Associated Machine

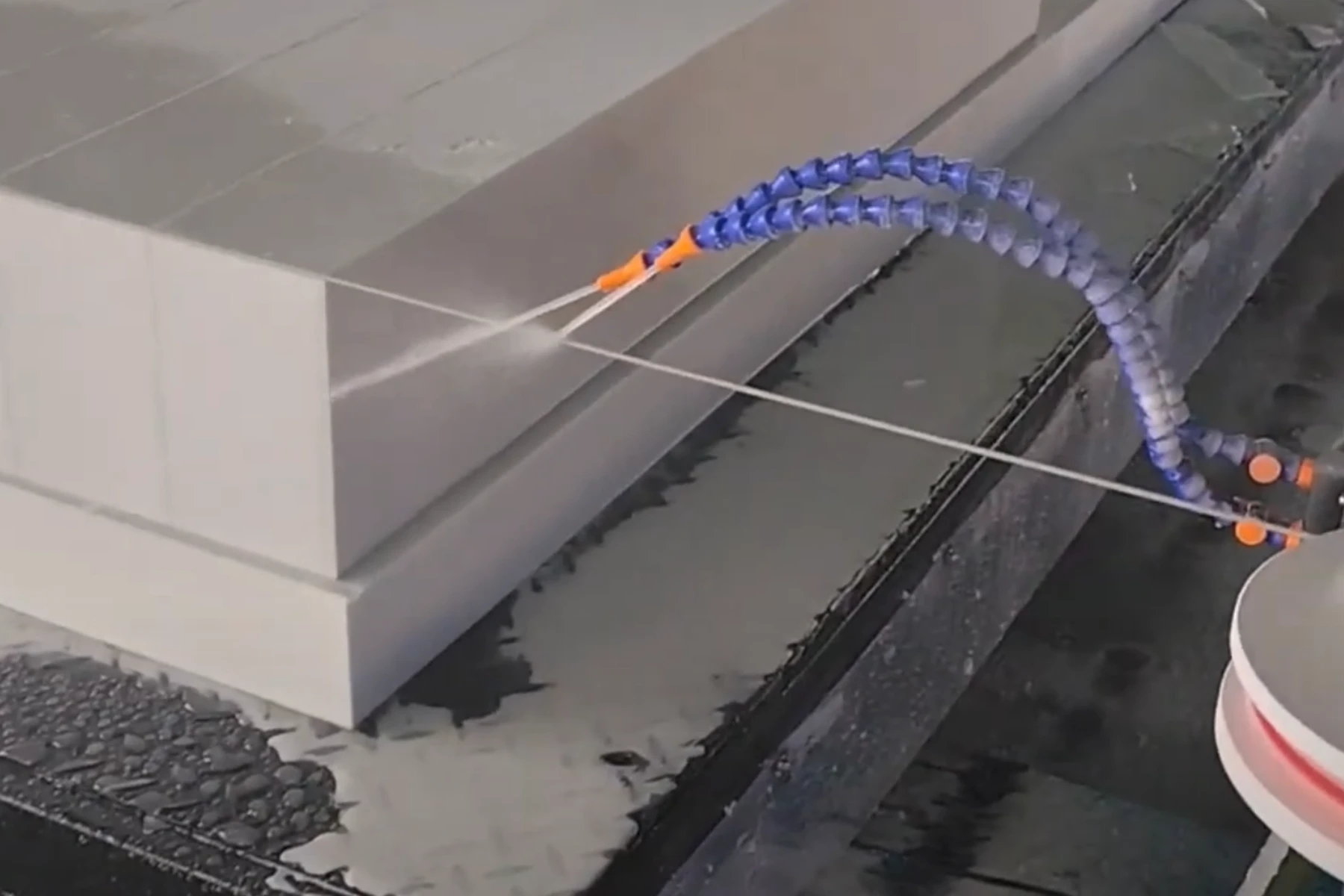

Foam Ceramic Corbel Cutting Challenge

A newly established processing factory in Mumbai aspired to enter the premium architectural decoration market, particularly focusing on foam ceramic corbels. However, as a small startup with limited experience, they faced significant challenges in selecting the right equipment and mastering production techniques. They needed a machine that could minimize trial-and-error costs while handling complex design requirements. After evaluating multiple suppliers, the Dinosaw CNC Wire Saw stood out as the perfect partner.

CNC Wire Saw Machine Helps Startups Break Through

The CNC Wire Saw Machine offered highly intelligent cutting solutions, making it ideal for startups. Its user-friendly interface significantly reduced employee training time, enabling rapid production deployment. The intelligent path-planning feature allowed the client to swiftly adjust processing parameters to accommodate diverse corbel designs. During the initial production phase, the machine not only boosted processing efficiency but also enabled the factory to produce multiple corbel samples within three weeks, securing their first orders.

What DINOSAW Can Do for You

With Dinosaw's support, the startup successfully entered the premium market. Their corbel products were praised for their quality and innovative designs, achieving a breakthrough in a short time. A client remarked, “Dinosaw’s equipment and service enabled us to enter a new market with lower risks. We look forward to more collaborations with Dinosaw in the future!”