CNC Wire Saw Introduction

Dinosaw CNC wire saws are versatile machines used for processing a variety of materials, including stone, metal, and glass. These machines offer advanced technology and stable performance, making them suitable for various cutting applications. Whether you’re working with large stone cutting projects or precision metal processing, Dinosaw is your reliable partner. We are committed to maximizing the performance of your equipment through technological innovation and high-quality after-sales service.

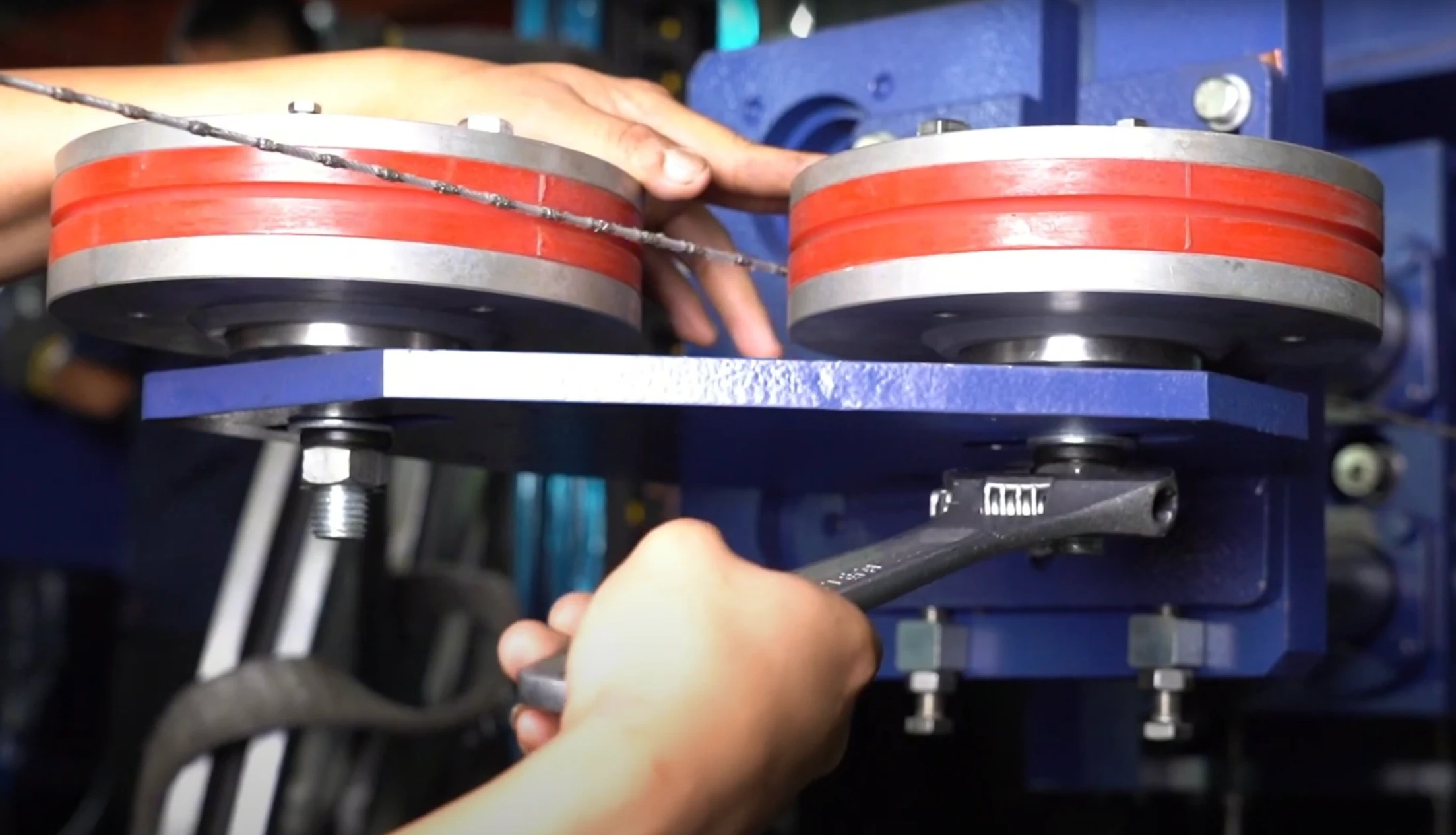

Guide Wheel Rubber Ring Uneven Wear Leading to Misaligned Cutting - Solution

This video will guide you through how to resolve the issue of uneven wear on the guide wheel and rubber ring, causing misaligned cutting in stretch-and-retract wire saw machines. Follow these steps:

Step 1: Adjust the Horizontal Position of the Guide Wheel

Locate the guide wheel and find the four fixing screws beneath it.

Use a wrench to loosen the fixing screws, then push the guide wheel outward on both sides.

Once the wire is free from the groove of the guide wheel, tighten the four fixing screws to secure the guide wheel in place for further adjustment.

Step 2: Adjust the Vertical Position of the Guide Wheel

Observe the alignment between the wire and the groove of the rubber ring.

Loosen the three side screws on the guide wheel to allow the adjustment of the set screws.

Adjust the guide wheel height:

If the groove in the rubber ring is higher than the wire, loosen the set screws to lower the guide wheel.

If the groove is lower than the wire, tighten the set screws to raise the guide wheel.

Ensure the groove of the rubber ring is parallel to the wire.

Once the guide wheel is correctly positioned, retighten the three side screws to secure the adjustment.

Step 3: Reset the Distance Between the Guide Wheel and the Wire

Loosen the bottom fixing screws and push the guide wheel (previously adjusted outward in Step 1) back into position.

Ensure the wire sits inside the groove of the rubber ring but does not directly contact it. Leave a small gap between the wire and the groove.

Rotate the guide wheel and observe the wire:

If the wire vibrates due to the rotation of the guide wheel, adjust the distance between the guide wheel and the wire.

If the wire remains steady, the adjustment is complete. Tighten the bottom fixing screws to secure the guide wheel.

Keeping Your Wire Saw Machine Running

At Dinosaw, we go beyond just providing machines—we offer comprehensive after-sales support to ensure your success. From installation and training to regular maintenance and system updates, our dedicated team is here to keep your CNC wire saw machine running smoothly. Trust Dinosaw to be your reliable partner every step of the way.