Associated Machine

Foam Ceramic Window Casing Cutting Challenge

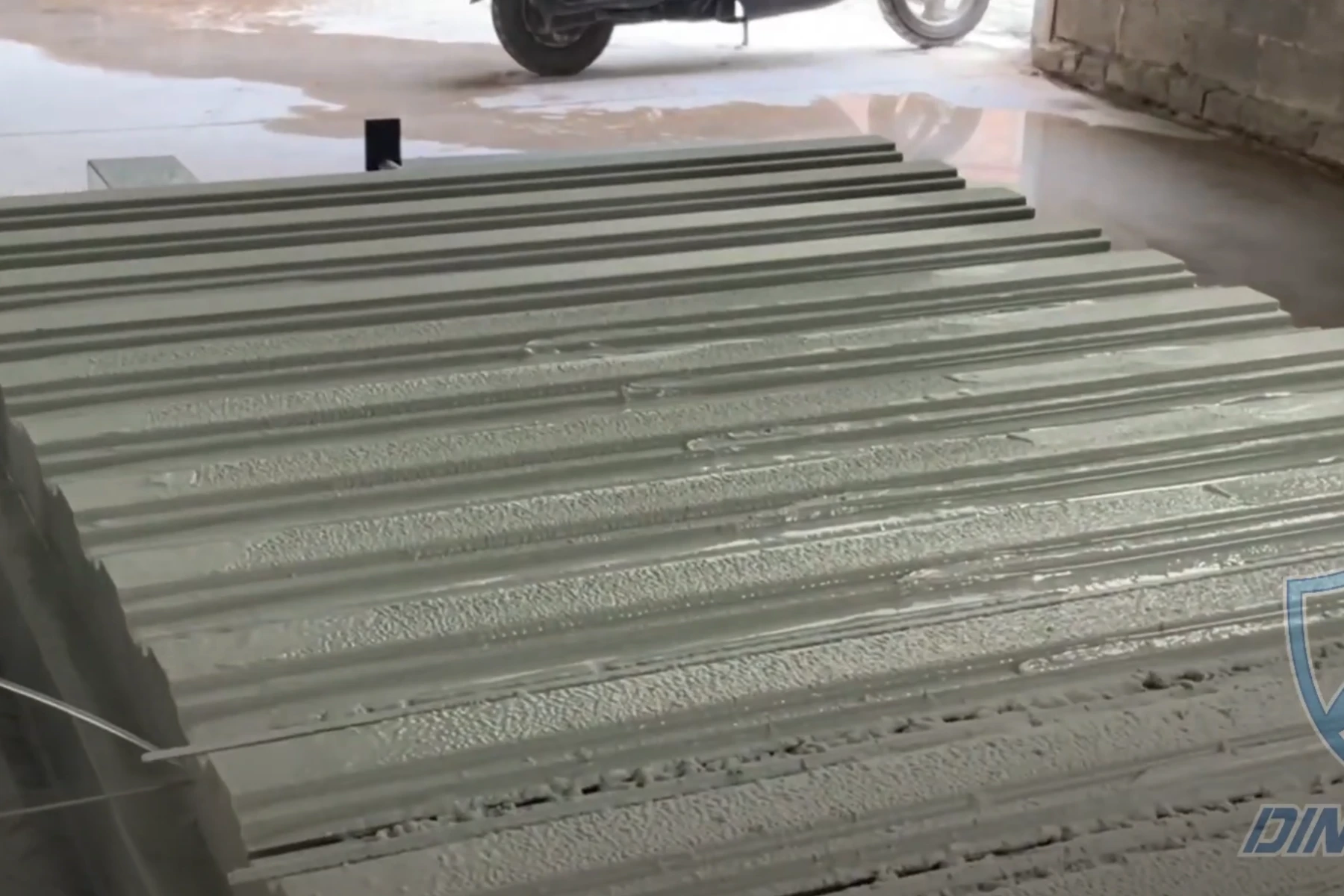

With the rapid growth of Ukraine's construction industry, the demand for green building materials, especially lightweight and eco-friendly foam ceramic products, has surged. A local processing factory decided to expand its product line to include window casings to cater to high-end construction projects. These products required precise dimensions and intricate designs, which traditional cutting equipment struggled to achieve in terms of efficiency and quality. To meet the challenges of this new market, the factory selected the Dinosaw CNC Wire Saw Machine.

CNC Wire Saw Machine Achieves Efficient Window Casing Production

Dinosaw provided a comprehensive solution tailored to the client’s needs. The YXSJ-1800-12H features intelligent path planning, automatically adjusting cutting trajectories to match the design specifications of window casings, ensuring precision within ±0.2mm. The machine’s batch processing mode allowed multiple pieces to be cut simultaneously, significantly boosting productivity. Additionally, its low-noise and energy-efficient operation aligned with Ukraine’s emphasis on sustainable manufacturing, further strengthening the client’s market position.

What DINOSAW Can Do for You

With the Dinosaw CNC Wire Saw Machine, the factory successfully scaled up window casing production, delivering high-quality initial orders and securing multiple long-term contracts. The machine’s reliability enabled the client to handle customized orders more flexibly, meeting diverse project requirements. The client shared, “This equipment not only enhanced our production capacity but also positioned us firmly in Ukraine’s high-end construction market, opening up new opportunities for future growth.”