CNC Wire Saw Introduction

Dinosaw CNC wire saw machines are versatile cutting tools widely used in industries such as stone, metal, and glass. With exceptional stability, precise control, and efficient performance, Dinosaw wire saws meet a wide range of processing needs. Whether working with hard and brittle materials like marble and granite, or with materials like glass and metal, Dinosaw provides precise and reliable solutions that help customers boost production efficiency and optimize processing results.

Positioning Box Fails to Expand/Contract - Solution

This video will guide you through the steps to resolve the issue of the CNC wire saw's positioning box failing to expand/contract. Please follow these steps:

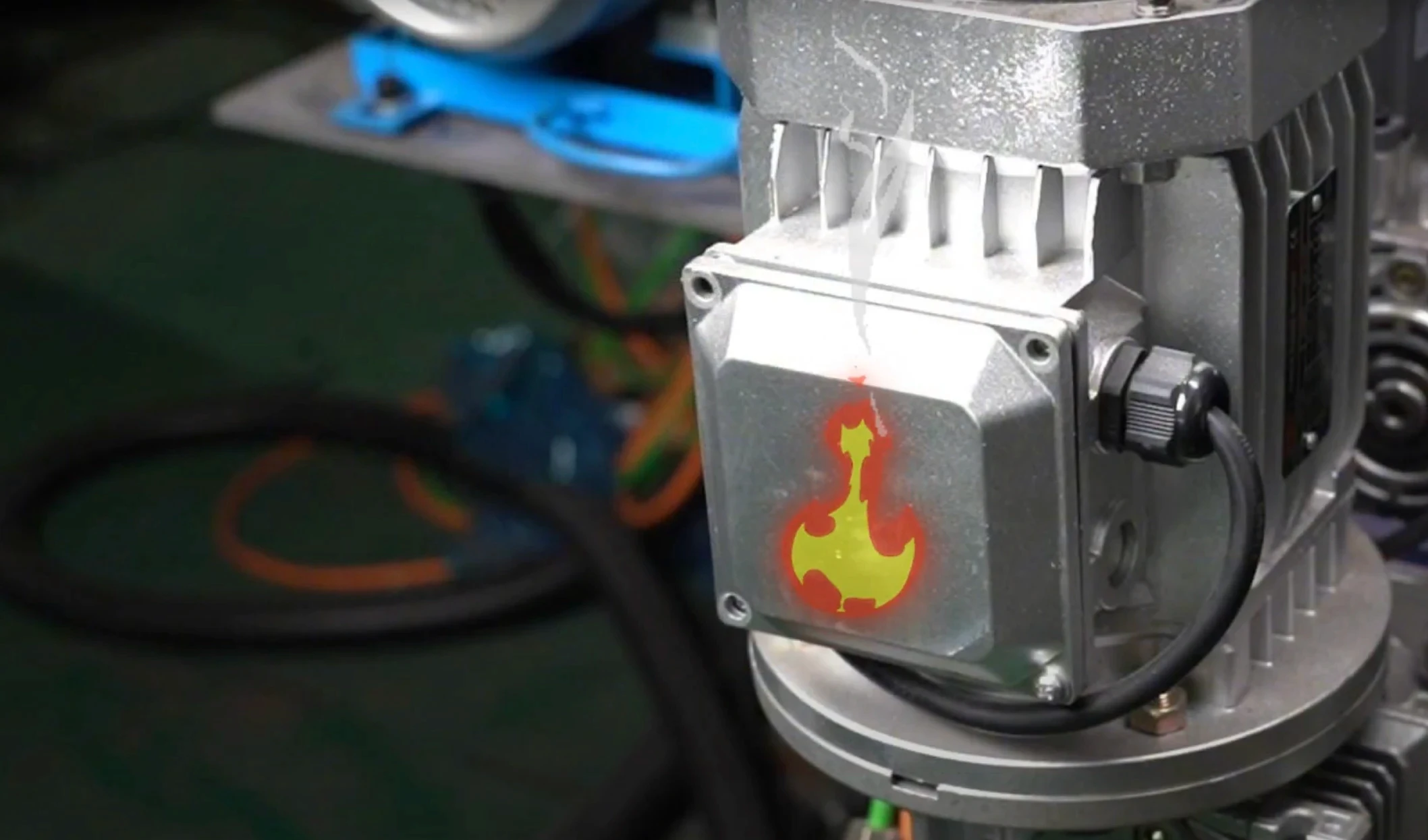

Step 1: Inspect the AC Contactor Motor and Gear Reducer

a. Check if the AC contactor engages properly:

Use the remote control to check if the AC contactor engages as expected.

If it does not engage, inspect the wiring or replace the AC contactor.

b. Inspect the gear reducer's key bar for damage or displacement:

If the key bar is damaged or displaced, replace it with a new one.

If the key bar is intact but has fallen out of position, check for signs of burnt residue or a scorched smell.

Step 2: Further Inspection of the Gear Reducer and Motor

If no abnormalities are found in Step 1, detach the gear reducer and motor for further inspection:

Try manually rotating the motor and gear reducer to see if anything is stuck.

If either component is stuck or cannot rotate, replace the affected part.

Step 3: Contact After-Sales Support

If the problem persists after completing the above steps, contact Dinosaw's after-sales service for further assistance.

Keeping Your Wire Saw Machine Running

At Dinosaw, we go beyond just providing machines—we offer comprehensive after-sales support to ensure your success. From installation and training to regular maintenance and system updates, our dedicated team is here to keep your CNC wire saw machine running smoothly. Trust Dinosaw to be your reliable partner every step of the way.