CNC Wire Saw Introduction

Dinosaw CNC wire saw machines are industrial tools designed for precision cutting of a wide range of materials, including stone, metal, glass, and more. With exceptional stability and precise control systems, Dinosaw wire saws meet diverse material and processing needs, helping customers enhance production efficiency and quality. Whether cutting marble, granite, ceramics, or hard, brittle materials like metal and glass, Dinosaw wire saw machines provide high-efficiency, precise solutions.

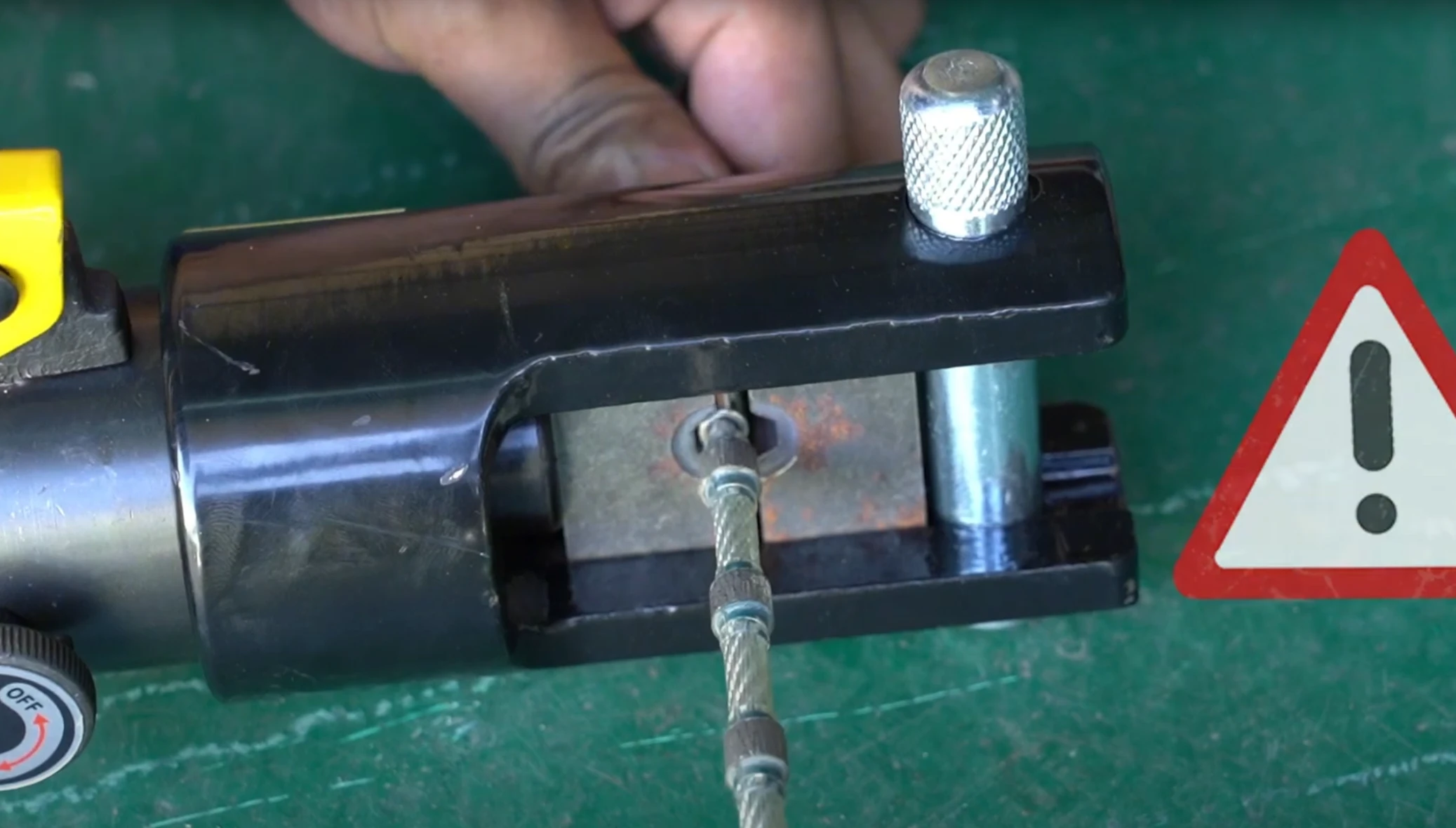

How to Splice a Diamond Wire Saw

This video will guide you through the process of correctly splicing a diamond wire saw, ensuring that the spliced wire performs smoothly and reliably for your machine. Follow these steps:

Prepare Tools and Materials

Make sure you have the correct diamond wire saw, splicing tools, and other necessary accessories.

Clean Both Ends of the Wire

Use cleaning tools to ensure both ends of the wire are free of oil, dirt, or any other debris.

Splice the Wire

Align the two ends of the wire correctly and use the splicing tool to securely fasten them.

Check the Splice Quality

Ensure the splice is firm and secure, and conduct a test to verify its functionality.

Keeping Your Wire Saw Machine Running

At Dinosaw, we go beyond just providing machines—we offer comprehensive after-sales support to ensure your success. From installation and training to regular maintenance and system updates, our dedicated team is here to keep your CNC wire saw machine running smoothly. Trust Dinosaw to be your reliable partner every step of the way.