Introduction: Achieve Flawless Surfaces with Professional Granite Polishing Pads

Granite polishing pads from DINOSAW are engineered for factories and workshops. With 20+ years in stone machinery, we help you reduce costs and boost efficiency.

Need a custom granite polisher? Specify

Pad type

Diamond polishing pads, resin pads, or hybrid designs.

Application

Slabs, tiles, or custom stone shapes.

Machine

Compatible with granite polishers, grinders, or CNC machines.

[Get Instant Quote]|[Explore Polishing and Grinding Machines]|[Explore Granite Polish Tools]

Polishing Granite with Diamond Pads: Step-by-Step Guide

Prepare the Surface

Clean granite slabs to remove debris. Check for cracks (repair if depth >1mm).

Select the Right Pad

Coarse grinding (50#-200#): Use diamond sanding pads. Fine polishing (1500#+): Switch to diamond buffing pads.

Set Up Your Equipment

Attach pads to granite polisher or grinder. Adjust speed: 1200-2500 RPM for dry pads; 800-1800 RPM for wet.

Key Tips

Wet polishing reduces dust by 90% (ideal for indoor use). For marble or concrete, use specialized stone polishing pads.

Why DINOSAW’s Diamond Polishing Pads Lead the Industry

Unmatched Durability

Our granite polishing pads last 3x longer than standard discs (tested on 30mm quartzite).

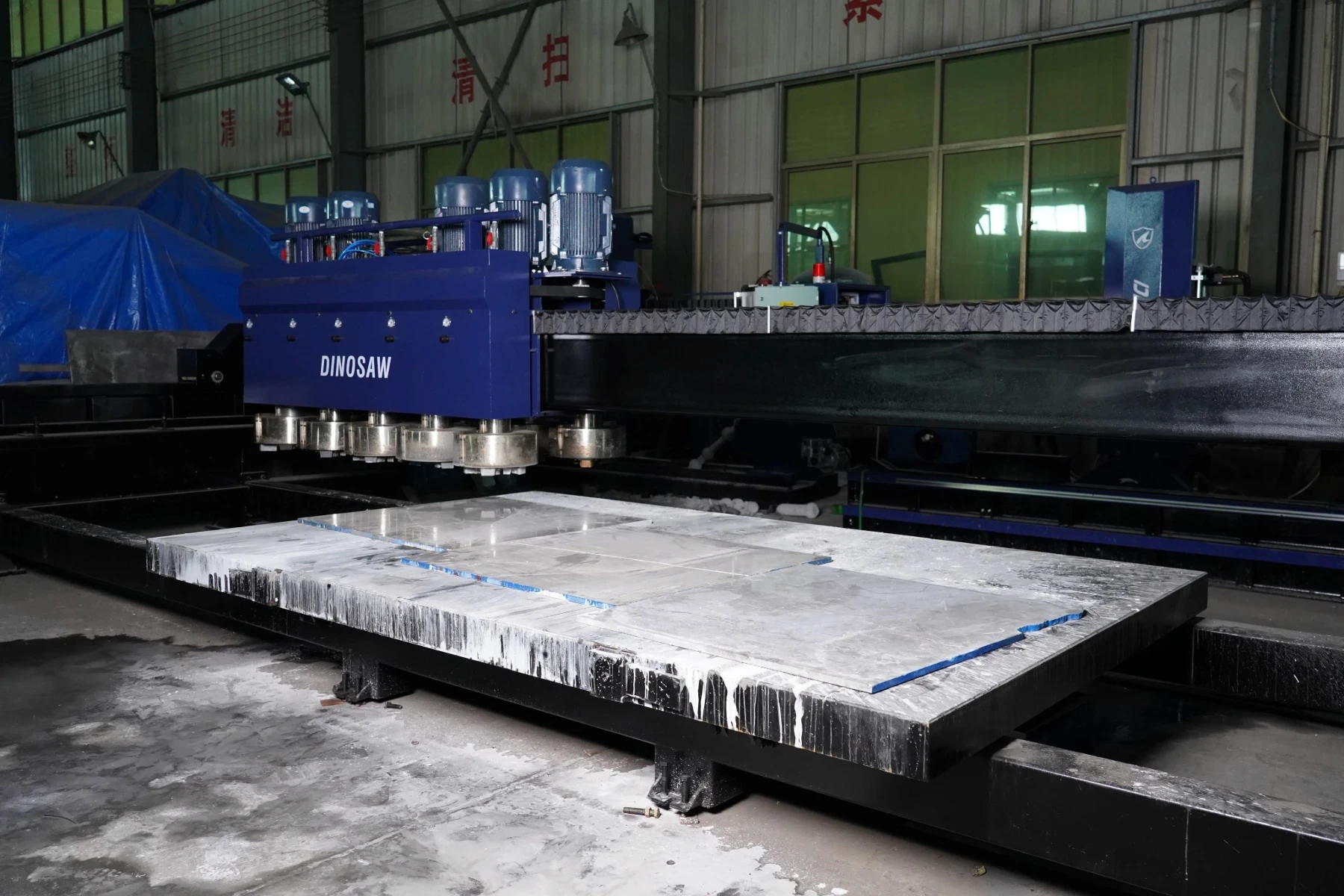

Full Compatibility

Works with all granite polishing tools: handheld grinders, bridge saws, robotic arms. Seamless shift from concrete polishing pads to granite discs.

Trusted by Global Factories

ISO-certified diamond abrasive pads. 12-month warranty for stone polishing tools.

Avoid Common Mistakes with Stone Polishing Pads

Do’s

Store diamond pads flat to prevent warping. Use tile polishing pads for delicate surfaces like ceramics.

Don’ts

Never exceed max RPM (causes pad delamination). Avoid using marble polishing pads on granite.

Critical Data

Dry diamond pads generate 0.19mg/m³ dust vs. 0.01mg/m³ with wet. Wrong grit sequence increases labor time by 50%.

Granite Polishing Machines & Accessories

Heavy-Duty Equipment

Automatic polishers for slabs up to 3m long. Dustless grinders with HEPA filters.

Essential Tools

Granite buffing pads: Restore faded countertops. Diamond polish pads for granite: 3000# grit for mirror finishes.

FAQs: Granite Polishing Essentials

Q: How do you polish granite edges with polishing pads?

Use flexible diamond polish pads (3” size) on angled grinders.

Q: Wet or dry polishing for outdoor granite?

Wet polishing pads prevent heat cracks in sunlight.

Q: Best pad for mixed stone workshops?

Choose multi-surface diamond abrasive pads (granite/marble/concrete).

Q: How to clean clogged pads?

Soak in pH-neutral solution for 15 minutes.

Conclusion: Transform Your Polishing Process Today

DINOSAW’s granite polishing pads deliver precision for slabs, tiles, and complex designs. With ISO-certified quality and bulk discounts, we’re the choice for smart factories.