Precision Cutting Starts with the Right Circular Diamond Saw

Circular diamond saw blades deliver unmatched durability for cutting granite, marble, and concrete. At DINOSAW, we engineer blades to meet industrial demands, backed by 24/7 technical support.

Need immediate solutions? Order now for fast shipping or find a local distributor near you.

Click to view more diamond tools

Keep reading to unlock

Blade selection guides for your specific material (granite, tile, concrete, etc.)

Pro tips to extend blade lifespan and reduce costs

Exclusive bulk discounts for contractors and OEMs

How to choose the best diamond saw blade

Construction Industry: Concrete & Reinforced Steel Cutting

Standard Concrete Cutting

Recommended Blade: Segmented Blade

Design:

Notched gaps between segments for airflow/cooling.

Cutting Method:

Wet Cutting: Preferred for dust suppression and blade longevity (prevents diamond overheating).

Dry Cutting: Emergency outdoor use only (max 30 seconds per cut).

Reinforced Concrete (Rebar)

Recommended Blade: Sintered Segmented Blade

Design:

Metal bond + high-density diamonds for impact resistance.

Parameters:

Wet cutting only, ≤5,000 RPM to avoid rebar friction sparks.

Stone Processing: Marble, Granite & Natural Stone

Marble Polishing

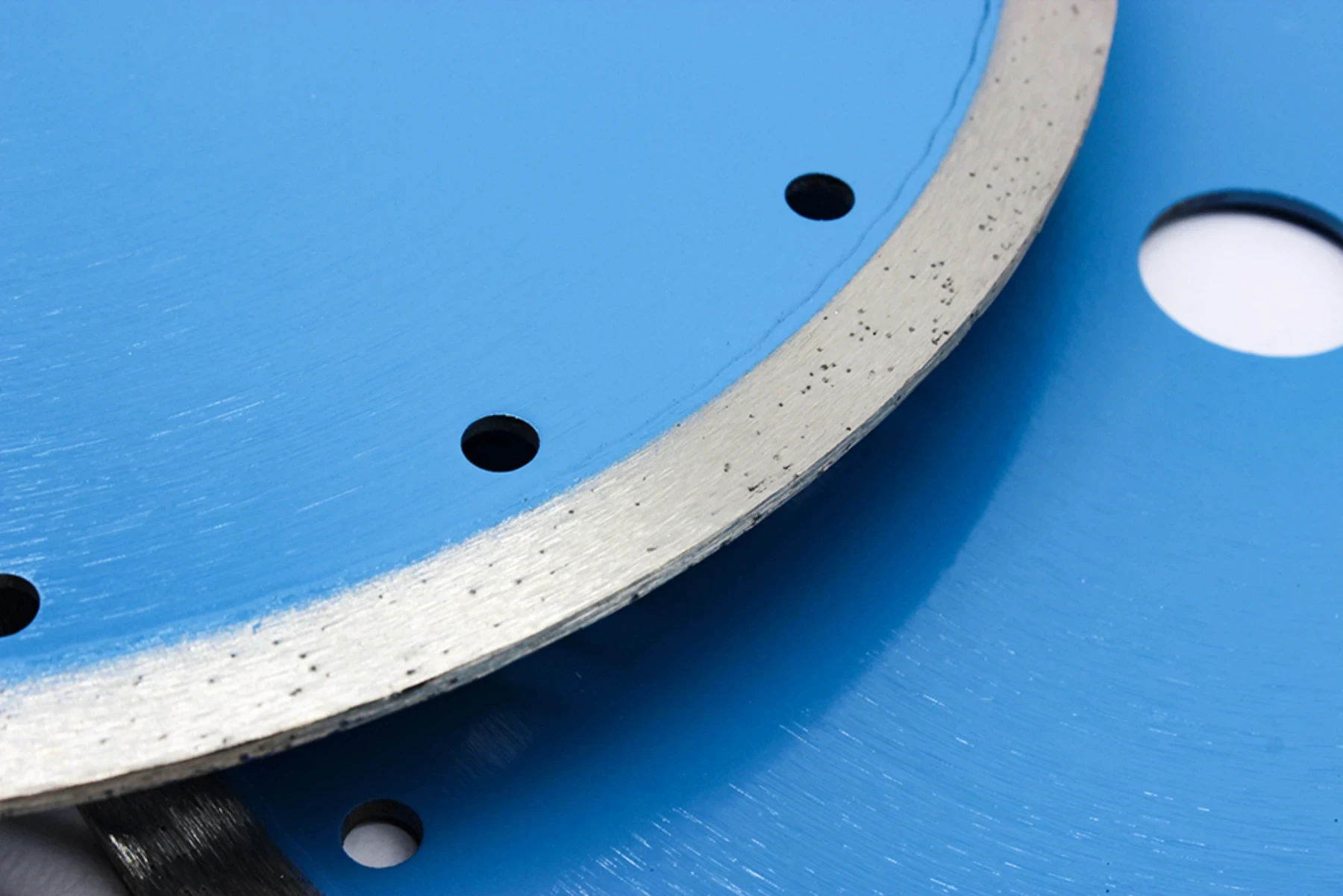

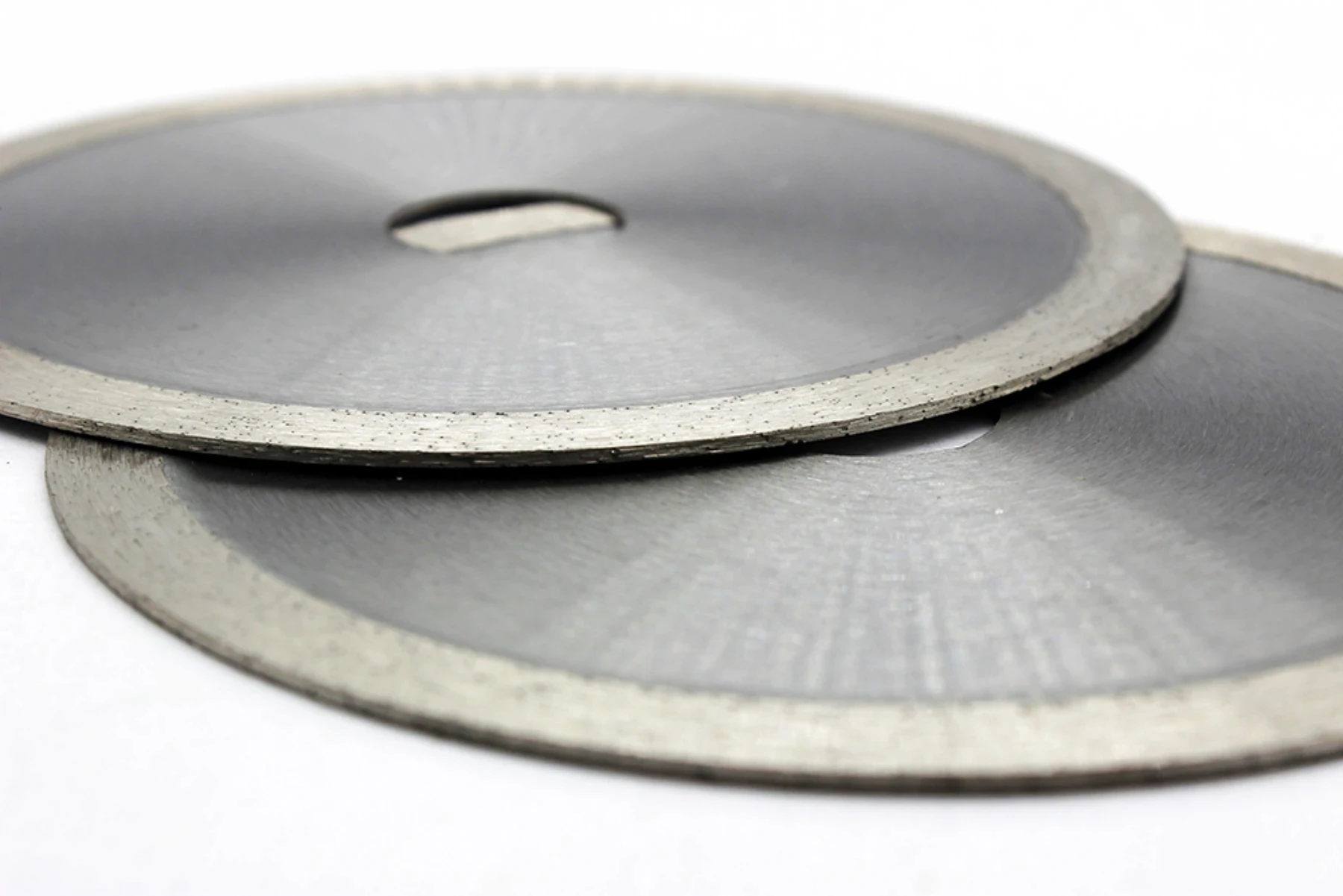

Recommended Blade: Continuous Rim Blade

Design:

Seamless edge with uniform diamond distribution.

Cutting Method:

Wet cutting mandatory (water temp: 20–25°C to stabilize bond).

Critical Tip:

Use soft-bond blades (copper-based) to prevent edge chipping.

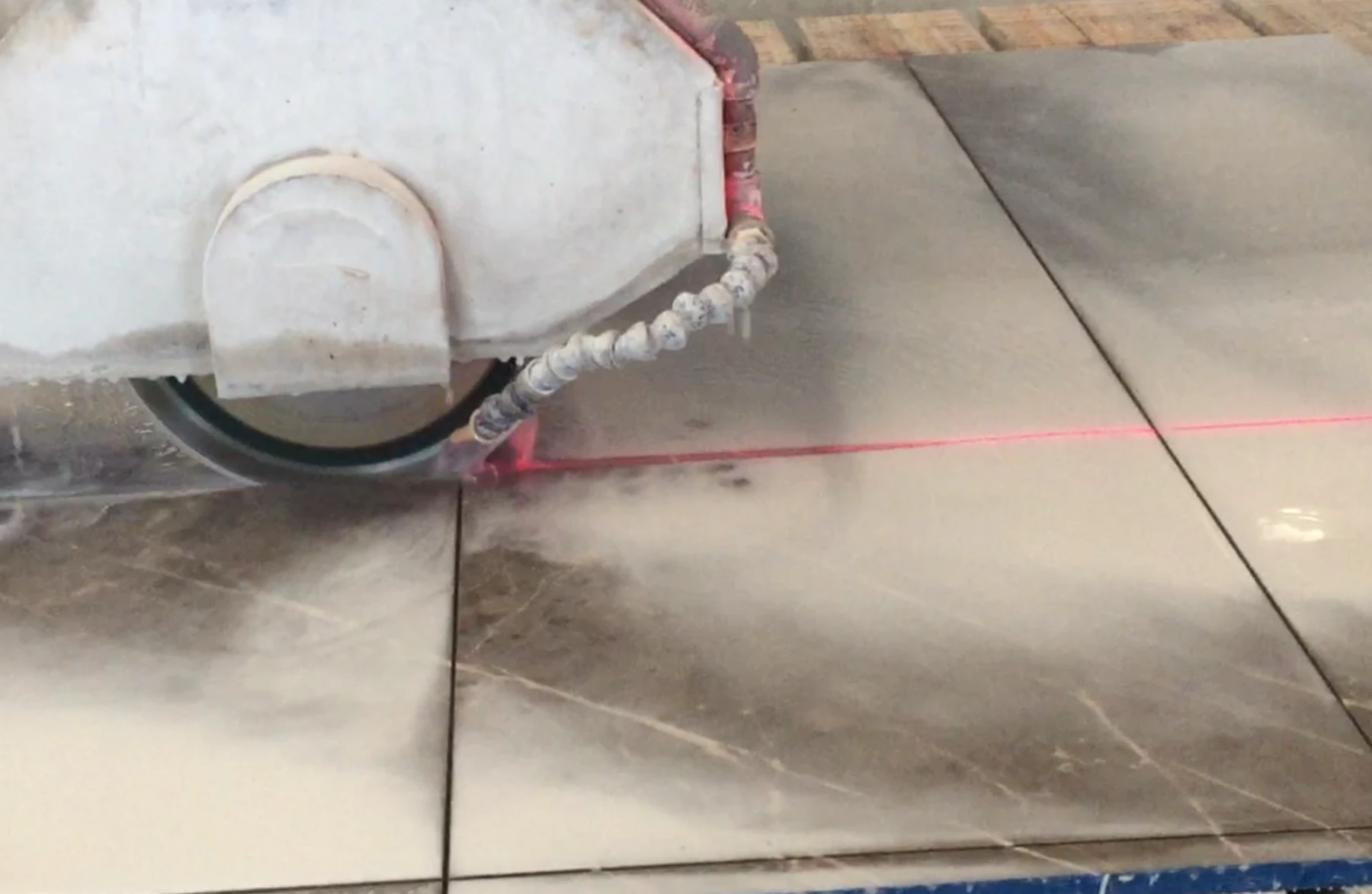

Granite Grooving

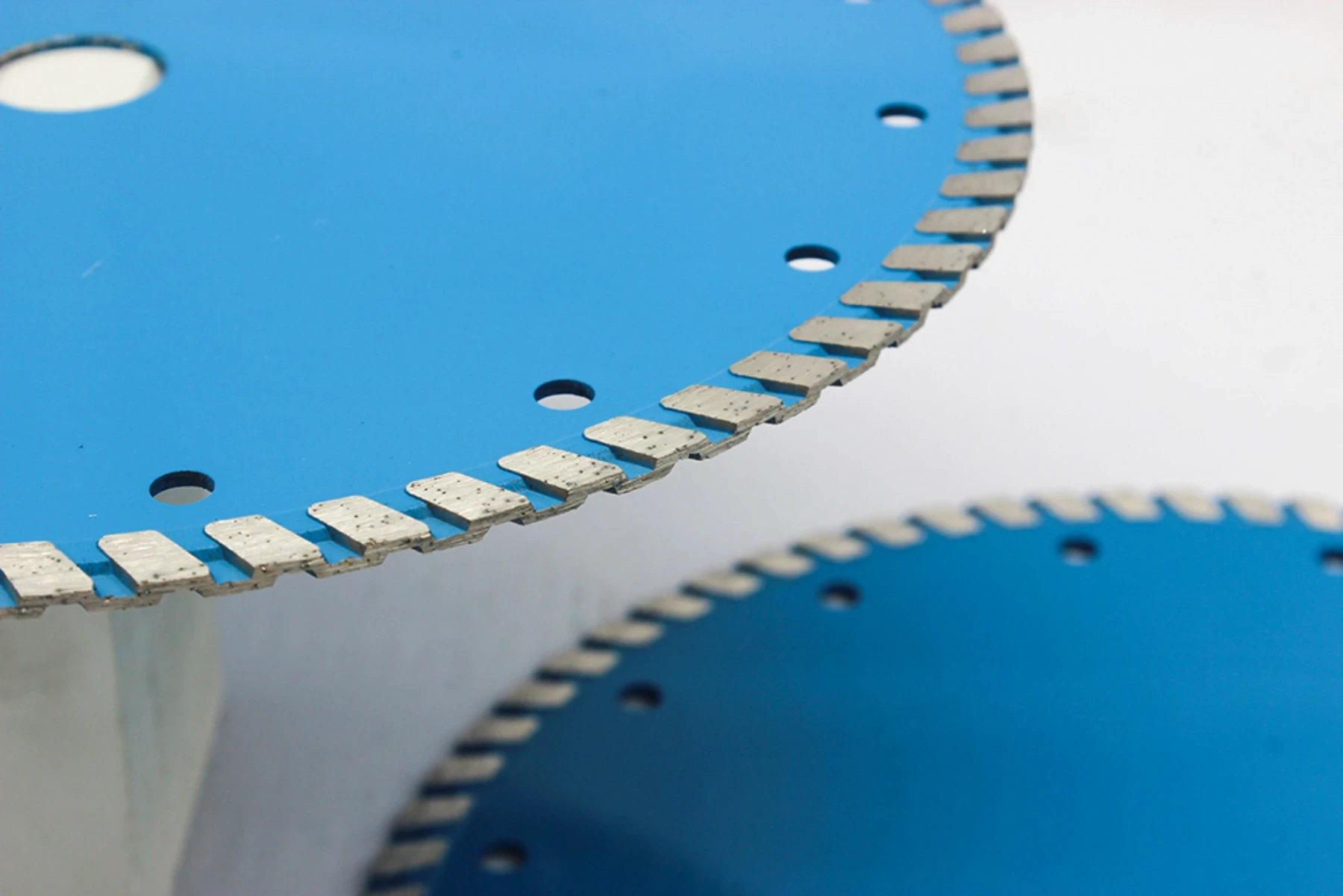

Recommended Blade: Turbo Blade

Design:

Turbine-shaped teeth balance speed and finish.

Parameters:

Dry (outdoor) or wet (indoor), 4,500 RPM.

Alternative:

Electroplated Diamond Blades for thin slabs (<3cm).

Ceramic & Tile Industry

Ceramic Tile Cutting

Recommended Blade: Ultra-Thin Continuous Rim Blade (≤1.2mm)

Design:

Narrow kerf reduces material waste.

Cutting Method:

Wet cutting for chip-free edges.

Diamond Specs:

50/60 grit + 25–30% concentration.

Porcelain/Quartz Countertops

Recommended Blade: Fine Turbo Blade

Design:

Vibration-dampening teeth for brittle materials.

Parameters:

Wet cutting with ≥2L/min water flow.

Municipal & Specialty Projects: Asphalt, Refractory Materials

Asphalt Pavement Repair

Recommended Blade: Soft-Bond Segmented Blade

Design:

Fast-wearing bond exposes fresh diamonds for sticky asphalt.

Cutting Method:

Dry cutting to avoid water contamination.

Refractory Bricks/Composites

Recommended Blade: Laser-Welded Diamond Blade

Design:

High-temperature resistance (>600°C).

Parameters:

Low-speed wet cutting (≤3,000 RPM) to prevent delamination.

Wet vs. Dry Cutting Diamond Saw: Cost-Benefit Analysis

Method | Best For | Pros | Cons | Cost Efficiency |

|---|---|---|---|---|

Wet saw cutting | Indoor precision tasks | 1. Dust-free (compliance) | 1. Water system cost | Ideal for long-term projects |

Dry saw cutting | Outdoor/emergency jobs | 1. No water needed | 1. Dust hazards (PPE required) | Cost-effective for small-scale tasks |

Decision Flowchart: 3 Steps to Optimize Blade Selection

Material Properties

Hardness (Mohs hardness ≥7 → soft bond)

Brittleness (high → continuous rim)

Cutting Environment

Indoor/outdoor → wet/dry method

Precision needs → tooth design (turbo/continuous)

Machine Compatibility

Blade diameter (≤ saw capacity)

Arbor size (tolerance ≤0.1mm)

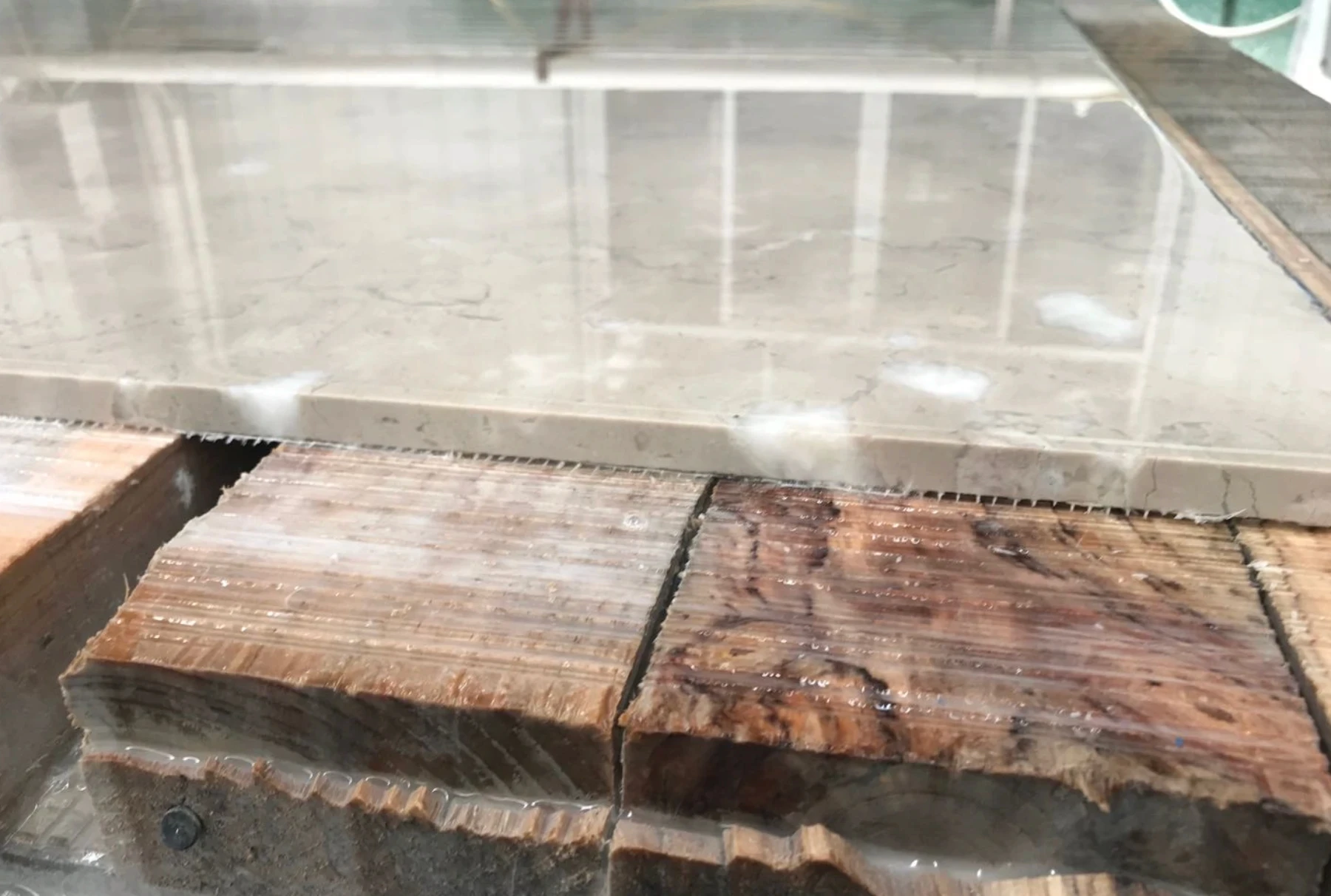

Case Study: Costly Mistakes in Blade Selection

Scenario: A stone factory used segmented blades for marble, causing 15% edge chipping.

Root Cause: Segmented blades generate vibration, unsuitable for brittle stone.

Solution: Switched to continuous rim blades + wet system → chipping rate dropped to 3%.

Savings: $12,000/year in material waste, 40% lower blade consumption.

Expert Answers to Common Queries

Can I use a diamond blade on a standard circular saw?

Yes, but ensure RPM stays below 5000 and use water cooling for hard materials.

How to cut granite without chipping?

Choose continuous rim blades and maintain steady cutting speed.

Upgrade Your Cutting Tools Today

Circular diamond saw blades from DINOSAW offer precision, durability, and cost savings.

Order now for fast delivery or request a custom quote for large projects. Start cutting smarter with tools trusted by professionals worldwide.