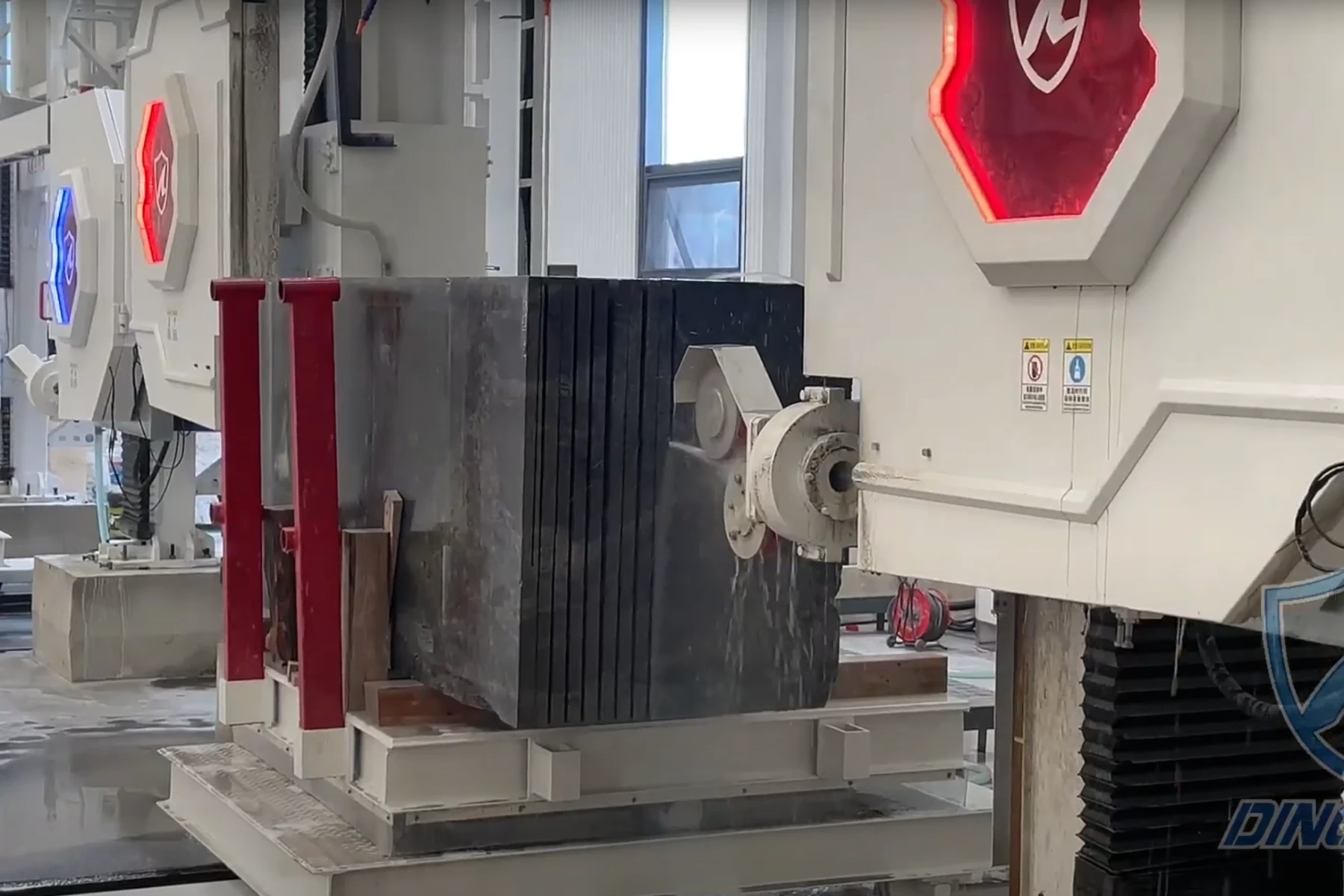

Stone Machining Centers

Stone machining centers are CNC-controlled systems for fabricating natural and engineered stones.

Key Features

Multi-functional capabilities for cutting, drilling, and milling.

High-speed precision for complex designs.

Applications

Fabricating countertops, detailed carvings, and custom stone surfaces.

Assembly Line Equipment

Assembly line equipment automates production processes to reduce manual intervention and increase output.

Key Features

Fully automated systems for seamless material flow.

Configurable layouts for specific production needs.

Applications

High-volume slab processing and modular manufacturing.

Hydraulic Stone Splitters

Hydraulic stone splitters use high pressure to break large stones into smaller blocks.

Key Features

Durable designs for demanding quarry or factory settings.

High-pressure systems for effective splitting.

Applications

Producing paving stones, cladding materials, and monuments.

Steps to Choosing the Right Industrial Machine

Define your needs by identifying the materials you process and the production goals you aim to achieve, such as cutting, calibrating, or shaping.

Compare machine features and capabilities to match your requirements. Waterjet cutting machines are ideal for precision tasks, thicknessing machines ensure uniformity, and stone machining centers handle detailed fabrication.

Consult Dinosaw experts to share your specific requirements and explore customization options.

Evaluate ROI by analyzing cost savings from reduced material waste and increased efficiency. Consider the long-term benefits of energy efficiency and machine durability.

Test and install the selected machine to ensure compatibility with your operations. Schedule professional installation and training for seamless integration.

Why Choose Dinosaw Industrial Machines?

Dinosaw machines combine innovative technology with robust engineering for unmatched precision, versatility, and durability. Designed to reduce waste, increase production capacity, and handle demanding industrial environments, Dinosaw machines also come with comprehensive global support, including after-sales services and operator training.

Conclusion

Choosing the right industrial machine is essential for optimizing production and achieving superior results. Dinosaw’s range of high-performance machines, from waterjet cutting systems to hydraulic stone splitters, ensures you’ll find the perfect solution for your needs.

Contact Dinosaw today to explore our advanced industrial machines and enhance your production capabilities!

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp: