Open Hours:

8:30am-20:30pm

Whatsapp:

Open Hours:

8:30am-20:30pm

Whatsapp:

Professional Stone Cutting Machines for Industrial Applications

Last Updated:

2025-04-15

Discover how Dinosaw advanced stone cutting machines, including bridge saws, block cutting machines, and manual saws, are transforming the processing of materials like granite, marble, basalt, travertine, refractory bricks, tiles, ceramics, carbon fiber, and acrylic. They provide precision and efficiency for cutting slabs, claddings, kitchen countertops, bar tops, sinks, washbasins, tabletops, staircases, walls, floor tiles, and fence stones, serving industries from construction to home decor worldwide.

Granite

Marble

quartz

slab

ceramic

sintered stone

firebrick

Professional Stone Cutting Machines for Industrial Applications

Last Updated:

2025-04-15

Discover how Dinosaw advanced stone cutting machines, including bridge saws, block cutting machines, and manual saws, are transforming the processing of materials like granite, marble, basalt, travertine, refractory bricks, tiles, ceramics, carbon fiber, and acrylic. They provide precision and efficiency for cutting slabs, claddings, kitchen countertops, bar tops, sinks, washbasins, tabletops, staircases, walls, floor tiles, and fence stones, serving industries from construction to home decor worldwide.

Granite

Marble

quartz

slab

ceramic

sintered stone

firebrick

Last Updated:

2025-01-15

Last Updated:

2025-01-15

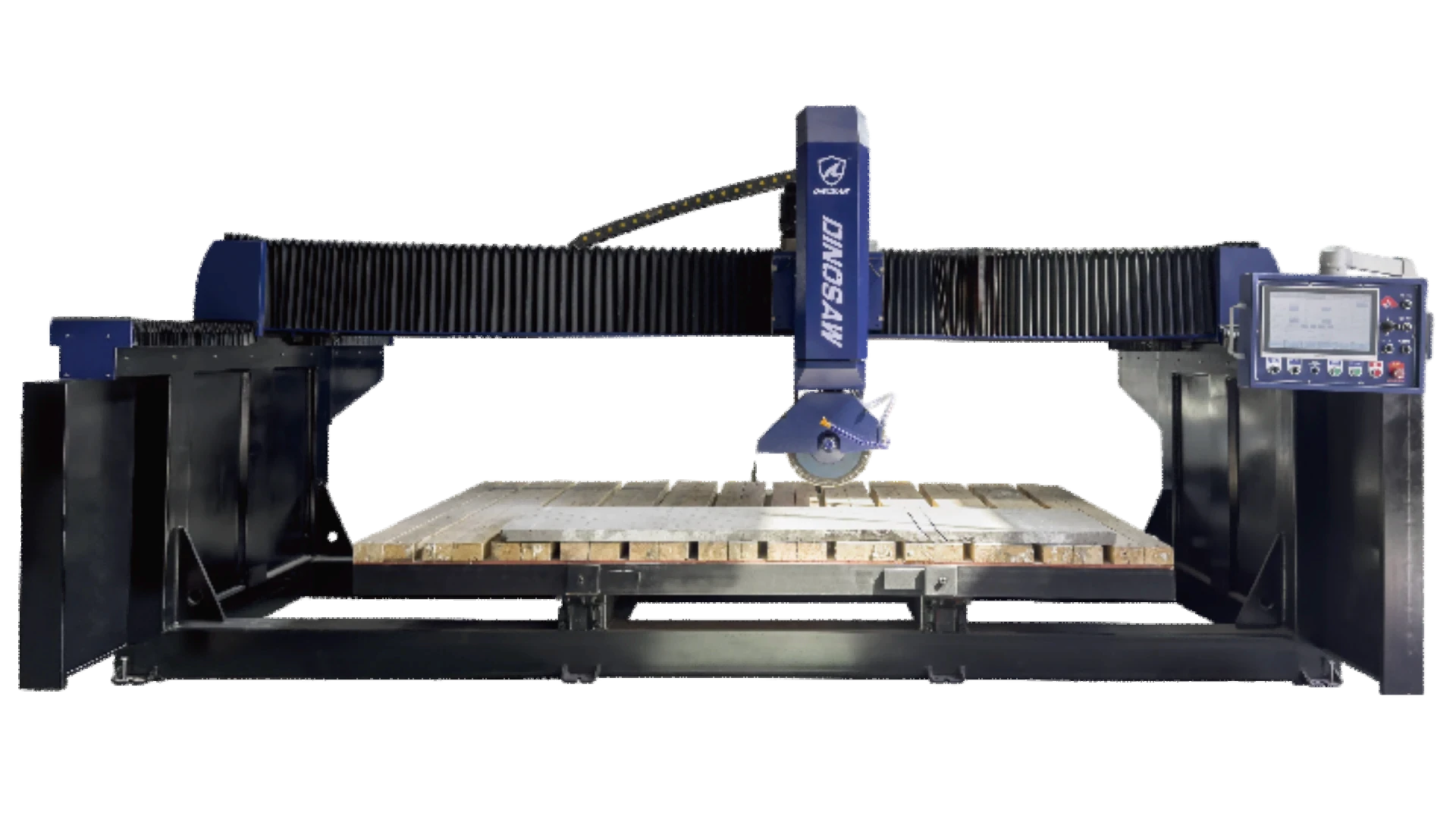

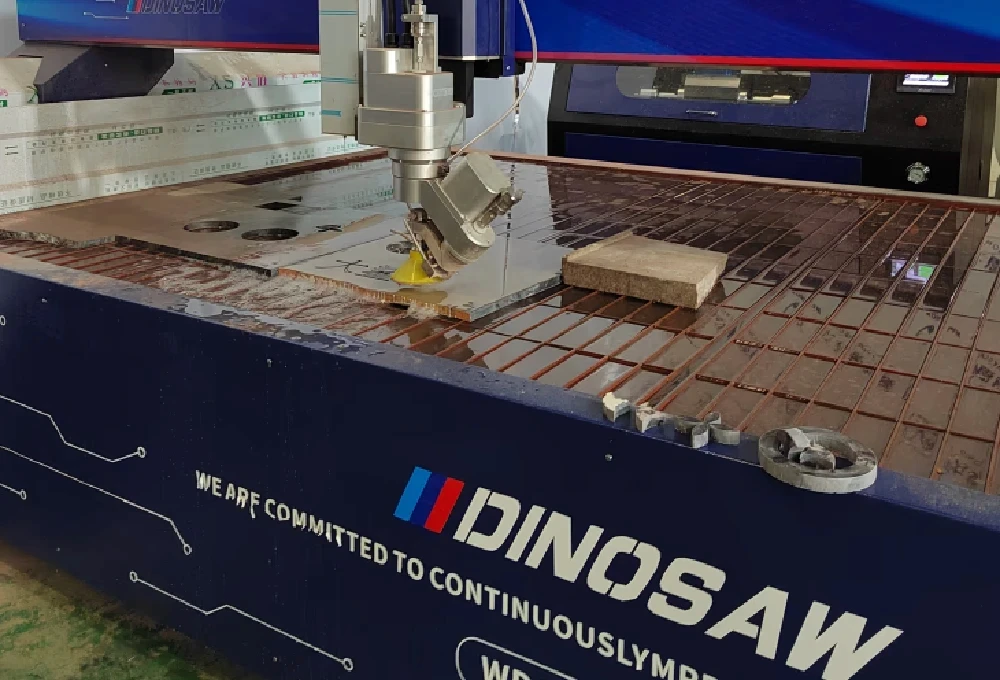

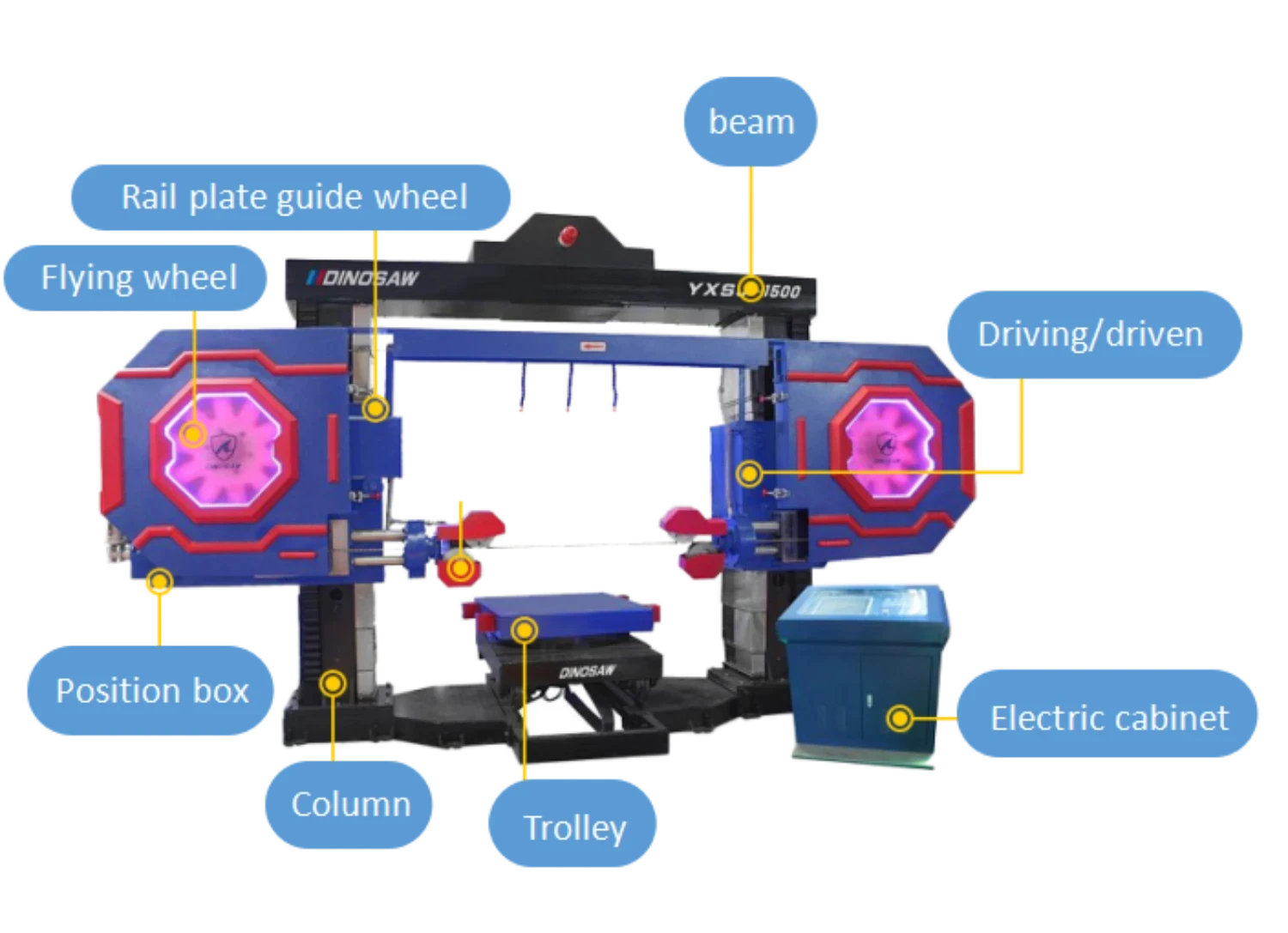

Bridge Saw

The Bridge Saw is our premium stone cutting machine designed for precision processing of hard materials. Built with a robust frame and advanced CNC control systems, it excels in cutting natural stones such as granite, marble, limestone, and basalt, as well as engineered materials like concrete, quartz, and porcelain. With multi-axis cutting capabilities and a rotating worktable, our stone Bridge Saw supports complex operations including straight cuts, bevel cuts, and intricate patterns. This industrial cutting machine is ideal for producing a variety of products such as slabs, tiles, countertops, sinks, vanities, wall panels, stair treads, and architectural components. Professional stone fabricators, construction companies, and high-end decorative stone producers choose DINOSAW Bridge Saws for their precision, efficiency, and versatility. Our cutting-edge technology ensures consistent quality and reduced material waste.

What is a Stone Cutting Machine?

A Stone Cutting Machine is a specialized industrial tool designed for processing natural stones (such as granite, marble, limestone) and construction materials (including concrete, ceramic, and engineered stone). Our product range includes three main categories:

Bridge Saws: Precision CNC cutting machines for detailed stone fabrication work, ideal for countertops, sinks, and architectural elements.

Block Cutting Machines: Heavy-duty equipment for efficient slabs production from stone blocks, perfect for high-volume manufacturing.

Manual Cutting Machines: Versatile, affordable solutions for smaller workshops and specific cutting tasks requiring flexibility and portability.

DINOSAW Stone Cutting Machines address common industry challenges such as material waste, precision requirements, and production efficiency. Our equipment combines intelligent technology with robust design to ensure reliable and high-quality stone processing for diverse applications.

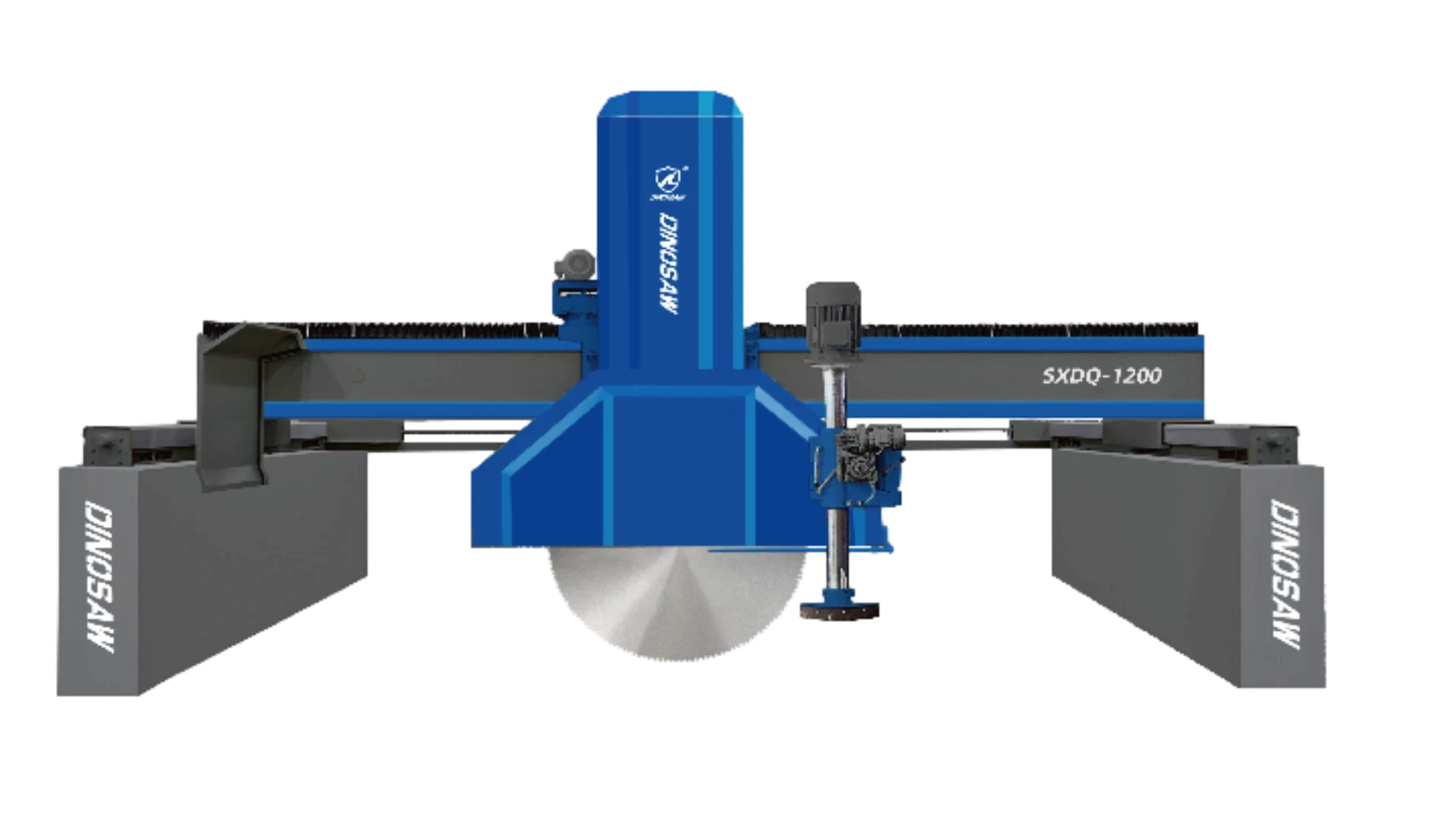

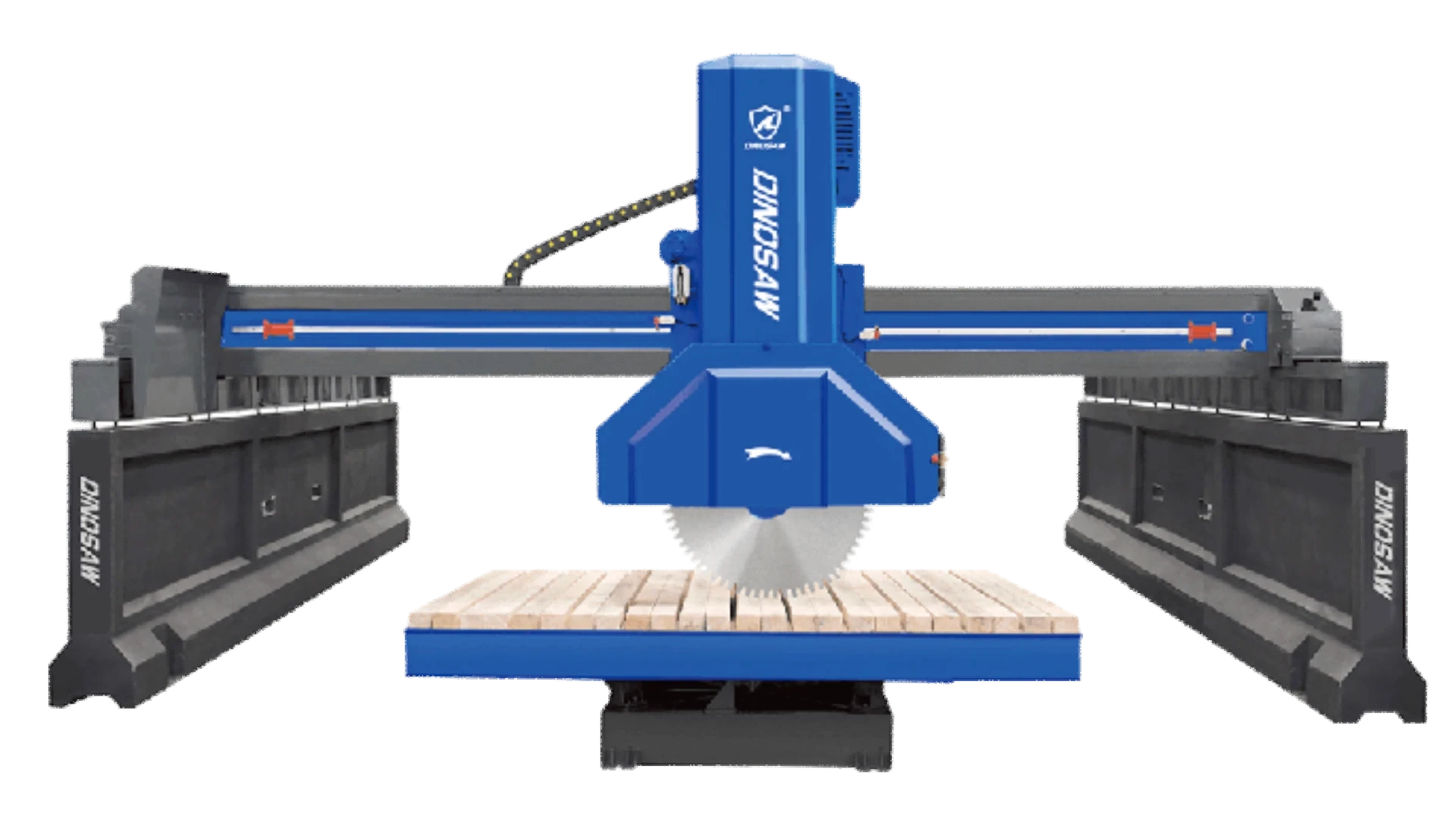

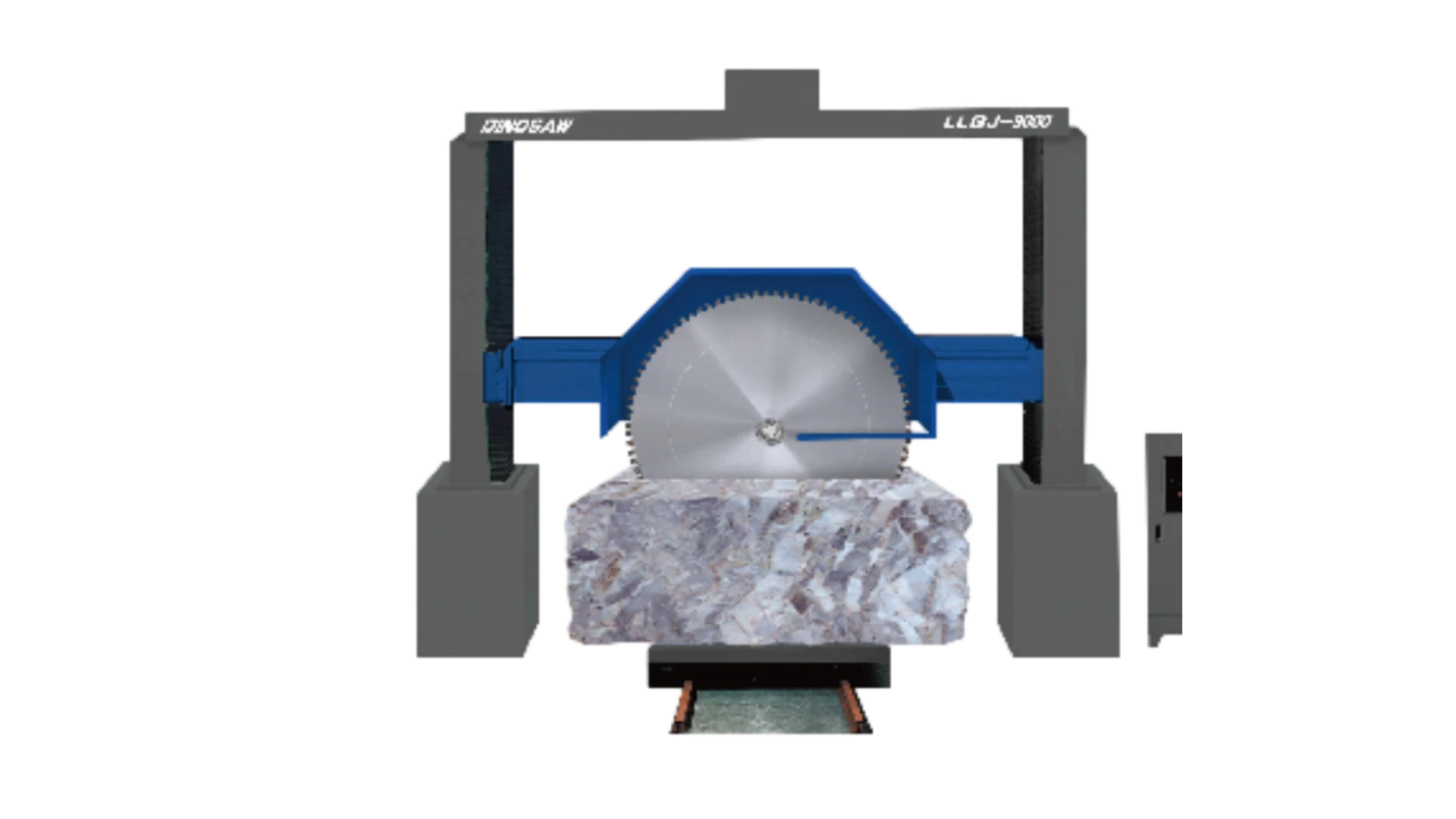

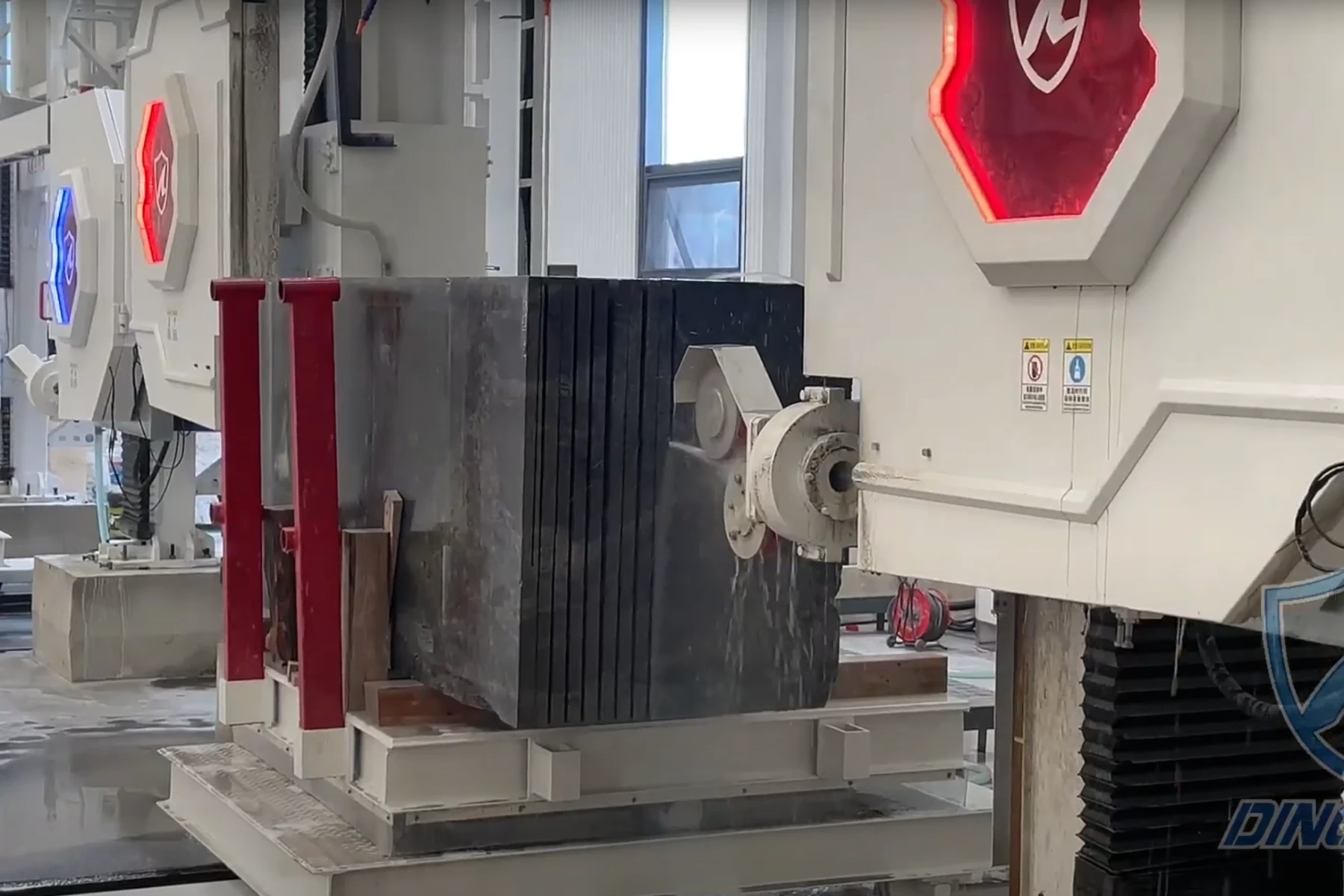

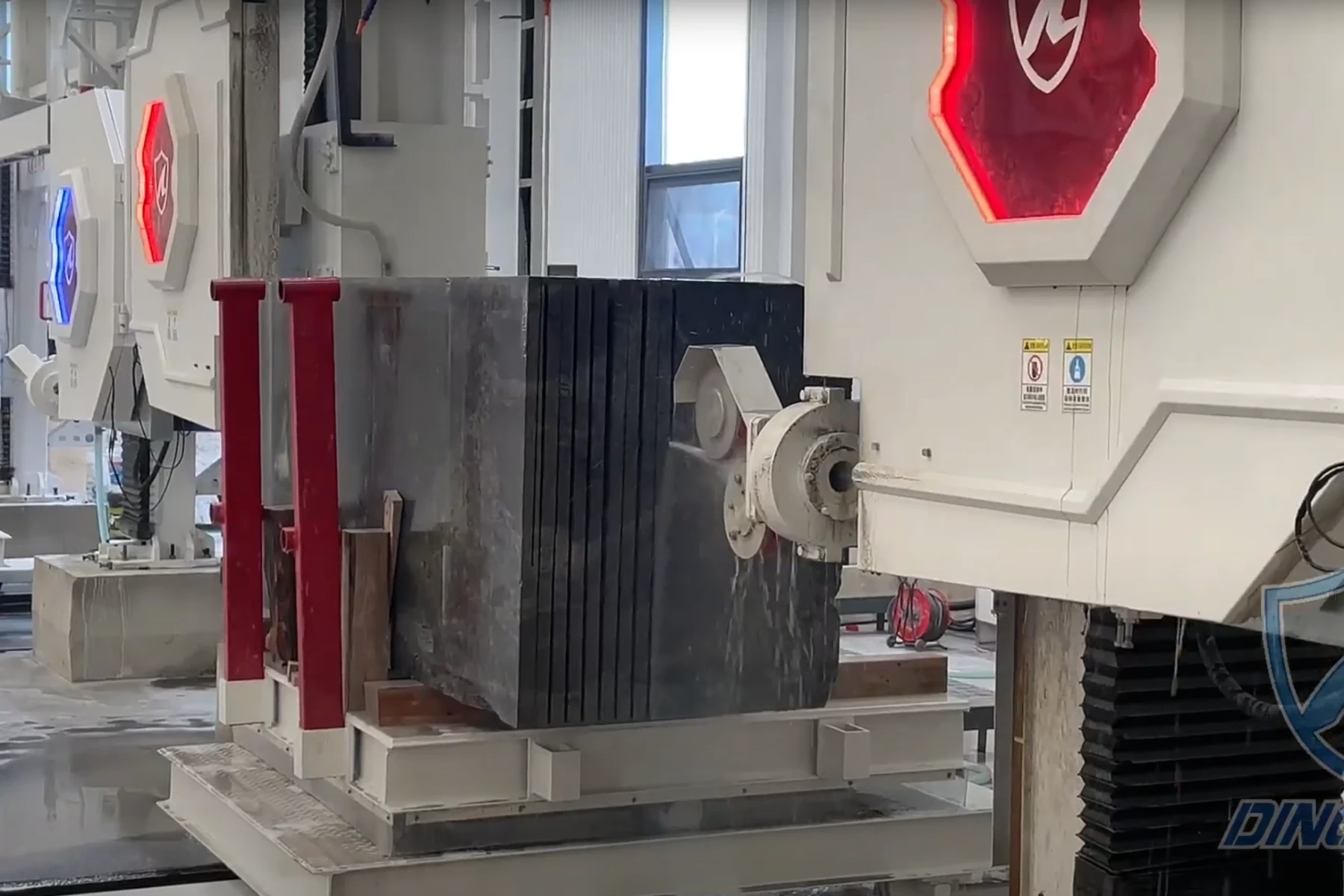

Block Cutting Machine

The Block Cutting Machine is our robust and efficient stone processing solution designed to transform large stone blocks into precise slabs or tiles with consistent thickness. Engineered for durability and high productivity, these machines are ideal for cutting natural stones including granite, marble, limestone, and construction materials like concrete. Our industrial stone block cutters feature a stable frame, powerful motor, and advanced cutting system that ensures smooth and accurate cuts. Available with multiple blades or single blade configurations, these machines offer flexibility to meet various production requirements, from high-volume slab production to specialized tile processing. Stone processing factories and construction material producers choose DINOSAW Block Cutting Machines for creating slabs, paving stones, wall cladding, and tiles with consistent quality and minimized material waste. Our machines deliver the reliability, precision, and efficiency essential for modern stone fabrication operations.

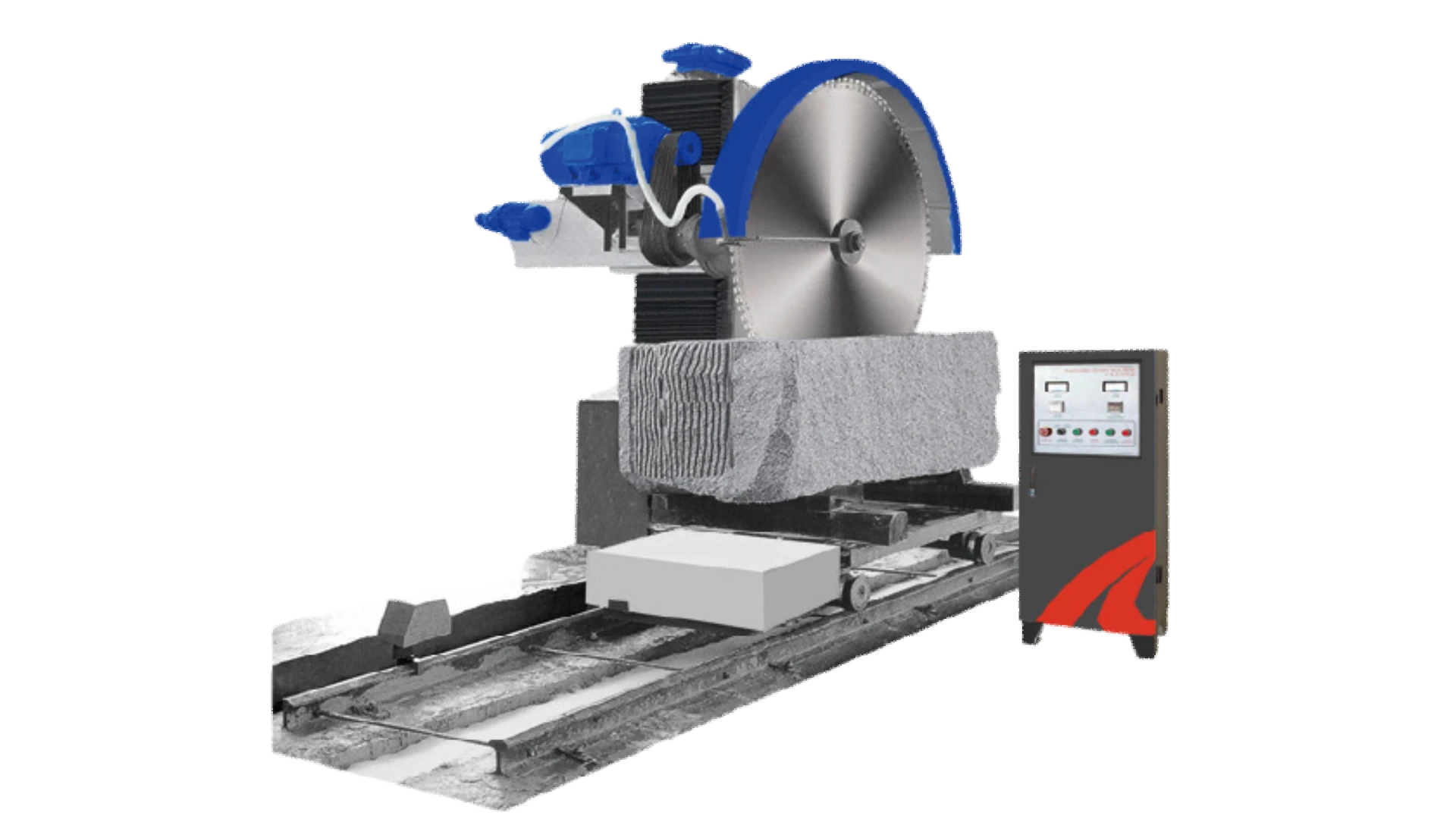

Manual Cutting machine

The Manual Stone Cutting Machine is our compact and efficient solution designed for precise cutting and edge finishing tasks. These versatile tools are perfect for processing various materials including tiles, ceramics, and softer natural stones like limestone and sandstone. Built with a durable frame and practical manual operation system, our manual stone cutters support 45-degree bevel cutting for creating smooth edges and precise angles. Their simplicity and portability make them ideal for small-scale workshops and on-site applications, offering flexibility for diverse cutting and finishing requirements. Small fabrication shops and contractors rely on DINOSAW Manual Cutting Machines for producing tiles, pavers, and decorative components with clean edges and precise finishes. Our machines deliver reliable performance and cost-effective solutions for small to medium-scale stone processing operations.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Comprehensive Guide to Choosing Stone Cutting Machine

Selecting the right Stone Cutting Machine is crucial for optimizing production processes and meeting specific customer demands. Whether working with granite, marble, or engineered materials, DINOSAW machines provide tailored solutions for your stone fabrication needs.

Understanding Your Raw Materials

Each material has unique processing requirements based on hardness, density, and form. Choosing the right machine ensures efficiency and precision.

Hard natural stones like granite, quartzite, and basalt require powerful and stable machines to maintain cutting accuracy. The Bridge Saw is designed to handle these tasks, ensuring consistent results and reducing tool wear.

Soft natural stones and non-stone materials like bluestone, acrylic, and composite panels benefit from the Manual Cutting Machine. This flexible solution is ideal for small-scale processing and budget-conscious projects.

Large stone blocks such as limestone and sandstone require consistent performance for slab production. The Block Cutting Machine ensures even thickness and smooth finishes, making it perfect for large-scale operations.

Construction materials like concrete and tiles demand precision and versatility. The Bridge Saw supports multiple angles and complex patterns, meeting these requirements with ease.

Matching the Stone Cutting Machine to Your Products

Production goals define the necessary features and capabilities in a Stone Cutting Machine.

For slabs and tiles, the Block Cutting Machine efficiently converts stone blocks into high-quality slabs and tiles, perfect for large-scale production.

For decorative interior products, the Bridge Saw offers precision cutting and CNC automation, ideal for high-end items like countertops and wall panels.

For architectural components, the Bridge Saw ensures smooth cutting for complex geometric shapes in large pieces like pillars and stair treads.

For outdoor decorative and structural products, the Block Cutting Machine excels in producing paving stones and curbstones, while the Bridge Saw handles detailed work on tombstones and monuments.

For small-scale custom products, the Manual Cutting Machine provides a reliable, budget-friendly option for projects like tabletops and custom décor.

Addressing Your Operational Challenges

Stone Cutting Machines help resolve common operational challenges.

To reduce high material waste, the Block Cutting Machine ensures precision and maximizes material usage.

For handling complex designs, the Bridge Saw’s CNC automation delivers precise results for intricate patterns and multi-angle cuts.

To overcome budget or space limitations, the Manual Cutting Machine offers a compact and affordable solution for small-scale operations.

Practical Steps to Choose Your Stone Cutting Machine

Evaluate your materials by identifying the type, hardness, and size you process most frequently.

Define your products, considering their shape, size, and complexity.

Analyze your production scale to determine whether speed, precision, or flexibility is your priority.

Pinpoint challenges, such as inefficiencies or limitations in your current processes.

Consult experts at Dinosaw to match your needs with the right machine, ensuring a tailored solution for your operations.

Why Dinosaw Machines Are the Right Fit

Dinosaw machines address real-world challenges with tailored solutions:

The Bridge Saw is ideal for customers needing high precision, complex designs, and versatility.

The Block Cutting Machine is designed for high-volume factories requiring efficient slab and tile production.

The Manual Cutting Machine is perfect for small workshops and budget-conscious operations, offering reliable performance for small-scale projects.

Conclusion

Choosing the right Stone Cutting Machine requires understanding your materials, production goals, and operational challenges. Dinosaw machines are designed to meet diverse needs, improving efficiency, reducing waste, and delivering superior results. Let Dinosaw help you find the perfect machine to support your success.

Bridge Saw

The Bridge Saw is our premium stone cutting machine designed for precision processing of hard materials. Built with a robust frame and advanced CNC control systems, it excels in cutting natural stones such as granite, marble, limestone, and basalt, as well as engineered materials like concrete, quartz, and porcelain. With multi-axis cutting capabilities and a rotating worktable, our stone Bridge Saw supports complex operations including straight cuts, bevel cuts, and intricate patterns. This industrial cutting machine is ideal for producing a variety of products such as slabs, tiles, countertops, sinks, vanities, wall panels, stair treads, and architectural components. Professional stone fabricators, construction companies, and high-end decorative stone producers choose DINOSAW Bridge Saws for their precision, efficiency, and versatility. Our cutting-edge technology ensures consistent quality and reduced material waste.

What is a Stone Cutting Machine?

A Stone Cutting Machine is a specialized industrial tool designed for processing natural stones (such as granite, marble, limestone) and construction materials (including concrete, ceramic, and engineered stone). Our product range includes three main categories:

Bridge Saws: Precision CNC cutting machines for detailed stone fabrication work, ideal for countertops, sinks, and architectural elements.

Block Cutting Machines: Heavy-duty equipment for efficient slabs production from stone blocks, perfect for high-volume manufacturing.

Manual Cutting Machines: Versatile, affordable solutions for smaller workshops and specific cutting tasks requiring flexibility and portability.

DINOSAW Stone Cutting Machines address common industry challenges such as material waste, precision requirements, and production efficiency. Our equipment combines intelligent technology with robust design to ensure reliable and high-quality stone processing for diverse applications.

Block Cutting Machine

The Block Cutting Machine is our robust and efficient stone processing solution designed to transform large stone blocks into precise slabs or tiles with consistent thickness. Engineered for durability and high productivity, these machines are ideal for cutting natural stones including granite, marble, limestone, and construction materials like concrete. Our industrial stone block cutters feature a stable frame, powerful motor, and advanced cutting system that ensures smooth and accurate cuts. Available with multiple blades or single blade configurations, these machines offer flexibility to meet various production requirements, from high-volume slab production to specialized tile processing. Stone processing factories and construction material producers choose DINOSAW Block Cutting Machines for creating slabs, paving stones, wall cladding, and tiles with consistent quality and minimized material waste. Our machines deliver the reliability, precision, and efficiency essential for modern stone fabrication operations.

Manual Cutting machine

The Manual Stone Cutting Machine is our compact and efficient solution designed for precise cutting and edge finishing tasks. These versatile tools are perfect for processing various materials including tiles, ceramics, and softer natural stones like limestone and sandstone. Built with a durable frame and practical manual operation system, our manual stone cutters support 45-degree bevel cutting for creating smooth edges and precise angles. Their simplicity and portability make them ideal for small-scale workshops and on-site applications, offering flexibility for diverse cutting and finishing requirements. Small fabrication shops and contractors rely on DINOSAW Manual Cutting Machines for producing tiles, pavers, and decorative components with clean edges and precise finishes. Our machines deliver reliable performance and cost-effective solutions for small to medium-scale stone processing operations.

The most popular related processing cases

You Can Refer To

Granite Mosaic Cutting Case - CNC Wire Saw Machine Supports Quanzhou Factory

Marble Block Slab Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Cement Product Cutting Case - CNC Wire Saw Machine Supports Spanish Factory

Granite Tombstone Case - CNC Wire Saw Machine Supports Chongqing Factory

More

Worth-reading articles on

industrial processing Machinery Cases

The practical videos On

How to install, use, and maintain industrial

Comprehensive Guide to Choosing Stone Cutting Machine

Selecting the right Stone Cutting Machine is crucial for optimizing production processes and meeting specific customer demands. Whether working with granite, marble, or engineered materials, DINOSAW machines provide tailored solutions for your stone fabrication needs.

Understanding Your Raw Materials

Each material has unique processing requirements based on hardness, density, and form. Choosing the right machine ensures efficiency and precision.

Hard natural stones like granite, quartzite, and basalt require powerful and stable machines to maintain cutting accuracy. The Bridge Saw is designed to handle these tasks, ensuring consistent results and reducing tool wear.

Soft natural stones and non-stone materials like bluestone, acrylic, and composite panels benefit from the Manual Cutting Machine. This flexible solution is ideal for small-scale processing and budget-conscious projects.

Large stone blocks such as limestone and sandstone require consistent performance for slab production. The Block Cutting Machine ensures even thickness and smooth finishes, making it perfect for large-scale operations.

Construction materials like concrete and tiles demand precision and versatility. The Bridge Saw supports multiple angles and complex patterns, meeting these requirements with ease.

Matching the Stone Cutting Machine to Your Products

Production goals define the necessary features and capabilities in a Stone Cutting Machine.

For slabs and tiles, the Block Cutting Machine efficiently converts stone blocks into high-quality slabs and tiles, perfect for large-scale production.

For decorative interior products, the Bridge Saw offers precision cutting and CNC automation, ideal for high-end items like countertops and wall panels.

For architectural components, the Bridge Saw ensures smooth cutting for complex geometric shapes in large pieces like pillars and stair treads.

For outdoor decorative and structural products, the Block Cutting Machine excels in producing paving stones and curbstones, while the Bridge Saw handles detailed work on tombstones and monuments.

For small-scale custom products, the Manual Cutting Machine provides a reliable, budget-friendly option for projects like tabletops and custom décor.

Addressing Your Operational Challenges

Stone Cutting Machines help resolve common operational challenges.

To reduce high material waste, the Block Cutting Machine ensures precision and maximizes material usage.

For handling complex designs, the Bridge Saw’s CNC automation delivers precise results for intricate patterns and multi-angle cuts.

To overcome budget or space limitations, the Manual Cutting Machine offers a compact and affordable solution for small-scale operations.

Practical Steps to Choose Your Stone Cutting Machine

Evaluate your materials by identifying the type, hardness, and size you process most frequently.

Define your products, considering their shape, size, and complexity.

Analyze your production scale to determine whether speed, precision, or flexibility is your priority.

Pinpoint challenges, such as inefficiencies or limitations in your current processes.

Consult experts at Dinosaw to match your needs with the right machine, ensuring a tailored solution for your operations.

Why Dinosaw Machines Are the Right Fit

Dinosaw machines address real-world challenges with tailored solutions:

The Bridge Saw is ideal for customers needing high precision, complex designs, and versatility.

The Block Cutting Machine is designed for high-volume factories requiring efficient slab and tile production.

The Manual Cutting Machine is perfect for small workshops and budget-conscious operations, offering reliable performance for small-scale projects.

Conclusion

Choosing the right Stone Cutting Machine requires understanding your materials, production goals, and operational challenges. Dinosaw machines are designed to meet diverse needs, improving efficiency, reducing waste, and delivering superior results. Let Dinosaw help you find the perfect machine to support your success.

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

Last Updated:

2025-04-15

Professional Stone Cutting Machines for Industrial Applications

Discover how Dinosaw advanced stone cutting machines, including bridge saws, block cutting machines, and manual saws, are transforming the processing of materials like granite, marble, basalt, travertine, refractory bricks, tiles, ceramics, carbon fiber, and acrylic. They provide precision and efficiency for cutting slabs, claddings, kitchen countertops, bar tops, sinks, washbasins, tabletops, staircases, walls, floor tiles, and fence stones, serving industries from construction to home decor worldwide.

Granite

Marble

quartz

slab

ceramic

sintered stone

firebrick

Bridge Saw

The Bridge Saw is our premium stone cutting machine designed for precision processing of hard materials. Built with a robust frame and advanced CNC control systems, it excels in cutting natural stones such as granite, marble, limestone, and basalt, as well as engineered materials like concrete, quartz, and porcelain. With multi-axis cutting capabilities and a rotating worktable, our stone Bridge Saw supports complex operations including straight cuts, bevel cuts, and intricate patterns. This industrial cutting machine is ideal for producing a variety of products such as slabs, tiles, countertops, sinks, vanities, wall panels, stair treads, and architectural components. Professional stone fabricators, construction companies, and high-end decorative stone producers choose DINOSAW Bridge Saws for their precision, efficiency, and versatility. Our cutting-edge technology ensures consistent quality and reduced material waste.

Block Cutting Machine

The Block Cutting Machine is our robust and efficient stone processing solution designed to transform large stone blocks into precise slabs or tiles with consistent thickness. Engineered for durability and high productivity, these machines are ideal for cutting natural stones including granite, marble, limestone, and construction materials like concrete. Our industrial stone block cutters feature a stable frame, powerful motor, and advanced cutting system that ensures smooth and accurate cuts. Available with multiple blades or single blade configurations, these machines offer flexibility to meet various production requirements, from high-volume slab production to specialized tile processing. Stone processing factories and construction material producers choose DINOSAW Block Cutting Machines for creating slabs, paving stones, wall cladding, and tiles with consistent quality and minimized material waste. Our machines deliver the reliability, precision, and efficiency essential for modern stone fabrication operations.

Manual Cutting machine

The Manual Stone Cutting Machine is our compact and efficient solution designed for precise cutting and edge finishing tasks. These versatile tools are perfect for processing various materials including tiles, ceramics, and softer natural stones like limestone and sandstone. Built with a durable frame and practical manual operation system, our manual stone cutters support 45-degree bevel cutting for creating smooth edges and precise angles. Their simplicity and portability make them ideal for small-scale workshops and on-site applications, offering flexibility for diverse cutting and finishing requirements. Small fabrication shops and contractors rely on DINOSAW Manual Cutting Machines for producing tiles, pavers, and decorative components with clean edges and precise finishes. Our machines deliver reliable performance and cost-effective solutions for small to medium-scale stone processing operations.

What is a Stone Cutting Machine?

A Stone Cutting Machine is a specialized industrial tool designed for processing natural stones (such as granite, marble, limestone) and construction materials (including concrete, ceramic, and engineered stone). Our product range includes three main categories:

Bridge Saws: Precision CNC cutting machines for detailed stone fabrication work, ideal for countertops, sinks, and architectural elements.

Block Cutting Machines: Heavy-duty equipment for efficient slabs production from stone blocks, perfect for high-volume manufacturing.

Manual Cutting Machines: Versatile, affordable solutions for smaller workshops and specific cutting tasks requiring flexibility and portability.

DINOSAW Stone Cutting Machines address common industry challenges such as material waste, precision requirements, and production efficiency. Our equipment combines intelligent technology with robust design to ensure reliable and high-quality stone processing for diverse applications.

The most popular related processing cases

You Can Refer To

The practical videos on

How to install, use, and maintain industrial

Worth-reading articles on

industrial processing Machinery Cases

Comprehensive Guide to Choosing Stone Cutting Machine

Selecting the right Stone Cutting Machine is crucial for optimizing production processes and meeting specific customer demands. Whether working with granite, marble, or engineered materials, DINOSAW machines provide tailored solutions for your stone fabrication needs.

Understanding Your Raw Materials

Each material has unique processing requirements based on hardness, density, and form. Choosing the right machine ensures efficiency and precision.

Hard natural stones like granite, quartzite, and basalt require powerful and stable machines to maintain cutting accuracy. The Bridge Saw is designed to handle these tasks, ensuring consistent results and reducing tool wear.

Soft natural stones and non-stone materials like bluestone, acrylic, and composite panels benefit from the Manual Cutting Machine. This flexible solution is ideal for small-scale processing and budget-conscious projects.

Large stone blocks such as limestone and sandstone require consistent performance for slab production. The Block Cutting Machine ensures even thickness and smooth finishes, making it perfect for large-scale operations.

Construction materials like concrete and tiles demand precision and versatility. The Bridge Saw supports multiple angles and complex patterns, meeting these requirements with ease.

Matching the Stone Cutting Machine to Your Products

Production goals define the necessary features and capabilities in a Stone Cutting Machine.

For slabs and tiles, the Block Cutting Machine efficiently converts stone blocks into high-quality slabs and tiles, perfect for large-scale production.

For decorative interior products, the Bridge Saw offers precision cutting and CNC automation, ideal for high-end items like countertops and wall panels.

For architectural components, the Bridge Saw ensures smooth cutting for complex geometric shapes in large pieces like pillars and stair treads.

For outdoor decorative and structural products, the Block Cutting Machine excels in producing paving stones and curbstones, while the Bridge Saw handles detailed work on tombstones and monuments.

For small-scale custom products, the Manual Cutting Machine provides a reliable, budget-friendly option for projects like tabletops and custom décor.

Addressing Your Operational Challenges

Stone Cutting Machines help resolve common operational challenges.

To reduce high material waste, the Block Cutting Machine ensures precision and maximizes material usage.

For handling complex designs, the Bridge Saw’s CNC automation delivers precise results for intricate patterns and multi-angle cuts.

To overcome budget or space limitations, the Manual Cutting Machine offers a compact and affordable solution for small-scale operations.

Practical Steps to Choose Your Stone Cutting Machine

Evaluate your materials by identifying the type, hardness, and size you process most frequently.

Define your products, considering their shape, size, and complexity.

Analyze your production scale to determine whether speed, precision, or flexibility is your priority.

Pinpoint challenges, such as inefficiencies or limitations in your current processes.

Consult experts at Dinosaw to match your needs with the right machine, ensuring a tailored solution for your operations.

Why Dinosaw Machines Are the Right Fit

Dinosaw machines address real-world challenges with tailored solutions:

The Bridge Saw is ideal for customers needing high precision, complex designs, and versatility.

The Block Cutting Machine is designed for high-volume factories requiring efficient slab and tile production.

The Manual Cutting Machine is perfect for small workshops and budget-conscious operations, offering reliable performance for small-scale projects.

Conclusion

Choosing the right Stone Cutting Machine requires understanding your materials, production goals, and operational challenges. Dinosaw machines are designed to meet diverse needs, improving efficiency, reducing waste, and delivering superior results. Let Dinosaw help you find the perfect machine to support your success.

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment